Design Tips for Effective Logo Printing on Cigarette Boxes

- Design Tips for Effective Logo Printing on Cigarette Boxes

- Why logo printing matters on a cigarette pack

- Know the cigarette pack substrate and dieline before designing

- Choose the right printing method for your cigarette pack

- Color management and pantone matching for consistent cigarette pack logos

- Typography and logo legibility on small cigarette pack panels

- Artwork preparation: file specs and prepress checklist

- Durability: coatings, laminations and tactile finishes for cigarette packs

- Regulatory and labeling considerations for cigarette pack printing

- Special effects and when to use them on a cigarette pack

- Production testing: proofs, mockups, and small pilot runs

- Packaging structural tips to protect and present your logo

- Branding showcase: how our product supports High Quality logo printing

- FAQ — Design and production questions for cigarette pack logo printing

- Contact us / View product

- Authoritative references

Design Tips for Effective Logo Printing on Cigarette Boxes

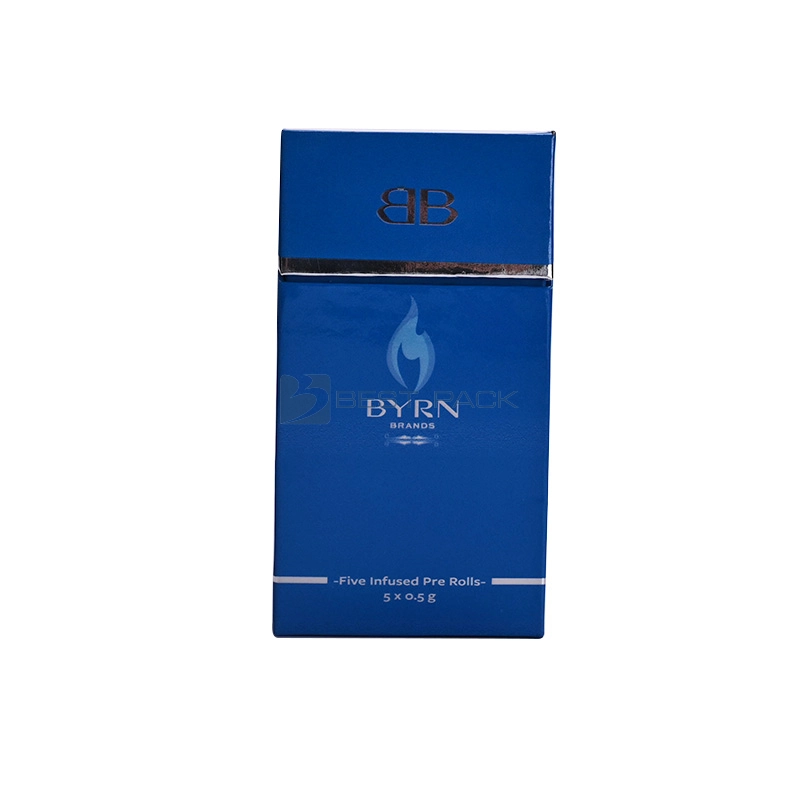

Our factory-direct custom pre-roll and cigarette paper boxes are designed for High Quality presentation, protection, and branding. Made with thick, durable paperboard, these boxes are ideal for non-tobacco herbal pre-rolls, cigarettes, or CBD/THC joints. Available in various capacities (5-pack, 10-pack, 20-pack) and fully customizable with your logo and design. Strong design execution depends heavily on the right partner, which is why buyers must focus on choosing suppliers and asking key questions for custom packaging orders.

Why logo printing matters on a cigarette pack

On-shelf and in-hand, a cigarette pack is one of the most visible brand touchpoints. Effective logo printing on a cigarette pack boosts brand recognition, communicates quality, and can influence perceived value. Because cigarette pack surfaces are small and often wrapped or varnished, some common challenges are limited print area, substrate texture, and regulatory labeling. Designing with these realities in mind helps you create a reproducible, crisp logo that performs in production and in the market.

Know the cigarette pack substrate and dieline before designing

Printing decisions must start with the box construction. Paperboard thickness, fiber composition, and coatings directly affect ink absorption, color vibrancy, and finishing options. Typical substrates for High Quality cigarette boxes are coated or uncoated paperboard in 240–700 gsm range. For the Factory Customized Printing LOGO Pack 10 20 5 Thick Case Pre Roll Non Tobacco Paper Box Cigarette Boxes, the thicker, rigid paperboard supports embossing and heavy foil stamping that thin stock cannot. Always request a dieline from your manufacturer and place critical logo elements at least 3–5 mm away from score lines, glue flaps, and edges to prevent distortion or trimming issues.

