How to Choose Factory Custom Cigarette Boxes with Logo

- Why factory-direct customized Cigarette Boxes matter for Best Pack

- Brand impact: first impressions and shelf presence

- Protection, preservation, and presentation

- Cost-efficiency and supply chain advantages

- Materials, structure and safety: selecting the right specifications

- Paperboard types and thickness

- Child-resistant packaging and regulatory considerations

- Structural design choices for protection and usability

- Printing, finishing and customization options

- Printing technologies and their uses

- Finishes, tactile elements and security features

- Artwork, color consistency and proofs

- How to select the right size, capacity and factory process

- Choosing capacity: 5-pack, 10-pack, 20-pack considerations

- Minimum order quantity (MOQ), lead times and sampling

- Quality assurance and certifications

- Practical steps to ordering your custom cigarette boxes

- Step-by-step ordering checklist

- Common pitfalls and how to avoid them

- Cost drivers and ways to optimize budget

- Brand advantages when you choose our factory solution

- Factory-direct quality and control

- Sustainability and certification options

- Customization and post-sale support

- FAQ

- Q1: Do you offer child-resistant cigarette boxes that meet safety standards?

- Q2: What is the typical lead time for custom printed cigarette boxes?

- Q3: Can I get physical samples before full production?

- Q4: What are the minimum order quantities (MOQs)?

- Q5: Are sustainable materials available?

- Q6: How should I provide my logo and artwork?

Choosing the right factory custom cigarette boxes with logo requires balancing branding, protection, regulatory compliance and cost. Whether you need stylish retail-ready packs for pre-rolls, durable cases for distribution, or child-resistant packaging that meets safety standards, this guide helps you evaluate materials, printing methods, structural options, capacities, and quality controls so your product looks great, stays safe, and sells well on shelf and online.

