Child Resistant Packaging

Ensure safety and compliance with our high-quality child-resistant packaging, tailored for the custom cannabis & cigarette packaging market. Our solutions combine safety, functionality, and a premium look to elevate your brand.

What is Child Resistant Packaging?

Child-resistant packaging is designed to prevent children from easily accessing harmful products, and it is a key safety and compliance requirement for cannabis & cigarette products.

We offer custom child-resistant packaging solutions, including drawer box packaging, pre-roll packaging boxes, and concentrate packaging boxes. These options are perfect for cannabis edibles, flowers, concentrates and vape products. Each one features a secure, certified childproof mechanism and maintains an eco-friendly, professional appearance. Protect your products and ensure compliance with our high-quality custom packaging, which is designed with safety and convenience in mind.

Discovered Custom Child Resistant Packaging Solutions

An ideal child-resistant packaging solution balances safety, adult-friendly usability, and compliance with regulatory standards. It incorporates secure locking or tamper-evident features that require intentional actions to open—challenging for children but straightforward for adults. The packaging must adhere to strict child-resistance guidelines, undergoing thorough safety testing to ensure it meets all necessary regulatory approvals before reaching the market.

Beyond safety, child-resistant packaging also prioritizes functionality and visual appeal. It should be durable enough to safeguard the contents, simple to store, and capable of preserving its child-resistant properties over time. Customizable options such as drawer box packaging, pre-roll packaging boxes, and concentrate packaging boxes can be specifically designed for cannabis & cigarette products, offering a secure, user-friendly, and brand-enhancing solution that improves the overall customer experience.

Ready to protect your products with top-tier childproof packaging?

Contact us now to customize packaging solutions that fit your cannabis & cigarette products' needs. Start' designing your packaging today!

Create High-Quality Custom Child-Resistant Packaging with a Trusted Cannabis & Cigarette Packaging Supplier

Consumers' purchases are heavily influenced by the product's packaging. Amid fierce brand competition, Best Pack's custom cannabis & cigarette packaging products can help your brand stand out with unforgettable designs.

Drawer Packaging

Drawer box packaging is a premium and functional solution widely used across industries such as cannabis, cosmetics, electronics, and luxury goods. Its slide-out drawer design offers an elegant unboxing experience while enhancing product protection and organization.

Customizable in size, material, and finish, drawer packaging gives brands full control over their visual identity. Options include matte or gloss lamination, embossing, foil stamping, and sustainable paper choices. By using drawer packaging, brands can elevate perceived value, strengthen their market presence, and deliver a memorable customer experience that reflects quality and care.

Pre-Roll Packaging

Pre-roll packaging is an essential solution for cannabis & cigarette products aiming to deliver both protection and presentation. Designed to preserve product freshness and integrity, this packaging ensures pre-rolls remain secure from moisture, odor, and physical damage during storage and transport.

Given the regulated nature of cannabis & cigarette products, pre-roll packaging often incorporates child-resistant features such as push-and-slide drawers, hidden lock buttons, or certified CR closures to comply with safety standards. These mechanisms help prevent unintended access while maintaining user convenience.

Pre-roll packaging is fully customizable, allowing brands to align their packaging with their identity through custom printing, premium finishes, and eco-friendly material options. Whether used for single pre-rolls or multi-pack formats, this packaging enhances consumer confidence and supports compliance, all while offering a sleek and memorable unboxing experience.

