Custom print finishes that elevate pre roll packaging

- Custom print finishes that elevate pre roll packaging

- Why print finishes matter for pre roll packaging (and Best Pack)

- Key custom print finishes for pre roll packaging

- Matte lamination / soft-touch coating

- Gloss lamination and high-gloss varnish

- Spot UV / gloss varnish accents

- Foil stamping (hot foil)

- Embossing and debossing

- Aqueous coatings and protective overprints

- Eco-friendly inks and water-based varnishes

- How to choose the right finish for different pre roll packaging needs

- Durability, protection, and functionality for pre roll packaging

- Comparing finishes: visual impact, durability, and cost

- Factory customization: what to expect from a supplier

- Regulatory and child-safety considerations for pre roll packaging

- Brand advantage: how Factory Customized Printing LOGO Pack 10 20 5 Thick Case Pre Roll Non Tobacco Paper Box Cigarette Boxes raise your product

- Practical tips for artwork and production

- Performance metrics: how to measure ROI of upgraded finishes

- Frequently Asked Questions (FAQ)

- Q: Can Factory Customized Printing LOGO Pack 10 20 5 Thick Case Pre Roll Non Tobacco Paper Box Cigarette Boxes be made child-resistant?

- Q: What is the typical lead time for finishes like foil stamping and embossing?

- Q: Are eco-friendly inks and finishes available?

- Q: What file formats should I provide for best color fidelity?

- Q: How do I balance cost and High Quality appearance?

- Contact us / View product

- References and sources

Custom print finishes that elevate pre roll packaging

Why print finishes matter for pre roll packaging (and Best Pack)

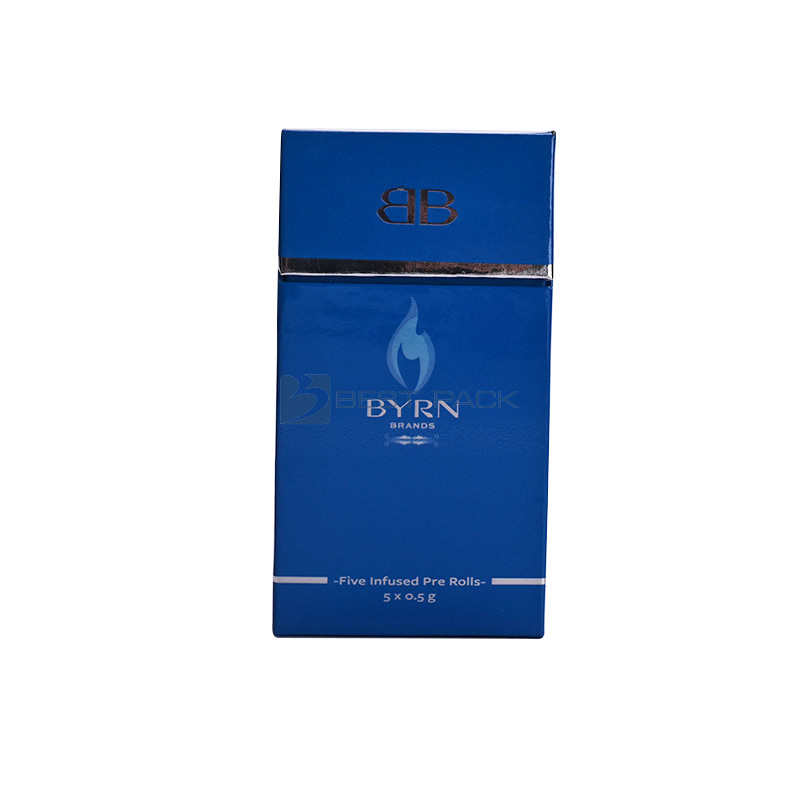

Pre roll packaging is more than a container — it is the first physical interaction a customer has with your product and brand. For products like Factory Customized Printing LOGO Pack 10 20 5 Thick Case Pre Roll Non Tobacco Paper Box Cigarette Boxes, High Quality print finishes provide tangible benefits: they increase shelf impact, convey quality, protect delicate contents (joints, pre-rolls, or cigarettes), and help meet regulatory and child-safety labeling expectations. Choosing the right finish for your pre roll packaging directly affects conversions, shelf performance, and perceived value. While custom print finishes create visual appeal, using sustainable materials for pre-roll packaging solutions ensures that your packaging is environmentally friendly. Choosing recyclable or biodegradable materials aligns with sustainability trends and meets consumer demand for eco-conscious products.

