Quality Control Checklist for Factory-Customized Cigarette Boxes

- Quality Control Checklist for Factory-Customized Cigarette Boxes

- Why a rigorous QC process matters for your custom cigarette box

- Define specifications up front: the foundation of a reliable custom cigarette box

- Materials and substrate inspection for durable custom cigarette box production

- Printing, color control, and brand fidelity for your custom cigarette box

- Finishing, coatings, and surface treatments

- Structural integrity and functional testing for custom cigarette box

- Quick pass/fail criteria

- Child-resistant and safety features—what to test for non-tobacco pre-roll boxes

- Environmental and chemical safety checks

- Production process controls and inline quality checks

- Sampling plans and acceptance criteria

- Final inspection, labeling, and shipment readiness for your custom cigarette box

- Quality checklist table (practical at-a-glance view)

- Record-keeping, traceability and corrective actions

- How to root the QC checklist in supplier contracts

- Brand advantages: why choose our factory for your custom cigarette box

- Frequently Asked Questions (FAQ)

- Q: What is the typical lead time for a custom cigarette box order?

- Q: Do you offer child-resistant options for non-tobacco pre-roll boxes?

- Q: What minimum order quantities (MOQs) apply for customized boxes?

- Q: How do you ensure consistent color across multiple production runs?

- Q: What environmental options are available?