Why factory-direct customized Cigarette Boxes matter for Best Pack

Brand impact: first impressions and shelf presence

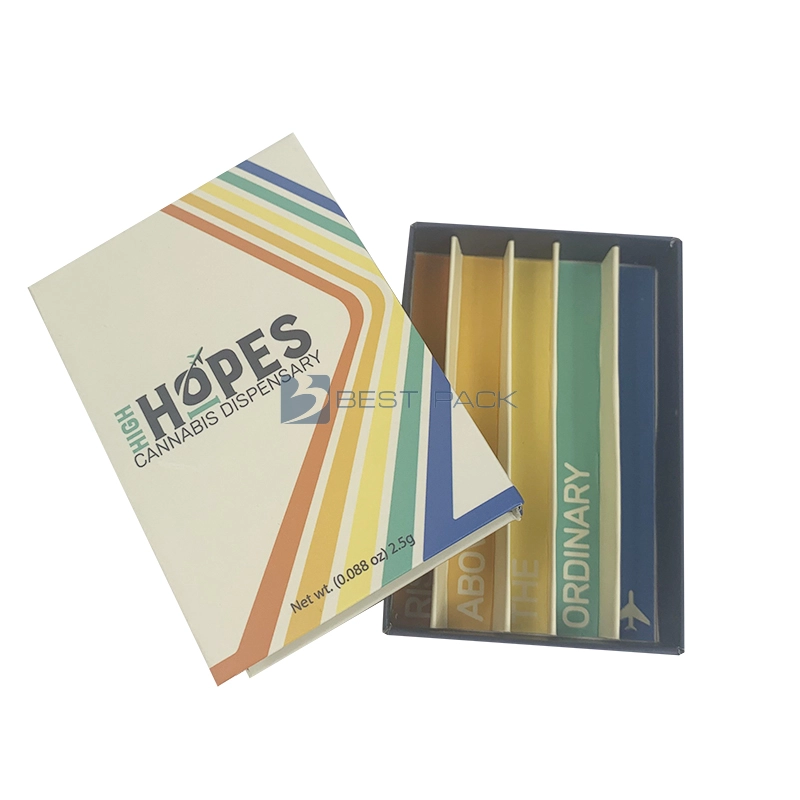

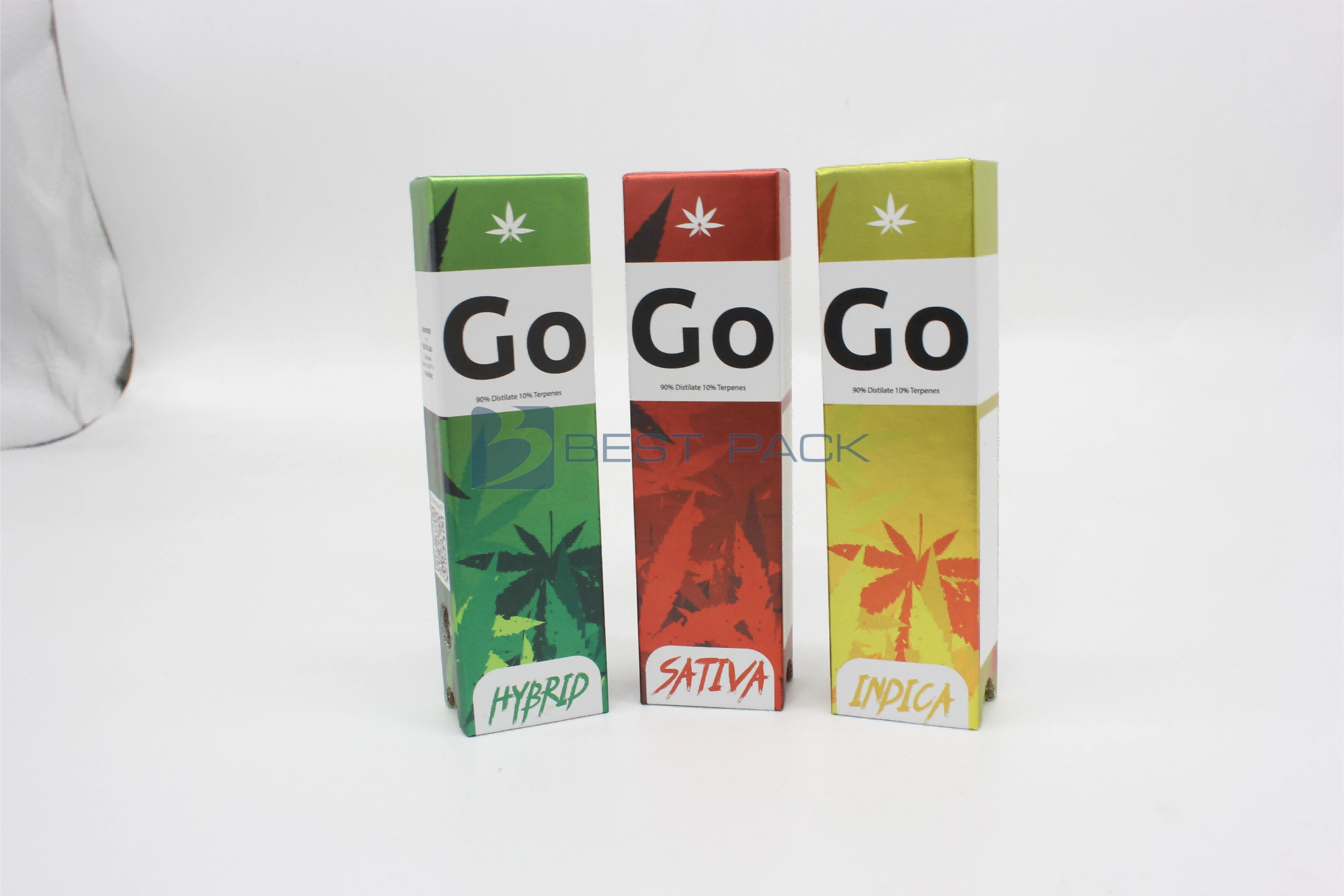

Packaging is often the first physical interaction a customer has with your product. For cigarette boxes and pre-roll packaging, a custom logo and well-executed design reinforce brand positioning, increase perceived value, and improve shelf visibility. High-quality printing, embossing, and foil stamping turn a simple cigarette box into a High Quality touchpoint that helps conversion both in retail and e-commerce channels.