Choose the right printing method for your cigarette pack

Different printing technologies produce different results. Match the method to your run length, artwork complexity, and desired finish:

| Printing Method | Best for | Resolution/Quality | Cost per Unit | Pros/Cons |

|---|---|---|---|---|

| Offset Lithography | Medium–large runs with pantone colors | High; consistent color | Low (large runs) | Excellent color control; setup cost higher |

| Digital (Inkjet / Electrophotographic) | Short runs, variable data | Very good for small runs | Higher per unit (short run) | No plates; fast turnaround; limited special effects |

| Flexography | High-speed, long runs (folding carton lines) | Good; improved with modern plates | Low (large runs) | Fast; works well on corrugated and coated boards |

| UV/Spot UV | Adding gloss/tactile highlights | Depends on base print | Moderate | Adds depth and protection; can be used selectively |

| Foil Stamping & Embossing | Luxury finishes and texture | Not about resolution; adds High Quality effect | High per effect | Elevates perceived value; increases cost and lead time |

For most High Quality cigarette pack projects, a combination of offset printing plus selective foil stamping and embossing is ideal. For shorter runs or frequent design changes, high-end digital presses now provide competitive quality.

Color management and pantone matching for consistent cigarette pack logos

Color inconsistency is a common source of brand dilution. Use Pantone spot colors for logos when exact matching matters. If using CMYK, create color-proof samples and request printed proofs from the factory. Consider the effect of varnish and coatings: gloss varnish will saturate and intensify colors; matte coatings will reduce reflectivity and soften colors. Ask for an approved press proof that uses the same substrate and finishing so you can judge the final appearance before the full run.

Typography and logo legibility on small cigarette pack panels

Legibility is critical: brand names must be readable at arm's length. Choose typefaces with open counters and avoid hairline strokes for small sizes. Minimum recommended logo text size for a typical cigarette pack is 6–7 pt (depending on font), but whenever possible increase size and weight. Keep contrast high against background colors. For embossed or foil details, ensure negative space around the logo is sufficient so the effect reads clearly and isn’t lost in texture or varnish.

Artwork preparation: file specs and prepress checklist

Submit vector files when possible (.AI, .EPS, or flattened PDF with fonts outlined). Include these items in your artwork package:

- Final dieline in the manufacturer’s template (with cut, fold, and glue areas clearly marked)

- Pantone or CMYK color specs; include tints and gradients as separate layers

- High-resolution images (300 dpi at print size) if photographic elements are used

- Bleed of 2–3 mm beyond the cut line

- Safety margin of 3–5 mm inside cut lines for critical text and logos

- Separate layers for special effects (foil, emboss, varnish) clearly labelled

Run a preflight check for embedded images, bleed, color spaces (CMYK for print), and font embedding. Ask the factory for a digital mockup and a physical sample before full production.

Durability: coatings, laminations and tactile finishes for cigarette packs

Coatings protect prints from scuffing and give a High Quality hand feel. Common choices include aqueous varnish (cost-effective), UV coatings (very durable and glossy), matte coatings, soft-touch lamination (velvet feel), and spot coatings to highlight logos. For the Factory Customized Printing LOGO Pack 10 20 5 Thick Case Pre Roll Non Tobacco Paper Box Cigarette Boxes, soft-touch and spot UV are popular because they pair well with embossing and foil, creating a layered sensory effect: visual, tactile and reflective. Choose coatings based on how the pack will be handled and sold — rugged retail channels benefit from more durable coatings.

Regulatory and labeling considerations for cigarette pack printing

Although these boxes are described for non-tobacco herbal pre-rolls, if you market products resembling tobacco products you must consider local regulations. Many jurisdictions regulate health warnings, ingredient lists, and packaging styles for tobacco and cannabis products. For example, the EU Tobacco Products Directive sets rules for labeling and cross-border advertising; the World Health Organization provides guidance on tobacco product packaging controls. Consult legal counsel and the manufacturer to ensure compliance with your target markets and to avoid designs that could be mistaken for regulated tobacco packaging when selling CBD/THC or herbal products.

Special effects and when to use them on a cigarette pack

Special effects like metallic foil, embossing, debossing, spot UV, and holographic finishes significantly increase perceived value. Use them strategically — one or two effects are usually enough. Consider the following rules:

- Reserve foil or embossing for the logo or a focal graphic only.

- Combine tactile and visual effects (soft-touch plus spot gloss) to create contrast.

- Keep packaging clean; too many effects create visual noise and increase cost.

Production testing: proofs, mockups, and small pilot runs

Always request a physical sample (pre-production mockup) printed on the same stock and with the same finishing as the final run. Review color, registration, emboss depth, foil adhesion, and folding behavior. For complex finishes run a small pilot batch to confirm consistency and to collect retail feedback. This step prevents expensive reworks on large print runs for your cigarette pack product line.

