Ensuring Child-Resistant Compliance in Custom Cigarette Boxes

- Ensuring Child-Resistant Compliance in Custom Cigarette Boxes

- Why child-resistant packaging matters for custom cigarette box products

- Regulatory landscape and standards to know for custom cigarette box compliance

- Core design principles for child-resistant custom cigarette boxes

- Materials and construction options for child-resistant custom cigarette boxes

- Child-resistant mechanisms suitable for custom cigarette box formats

- Testing, certification and user panels for child-resistant claims

- Labeling, warnings and instructions for safe use

- Manufacturing and quality control: ensuring repeatable child resistance

- Comparing child-resistant implementation options

- Cost, lead time and scalability considerations for custom cigarette box projects

- How our Factory Customized Printing LOGO Pack 10 20 5 Thick Case supports compliant solutions

- Branding and consumer experience without compromising safety

- Frequently Asked Questions (FAQ)

- Q: Is child-resistant the same as child-proof?

- Q: Do I need certification to say my custom cigarette box is child-resistant?

- Q: Can child-resistant features be added to existing custom cigarette box artwork?

- Q: How do I balance adult usability with child resistance?

- Q: Are there special rules for CBD/THC pre-rolls?

- Next steps — ordering, prototyping and testing

- Authoritative references and resources

- Contact us / See product

Ensuring Child-Resistant Compliance in Custom Cigarette Boxes

Why child-resistant packaging matters for custom cigarette box products

Child safety is both an ethical responsibility and a legal requirement for manufacturers and brands packaging nicotine and non-nicotine products such as pre-rolls, CBD/THC joints, and cigarettes. A well-designed custom cigarette box protects contents from damage and unauthorized access, reduces accidental ingestion risks, and helps Best Pack meet regulatory obligations. Whether you sell 5-pack, 10-pack, or 20-pack boxes, integrating child-resistant features early in the design process reduces redesign costs and speeds time to market.

Regulatory landscape and standards to know for custom cigarette box compliance

Understanding applicable regulations is the first step. Key, widely recognized references include:

- U.S. Poison Prevention Packaging Act (PPPA) enforced by the Consumer Product Safety Commission (CPSC) — sets child-resistant packaging requirements for many household substances and is often used as a benchmark for other product categories.

- ISO 8317: Reclosable packages — Child-resistant packaging — Test methods for reclosable packages — describes child/adult panel testing procedures and pass/fail criteria widely accepted for reclosable child-resistant packaging.

- Local/state regulations (for cannabis/CBD/THC products) — many U.S. states and countries require child-resistant packaging and have specific labeling rules for cannabinoid products.

Meeting these standards demonstrates a responsible approach and increases acceptance among wholesalers, retailers and compliance auditors.

Core design principles for child-resistant custom cigarette boxes

Designing a child-resistant custom cigarette box requires balancing accessibility for intended adult users, repeat usability, and robustness. Follow these core principles:

- Require a two-step or dual-action motion that is intuitive for adults but difficult for young children.

- Use tactile and visual cues for adults — e.g., embossed arrows, textured tabs — to guide correct opening without being obvious to children.

- Ensure durability: thick, rigid paperboard and reinforced hinges reduce accidental failure. Materials should survive repeated openings and environmental conditions.

- Include secure closures that remain effective across product lifecycles (e.g., after transportation, shelf handling).

- Provide clear, compliant labeling showing warnings and the proper method to open the package.

Materials and construction options for child-resistant custom cigarette boxes

Choice of materials affects both safety and brand presentation. For custom cigarette boxes, common options include heavy paperboard, laminated card stock, and integrated plastic components for locking mechanisms.