Protection, preservation, and presentation

Factory customized cigarette boxes made from thick paperboard protect fragile pre-rolls, cigarettes, and CBD/THC joints during shipping and handling. Good internal structure—insert trays, tuck flaps, or slide cases—prevents damage while preserving aroma and shape. For non-tobacco herbal products, moisture control, sealed designs, and sturdy construction ensure product quality on arrival.

Cost-efficiency and supply chain advantages

Working directly with a factory offers better control over costs, minimum order quantities (MOQs), lead times, and quality assurance. Factory-direct relationships reduce middleman margins, allow tailored production runs (5-pack, 10-pack, 20-pack), and enable quicker iterations when testing new designs or seasonal packaging variations.

Our product offering — the Factory Customized Printing LOGO Pack 10 20 5 Thick Case Pre Roll Non Tobacco Paper Box Cigarette Boxes — is designed to address these priorities with factory-direct pricing, robust paperboard construction, and full logo customization.

Our factory-direct custom pre-roll and cigarette paper boxes are designed for High Quality presentation, protection, and branding. Made with thick, durable paperboard, these boxes are ideal for non-tobacco herbal pre-rolls, cigarettes, or CBD/THC joints. Available in various capacities (5-pack, 10-pack, 20-pack) and fully customizable with your logo and design.

Materials, structure and safety: selecting the right specifications

Paperboard types and thickness

Select a paperboard grade based on desired rigidity and finish. Common options include:

- Solid bleached sulfate (SBS): High Quality white surface for high-quality printing and finishing.

- Coated recycled board (CCB): cost-effective, good printability, eco-friendly option.

- Grey board (chipboard) with white top: sturdy and economical for inner trays or thick cases.

Wall thickness is typically expressed in GSM or points (pt). For cigarette boxes and pre-roll cases, 300–600 GSM (approx. 8–16 pt) is common for outer shells; inner trays and inserts may use 350–1000 GSM depending on rigidity needs.

Child-resistant packaging and regulatory considerations

If your product category requires child-resistant packaging, incorporate mechanisms such as push-and-slide locks, dual-action openings, or blister retention that meet local regulations. For background on child-resistant standards and rationale, refer to the authoritative overview at Wikipedia and safety guidance from the U.S. Consumer Product Safety Commission (CPSC).

Always verify applicable local requirements: different countries and regions have varying rules for tobacco, CBD/THC, and herbal product packaging. Your factory should be able to accommodate child-resistant features and provide documentation of testing where required.

Structural design choices for protection and usability

Common form factors for factory customized cigarette boxes include tuck-end boxes, telescopic two-piece cases (thick case), slide-out sleeves, and clamshells. Choose based on these priorities:

- Protection: telescopic thick cases and rigid trays offer the best drop and crush resistance.

- Unboxing experience: slide or drawer boxes with soft-touch finishes elevate perceived quality.

- Child-resistance: incorporate locking tabs or inner retention blisters.

Printing, finishing and customization options

Printing technologies and their uses

Decide on printing methods according to volume and visual goals:

- Digital printing: low to medium volumes, fast turnaround, variable data printing (ideal for limited runs or testing multiple designs).

- Offset printing: best for high-volume production with consistent color and lower unit cost at scale.

- UV printing and varnish: spot UV adds gloss accents; full UV coatings increase durability.

Finishes, tactile elements and security features

Finishes enhance brand perception and protect artwork:

- Lamination: matte or gloss to protect surfaces and alter tactile feel.