Packaging structural tips to protect and present your logo

The dieline and structural design influence how the logo is seen. Consider these points:

- Place the primary logo on the front panel that remains flat when closed.

- Avoid placing key elements across folds or edges.

- Use tuck-in or rigid cases for higher perceived value and to preserve logo integrity.

- Window cutouts can showcase contents but ensure logo readability isn’t affected.

Branding showcase: how our product supports High Quality logo printing

The Factory Customized Printing LOGO Pack 10 20 5 Thick Case Pre Roll Non Tobacco Paper Box Cigarette Boxes was developed with these production realities in mind: thick, durable paperboard for embossing and foil, customizable capacities for different SKUs (5-pack, 10-pack, 20-pack), and full support for spot colors and special finishes. We provide dielines, prepress guidance, and physical proofs. For brands prioritizing a High Quality tactile and visual experience, this pack is optimized for quality logo reproduction and consistent brand presentation across production runs.

FAQ — Design and production questions for cigarette pack logo printing

Q: What file format should I send for logo printing?

A: Vector files (.AI, .EPS, or print-ready PDFs with outlined fonts) are best. Include Pantone references and a dieline. High-resolution raster images (300 dpi) are acceptable for photos.

Q: Can you match my Pantone color?

A: Yes — for offset printing we can match Pantone spot colors. For CMYK jobs we provide color proofs; expect slight variations depending on substrate and coating.

Q: Which finish gives the most High Quality look?

A: Combination finishes: soft-touch lamination plus a metallic foil logo with a shallow emboss creates a luxurious, tactile effect ideal for High Quality cigarette pack boxes.

Q: What’s the typical lead time?

A: Proofing and plate setup can take 5–10 business days; production depends on run size and finishing, typically 10–25 business days after sample approval.

Q: Are there regulatory issues I need to consider?

A: Yes. If your product resembles tobacco or is a regulated product (CBD/THC), local labeling and packaging laws may apply. Consult legal guidance for target markets.

Contact us / View product

If you’re ready to create a cigarette pack that showcases your logo precisely and durably, contact our sales team for a free dieline and sample quote. View the Factory Customized Printing LOGO Pack 10 20 5 Thick Case Pre Roll Non Tobacco Paper Box Cigarette Boxes product page or request a printed sample to evaluate color, finish, and tactile effects before production.

Authoritative references

- Packaging — Wikipedia: https://en.wikipedia.org/wiki/Packaging

- Printing — Wikipedia: https://en.wikipedia.org/wiki/Printing

- World Health Organization — WHO Framework Convention on Tobacco Control: https://www.who.int/teams/health-promotion/tobacco-control/who-framework-convention-on-tobacco-control

- European Commission — Tobacco Products: https://ec.europa.eu/health/tobacco/products_en

Top finishing techniques that enhance custom cigarette boxes

Integrating Security Features into Custom Cigarette Packaging

Designing Safe Cigarette Box Packaging for 2026 Compliance

Where to Buy cigarette packaging box

FAQs

How do you ensure product quality?

We maintain strict quality control at every stage, from material selection to final production, ensuring high-quality standards.

Can you ship internationally?

Yes, we export worldwide and work with reliable logistics partners for timely delivery.

What types of packaging do you specialize in?

We specialize in electronic packaging, plastic boxes (PVC/PET/PP), paper boxes, paper bags, and custom book printing.

What services do you provide?

We offer one-stop packaging solutions, including design, printing, and handicraft processing for electronic boxes, plastic boxes, paper boxes, paper bags, and book printing.

About us

What is the box size and structure?

1. All boxes are customized and all detailed requirements can be provided by clients, we are definitely your OEM service supplier.

2. If you have no idea about the measurements and structure on your products, our professional design team can suggest and solute for you .

Custom Printed Paperboard Cardboard Cigarette Box Packaging Case Disposable Paper Box for Cigarette Clamshell paper box

Custom Vape Packaging Box with CR Telescoping Design

The CR telescoping box is a sophisticated and secure packaging solution designed specifically for vape products. Featuring a telescoping (two-piece) structure, this box offers excellent protection and an elegant presentation, enhancing both the unboxing experience and brand appeal.

Custom Logo Child-Resistant Pre-Roll Box Packaging Biodegradable Handmade Luxury 5 Pack Embossing Childproof Pre Roll Package

Custom CR Vape Packaging Cardboard Boxes with Child-Resistant Design

CR custom vape packaging cardboard boxes are specially designed child-resistant packaging solutions crafted to ensure safety, protection, and premium presentation for vape products. Made from sturdy cardboard materials, these boxes balance regulatory compliance with brand aesthetics.

Best pack

Best pack

Best pack