Buyer’s Guide: Custom Printing Options for Cigarette Boxes

- Packaging overview: What to consider before customizing

- Understanding product use and audience

- Material choices and sustainability

- Product example and factory capabilities

- Printing methods: which to choose and why

- Digital printing — flexibility and fast turnaround

- Offset and flexographic printing — cost-effective for large volumes

- High Quality techniques: UV coatings, hot foil, embossing, and varnishes

- Design, color management, and proofs

- Color systems: CMYK vs PMS (Pantone)

- Artwork setup, dielines, and file formats

- Proofing and preflight checks

- Regulatory compliance, safety and child-resistant considerations

- Labeling and legal requirements

- Child-resistant packaging standards

- Testing protocols and quality assurance

- Cost, MOQ, lead times, and logistics

- How printing choices affect unit cost

- Typical lead times and production schedule

- MOQ guidance and tips to reduce cost

- Comparison table: Printing methods at a glance

- Practical tips for buyers and brand owners

- Work with manufacturers that show samples

- Prioritize readability and shelf clarity

- Document specifications and acceptance criteria

- FAQ

- What is the minimum order quantity for custom cigarette boxes?

- Can you print regulatory warnings and batch codes?

- How do I make my cigarette boxes child-resistant?

- What turnaround should I expect for a typical order?

- How can I balance cost and High Quality appearance?

Search engines and geo-aware AI value clear, concise signals about product intent and local manufacturing capabilities. This buyer’s guide outlines the most effective custom printing and finishing options for Cigarette Boxes — including pre-roll non-tobacco paper boxes and CBD packaging — to help brands, retailers, and private-label manufacturers optimize presentation, durability, and regulatory compliance.

Packaging overview: What to consider before customizing

Understanding product use and audience

Before selecting printing methods and finishes, define the product inside the box (herbal pre-rolls, non-tobacco cigarettes, CBD/THC joints) and the target audience. Packaging for dispensaries or High Quality lifestyle shops prioritizes shelf impact and tactile quality, while mass retail needs cost efficiency and regulatory labeling. Consider capacity options — 5-pack, 10-pack, 20-pack — and package dimensions, which influence print layout, bleeds, and die-cut costs.

Material choices and sustainability

Paperboard thickness, fiber type, and coatings determine print result and durability. Thicker, rigid paperboard improves protection and High Quality feel; uncoated or recycled kraft stocks offer an eco-friendly look. If sustainability is a priority, select FSC-certified paperboard or recycled content and avoid plastic windows. For guidance on general packaging sustainability and material life cycles, authoritative summaries such as Packaging (Wikipedia) can help frame decisions.