Our product line illustrates a practical, factory-direct solution:

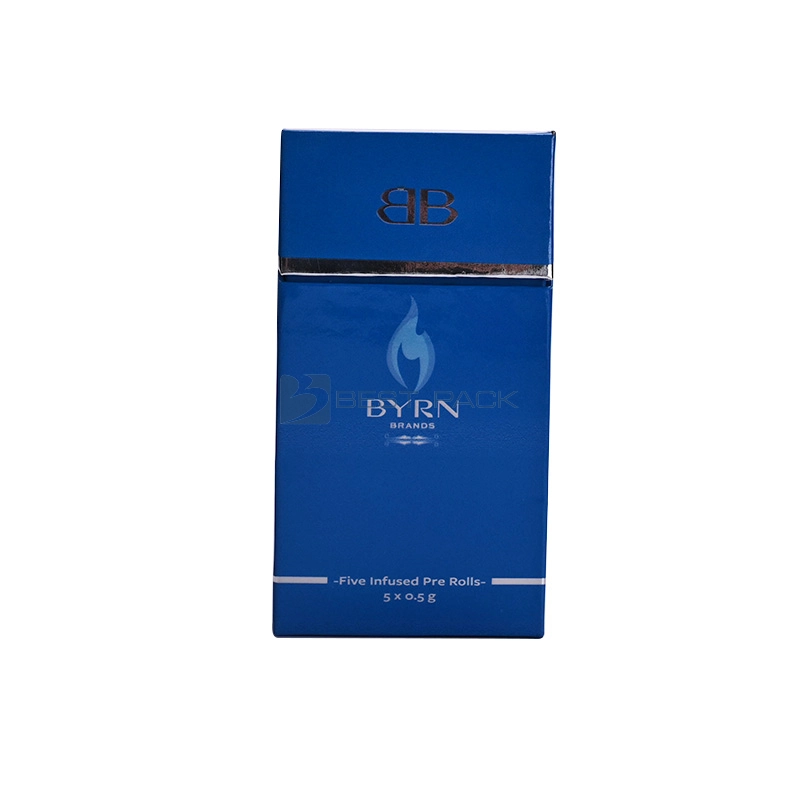

Factory Customized Printing LOGO Pack 10 20 5 Thick Case Pre Roll Non Tobacco Paper Box Cigarette Boxes

Our factory-direct custom pre-roll and cigarette paper boxes are designed for High Quality presentation, protection, and branding. Made with thick, durable paperboard, these boxes are ideal for non-tobacco herbal pre-rolls, cigarettes, or CBD/THC joints. Available in various capacities (5-pack, 10-pack, 20-pack) and fully customizable with your logo and design.

Typical material choices and their benefits:

- Thick paperboard (folding carton): High print quality, rigid structure when scored correctly, cost-effective for high-volume custom printing.

- Coated/layered board with lamination: Adds moisture resistance and abrasion protection for retail handling.

- Small integral plastic components (e.g., locking tabs): Enable more reliable mechanical child-resistant features while maintaining a predominantly paper-based aesthetic.

Child-resistant mechanisms suitable for custom cigarette box formats

Not every mechanism fits every form factor. Choose a method based on box size (5/10/20 pack), production capabilities, user expectations, and testing requirements. Common mechanisms include:

- Dual-action tab and sliding tray: Requires pressing a tab while sliding out an inner tray — effective for tuck-top and drawer-style boxes.

- Push-and-lift lid with catch: Requires simultaneous downward pressure and upward lift — suitable for flip-top boxes.

- Press-and-slide lock: A small plastic or reinforced cardboard latch that must be squeezed and slid.

- Blister or sealed single-dose pods inside box: Adds extra barrier for children when the external box is opened.

Each mechanism can be integrated into a custom cigarette box while preserving branding opportunities on external panels.

Testing, certification and user panels for child-resistant claims

To make a defensible child-resistant claim, follow recognized testing protocols (for example ISO 8317) which use test panels composed of children and adults:

- Child panel testing: Assesses how many children (typically ages 42–51 months) can open the package within a set time. Passing thresholds are strict to demonstrate resistance.

- Adult panel testing: Ensures intended adults can open and close the packaging reliably.

- Durability testing: Simulates real-world wear (open/close cycles, vibration, temperature) to confirm continued resistance.

Work with accredited testing labs experienced in consumer packaging and ISO standards. Maintain full test records, photographs, and batch references for compliance audits.

