How to Choose Custom Cigarette Boxes for Bulk B2B Orders

- How to Choose Custom Cigarette Boxes for Bulk B2B Orders

- Why choosing the right custom cigarette box matters for B2B buyers

- Product example: what a factory-direct option looks like

- Define functional requirements before ordering a custom cigarette box

- Choose the right material and thickness for durability and feel

- Materials comparison table

- Printing and finishing: achieve consistent brand presentation

- Key considerations for printing

- Child resistance, safety, and regulatory compliance for custom cigarette box

- Where to check regulations

- MOQ, cost drivers, and lead times for bulk B2B orders

- Typical MOQ and lead time comparison

- Quality control, samples and factory audits to mitigate risk

- Logistics and sustainability: optimize packing and reduce costs

- How Factory Customized Printing LOGO Pack 10 20 5 Thick Case Pre Roll Non Tobacco Paper Box Cigarette Boxes supports B2B buyers

- Decision checklist before placing a bulk order for custom cigarette box

- Comparison table: quick guide for B2B buyers

- FAQ — Frequently Asked Questions about custom cigarette box for B2B

- Q: What is the minimum order quantity (MOQ) for custom cigarette box?

- Q: Can these boxes include child-resistant features?

- Q: How long will production and delivery take for a bulk order?

- Q: What are common quality checks I should request?

- Q: Can I request eco-friendly materials and inks?

- Q: How do I get pricing for the Factory Customized Printing LOGO Pack 10 20 5 Thick Case Pre Roll Non Tobacco Paper Box Cigarette Boxes?

- Call to action — Get a quote or see samples

- Authoritative references and further reading

How to Choose Custom Cigarette Boxes for Bulk B2B Orders

Why choosing the right custom cigarette box matters for B2B buyers

For distributors, retailers, and white-label brands, the right custom cigarette box is more than a container — it protects product integrity, communicates brand value, and impacts regulatory compliance and shipping efficiency. Buying in bulk amplifies both risks and savings: a poor choice multiplies returns and complaints, while an optimized choice reduces costs and improves shelf appeal. The right packaging solution is therefore a strategic decision for any B2B purchase.

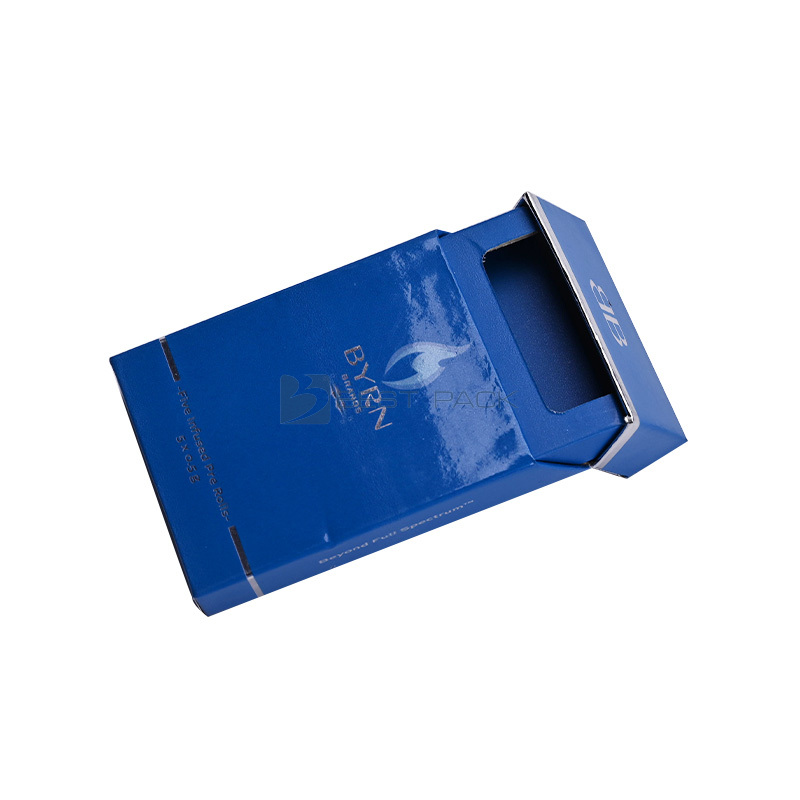

Product example: what a factory-direct option looks like

Factory Customized Printing LOGO Pack 10 20 5 Thick Case Pre Roll Non Tobacco Paper Box Cigarette Boxes

