Ensuring Child-Resistant Features in Cigarette Boxes

- Designing Child-Resistant Cigarette Boxes: Principles and Materials

- Material choices and structural design

- Mechanical and passive mechanisms for child resistance

- Designing for durability and repeat use

- Standards, Testing, and Compliance Across Regions

- Key international and national standards

- Testing protocols and documentation

- Regional nuances and legal considerations

- Balancing Safety, Usability, and Branding for Pre-Roll Packaging

- Adult usability vs child safety: finding the balance

- Branding and customization without compromising safety

- Labeling, warnings, and traceability

- Implementation Roadmap for Manufacturers and Retailers

- Step-by-step development process

- Cost, production, and quality-control comparison

- Recommended testing partners and labs

- FAQs — Child-Resistant Cigarette Boxes and Packaging

- Q: Are cigarette boxes required to be child-resistant?

- Q: How do I test whether my Cigarette Boxes are child-resistant?

- Q: Will adding child-resistant features increase production costs significantly?

- Q: Can I still print custom logos and high-end finishes on child-resistant boxes?

- Q: What should be printed on the box to help compliance?

- Q: Where can I find guidance for poisoning prevention and labeling?

- Next Steps & How We Can Help

- References

This guide helps manufacturers, brand owners, and packaging engineers design and certify child-resistant Cigarette Boxes that protect children while remaining convenient for adult consumers. It covers design principles, accepted standards, performance testing, user experience trade-offs, and real-world implementation steps tailored to pre-roll and cigarette paperboard boxes used for non-tobacco herbal pre-rolls, CBD/THC joints, and conventional cigarettes.

Designing Child-Resistant Cigarette Boxes: Principles and Materials

Material choices and structural design

Choosing the right materials is the first step toward effective child-resistant packaging. Thick, durable paperboard offers a good balance of rigidity for locking features and printability for branding. Multi-ply paperboard or chipboard with a high burst and bending strength allows engineered closures (e.g., tuck locks with internal shields) to function consistently over a product's shelf life. Laminates and coatings that increase abrasion resistance also improve longevity of mechanical features and printed instructions.

Mechanical and passive mechanisms for child resistance

Many child-resistant designs rely on mechanical interactions that are difficult for a young child to perform but straightforward for a typical adult. Common approaches adapted to Cigarette Boxes include:

- Two-step closures (push-and-slide or squeeze-and-pull) that require sequence and force control.

- Internal shields or hidden inner trays that must be deliberately exposed to remove contents.

- Lock tabs, breakaway seals, or tear strips that leave a tamper-proof element but are not a permanent barrier to adults.

When designing for pre-rolls or non-tobacco joints, consider small-part containment and odor-sealing requirements alongside child safety—especially if cannabis or CBD products require additional regulatory controls.

Designing for durability and repeat use

Durability testing should simulate repeated opening cycles because adult customers may open and close packaging numerous times. Select paperboard thickness (the product Factory Customized Printing LOGO Pack 10 20 5 Thick Case Pre Roll Non Tobacco Paper Box Cigarette Boxes is built on) and fastening methods to withstand wear. Reinforce stress points (hinges, tuck flaps) with glued joints, hidden reinforcement strips, or thin chipboard inserts when needed.

Standards, Testing, and Compliance Across Regions

Key international and national standards

Child-resistant packaging is governed by different standards depending on product category and region. Two primary references frequently used by packaging professionals are:

- ISO 8317 (issued as an ISO standard for reclosable child-resistant packaging) — widely used as a technical benchmark for test methods and performance requirements.

- Industry overviews of child-resistant packaging on platforms like Wikipedia provide context and links to standards and history.

In the United States, child-resistant packaging for certain hazardous substances is regulated under the Poison Prevention Packaging Act (PPPA) and enforced by the U.S. Consumer Product Safety Commission (CPSC). For tobacco-related items, additional labeling and product rules may come from the U.S. Food and Drug Administration (FDA) or local authorities depending on product classification.

Testing protocols and documentation

Testing usually involves two distinct groups: child panel tests (typically with children 42–51 months old) and adult-useability panels (to ensure adults can open the package). Standards specify sample sizes, test environment, and failure thresholds. Retain full testing documentation, lot numbers, and test lab certificates to demonstrate due diligence during audits and sales in regulated markets.

Regional nuances and legal considerations

Regulations differ: some jurisdictions mandate child-resistant closures for cannabinoids and nicotine products, while others apply generalized poison-prevention rules. Always review local regulatory guidance early in product development. For global distribution, plan for the most stringent expected regime or modular packaging options that can be adapted per market.

