Child-Resistant Features for Paperboard Cigarette Packaging

- Design Principles for Child-Resistant Paperboard Packaging

- Understanding the safety goal

- Material strategies: balancing rigidity and recyclability

- Human factors and user experience

- Proven Child-Resistant Mechanisms for Paperboard Boxes

- Positive-lock clamshell with interlocking tabs

- Slide-and-press multi-step closures

- Resealable tear-strip plus reclosure lock

- Testing, Standards and Compliance Considerations

- Relevant standards and testing protocols

- Design verification: testing cycle

- Labeling and legal considerations

- Practical Design Trade-offs: Cost, Sustainability, and Brand Impact

- Cost vs. performance

- Sustainability trade-offs

- Branding and shelf presence

- Materials and Manufacturing Recommendations

- Recommended paperboard grades and finishes

- Assembly and die-cutting best practices

- Quality control checkpoints

- Feature Comparison: Common Child-Resistant Options

- Semantic Keywords and Search Terms for cigarette paper box

- Why Choose Best Pack?

- FAQ (Frequently Asked Questions)

- Q1: Can paperboard packaging actually be child-resistant?

- Q2: Which standard should I test against for reclosable cigarette packaging?

- Q3: Will adding child-resistant features make my packaging non-recyclable?

- Q4: How does child-resistant design affect manufacturing cost?

- Q5: Can Best Pack help with testing and certification?

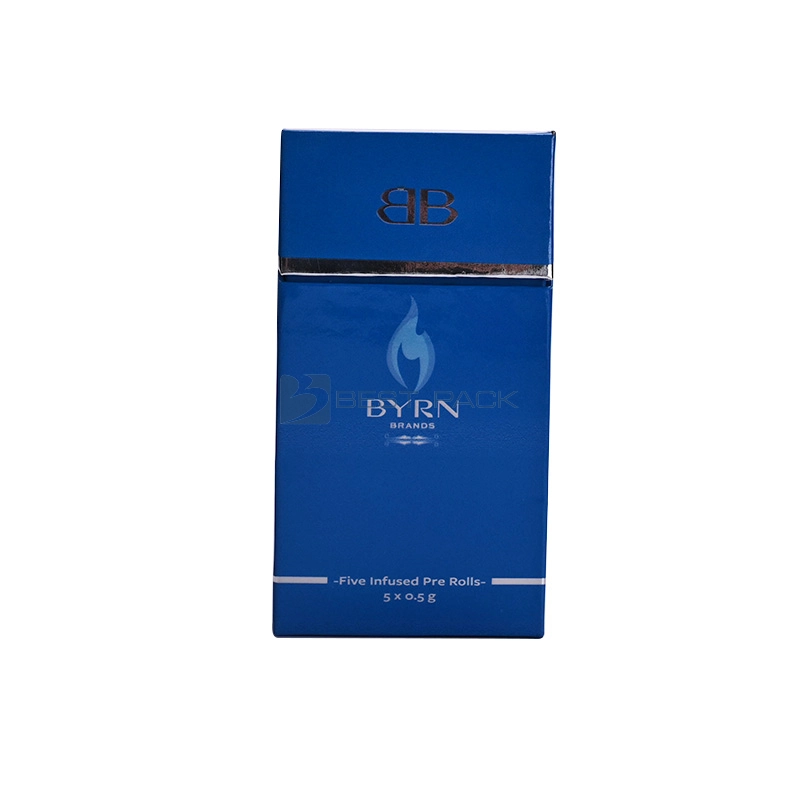

As manufacturers and brands move toward sustainable materials, designing effective child-resistant paperboard solutions becomes critical. This overview explains practical, testable child-resistant features for cigarette paper box clamshells and disposable paper boxes, describing how Best Pack's Custom Printed Paperboard Cardboard Cigarette Box Packaging Case Disposable Paper Box for Cigarette Clamshell paper box can combine safety, brand presentation, and recyclability. Adding safety elements affects unit economics, which is why teams evaluate cost-efficient packaging case options for cigarette suppliers.