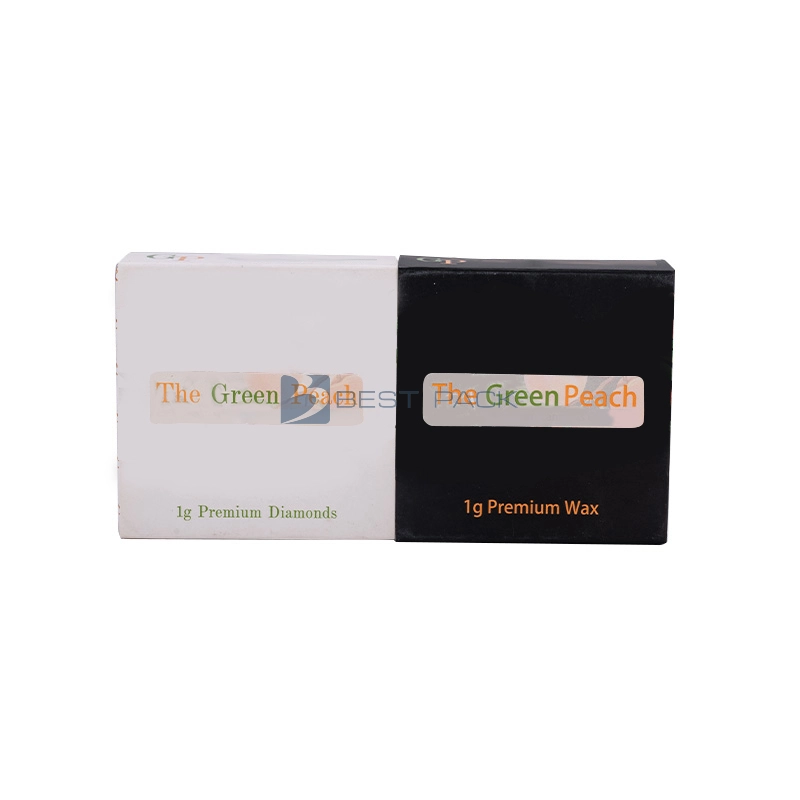

Concentrate Packaging

Concentrate packaging is specifically designed to preserve the potency, purity, and integrity of cannabis extracts such as wax, shatter, rosin, and live resin. These products require airtight, tamper-resistant, and sometimes child-resistant packaging to ensure quality and compliance from production to consumption.

Typically made from glass, plastic, or silicone with secure closures, concentrate packaging may also include outer boxes for added protection and branding. Many designs incorporate child-resistant features like push-and-turn caps or locking mechanisms to meet safety standards, especially in regulated markets.

To enhance shelf appeal and brand recognition, concentrate packaging can be customized with full-color labels, foil accents, embossing, or custom die-cut cartons. Interior linings or UV-blocking materials can be added to further protect the product from light and heat.

Whether in jars, syringes, or snap packs, concentrate packaging ensures a professional presentation while maintaining freshness, safety, and full regulatory compliance—giving consumers confidence in the quality of the product inside.

▷ Ready for Custom Child Resistant Packaging? ◁

Create unique and eye-catching cannabis childproof packaging with endless customizing options. Take these few steps to get your custom CR packaging started!

Step 1: Choose A Material

Step 2: Choose A Printing Method

Step 3: Choose A Coating/Lamination

Glossy Lamination

Glossy lamination is a clear, shiny coating applied to packaging surfaces to enhance color vibrancy, provide a smooth finish, and add moisture and scratch resistance.

Soft Touch Limination

Soft-touch lamination is a matte coating that gives packaging a smooth, velvety texture, enhancing tactile appeal while providing protection against scratches and fingerprints.

Matt Lamination

Matte lamination is a non-glossy, smooth coating applied to packaging that reduces glare, offers a sophisticated look, and protects against scratches and fingerprints.

Step 4: Choose Finishings

Striking Custom Child Resistant Packaging Options

Explore our

child resistant packaging examples, and hopefully you can gain some ideas from them.

Unrivaled Support from Cannabis & Cigarette Packaging Experts

Our dedicated cannabis & cigarette packaging expert is here to guide you through every step of the custom packaging process, from the initial consultation to full production and delivery, with ease. Whether you're new to packaging or have an established product ready to level up, our customer service team is committed to helping you succeed!

Frequently asked questions

Explore our FAQs for quick and clear answers about our packaging solutions. More FAQs➝

About us

How many kinds the printing process you have?

We can make Silk screen printing, offset printing, and also hot silver stamping

The process of your packaging box production?

1. Make knife mold as per box size and structure

2. order material as per mold

3. make printing on material if need to print

4. suppress and cut material

5. Makeboxes with glue edge in machine

6. Package boxes into cartons

What is the box size and structure?

1. All boxes are customized and all detailed requirements can be provided by clients, we are definitely your OEM service supplier.

2. If you have no idea about the measurements and structure on your products, our professional design team can suggest and solute for you .

Are you able to do design for my products?

Yes, just send us your logo artwork in Vector file, such as AI or PDF format,and text information you want to print ,we can put it on box to make the design to let you check. Once you say ok, then we go on to make samples or production.

When can I get the quotation?

1. The quotation will be offered within 24 hours after getting your detailed request.

2. If you get the urgent inquiry, please call us or mark it via E-mail, then we could make it into priority list.

How much of your samples cost ?

1. If samples are without printing, we can make free samples as per your box size or structure;

2. If samples are silk printing, normally USD 25 per color,depending on your logo colors;

3. If samples are offset printing, need USD 180 as offset printing mold cost is high.

Leading time for samples production?

Normally we need 3-7 days for samples making, 10-12 days to complete your orders,but the delivery time more depends on the order QTY.

Get in Touch with Best Pack

We’re here to help bring your ideas to life!

Best pack

Best pack

Best pack