Labeling, warnings and instructions for safe use

Labels are part of the safety system. For a compliant custom cigarette box:

- Include clear warning statements about keeping product away from children and accidental ingestion hazards.

- Provide a simple graphic or short two-step instruction showing how to open the package (useful for adult users).

- Comply with local language requirements and symbol standards where the product will be sold.

Manufacturing and quality control: ensuring repeatable child resistance

Consistency is essential. Key manufacturing and QC steps:

- Documented printing and die-cut specifications so every run produces parts that mate correctly.

- Incoming material inspections for board caliper, stiffness, and lamination quality.

- First article inspection (FAI) and routine sampling of assembled boxes for opening force, latch engagement, and dimensional tolerances.

- Batch-level traceability and retention samples in case of product complaints or recalls.

Comparing child-resistant implementation options

The following table compares common methods for child-resistant custom cigarette boxes, so you can select the best balance of cost, user experience, and compliance complexity.

| Method | Best for | Compliance complexity | Estimated cost impact | Branding impact |

|---|---|---|---|---|

| Dual-action tab + sliding tray | Drawer-style 5/10 pack boxes | Moderate (mechanical design + testing) | Medium | High — large exterior panels available |

| Push-and-lift flip-top | Flip-top cigarette boxes | Moderate | Low–Medium | High — preserves classic look |

| Press-and-slide latch (integrated) | Thin paperboard boxes | Medium–High (precision die-cutting) | Medium | Medium |

| Internal blister/pod | Single-dose or High Quality retail | High (added component + testing) | High | Medium — inside product protected |

Cost, lead time and scalability considerations for custom cigarette box projects

Key drivers of cost and lead time:

- Die tooling and engineering: initial setup for custom locks or trays increases up-front cost but amortizes over volume.

- Material selection: higher GSM boards and laminates raise unit costs.

- Assembly complexity: added mechanical parts or multi-step assembly increase labor or automation needs.

- Testing and certification time: plan for partner lab scheduling and potential iterative redesigns.

For many brands, starting with a 5,000–10,000 unit pilot run that includes prototype testing is an effective way to validate child-resistant performance and customer acceptance before scaling to larger quantities.

How our Factory Customized Printing LOGO Pack 10 20 5 Thick Case supports compliant solutions

Our factory specializes in custom cigarette box production with a focus on durable paperboard, precise die-cutting and optional integrated locking features. Advantages we deliver:

- Factory-direct control over material specs and assembly — faster iterations and consistent quality.

- Customization for 5/10/20 pack sizes to match product SKUs and retail expectations.

- Support for integrating child-resistant mechanisms (dual-action, sliding trays, latch systems) while keeping High Quality printing and finishing options.

- Assistance with test planning and documentation for ISO 8317-style child/adult panel testing.

Branding and consumer experience without compromising safety

Child-resistance need not mean bland packaging. Thoughtful design can preserve elegance while meeting safety requirements. Use embossing, spot UV, and structured folds to maintain a High Quality look. Provide clear opening instructions and a reassuring brand message about safety and responsibility to create trust with retailers and consumers.

Frequently Asked Questions (FAQ)

Q: Is child-resistant the same as child-proof?

A: No. “Child-resistant” means packaging reduces the likelihood of a child accessing the contents but does not guarantee absolute prevention. “Child-proof” implies total prevention and is not a normal regulatory term. Standards like ISO 8317 set practical thresholds for resistance.

Q: Do I need certification to say my custom cigarette box is child-resistant?

A: While regulations vary by jurisdiction, relying on standardized testing (e.g., ISO 8317) and records from accredited labs is the accepted route to substantiate claims. Keep documentation for audits or retailer requirements.

Q: Can child-resistant features be added to existing custom cigarette box artwork?

A: Often yes, but some mechanisms require die changes or material upgrades. Early collaboration between Best Pack designer and the packaging engineer minimizes unexpected changes or rework.

Q: How do I balance adult usability with child resistance?

A: Use adult panel testing during development to ensure the motion is intuitive for adults (clear tactile cues, short instructions). Avoid overly complex motions that frustrate the adult user.