Key custom print finishes for pre roll packaging

Below are the most effective print finishes used in High Quality pre roll packaging. Each finish can be applied alone or combined for layered effects (for example, matte lamination plus spot UV for selective gloss accents).

Matte lamination / soft-touch coating

Matte or soft-touch finishes give a luxurious, velvety feel and reduce glare under retail lighting. They’re ideal for brands that want a High Quality, understated look. Soft-touch also improves grip, reducing the chance that customers will drop delicate pre-rolls.

Gloss lamination and high-gloss varnish

Gloss finishes increase color saturation and make designs pop, which is useful for bold, vibrant branding. Gloss is often paired with high-contrast graphics to attract attention in crowded retail environments.

Spot UV / gloss varnish accents

Spot UV selectively applies a glossy coating to specific design elements (logos, patterns, or images) on a matte or uncoated background. The contrast between matte and glossy surfaces creates a tactile and visual focal point that highlights brand elements without overwhelming the design.

Foil stamping (hot foil)

Metallic foil adds immediate High Quality perception and can communicate luxury or craft. Foil stamping is excellent for logos, seal icons, or limited-edition releases. Color options include gold, silver, copper, and a range of holographic foils for specialty runs.

Embossing and debossing

Embossing (raised) and debossing (impressed) increase perceived value through tactile branding. When used with foil or spot UV, they become even more effective at drawing attention to logos and quality marks.

Aqueous coatings and protective overprints

Aqueous coatings add a protective layer that resists fingerprints, scuffing, and moisture. They are a cost-effective way to improve durability while preserving print clarity.

Eco-friendly inks and water-based varnishes

Brands that prioritize sustainability can use soy- or vegetable-based inks and water-based varnishes to reduce environmental impact. These options are often compatible with recycled or FSC-certified paperboard used in Factory Customized Printing LOGO Pack 10 20 5 Thick Case Pre Roll Non Tobacco Paper Box Cigarette Boxes.

How to choose the right finish for different pre roll packaging needs

Choosing a finish depends on brand positioning, retail environment, product type (CBD/THC vs. herbal non-tobacco), and budget. Below are practical selection guidelines:

- High Quality/luxury brand: Soft-touch + spot UV or foil stamping + embossing to convey craftsmanship.

- Vibrant/retail-forward brand: Gloss lamination + full-color CMYK printing to stand out on shelves.

- Value / mass-market brand: Aqueous coating or matte varnish for durability at lower cost.

- Sustainable brand: Uncoated or matte recycled board with eco inks and minimal finishing.

Durability, protection, and functionality for pre roll packaging

Thick paperboard and suitable finishes protect contents from crushing, moisture, and light exposure. Factory Customized Printing LOGO Pack 10 20 5 Thick Case Pre Roll Non Tobacco Paper Box Cigarette Boxes are built with heavy paperboard to reduce transit damage and protect fragile pre-rolls. Consider these functional additions:

- Inner trays or inserts to keep rolls from shifting.

- Barrier coatings or liners if product is sensitive to humidity.

- Child-resistant closures or tamper-evident seals when regulated.

