Bulk packaging tips for Pack 10 20 5 pre roll orders

- Bulk packaging tips for Pack 10 20 5 pre roll orders

- Why pre roll packaging matters for bulk orders

- Choose the right pack configuration: 5, 10, or 20 pre roll packaging

- Quick comparison of Pack 5 / 10 / 20 configurations

- Material selection for durable, attractive pre roll packaging

- Balancing cost and protection

- Printing, branding, and artwork tips for pre roll packaging

- Digital vs. offset printing for bulk pre roll packaging

- Child-resistant solutions and regulatory considerations for pre roll packaging

- Logistics: packing, palletization and shipping bulk pre roll boxes

- Quality control and production QA for large pre roll box runs

- Sustainability options for pre roll packaging

- Cost-saving strategies for bulk pre roll packaging

- Integrating branding and retail shelf strategy with your pre roll packaging

- Brand summary — why choose our Factory Customized Printing LOGO Pack 10 20 5 boxes

- Frequently Asked Questions (FAQ)

- Q1: What is the minimum order quantity (MOQ) for customized Pack 10 20 5 pre roll boxes?

- Q2: Can you add child-resistant features to these boxes?

- Q3: How long does a bulk run take from artwork approval to delivery?

- Q4: Are the boxes suitable for CBD or THC pre-rolls?

- Q5: What sustainability options are available?

- Q6: Do you provide samples before I approve a full production run?

- Contact us / View product

- References and sources

Bulk packaging tips for Pack 10 20 5 pre roll orders

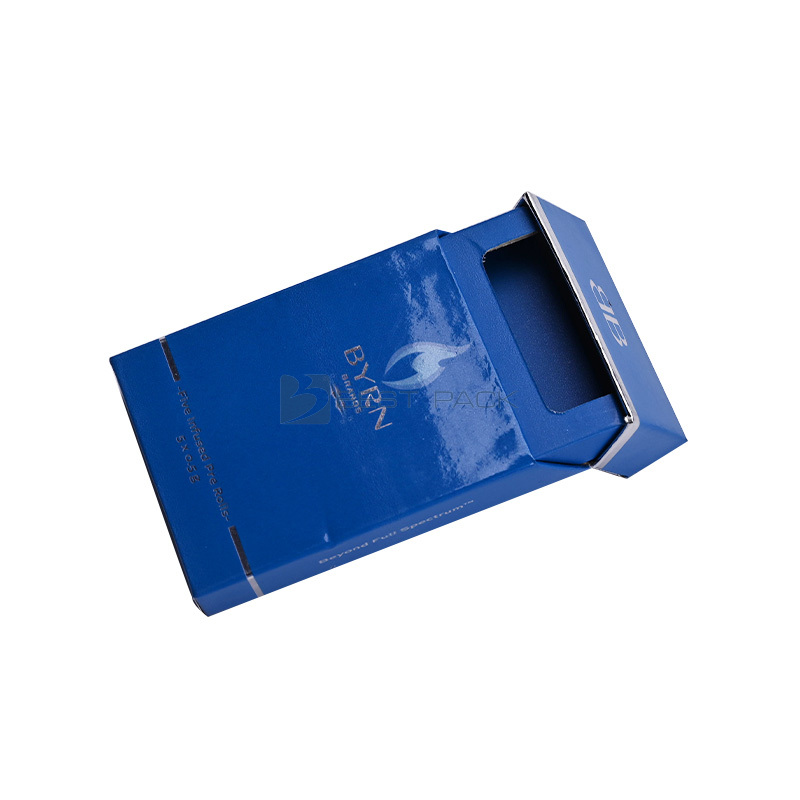

Our factory-direct custom pre-roll and cigarette paper boxes are designed for High Quality presentation, protection, and branding. Made with thick, durable paperboard, these boxes are ideal for non-tobacco herbal pre-rolls, cigarettes, or CBD/THC joints. Available in various capacities (5-pack, 10-pack, 20-pack) and fully customizable with your logo and design.