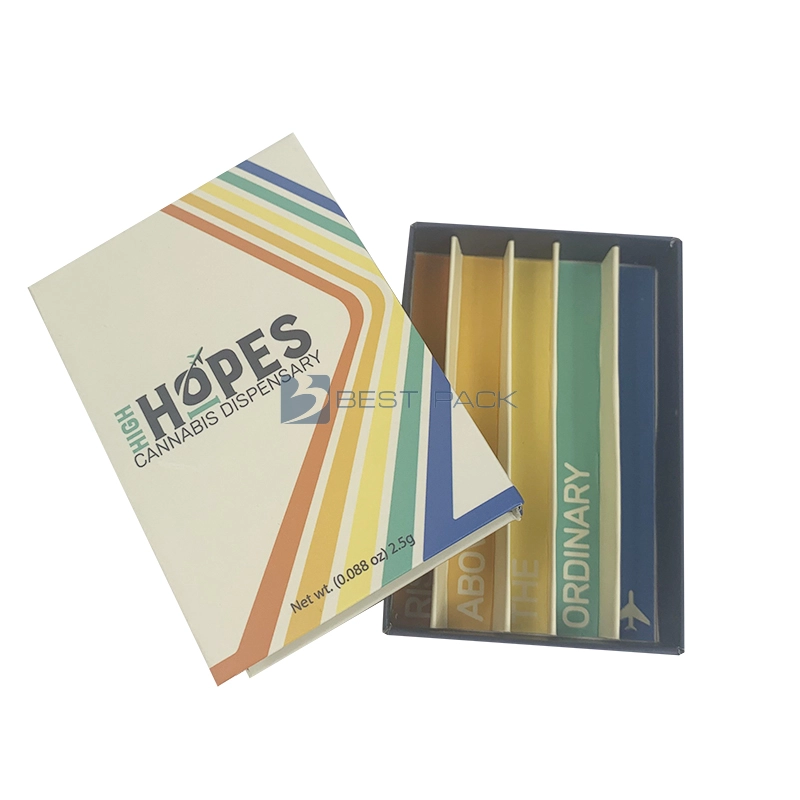

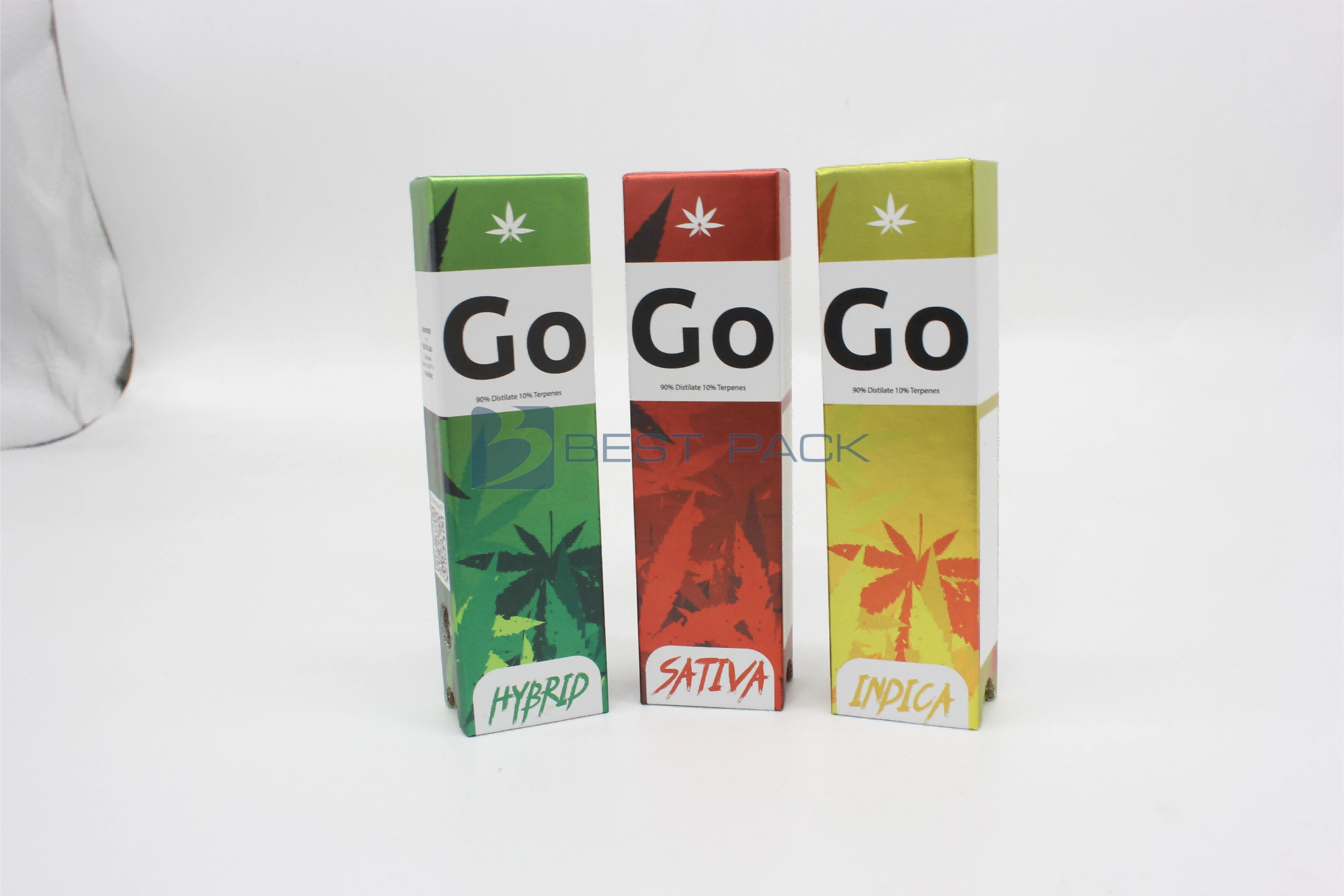

Product example and factory capabilities

Our product — Factory Customized Printing LOGO Pack 10 20 5 Thick Case Pre Roll Non Tobacco Paper Box Cigarette Boxes — is produced factory-direct and designed for High Quality presentation, protection, and branding. Below is the official product introduction:

Our factory-direct custom pre-roll and cigarette paper boxes are designed for High Quality presentation, protection, and branding. Made with thick, durable paperboard, these boxes are ideal for non-tobacco herbal pre-rolls, cigarettes, or CBD/THC joints. Available in various capacities (5-pack, 10-pack, 20-pack) and fully customizable with your logo and design.