Comparing finishes: visual impact, durability, and cost

Use the table below to quickly compare finishes. Cost levels are relative (Low / Medium / High) and depend on run size, complexity, and foil/emboss tooling.

| Finish | Visual impact | Durability | Relative cost | Best use |

|---|---|---|---|---|

| Matte / Soft-touch | Subtle, High Quality | High (fingerprints less visible) | Medium | Luxury CBD/THC, limited editions |

| Gloss | High color saturation | Medium (shows fingerprints) | Low–Medium | Mass retail, colorful designs |

| Spot UV | High contrast focal points | Medium | Medium–High | Highlight logos/patterns |

| Foil stamping | Very high, High Quality | High | High | Luxury branding, limited runs |

| Emboss/Deboss | High tactile prestige | High | High | Brand marks, seals |

| Aqueous coating | Neutral | High (protective) | Low | Cost-effective protection |

Sources for general packaging finish performance and industry practice are listed at the end.

Factory customization: what to expect from a supplier

When ordering Factory Customized Printing LOGO Pack 10 20 5 Thick Case Pre Roll Non Tobacco Paper Box Cigarette Boxes, confirm the following with your supplier to ensure the finish meets your expectations:

- Proofing process: digital proofs, color swatches, and physical pre-production samples for finishes like foil and embossing.

- Pantone / CMYK color matching capabilities.

- Turnaround time for tooling (foils/emboss dies) and for standard runs.

- MOQ (minimum order quantity) and cost breaks for different finish combinations.

- Sustainability options: recycled board, FSC certification, eco-inks, and recyclable coatings.

Regulatory and child-safety considerations for pre roll packaging

Packaging for CBD/THC and herbal pre-rolls must comply with regional rules around labeling, child-resistant packaging, and warnings. While finishes won’t replace required child-resistant closures, they should be compatible with those mechanisms (e.g., lamination that withstands repeated opening). Always confirm local regulations before finalizing artwork and finish choices. For example, Health Canada and many U.S. states require specific child-resistant features and warning labels for cannabis products; be sure your chosen finish allows legible, durable printing of required text.

Brand advantage: how Factory Customized Printing LOGO Pack 10 20 5 Thick Case Pre Roll Non Tobacco Paper Box Cigarette Boxes raise your product

Combining High Quality finishes with factory-direct quality control gives you measurable branding advantages:

- Consistent brand presentation: Factory-controlled printing reduces color variation across batches.

- Cost efficiency: Direct manufacturing reduces middleman markups and enables better pricing for higher-spec finishes.

- Customization at scale: Multiple pack sizes (5, 10, 20) let you target different price points while keeping a consistent design system.

- Quality materials: Thick paperboard improves feel and protection, enhancing perceived value and customer satisfaction.

- Sustainability options: Recycled or FSC-certified boards, and eco-inks, are available to match brand commitments.

Practical tips for artwork and production

To ensure your finishes translate well from concept to shelf, follow these practical steps:

- Provide vector artwork (AI, EPS, PDF) with fonts outlined for sharp logos and text.

- Supply Pantone references for brand-critical colors; use CMYK for photographic images.

- Specify dielines and safe/text bleed areas for each pack size (5/10/20 packs).

- Request physical proofs for foil, emboss, and soft-touch combinations before full production.

Performance metrics: how to measure ROI of upgraded finishes

Measure the impact of upgraded finishes with specific KPIs:

- Conversion lift: track sales before and after packaging switch in equivalent periods.

- Average order value (AOV): High Quality packaging may justify higher price points or increase bundle purchase rates.

- Retail velocity: units sold per week in brick-and-mortar locations.

- Customer feedback and return rates: reduced damage claims indicate better protection from finishes and board weight.

Frequently Asked Questions (FAQ)

Q: Can Factory Customized Printing LOGO Pack 10 20 5 Thick Case Pre Roll Non Tobacco Paper Box Cigarette Boxes be made child-resistant?

A: The printed boxes are compatible with child-resistant inserts and closures. While finishes like soft-touch or lamination don’t themselves make a package child-resistant, the box design can integrate CR mechanisms or be used as an outer sleeve with a CR inner container. Always follow local legal requirements and test CR mechanisms as part of the production run.

Q: What is the typical lead time for finishes like foil stamping and embossing?