Why pre roll packaging matters for bulk orders

When you order pre roll packaging in bulk, you're not only buying protection for the product — you're buying the first impression consumers have of Best Pack and the logistical efficiency you need to scale. The term pre roll packaging applies to boxes designed specifically for holding rolled products in quantities such as 5, 10, or 20. Proper packaging balances protection (mechanical and environmental), branding, legal/compliance requirements (including child-resistant options), and cost-efficiency.

Choose the right pack configuration: 5, 10, or 20 pre roll packaging

Selecting the optimal pack size depends on your target market, retail partner expectations, and price positioning. Smaller 5-packs often suit High Quality single-use experiences or sample packs. 10-packs are commonly used for everyday consumer sales, while 20-packs work well for value or heavy-use segments. Choosing the correct size affects box dimensions, internal supports, printing layout, and shipping configurations.

Quick comparison of Pack 5 / 10 / 20 configurations

| Pack size | Typical use case | Recommended internal protection | Retail impact |

|---|---|---|---|

| 5-pack | High Quality sampler, gift packs, boutique dispensaries | Single tray with snug channels or foam inserts | Higher perceived value; good for higher-margin SKUs |

| 10-pack | Standard consumer size; balance of value and portability | Divider or molded paperboard trays | Most versatile for shelf display and vending |

| 20-pack | Value pack, high-usage customers, multi-packs for retail | Multiple channels/trays, possible plastic or kraft divider | Lower unit cost; requires strong outer packaging |

Notes: table is for guideline use only; choose internal supports based on product fragility and transit expectations.

Material selection for durable, attractive pre roll packaging

Material choice affects protection, printability, sustainability, and unit cost. For the Factory Customized Printing LOGO Pack 10 20 5 Thick Case Pre Roll Non Tobacco Paper Box Cigarette Boxes, thick paperboard is a strong default — it provides rigidity for stacking, good print canvas, and is widely recyclable. Consider the following:

- Paperboard thickness: 18–24 pt (coated CCNB or SBS) is common for rigid-feel boxes; choose heavier board for 20-packs to resist crush.

- Coatings: Matte aqueous or soft-touch lamination gives a High Quality feel; gloss coatings boost color vibrancy but can show scuffs.

- Inserts: Die-cut paperboard trays, pulp inserts, or recyclable foam can keep pre-rolls secure in transit.

- Barrier needs: If your product requires moisture or oxygen protection, add a thin foil barrier liner or include a small desiccant in each inner pack.

Balancing cost and protection

Bulk buyers should ask manufacturers for cost/benefit options. Thicker board and additional inserts increase per-unit costs but reduce product losses and returns. Request sample packs to test drop resistance and shelf appearance before approving large runs.

Printing, branding, and artwork tips for pre roll packaging

For factory-customized printing with your logo, follow these best practices to ensure consistent, high-quality results across large orders:

- Color management: Use CMYK values and provide Pantone PMS colors when exact matches are required. Request printed proofs (digital or press proofs) before full production.

- Bleed and safe zones: Keep important elements (logos, text) at least 3–5 mm inside the trim line to avoid cutting variations.

- High-resolution artwork: Supply vector logos and high-resolution images (300 dpi minimum) to avoid pixelation on large-format printing.

- Embossing & foil: Use sparingly to highlight brand elements; these features increase lead time and cost but enhance perceived value.

Digital vs. offset printing for bulk pre roll packaging

Digital printing excels for low-to-medium volumes and faster turnarounds with variable data, while offset printing becomes more cost-effective at higher quantities and offers slightly better color fidelity for large areas. For true bulk runs of Pack 10/20/5, offset is usually the economical choice if artwork is finalized.

Child-resistant solutions and regulatory considerations for pre roll packaging

Even for non-tobacco herbal products, many jurisdictions require or recommend child-resistant (CR) packaging — or retailers demand it. Options include push-and-turn closures, tuck-flap designs with additional locking features, or internal CR sachets/containers inside the outer printed box.