Balancing Safety, Usability, and Branding for Pre-Roll Packaging

Adult usability vs child safety: finding the balance

Effective child-resistant packaging must still be convenient for adults—especially customers with reduced dexterity. Usability testing is not optional: involve representative adult users (including older adults) to measure time-to-open, perceived effort, and any confusion points. If adult consumers find the package too difficult, they may transfer product to secondary containers, undermining child safety.

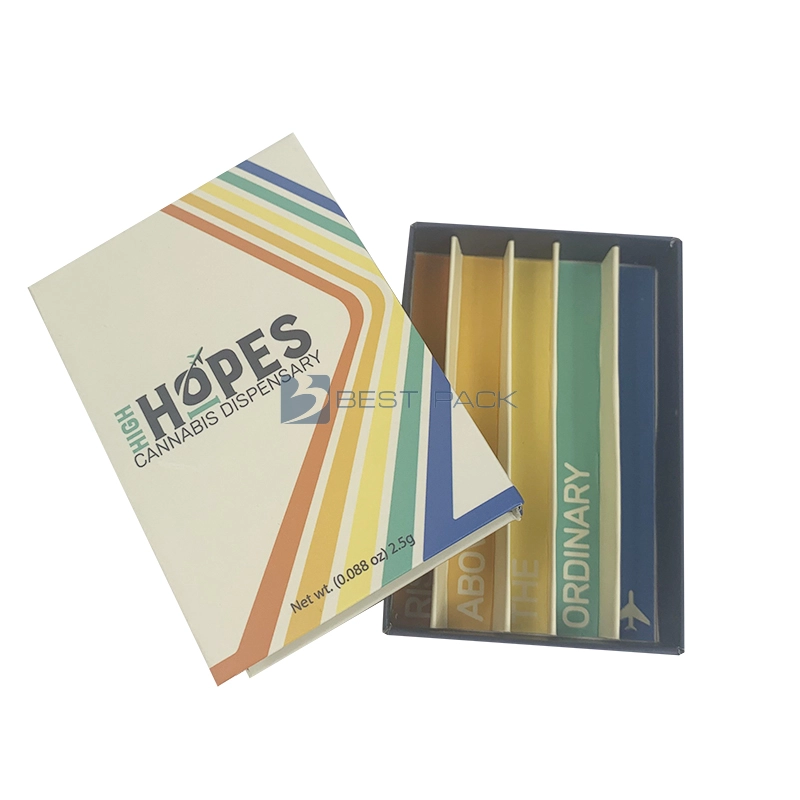

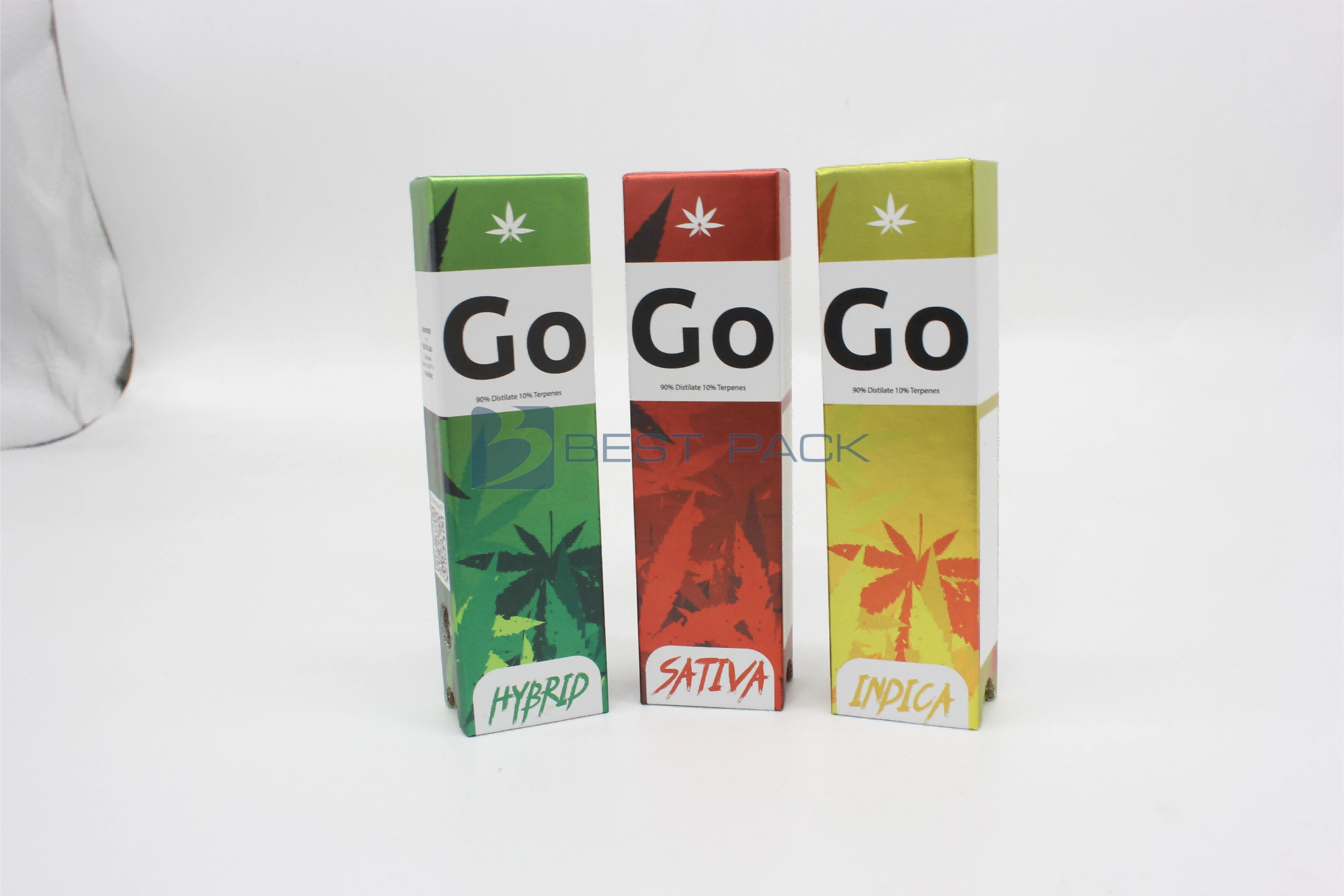

Branding and customization without compromising safety

The Factory Customized Printing LOGO Pack 10 20 5 Thick Case Pre Roll Non Tobacco Paper Box Cigarette Boxes is designed for High Quality presentation, protection, and branding. Below is the official product introduction that can be used on product pages and spec sheets:

Our factory-direct custom pre-roll and cigarette paper boxes are designed for High Quality presentation, protection, and branding. Made with thick, durable paperboard, these boxes are ideal for non-tobacco herbal pre-rolls, cigarettes, or CBD/THC joints. Available in various capacities (5-pack, 10-pack, 20-pack) and fully customizable with your logo and design.

When applying custom print and finishing options (UV coating, foil stamping, embossing), preserve the function of closures and test each print/finish variant. Some coatings can reduce the friction required for push-and-slide mechanisms, and heavy foils can stiffen flaps—always retest after final printing.

Labeling, warnings, and traceability

Place clear child-safety warnings, tamper-evidence labels, batch codes, and expiry/manufacture dates on accessible but non-obstructive locations. QR codes linking to safety instructions, verified testing certificates, or age-verification pages can add transparency for retailers and regulators.

Implementation Roadmap for Manufacturers and Retailers

Step-by-step development process

- Requirements gathering: define markets, user groups, product contents (e.g., non-tobacco pre-rolls, CBD), and regulatory constraints.

- Concept design: sketch mechanisms (two-step, inner tray, tamper seal) matched to chosen paperboard thickness.