A: Lead time varies by supplier and complexity. Tooling for foil and emboss dies typically adds 5–10 business days for the first run, with production times of another 10–20 business days depending on quantity and current factory schedules. Confirm specific timelines with your manufacturer.

Q: Are eco-friendly inks and finishes available?

A: Yes. Many factories offer soy/vegetable-based inks, water-based varnishes, and recyclable laminations. If sustainability is a priority, request FSC-certified board and confirm recyclability of combined materials.

Q: What file formats should I provide for best color fidelity?

A: Vector artwork (AI, EPS, high-res PDF) with outlined text, plus Pantone color references for brand-critical elements. Include dielines and specify intended finishes so proofing can reflect the final appearance.

Q: How do I balance cost and High Quality appearance?

A: Combine one high-impact finish (e.g., foil or soft-touch) with a cost-effective protective coating (aqueous) to get High Quality perception without the highest spend. Discuss MOQ pricing tiers—larger runs significantly reduce per-unit cost for high-end finishes.

Contact us / View product

To explore finish samples, request a quote, or view Factory Customized Printing LOGO Pack 10 20 5 Thick Case Pre Roll Non Tobacco Paper Box Cigarette Boxes, contact our sales team. We offer sample packs showing different finish combinations and can advise on compliance, durability testing, and cost-optimized production plans.

References and sources

- Packaging industry best practices and finish descriptions — Packaging World, Packaging Europe.

- Market context for cannabis and CBD packaging requirements — U.S. FDA guidance on labeling and Health Canada cannabis packaging regulations.

- Materials and sustainability guidance — Forest Stewardship Council (FSC) and general eco-ink producers.

Note: consult local regulators for jurisdiction-specific child-resistant and labeling requirements. For production-specific timelines, costs, and sample approvals, contact the manufacturer directly.

How Factory Customized LOGO Packs Boost Brand Recognition

The latest trends for cigar box custom

How Child Resistant Paper Boxes Can Strengthen Brand Trust and Loyalty

Sustainable Cigarette Box Solutions: Child Safety Trends 2026

About us

What is the box size and structure?

1. All boxes are customized and all detailed requirements can be provided by clients, we are definitely your OEM service supplier.

2. If you have no idea about the measurements and structure on your products, our professional design team can suggest and solute for you .

How much of your samples cost ?

1. If samples are without printing, we can make free samples as per your box size or structure;

2. If samples are silk printing, normally USD 25 per color,depending on your logo colors;

3. If samples are offset printing, need USD 180 as offset printing mold cost is high.

FAQs

Can you ship internationally?

Yes, we export worldwide and work with reliable logistics partners for timely delivery.

What types of packaging do you specialize in?

We specialize in electronic packaging, plastic boxes (PVC/PET/PP), paper boxes, paper bags, and custom book printing.

How do you ensure product quality?

We maintain strict quality control at every stage, from material selection to final production, ensuring high-quality standards.

Custom CR Vape Packaging Cardboard Boxes with Child-Resistant Design

CR custom vape packaging cardboard boxes are specially designed child-resistant packaging solutions crafted to ensure safety, protection, and premium presentation for vape products. Made from sturdy cardboard materials, these boxes balance regulatory compliance with brand aesthetics.

Custom Luxury Pre Roll Packaging Boxes with Child-Resistant Paper Tray

Our luxury pre-roll packaging boxes are designed to combine elegant presentation with top-tier safety features. Featuring a child-resistant mechanism and a custom paper tray insert, these boxes ensure secure storage while delivering a premium unboxing experience for pre-roll products.

Custom Child-Lock Pre-Roll 5-Pack Packaging Boxes

Our custom child-lock packaging for pre-roll 5-packs is purposefully engineered to combine premium design with certified safety. This packaging solution ensures that five pre-rolls are securely housed in a compact, stylish, and child-resistant format—ideal for compliant cannabis brands that value both form and function.

Best pack

Best pack

Best pack