- Soft-touch coating: luxury velvet-like feel frequently used on High Quality cigarette boxes.

- Foil stamping, embossing/debossing: add High Quality metal accents and texture for your logo.

- Tamper-evident seals and QR security codes: useful for authenticity verification and supply chain traceability.

Artwork, color consistency and proofs

Request color proofs (digital or physical) and a pre-press mockup to confirm logo placement, color accuracy, and dieline fit. Ensure your factory provides Pantone color matching or color profiles for offset runs to maintain brand consistency across batches.

How to select the right size, capacity and factory process

Choosing capacity: 5-pack, 10-pack, 20-pack considerations

Decide capacity based on your product strategy: single-use or sample packs (5), standard retail (10), or economy/multi-pack (20). The product 'Factory Customized Printing LOGO Pack 10 20 5 Thick Case Pre Roll Non Tobacco Paper Box Cigarette Boxes' supports these common capacities, giving flexibility for multiple SKUs and price points.

| Capacity | Common Use | Typical Paperboard | Avg. Unit Cost Range (indicative) |

|---|---|---|---|

| 5-pack | Samples, trial packs, dispensary pre-rolls | 400–600 GSM | Higher per unit (low qty) |

| 10-pack | Standard retail, gift options | 350–600 GSM | Moderate |

| 20-pack | Value packs, multi-packs for distribution | 350–600 GSM, sometimes reinforced | Lower per unit (economies of scale) |

Minimum order quantity (MOQ), lead times and sampling

Understand the factory's MOQ for custom printed cigarette boxes. Digital printing allows smaller MOQs (often a few hundred units), while offset printing may require several thousand units to be cost-effective. Typical lead times range from 10–30 business days depending on complexity, printing method, and child-resistant testing. Always request a physical sample before full production.

Quality assurance and certifications

Assess the factory's quality control: inline inspections, pre-shipment checks, material certificates (FSC for responsible sourcing), and compliance documentation. If you require child-resistant functionality, ask for testing reports and compliance certificates. For general safety and industry context, consult the CPSC (CPSC) and international packaging resources like Wikipedia's summary.

Practical steps to ordering your custom cigarette boxes

Step-by-step ordering checklist

Follow this practical checklist to reduce errors:

- Define product capacity (5/10/20) and geometry (tube, flat, thick case).

- Choose paperboard grade and structural type (tuck-end, slide, telescopic).

- Select printing method and finishes; request proofs.

- Confirm child-resistant requirements and request test certifications if applicable.

- Review MOQ, pricing tiers, lead times and sample policy.

- Approve pre-production sample (PPS) and sign production agreement.

Common pitfalls and how to avoid them

Frequent mistakes include under-specifying the board thickness, ignoring dieline tolerances, insufficient color approval, and overlooking child-resistant verifications. Avoid these by requesting physical prototypes, asking for material certificates (such as FSC), and confirming that the factory will perform drop and crush testing when required.

Cost drivers and ways to optimize budget

Cost factors include printing method, special finishes, board thickness, and child-resistant mechanisms. Optimize costs by consolidating SKUs for larger print runs, choosing hybrid finishes (spot UV rather than full), and negotiating MOQ tiers. Factory-direct ordering typically yields the best unit pricing at scale.

Brand advantages when you choose our factory solution

Factory-direct quality and control

Working with our factory for the 'Factory Customized Printing LOGO Pack 10 20 5 Thick Case Pre Roll Non Tobacco Paper Box Cigarette Boxes' gives you direct oversight of production, tighter QC, and shorter communication loops. We maintain strict inline inspections and provide pre-shipment images and reports to ensure consistent quality.

Sustainability and certification options

We offer FSC-certified board options and recyclable lamination choices to support sustainability goals. Environmentally responsible packaging is increasingly important to consumers and retailers, and using certified materials enhances brand trust and shelf acceptance.

Customization and post-sale support

Our design team assists with dielines, mockups, color matching, and child-resistant integration. After the sale, we provide re-order tracking, batch consistency checks, and options for inventory storage and staggered delivery to align with your distribution needs.