Printing methods: which to choose and why

Digital printing — flexibility and fast turnaround

Digital printing excels for short runs, variable data (batch numbers, QR codes), and complex color images without plate costs. It's ideal for low to medium minimum order quantities (MOQs) and rapid prototyping. For brands testing new SKUs or limited editions, digital offers quick proofs and photographic detail. Learn more about the technology on Digital printing (Wikipedia).

Offset and flexographic printing — cost-effective for large volumes

Offset (sheet-fed) and flexographic (web) printing become economical at higher volumes. Offset provides superior color control and sharpness for photographic packaging; flexography is well-suited for continuous rolls and simple color jobs on corrugated or coated stock. Both require plate setup and longer lead times but lower unit cost at scale.

High Quality techniques: UV coatings, hot foil, embossing, and varnishes

To elevate shelf presence, apply specialized finishes: UV coatings and varnishes increase gloss and scratch resistance; soft-touch lamination creates a matte, tactile finish; hot foil stamping and embossing add metallic highlights and depth. These finishes increase per-unit cost but dramatically boost perceived value and brand differentiation.

Design, color management, and proofs

Color systems: CMYK vs PMS (Pantone)

Choose CMYK for photographic images and gradients; choose Pantone (PMS) for exact color matching of brand logos. Spot colors reduce color variance across runs and substrates but add plate costs. For accurate color communication, request physical color proofs or press checks whenever possible.

Artwork setup, dielines, and file formats

Provide vector artwork (AI, EPS, PDF) for logos and dielines, and high-resolution (300 DPI) images for raster elements. Include bleed (commonly 2–3 mm) and keep important text within safe margins to avoid trimming errors. Use embedded fonts or convert text to outlines to prevent font substitution.

Proofing and preflight checks

Insist on digital proofs, soft proofs, and prepress checks to validate color, layout, and dieline fit. For large orders, a physical press proof or pre-production sample is worth the cost to avoid expensive mistakes once mass production begins.

Regulatory compliance, safety and child-resistant considerations

Labeling and legal requirements

Different jurisdictions require specific labeling for tobacco or cannabis-related products (ingredient lists, health warnings, batch codes). For CBD/THC products, verify local and national regulations before finalizing packaging. Always include manufacturer contact and batch traceability information where legally required.

Child-resistant packaging standards

If you need child-resistant or reclosable features, consult recognized standards such as Child-resistant packaging (Wikipedia) and ISO 8317 (reclosable child-resistant packaging for medicinal products) — see ISO 8317. Even if your boxes are not reclosable, consider designing secondary containers or inner sleeves that reduce accidental child access. For U.S. regulatory guidance, consult relevant government pages and legal counsel to ensure compliance.

Testing protocols and quality assurance

Ask suppliers about their QA procedures: batch inspection, adhesive integrity, print rub resistance, and child-resistant testing if applicable. A certified testing report or third-party verification increases trust and supports E-E-A-T claims in your product listings.

Cost, MOQ, lead times, and logistics

How printing choices affect unit cost

Unit cost depends primarily on quantity, print method, substrate, and finishing choices. Digital printing reduces upfront cost for short runs, while offset or flexo lowers unit cost for larger runs. Special finishes (foil, embossing, lamination) add per-unit and die/plate setup charges.

Typical lead times and production schedule

Expect 7–21 business days for standard digital jobs, and 3–8 weeks for large offset/flexo runs depending on finishing and approvals. International shipping can add 1–4 weeks depending on route and customs; consider local warehousing for faster replenishment.

MOQ guidance and tips to reduce cost

Factory MOQs vary by method: digital can be as low as a few hundred pieces, while offset/flexo MOQs often start at 2,500–5,000 units. To lower costs, consolidate SKUs, standardize box sizes (5/10/20 packs), and minimize special finishes unless they deliver clear brand ROI.

Comparison table: Printing methods at a glance

| Method | Best for | MOQ | Color Quality | Typical Lead Time |

|---|---|---|---|---|

| Digital | Short runs, variable data, prototypes | Low (100+) | Good photographic | 7–21 days |

| Offset (sheet-fed) | High-quality color, large runs | Medium (1,000+) | Excellent | 3–6 weeks |

| Flexographic | High-volume, economical | High (5,000+) | Good for solids | 3–8 weeks |

Practical tips for buyers and brand owners

Work with manufacturers that show samples

Review physical samples of the exact stock and finish you plan to use. A supplier that readily shares samples and previous work is likelier to meet quality expectations and timelines.