Design Principles for Child-Resistant Paperboard Packaging

Understanding the safety goal

The core objective of child-resistant packaging is to substantially reduce the likelihood that children under a specified age can access hazardous contents while keeping the product reasonably accessible to adults. For cigarette paper box solutions, this means combining mechanical features with material selection and clear user instructions. Semantic keywords used in this section include cigarette paper box, paperboard clamshell, child-proof closure.

Material strategies: balancing rigidity and recyclability

Paperboard for cigarette boxes must be sturdy enough to support locking tabs and folding features. Options include multi-ply virgin paperboard, recycled fiber with increased grammage, and laminated or coated layers for durability. Each option affects recyclability and cost: uncoated 2-ply or 3-ply paperboard typically maximizes recyclability, while thin polymers or foil-laminates improve moisture resistance but complicate recycling streams. For Best Pack's Custom Printed Paperboard Cardboard Cigarette Box Packaging Case Disposable Paper Box for Cigarette Clamshell paper box, we prioritize high-stiffness food-grade paperboard that supports structural child-resistant mechanisms while remaining widely recyclable.

Human factors and user experience

Adult usability is essential: closures that are too difficult can lead to misuse or removal of the safety feature. Effective designs use clear tactile cues, intuitive push-and-slide actions, or two-step operations that adults can perform easily (press-and-slide, squeeze-and-pull) but that are challenging for young children. User instruction icons and short printed directions on the cigarette paper box help maintain ease-of-use without compromising safety.

Proven Child-Resistant Mechanisms for Paperboard Boxes

Positive-lock clamshell with interlocking tabs

A rigid clamshell cigarette paper box with internal interlocking tabs is a widely used approach. The clamshell folds shut and requires simultaneous manipulation of internal tabs that must be depressed or slid in a sequence—actions typically beyond a toddler's dexterity. For example, a recessed tab that must be pushed inward while lifting the lid provides a reliable adult-only opening. This mechanism suits the Custom Printed Paperboard Cardboard Cigarette Box Packaging Case Disposable Paper Box: it preserves branding on the exterior while hiding the locking elements internally.

Slide-and-press multi-step closures

Slide-and-press mechanisms combine a sliding sleeve with an internal latch: the outer sleeve prevents direct access to the inner tray until a hidden push-button or squeeze is engaged. These mechanisms are relatively simple to die-cut and assemble from paperboard and can be enhanced with scored folding lines and a small adhesive tab to control reclosure force. Such closures are a good fit where the cigarette clamshell paper box must be thin yet child-resistant.

Resealable tear-strip plus reclosure lock

For disposable paper boxes, a tamper-evident tear strip followed by a resealable child-resistant reclosure (for example, a SNAP-lock that requires two independent actions) balances single-use tamper protection and post-opening child resistance for a short period. This hybrid approach keeps raw material costs down while offering layered safety on a disposable cigarette paper box design.

Testing, Standards and Compliance Considerations

Relevant standards and testing protocols

Reclosable child-resistant packaging is commonly evaluated against internationally recognized protocols such as ISO 8317 (reclosable packaging for medicinal products) and national test methods. While cigarette packaging is not medicinal, ISO 8317 provides useful methodology—requiring specified percentages of children (and adults) to be unable to open (or succeed in opening) the package within given times. For industry context see the Child-resistant packaging - Wikipedia entry and guidance from regulatory bodies such as the U.S. Consumer Product Safety Commission (CPSC).

Design verification: testing cycle

Designers should follow a three-step verification cycle: prototype -> user testing (both adult and child panels) -> iterate. Prototype in the intended paperboard material and use representative print and coatings. Conduct child panel tests under controlled supervision to measure time-to-access and failure rates. Adult usability testing (including elderly users) ensures the closure remains practical. Documentation of test results and design revisions supports compliance claims and brand due diligence.