FAQ

Q1: Do you offer child-resistant cigarette boxes that meet safety standards?

A1: Yes — our factory can integrate child-resistant mechanisms and provide documentation of testing where applicable. Confirm regional regulations ahead of production so we can tailor designs to meet local compliance needs. See background on child-resistant packaging at Wikipedia and regulatory guidance from CPSC.

Q2: What is the typical lead time for custom printed cigarette boxes?

A2: Lead time depends on printing method, complexity and child-resistant testing. Digital runs typically take 10–15 business days; offset production can take 15–30 business days. Rush options may be available for an additional fee.

Q3: Can I get physical samples before full production?

A3: Yes — physical samples and pre-production samples (PPS) are strongly recommended. We create prototype samples for structural verification and print proofs for color approval prior to mass production.

Q4: What are the minimum order quantities (MOQs)?

A4: MOQs depend on printing method. Digital printing supports lower MOQs (often a few hundred units). Offset printing is more economical at higher volumes (usually several thousand units). Contact us with your desired configuration for precise MOQ information.

Q5: Are sustainable materials available?

A5: Yes — we provide recyclable and FSC-certified paperboard options, along with eco-friendly inks and coatings. We can advise on the most sustainable yet cost-effective materials for your design.

Q6: How should I provide my logo and artwork?

A6: Provide vector formats (AI, EPS, PDF) for logos and high-resolution images (300 dpi) for raster artwork. Include Pantone numbers if you require exact color matching. Our pre-press team will review files and suggest optimizations for print.

Ready to order or want a sample? View the product or contact our sales team for a custom quote and design consultation: View Factory Customized Printing LOGO Pack 10 20 5 Thick Case Pre Roll Non Tobacco Paper Box Cigarette Boxes or Contact Us.

References: Child-resistant packaging overview — Wikipedia; US Consumer Product Safety Commission — CPSC.

Sustainable Options for Child-Resistant Pre-Roll Packaging

Best printing finishes for custom cigarette box branding

Top eco-friendly materials for custom cigarette boxes

Tips for buy custom cigarette boxes

FAQs

What services do you provide?

We offer one-stop packaging solutions, including design, printing, and handicraft processing for electronic boxes, plastic boxes, paper boxes, paper bags, and book printing.

What types of packaging do you specialize in?

We specialize in electronic packaging, plastic boxes (PVC/PET/PP), paper boxes, paper bags, and custom book printing.

Can you ship internationally?

Yes, we export worldwide and work with reliable logistics partners for timely delivery.

Do you support custom designs?

Yes, we provide custom packaging designs tailored to your brand and product needs.

About us

When can I get the quotation?

1. The quotation will be offered within 24 hours after getting your detailed request.

2. If you get the urgent inquiry, please call us or mark it via E-mail, then we could make it into priority list.

Manufacture Personalized Blank Cigarette Boxes Custom Pre Roll Box Child Resistant Drawer Cardboard Childproof Box

Various Style Design Drawer-Style Packaging Paper Cigarette Boxes Flip Top Closure Pre Rolled Cones Box With Dividers With Child Resistant.

Factory Paperboard Child Resist Childproof Button Box Drawer Craft Packing Box Cigarette Box for Cigarettes

Discover Best Pack’s Factory Paperboard Child-Resistant Childproof Button Box—an ideal cigarette packing box featuring a secure drawer craft packing design. Engineered for safety and style, this childproof button box ensures reliable child resistance while enhancing your cigarette storage experience.

Custom CR Vape Packaging Cardboard Boxes with Child-Resistant Design

CR custom vape packaging cardboard boxes are specially designed child-resistant packaging solutions crafted to ensure safety, protection, and premium presentation for vape products. Made from sturdy cardboard materials, these boxes balance regulatory compliance with brand aesthetics.

Best pack

Best pack

Best pack