Our factory-direct custom pre-roll and cigarette paper boxes are designed for High Quality presentation, protection, and branding. Made with thick, durable paperboard, these boxes are ideal for non-tobacco herbal pre-rolls, cigarettes, or CBD/THC joints. Available in various capacities (5-pack, 10-pack, 20-pack) and fully customizable with your logo and design.

Define functional requirements before ordering a custom cigarette box

Start by listing the functional requirements: capacity (5, 10, 20 units), product dimensions, fragility, humidity sensitivity, whether you need child-resistant features, shelf display needs, and intended market regulations. For B2B buyers, also consider packing flow (will cartons be handled by automated equipment?), pallet configuration, and retailer carton labeling requirements. Having clear specs minimizes iterations and helps suppliers quote accurately.

Choose the right material and thickness for durability and feel

Material choice affects protection, print quality, cost, and sustainability. Common materials for a custom cigarette box include SBS (solid bleached sulfate), coated/uncoated paperboard, and kraft board. Thickness (measured in GSM or ply) influences resistance to crushing and bending during transport. For High Quality non-tobacco pre-roll boxes, thicker paperboard (e.g., 300–450 gsm) often strikes the right balance of stiffness and printability.

Materials comparison table

| Material | Pros | Cons | Best for |

|---|---|---|---|

| SBS (Coated paperboard) | Excellent print finish, bright whites, High Quality look | Higher cost, less raw/eco aesthetic | High Quality brands, full-color graphics |

| Kraft (recycled) | Eco-friendly look, lower cost, high stiffness | Limited print finish, muted colors | Eco brands, rustic aesthetics |

| Uncoated paperboard | Matte finish, good for spot printing, lower sheen | Lower color vibrancy | Minimalist brands, natural feel |

Printing and finishing: achieve consistent brand presentation

Printing choices determine visual impact and cost. Digital printing is ideal for short runs and fast turnarounds; offset printing offers lower unit cost at larger volumes and superior color consistency. Typical finishes for a custom cigarette box include matte/gloss lamination, soft-touch coating, foil stamping, embossing, spot UV, and die-cut windows. Choose finishes that match the brand story: foil and embossing communicate High Quality, while matte or uncoated conveys natural and understated.

Key considerations for printing

- Color fidelity: request Pantone or color proofs for consistent brand colors.

- Durability: choose lamination or coating if boxes will be handled frequently or exposed to humidity.

- Variable data: if each box needs unique codes or serial numbers, confirm digital printing capability and data management workflow.

Child resistance, safety, and regulatory compliance for custom cigarette box

Even for non-tobacco products like herbal pre-rolls or CBD joints, some markets require child-resistant packaging or clear labeling. Consider industry standards and local regulations when designing a custom cigarette box: child-resistant closures, tamper-evident features, and required health or ingredient labeling can affect box structure and printing layout. For markets with stringent rules, specify compliance up front to avoid redesigns.

Where to check regulations

Consult local regulatory bodies (e.g., FDA in the U.S. for tobacco or nicotine products), consumer safety commissions for child-resistant packaging guidance, and market-specific cannabis/CBD requirements. When in doubt, work with a packaging supplier experienced in regulatory packaging for your target region.

MOQ, cost drivers, and lead times for bulk B2B orders

Understanding minimum order quantities (MOQ), unit cost drivers, and lead times helps you plan inventory and cash flow. MOQs vary by printing method and supplier: digital printing MOQs can be as low as a few hundred units, while offset often requires thousands. Key cost drivers include material type, board thickness, print complexity (number of colors, special finishes), die-cut complexity, and post-print finishing.