- Compliance: Check local laws and retail partner requirements. In the U.S., some cannabis products are subject to state-level CR requirements; the Poison Prevention Packaging Act (PPPA) and Consumer Product Safety Commission guidance are relevant references for child-resistant design philosophies.

- Testing: If you advertise your packaging as child-resistant, work with a certified lab to test and certify the closure design. Uncertified claims can result in recalls or legal issues.

Logistics: packing, palletization and shipping bulk pre roll boxes

Bulk pre roll orders require planning for efficient packing, minimized damage, and predictable shipping costs. Key recommendations:

- Inner-to-outer packing: Place individual packs into corrugate trays or tuck into master cartons that are sized to prevent movement. Use dividers for 10/20-packs to eliminate product rub.

- Pallet optimization: Stack uniformly and use slip sheets to prevent abrasion. Determine pallet pattern (column vs. interlocking) based on carton strength.

- Drop testing & cushioning: For interstate or international shipping, simulate worst-case courier handling and include additional cushioning if necessary.

- Labeling: Include clear external carton labels with SKU, quantity, lot code, and handling instructions to speed warehouse processing.

Quality control and production QA for large pre roll box runs

QA is vital for bulk orders. Implement a clear QC plan with your supplier that includes pre-production approvals, inline checks, and final inspections:

- Approve structural and color proofs before production.

- Specify acceptable tolerances for cut, crease, and print register.

- Request random sample checks during production and a final QC report with photos.

- Negotiate remedies for defects — reprint or partial credit — within your contract.

Sustainability options for pre roll packaging

Consumers increasingly expect responsible packaging. Options include using recycled paperboard (FSC-certified if possible), soy-based inks, and eliminating unnecessary plastic. Sustainable choices can be highlighted on the box, but ensure claims are accurate and verifiable.

Cost-saving strategies for bulk pre roll packaging

Bulk buyers can reduce costs without sacrificing quality by:

- Increasing order quantity to hit lower per-unit pricing on offset runs.

- Standardizing sizes across SKUs to reuse die tooling and reduce setup charges.

- Choosing fewer specialty finishes — reserve embossing/foil for hero SKUs.

- Consolidating SKUs for production runs to reduce changeovers and waste.

Integrating branding and retail shelf strategy with your pre roll packaging

Your packaging must perform both as protection and a sales tool. For retailers, consider shelf-facing orientation, a clear front-of-pack message about product benefits (e.g., non-tobacco, herbal, CBD), and easy scanning for inventory (barcode placement). For direct-to-consumer sales, emphasize unboxing experience with inner messaging and quality finishes.

Brand summary — why choose our Factory Customized Printing LOGO Pack 10 20 5 boxes

Our factory-direct offering delivers consistent quality, competitive pricing, and real customization for Pack 5, 10, and 20 pre-roll boxes. Key advantages:

- High Quality materials: Thick, durable paperboard that protects product and prints beautifully.

- Flexible capacities: Standardized 5/10/20 formats that fit most retail and consumer needs.

- Full customization: Logos, full-color printing, finishes, and optional child-resistant designs.

- Factory reliability: Direct manufacturing control reduces lead times and keeps unit costs low at scale.

- Compliance support: Guidance for CR options and labeling consistent with industry expectations.

Frequently Asked Questions (FAQ)

Q1: What is the minimum order quantity (MOQ) for customized Pack 10 20 5 pre roll boxes?

A: MOQs vary by supplier and by print method. For offset printing, typical MOQs range from 2,000–10,000 units depending on size and complexity. Digital printing enables lower MOQs (often 250–1,000 units). Contact our sales team with your exact specifications for a firm quote.

Q2: Can you add child-resistant features to these boxes?

A: Yes. We offer a range of child-resistant solutions — tuck-lock modifications, internal CR containers, or certified mechanical closures. If CR certification is required, plan additional lead time and testing costs.