Q: Are there special rules for CBD/THC pre-rolls?

A: Many jurisdictions have additional requirements for cannabinoid products — including mandatory child-resistant packaging, specific labeling, and tamper-evident features. Confirm local state/provincial regulations and adjust design and testing plans accordingly.

Next steps — ordering, prototyping and testing

If you are launching a new SKU or upgrading packaging, take these steps:

- Define product form factor (5/10/20 pack), expected life cycle and retail channel.

- Engage packaging engineering to select an appropriate child-resistant mechanism and material.

- Produce prototypes and perform internal usability testing for adults and preliminary child resistance checks.

- Commission accredited lab testing (ISO 8317-style) and iterate if needed.

- Finalize tooling, run a pilot batch with QC sampling, then scale production.

To view product options or request a custom quote, contact our sales team. We offer prototyping, die-making, sample approvals and guidance through child-resistant testing and documentation to help Best Pack launch confidently.

Authoritative references and resources

- U.S. Consumer Product Safety Commission — Poison Prevention Packaging Act (PPPA): https://www.cpsc.gov/Regulations-Laws--Standards/Statutes/Poison-Prevention-Packaging-Act

- ISO 8317: Reclosable packages — Child-resistant packaging — Test methods for reclosable packages: https://www.iso.org/standard/63105.

- World Health Organization — Framework Convention on Tobacco Control (FCTC): https://www.who.int/fctc

- European Commission — Tobacco products: https://ec.europa.eu/health/tobacco/products_en

Contact us / See product

Ready to design a compliant, attractive and brand-forward custom cigarette box? Contact our packaging specialists to request samples, technical drawings and child-resistant design options for the Factory Customized Printing LOGO Pack 10 20 5 Thick Case Pre Roll Non Tobacco Paper Box Cigarette Boxes. Email sales@yourcompany.com or visit our product page to start a project.

Sustainable Materials for Custom Cigarette Box Suppliers

Everything You Need to Know About cigarette packaging design

Custom cigarette box sustainability: materials and tips

Regulatory Changes for Cigarette Box CR Packaging in 2026

FAQs

How do you ensure product quality?

We maintain strict quality control at every stage, from material selection to final production, ensuring high-quality standards.

About us

Are you able to do design for my products?

Yes, just send us your logo artwork in Vector file, such as AI or PDF format,and text information you want to print ,we can put it on box to make the design to let you check. Once you say ok, then we go on to make samples or production.

How much of your samples cost ?

1. If samples are without printing, we can make free samples as per your box size or structure;

2. If samples are silk printing, normally USD 25 per color,depending on your logo colors;

3. If samples are offset printing, need USD 180 as offset printing mold cost is high.

What is the box size and structure?

1. All boxes are customized and all detailed requirements can be provided by clients, we are definitely your OEM service supplier.

2. If you have no idea about the measurements and structure on your products, our professional design team can suggest and solute for you .

Leading time for samples production?

Normally we need 3-7 days for samples making, 10-12 days to complete your orders,but the delivery time more depends on the order QTY.

Custom Printed Paperboard Cardboard Cigarette Box Packaging Case Disposable Paper Box for Cigarette Clamshell paper box

Custom Vape Packaging Box with CR Telescoping Design

The CR telescoping box is a sophisticated and secure packaging solution designed specifically for vape products. Featuring a telescoping (two-piece) structure, this box offers excellent protection and an elegant presentation, enhancing both the unboxing experience and brand appeal.

Custom Logo Child-Resistant Pre-Roll Box Packaging Biodegradable Handmade Luxury 5 Pack Embossing Childproof Pre Roll Package

Custom CR Vape Packaging Cardboard Boxes with Child-Resistant Design

CR custom vape packaging cardboard boxes are specially designed child-resistant packaging solutions crafted to ensure safety, protection, and premium presentation for vape products. Made from sturdy cardboard materials, these boxes balance regulatory compliance with brand aesthetics.

Best pack

Best pack

Best pack