Typical MOQ and lead time comparison

| Method | Typical MOQ | Estimated Lead Time (production) | Cost per unit (indicative) |

|---|---|---|---|

| Digital printing | 100–1,000 | 7–14 days | Higher at low volume, drops with volume |

| Offset printing | 3,000–10,000+ | 14–30 days | Lower per-unit at high volume |

| Flexo (corrugated outer cartons) | 1,000+ | 10–21 days | Moderate |

Quality control, samples and factory audits to mitigate risk

Implement a quality assurance process for all bulk B2B orders. Steps include: approving dielines and structural samples, ordering pre-production (PP) samples for color and fit-checks, performing in-line QC during production, and a final pre-shipment inspection (PSI) to check quantities, print quality, and packaging integrity. For large orders, consider factory audits or third-party inspection to verify material specs and labor standards.

Logistics and sustainability: optimize packing and reduce costs

Design your custom cigarette box with shipping in mind. Flat-pack designs reduce freight costs; nesting and board thickness affect pallet count. Additionally, sustainable choices (recycled board, recyclable adhesives, minimal plastic) reduce environmental impact and may be required by some retailers. Certifications such as FSC or recycled-content claims strengthen buyer confidence. Aligning structural design with logistic needs reduces damage, return rates, and overall cost per sale.

How Factory Customized Printing LOGO Pack 10 20 5 Thick Case Pre Roll Non Tobacco Paper Box Cigarette Boxes supports B2B buyers

The product Factory Customized Printing LOGO Pack 10 20 5 Thick Case Pre Roll Non Tobacco Paper Box Cigarette Boxes is designed for B2B customers who need reliable, scalable packaging. Key advantages include:

- Factory-direct production: lower unit cost and more control over lead times for bulk orders.

- Available capacities: 5-pack, 10-pack, and 20-pack options to match different retail SKUs and price points.

- Durable paperboard: thicker stock reduces damage in transit and presents a High Quality feel on shelf.

- Full customization: logo printing and bespoke artwork options help with brand consistency and compliance labeling.

- Designed for non-tobacco pre-rolls and CBD/THC joints: packaging dimensions and structure cater to fragile cylindrical products while supporting optional child-resistant solutions.

Decision checklist before placing a bulk order for custom cigarette box

Use this checklist to reduce surprises and optimize value:

- Confirm exact internal dimensions and product fit.

- Decide material and finish that match brand and budget.

- Confirm whether child-resistant/tamper-evident features are required for your market.

- Request samples (structural and printed) before mass production.

- Verify MOQ, lead time, and total landed cost including freight and duties.

- Arrange a pre-shipment inspection or accept third-party QA.

Comparison table: quick guide for B2B buyers

| Need | Recommended Material/Option | Why it matters |

|---|---|---|

| High Quality shelf look | SBS + foil/embossing + soft-touch lamination | High perceived value and vibrant print |

| Eco positioning | Kraft or recycled board + water-based inks | Lower environmental impact, retail-friendly |

| Low MOQ | Digital print on coated board | Fast turnaround, cost-effective for small runs |

| High-volume cost efficiency | Offset printing on paperboard | Lowest cost per unit at scale |

FAQ — Frequently Asked Questions about custom cigarette box for B2B

Q: What is the minimum order quantity (MOQ) for custom cigarette box?

A: MOQ depends on printing method and supplier. Digital printing MOQs can be as low as 100–500 units. Offset printing typically requires 3,000+ units for cost-efficiency. Always confirm with your supplier.

Q: Can these boxes include child-resistant features?

A: Yes—child-resistant or tamper-evident closures can be integrated, but design complexity and testing requirements can increase lead time and cost. Specify regulatory needs upfront so the supplier can provide compliant solutions.

Q: How long will production and delivery take for a bulk order?

A: Typical production lead times range from 7–30 days depending on printing method, finishes, and order size. Add shipping time based on origin and destination. Factory-direct suppliers can often provide expedited options for a fee.

Q: What are common quality checks I should request?