- Prototype: produce functional prototypes using the actual material and print finishes.

- Testing: run child and adult panel tests per applicable standards (ISO 8317 or local equivalents).

- Iterate: address failures, refine construction, and retest as necessary.

- Production: lock tooling and quality checks, including cycle testing and in-line QC sampling.

Cost, production, and quality-control comparison

Below is a practical comparison table of common child-resistant mechanisms for paperboard Cigarette Boxes. Use this matrix when selecting the best solution for your Factory Customized Printing LOGO Pack 10 20 5 Thick Case Pre Roll Non Tobacco Paper Box Cigarette Boxes.

| Mechanism | Effectiveness | Adult Usability | Estimated Cost Impact | Printing/Branding Impact |

|---|---|---|---|---|

| Two-step push-and-slide | High (if well executed) | Good (after instruction) | Moderate (tooling/precision required) | Low (compatible with printing) |

| Inner tray / hidden compartment | Very High | Moderate (extra step) | High (additional parts) | Moderate (limited printable area inside) |

| Breakaway tamper seal + inner closure | High (single-use tamper) | High (simple first-open) | Low–Moderate (seal die-cut) | Low (seal area usable for branding) |

| Squeeze-to-open plastic window (hybrid) | Moderate–High | Good | Moderate–High (materials/assembly) | Moderate (design integration needed) |

Recommended testing partners and labs

For objective certification, engage accredited test labs that can perform child panel testing and provide written reports aligned to ISO 8317 or CPSC guidance. Many international packaging test labs can run reproducible tests and offer additional services like accelerated aging and cycle fatigue testing.

FAQs — Child-Resistant Cigarette Boxes and Packaging

Q: Are cigarette boxes required to be child-resistant?

A: Requirements vary by product type and jurisdiction. Some countries require child-resistant packaging for cannabis products, certain nicotine products, or items considered hazardous under the Poison Prevention Packaging Act (PPPA) administered by the U.S. CPSC. Consult local regulatory guidance early in design.