Labeling and legal considerations

Even with a child-resistant closure, clear labeling on the cigarette paper box is important: warnings, age-restriction icons, and disposal instructions reduce misuse. Where regional regulations exist for tobacco packaging (plain packaging laws, health warning placement, and material restrictions), align child-resistant design with those mandates to avoid conflicts. Consult legal counsel for country-specific compliance.

Practical Design Trade-offs: Cost, Sustainability, and Brand Impact

Cost vs. performance

Adding child-resistant features increases tooling complexity and per-unit cost. Simple tab-and-recess designs are cost-effective for medium-volume production; multi-component slide or dual-action mechanisms raise die-cutting costs and assembly time. Best Pack's Custom Printed Paperboard Cardboard Cigarette Box Packaging Case Disposable Paper Box for Cigarette Clamshell paper box is engineered to balance manufacturing efficiency with robust locking features to fit most mid-to-high volume budgets.

Sustainability trade-offs

Child-resistant closures may require additional components or adhesives that affect recyclability. Selecting mono-material paperboard solutions with structural folds (rather than mixed-material inserts) preserves recyclability. Where a thin PET window or laminate is necessary, clearly communicate recycling instructions on the cigarette paper box. Best practice is to prioritize recyclable coatings and minimize mixed-material bonds.

Branding and shelf presence

Custom printing and embossing on a child-resistant paperboard cigarette box allow brands to maintain visual identity without undermining safety. Use high-quality litho printing or digital print for variable designs and include tactile elements (deboss, spot UV) that also provide adult-friendly grip points for operating closures. The disposable paper box format can be optimized for retail display while keeping child-resistant performance intact.

Materials and Manufacturing Recommendations

Recommended paperboard grades and finishes

For structural closures choose 350–600 gsm solid bleached or recycled sulfate board depending on desired stiffness. Uncoated or matte coated surfaces can improve grip for adult users, while water-based varnishes add moderate moisture resistance with minimal recycling impact. Avoid full polymer laminations where possible to keep the cigarette paper box recyclable.

Assembly and die-cutting best practices

Precision die-cutting and creasing are essential for consistent closure performance. Tolerance control on tab fit and engagement depth avoids weak locks or overly stiff closures. For clamshells, reinforce hinge areas with small adhesive beads or mechanical locks to improve longevity during handling and retail stocking.

Quality control checkpoints

Implement QC checks at sample, pre-run, and production run levels. Verify closure engagement force, tab alignment, print registration, and coating adhesion. Maintain batch records for traceability, especially if performing post-market safety evaluations.

Feature Comparison: Common Child-Resistant Options

| Feature | How it reduces child access | Impact on recyclability | Estimated cost impact |

|---|---|---|---|

| Interlocking internal tabs (clamshell) | Requires coordinated action (press and lift) not intuitive for children | High (mono-paperboard) | Low–Medium |

| Slide-and-press sleeve | Hidden latch requires two-step action | Medium (if sleeve same material) | Medium |

| Tear strip + resealable lock | Tamper-evident first; resealable lock adds short-term resistance | Variable (depends on adhesives) | Low–Medium |

| Polymeric snap insert | Robust locking; requires specific manipulation | Low (mixed materials) | High |

Semantic Keywords and Search Terms for cigarette paper box

To improve discoverability and alignment with user intent, include related terms naturally in product pages and documentation. Example semantic keywords: cigarette paper box, paperboard cigarette box, cardboard cigarette packaging, cigarette clamshell paper box, disposable paper box for cigarette, custom printed cigarette boxes, child-resistant cigarette packaging, eco-friendly cigarette boxes. These phrases should appear in s, alt text, and product descriptions to help both search engines and buyers find appropriate solutions.

Why Choose Best Pack?