A: Approve dieline and structure, request a pre-production sample (PP), verify color proofs, and require a pre-shipment inspection to confirm counts, print quality, and packaging integrity.

Q: Can I request eco-friendly materials and inks?

A: Yes. Many factories offer recycled paperboard, FSC-certified options, and soy- or water-based inks. Confirm recyclability claims and available certifications before ordering.

Q: How do I get pricing for the Factory Customized Printing LOGO Pack 10 20 5 Thick Case Pre Roll Non Tobacco Paper Box Cigarette Boxes?

A: Contact the supplier with your product dimensions, desired material, print files, finishes, and target quantity. For bulk B2B orders, request a tiered quote (e.g., pricing for 1k, 5k, 10k units) to compare unit-cost reductions.

Call to action — Get a quote or see samples

Ready to purchase or evaluate samples? Contact our sales team to request a quote, view pre-production samples, or discuss child-resistant and compliance options. Ask specifically about Factory Customized Printing LOGO Pack 10 20 5 Thick Case Pre Roll Non Tobacco Paper Box Cigarette Boxes and provide your desired capacity (5/10/20 pack), material, and artwork. Our team will provide lead times, MOQ details, and shipping estimates for bulk B2B orders.

Authoritative references and further reading

- Packaging (general overview) — Wikipedia: https://en.wikipedia.org/wiki/Packaging

- Child-resistant packaging — Wikipedia: https://en.wikipedia.org/wiki/Child-resistant_packaging

- U.S. Consumer Product Safety Commission (Child-Resistant Packaging guidance): https://www.cpsc.gov/Business--Manufacturing/Business-Education/Business-Guidance/Child-Resistant-Packaging

- U.S. Food & Drug Administration (tobacco product guidance, useful for packaging regulations research): https://www.fda.gov/tobacco-products

- Cardboard and paperboard overview — Wikipedia: https://en.wikipedia.org/wiki/Cardboard

- EPA Sustainable Management of Materials (paper recycling): https://www.epa.gov/smm/sustainable-management-materials

What Is Child Resistant Box Packaging and Why Your Brand Needs It

Design Tips for Creating Functional and Attractive Child-Safe Paper Boxes

Tips for buy personalized cigar box

The latest trends for cigarette pack designs

FAQs

What types of packaging do you specialize in?

We specialize in electronic packaging, plastic boxes (PVC/PET/PP), paper boxes, paper bags, and custom book printing.

How do you ensure product quality?

We maintain strict quality control at every stage, from material selection to final production, ensuring high-quality standards.

Can you ship internationally?

Yes, we export worldwide and work with reliable logistics partners for timely delivery.

About us

How much of your samples cost ?

1. If samples are without printing, we can make free samples as per your box size or structure;

2. If samples are silk printing, normally USD 25 per color,depending on your logo colors;

3. If samples are offset printing, need USD 180 as offset printing mold cost is high.

When can I get the quotation?

1. The quotation will be offered within 24 hours after getting your detailed request.

2. If you get the urgent inquiry, please call us or mark it via E-mail, then we could make it into priority list.

Custom Printed Paperboard Cardboard Cigarette Box Packaging Case Disposable Paper Box for Cigarette Clamshell paper box

Custom Vape Packaging Box with CR Telescoping Design

The CR telescoping box is a sophisticated and secure packaging solution designed specifically for vape products. Featuring a telescoping (two-piece) structure, this box offers excellent protection and an elegant presentation, enhancing both the unboxing experience and brand appeal.

Custom Logo Child-Resistant Pre-Roll Box Packaging Biodegradable Handmade Luxury 5 Pack Embossing Childproof Pre Roll Package

Custom CR Vape Packaging Cardboard Boxes with Child-Resistant Design

CR custom vape packaging cardboard boxes are specially designed child-resistant packaging solutions crafted to ensure safety, protection, and premium presentation for vape products. Made from sturdy cardboard materials, these boxes balance regulatory compliance with brand aesthetics.

Best pack

Best pack

Best pack