Q3: How long does a bulk run take from artwork approval to delivery?

A: Typical lead times are 3–6 weeks for standard offset printing and production, depending on quantity, finishing options, and shipping destination. Rush production (additional cost) may be available for urgent orders.

Q4: Are the boxes suitable for CBD or THC pre-rolls?

A: Yes. These boxes are designed for non-tobacco herbal pre-rolls including CBD/THC joints. Be aware of local regulations regarding labeling and child-resistant requirements for cannabis products.

Q5: What sustainability options are available?

A: We offer recycled and FSC-certified paperboard options, soy-based inks, and minimal plastic solutions. We can provide sustainability statements for your packaging upon request.

Q6: Do you provide samples before I approve a full production run?

A: Yes — we provide printed samples and structural mockups. For bulk orders, we recommend approving a pre-production sample (PPS) and a press proof prior to full print to avoid costly errors.

Contact us / View product

To discuss pricing, samples, or compliance options for your Pack 5/10/20 pre-roll orders, contact our customer service or request a product quote. Click to view the Factory Customized Printing LOGO Pack 10 20 5 Thick Case Pre Roll Non Tobacco Paper Box Cigarette Boxes and request a sample today. Finally, labeling and regulatory tips for pre-roll packaging are crucial for ensuring that your products comply with local laws and regulations. Proper labeling ensures that your packaging meets legal requirements while also educating consumers about the product.

References and sources

Reliable industry sources and regulatory references used for recommendations in this

- Grand View Research — Cannabis Packaging Market Size, Share & Trends Analysis (industry market trends)

- U.S. Consumer Product Safety Commission & Poison Prevention Packaging Act (PPPA) — guidance on child-resistant packaging principles

- Packaging World — articles and best practices on protective packaging, print processes, and child-resistant solutions

- Leafly / industry trade publications — consumer packaging preferences and branding trends (for cannabis and herbal products)

Where to Buy child safe pre roll packaging box in Guangzhou

How to Procure Custom Printed Paperboard Cigarette Boxes in Bulk

Custom cigarette box sustainability: materials and tips

Pre-Roll Cone Packaging: Compliance and Safety Standards

FAQs

How do you ensure product quality?

We maintain strict quality control at every stage, from material selection to final production, ensuring high-quality standards.

What types of packaging do you specialize in?

We specialize in electronic packaging, plastic boxes (PVC/PET/PP), paper boxes, paper bags, and custom book printing.

About us

How many kinds the printing process you have?

We can make Silk screen printing, offset printing, and also hot silver stamping

Are you able to do design for my products?

Yes, just send us your logo artwork in Vector file, such as AI or PDF format,and text information you want to print ,we can put it on box to make the design to let you check. Once you say ok, then we go on to make samples or production.

What is the box size and structure?

1. All boxes are customized and all detailed requirements can be provided by clients, we are definitely your OEM service supplier.

2. If you have no idea about the measurements and structure on your products, our professional design team can suggest and solute for you .

Custom CR Vape Packaging Cardboard Boxes with Child-Resistant Design

CR custom vape packaging cardboard boxes are specially designed child-resistant packaging solutions crafted to ensure safety, protection, and premium presentation for vape products. Made from sturdy cardboard materials, these boxes balance regulatory compliance with brand aesthetics.

Custom Luxury Pre Roll Packaging Boxes with Child-Resistant Paper Tray

Our luxury pre-roll packaging boxes are designed to combine elegant presentation with top-tier safety features. Featuring a child-resistant mechanism and a custom paper tray insert, these boxes ensure secure storage while delivering a premium unboxing experience for pre-roll products.

Custom Child-Lock Pre-Roll 5-Pack Packaging Boxes

Our custom child-lock packaging for pre-roll 5-packs is purposefully engineered to combine premium design with certified safety. This packaging solution ensures that five pre-rolls are securely housed in a compact, stylish, and child-resistant format—ideal for compliant cannabis brands that value both form and function.

Best pack

Best pack

Best pack