Q: How do I test whether my Cigarette Boxes are child-resistant?

A: Follow recognized standards (e.g., ISO 8317) or local regulatory testing protocols. Testing typically includes child-panel exposure tests and adult-useability tests conducted by accredited labs. Document results for compliance records.

Q: Will adding child-resistant features increase production costs significantly?

A: Costs vary with the complexity of the mechanism. Simple tamper seals add little cost; engineered internal trays or multi-part assemblies increase tooling and unit costs. Use the comparison table above to weigh trade-offs and consider economies of scale with factory-direct production.

Q: Can I still print custom logos and high-end finishes on child-resistant boxes?

A: Yes. High-quality printing, embossing, hot foil, and coatings are compatible with child-resistant paperboard boxes, but each finish should be re-tested to ensure it does not interfere with mechanical functions. The product Factory Customized Printing LOGO Pack 10 20 5 Thick Case Pre Roll Non Tobacco Paper Box Cigarette Boxes is designed for customization while maintaining structural integrity.

Q: What should be printed on the box to help compliance?

A: Include clear warnings (child-safety icons), instructions for opening, tamper evidence indicators, batch/lot codes, manufacture/expiry dates if applicable, and contact information. For regulated products like CBD/THC, include any legally required disclaimers and responsible-use instructions.

Q: Where can I find guidance for poisoning prevention and labeling?

A: Authoritative resources include the U.S. CPSC (Poison Prevention Packaging Act) CPSC PPPA guidance, international standards (e.g., ISO 8317), and public health organizations like the CDC for poisoning prevention statistics and advice.

Next Steps & How We Can Help

If you’re evaluating safe, branded packaging solutions for pre-rolls, cigarettes, or CBD/THC joints, our Factory Customized Printing LOGO Pack 10 20 5 Thick Case Pre Roll Non Tobacco Paper Box Cigarette Boxes are engineered for a balance of High Quality presentation, durability, and child-resistant features. We offer prototyping, child-panel testing coordination, and full production runs with custom printing and finishes.

Contact our packaging specialists to discuss testing, samples, or volume pricing. For immediate product details and to request a quote, please contact us or view the product page.

Contact: Email: sales@example.com | Phone: +1-800-555-0123

References

- Wikipedia — Child-resistant packaging

- ISO 8317 — Child-resistant packaging standards (ISO)

- U.S. CPSC — Poison Prevention Packaging Act (PPPA)

- CDC — Poisoning prevention and statistics

For a customized quote or sample of our Factory Customized Printing LOGO Pack 10 20 5 Thick Case Pre Roll Non Tobacco Paper Box Cigarette Boxes, please contact our sales team or visit our product catalog.

What are the application scenarios of pre roll cone packaging?

Cost Factors to Consider When Ordering Child Resistant Paper Boxes in Bulk

Sustainable Cigarette Box Solutions: Child Safety Trends 2026

The B2B Buyer’s Guide to cigarette box

FAQs

Can you ship internationally?

Yes, we export worldwide and work with reliable logistics partners for timely delivery.

What services do you provide?

We offer one-stop packaging solutions, including design, printing, and handicraft processing for electronic boxes, plastic boxes, paper boxes, paper bags, and book printing.

About us

How much of your samples cost ?

1. If samples are without printing, we can make free samples as per your box size or structure;

2. If samples are silk printing, normally USD 25 per color,depending on your logo colors;

3. If samples are offset printing, need USD 180 as offset printing mold cost is high.

Leading time for samples production?

Normally we need 3-7 days for samples making, 10-12 days to complete your orders,but the delivery time more depends on the order QTY.

How many kinds the printing process you have?

We can make Silk screen printing, offset printing, and also hot silver stamping

Manufacture Personalized Blank Cigarette Boxes Custom Pre Roll Box Child Resistant Drawer Cardboard Childproof Box

Various Style Design Drawer-Style Packaging Paper Cigarette Boxes Flip Top Closure Pre Rolled Cones Box With Dividers With Child Resistant.

Factory Paperboard Child Resist Childproof Button Box Drawer Craft Packing Box Cigarette Box for Cigarettes

Discover Best Pack’s Factory Paperboard Child-Resistant Childproof Button Box—an ideal cigarette packing box featuring a secure drawer craft packing design. Engineered for safety and style, this childproof button box ensures reliable child resistance while enhancing your cigarette storage experience.

Custom CR Vape Packaging Cardboard Boxes with Child-Resistant Design

CR custom vape packaging cardboard boxes are specially designed child-resistant packaging solutions crafted to ensure safety, protection, and premium presentation for vape products. Made from sturdy cardboard materials, these boxes balance regulatory compliance with brand aesthetics.

Best pack

Best pack

Best pack