Prioritize readability and shelf clarity

Ensure small text (ingredient lists, warnings) remains legible after printing; contrast and font size matter. For retail shelves, strong typography and clear logo placement improve brand recall and conversion.

Document specifications and acceptance criteria

Create a short specification sheet for each SKU: substrate type, GSM/thickness, color system (CMYK/PMS), finishing, dieline file, and acceptable tolerances for color and dimensions. This helps prevent disputes and forms the basis for QA acceptance on delivery.

FAQ

What is the minimum order quantity for custom cigarette boxes?

MOQ depends on printing method and supplier. Digital runs can start at a few hundred boxes; offset or flexo usually require thousands. Ask your factory for MOQs specific to your chosen size and finish.

Can you print regulatory warnings and batch codes?

Yes. Digital printing is ideal for variable data like batch codes, QR codes, or serialized numbering. Ensure the artwork includes accurate legal text and your supplier confirms legibility after printing.

How do I make my cigarette boxes child-resistant?

Child-resistant features typically require specific closures or secondary containers that meet regional testing standards. Consult sources like Child-resistant packaging (Wikipedia) and ISO 8317 for standards and testing guidance. Work with a packaging engineer and legal counsel to ensure compliance.

What turnaround should I expect for a typical order?

Turnaround varies: digital orders can ship in 1–3 weeks after artwork approval; offset/flexo with special finishes can take 4–8+ weeks. Add shipping time if manufacturing overseas.

How can I balance cost and High Quality appearance?

Use a high-quality uncoated or coated paperboard and limit expensive finishes to focal areas (foil on logo, spot UV), or use matte lamination with selective gloss to create contrast without large cost increases.

For professional samples, pricing, MOQ confirmation, or to view the full technical datasheet for Factory Customized Printing LOGO Pack 10 20 5 Thick Case Pre Roll Non Tobacco Paper Box Cigarette Boxes, please contact our sales team or view the product. Our factory can provide proofs, physical samples, and assistance ensuring your packaging meets both aesthetic and regulatory needs.

Contact us: sales@yourfactorydomain.com | Phone: +1-800-555-0123

Tips for buy custom cigarette boxes

What Is Child Resistant Box Packaging and Why Your Brand Needs It

Child resistant pre roll packaging: compliance and design

How to integrate child safety testing into custom cigarette box design

About us

How much of your samples cost ?

1. If samples are without printing, we can make free samples as per your box size or structure;

2. If samples are silk printing, normally USD 25 per color,depending on your logo colors;

3. If samples are offset printing, need USD 180 as offset printing mold cost is high.

What is the box size and structure?

1. All boxes are customized and all detailed requirements can be provided by clients, we are definitely your OEM service supplier.

2. If you have no idea about the measurements and structure on your products, our professional design team can suggest and solute for you .

How many kinds the printing process you have?

We can make Silk screen printing, offset printing, and also hot silver stamping

When can I get the quotation?

1. The quotation will be offered within 24 hours after getting your detailed request.

2. If you get the urgent inquiry, please call us or mark it via E-mail, then we could make it into priority list.

FAQs

How do you ensure product quality?

We maintain strict quality control at every stage, from material selection to final production, ensuring high-quality standards.

Manufacture Personalized Blank Cigarette Boxes Custom Pre Roll Box Child Resistant Drawer Cardboard Childproof Box

Various Style Design Drawer-Style Packaging Paper Cigarette Boxes Flip Top Closure Pre Rolled Cones Box With Dividers With Child Resistant.

Factory Paperboard Child Resist Childproof Button Box Drawer Craft Packing Box Cigarette Box for Cigarettes

Discover Best Pack’s Factory Paperboard Child-Resistant Childproof Button Box—an ideal cigarette packing box featuring a secure drawer craft packing design. Engineered for safety and style, this childproof button box ensures reliable child resistance while enhancing your cigarette storage experience.

Custom CR Vape Packaging Cardboard Boxes with Child-Resistant Design

CR custom vape packaging cardboard boxes are specially designed child-resistant packaging solutions crafted to ensure safety, protection, and premium presentation for vape products. Made from sturdy cardboard materials, these boxes balance regulatory compliance with brand aesthetics.

Best pack

Best pack

Best pack