Best Pack's Custom Printed Paperboard Cardboard Cigarette Box Packaging Case Disposable Paper Box for Cigarette Clamshell paper box offers a pragmatic balance of safety, customization, and sustainability. Key advantages include:

- Custom die-cut child-resistant clamshell designs tuned for adult usability.

- High-quality printing options to preserve brand identity while meeting safety labeling needs.

- Material options focused on mono-paperboard constructions to maximize recyclability.

- Prototype and testing support to document performance against child-resistance protocols.

FAQ (Frequently Asked Questions)

Q1: Can paperboard packaging actually be child-resistant?

A1: Yes. When engineered correctly—with structural locks, multi-step closures, and appropriate material stiffness—a paperboard cigarette paper box can provide significant child-resistance. However, any design should be validated with child and adult testing to measure real-world performance.

Q2: Which standard should I test against for reclosable cigarette packaging?

A2: While cigarette packaging is not specifically covered by medical packaging standards, ISO 8317 provides a widely-accepted methodology for testing reclosable child-resistant packaging. Many manufacturers adapt ISO 8317 test procedures as a benchmark. See Child-resistant packaging - Wikipedia for context and links to standards guidance.

Q3: Will adding child-resistant features make my packaging non-recyclable?

A3: Not necessarily. Choosing mono-material paperboard designs and minimizing mixed-material laminates will keep most constructions recyclable. Avoid permanent polymer inserts or heavy metallized coatings if recyclability is a priority.

Q4: How does child-resistant design affect manufacturing cost?

A4: Costs vary depending on complexity. Simple tab closures add little cost, while multi-component slides or polymer snap-inserts increase tooling and assembly expenses. Best Pack offers cost-optimized solutions across budgets with transparent pricing for prototypes and production runs.

Q5: Can Best Pack help with testing and certification?

A5: Yes. Best Pack can assist with prototyping, arranging independent usability and child panel testing, and documenting results to support claims. Contact our team for tailored testing packages for your cigarette paper box design.

If you want to view the product or request a quote for Custom Printed Paperboard Cardboard Cigarette Box Packaging Case Disposable Paper Box for Cigarette Clamshell paper box, please view the product and contact our sales team.

Authoritative references used in this article include the Wikipedia overview of child-resistant packaging and guidance from the U.S. Consumer Product Safety Commission on packaging safety and testing methodologies.

Contact Best Pack customer service for custom designs, material samples, and testing support: Contact Best Pack.

The B2B Buyer’s Guide to cigarette carton box

Labeling and regulatory tips for pre roll packaging

Tamper-evident seals for pre roll non tobacco boxes

Shipping and protection: thick case solutions for pre rolls

FAQs

Do you support custom designs?

Yes, we provide custom packaging designs tailored to your brand and product needs.

What types of packaging do you specialize in?

We specialize in electronic packaging, plastic boxes (PVC/PET/PP), paper boxes, paper bags, and custom book printing.

How do you ensure product quality?

We maintain strict quality control at every stage, from material selection to final production, ensuring high-quality standards.

About us

The process of your packaging box production?

1. Make knife mold as per box size and structure

2. order material as per mold

3. make printing on material if need to print

4. suppress and cut material

5. Makeboxes with glue edge in machine

6. Package boxes into cartons

When can I get the quotation?

1. The quotation will be offered within 24 hours after getting your detailed request.

2. If you get the urgent inquiry, please call us or mark it via E-mail, then we could make it into priority list.

Custom Design Paperboard Child Resist Childproof Button Box Cigarette Size Drawer Craft Packing Box

Custom Printed Paperboard Cardboard Cigarette Box Packaging Case Disposable Paper Box for Cigarette Clamshell paper box

Custom Vape Packaging Box with CR Telescoping Design

The CR telescoping box is a sophisticated and secure packaging solution designed specifically for vape products. Featuring a telescoping (two-piece) structure, this box offers excellent protection and an elegant presentation, enhancing both the unboxing experience and brand appeal.

Best pack

Best pack

Best pack