- Contact and product CTA

- Authority references

Quality Control Checklist for Factory-Customized Cigarette Boxes

Why a rigorous QC process matters for your custom cigarette box

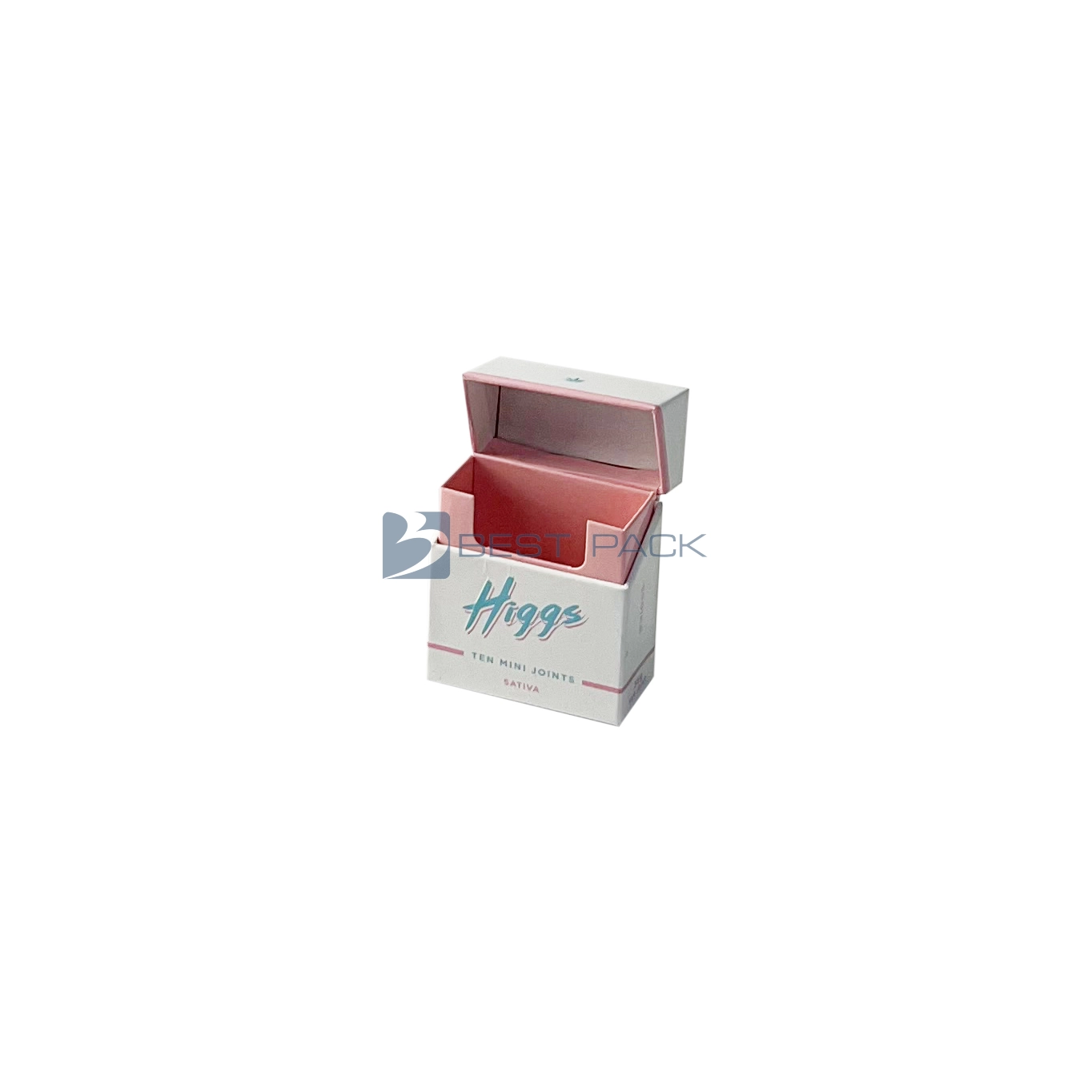

When ordering a custom cigarette box from a factory, you’re buying more than a container — you’re buying protection, presentation, and Best Pack’s first physical impression. A thorough quality control (QC) framework prevents costly rework, protects end-user safety (especially for non-tobacco and CBD/THC products), and ensures regulatory compliance. Whether you need a 5-pack, 10-pack or 20-pack configuration, using a factory-level checklist helps guarantee every batch meets your requirements.

Product snapshot:

Our factory-direct custom pre-roll and cigarette paper boxes are designed for High Quality presentation, protection, and branding. Made with thick, durable paperboard, these boxes are ideal for non-tobacco herbal pre-rolls, cigarettes, or CBD/THC joints. Available in various capacities (5-pack, 10-pack, 20-pack) and fully customizable with your logo and design.

Define specifications up front: the foundation of a reliable custom cigarette box

Before production, document every requirement clearly: material grade (GSM or thickness in mm), substrate type (SBS, CCNB, recycled board), color profiles (Pantone or CMYK values), dielines, tolerances, printing methods (offset, digital, flexo), surface finishes (gloss/matte lamination, aqueous, spot UV), and special features (embossing, foil stamping, window). A precise spec sheet reduces ambiguity and is the baseline for pass/fail decisions in QC.

Materials and substrate inspection for durable custom cigarette box production

Materials set the physical limits of any custom cigarette box. Inspect incoming rolls/sheets for correct grade, color, density, and moisture content. For thick case pre-roll boxes, measure board thickness across multiple points per sheet. Reject batches with delamination, oil spots, tears, or uneven caliper. Keep material certificates from suppliers (e.g., FSC, recycled content) to support sustainability claims.

Printing, color control, and brand fidelity for your custom cigarette box

Printing is where brand quality is visible. Use approved press proofs (digital or contract proof) and a first-article inspection before mass runs. Implement color control with spectrophotometer readings (Delta E targets) and maintain a master Pantone library for consistent logo reproduction. Check for registration errors, ink stacking, smudges, and inaccurate type. For variable-data printing (batch codes or warnings), verify legibility at final size.

Finishing, coatings, and surface treatments

Surface finishes affect look and durability. Inspect lamination adhesion, check for whitening on scored edges, and verify spot UV placement aligned to dieline. Test that varnishes cure properly and do not create tackiness that traps dust. For foil stamping and embossing, confirm die alignment and even pressure to avoid crushed or over-stamped areas.

Structural integrity and functional testing for custom cigarette box

Structural checks ensure the custom cigarette box protects its contents during handling and transit. Typical tests include:

- Dimension tolerance checks against dielines (length, width, height).

- Closure and hinge function tests — ensure easy open/close life cycles without deformation.

- Crush and compression testing to simulate stacking loads.

- Drop tests from defined heights to check content protection and box resilience.

- Fit and capacity verification for 5, 10 and 20 pack options to avoid loose or over-tight fits.

Quick pass/fail criteria

Set numeric acceptance criteria (e.g., box collapse force > X N; drop from 1.2 m with zero catastrophic failure). Use statistical sampling (see Sampling plan below) for efficiency.

Child-resistant and safety features—what to test for non-tobacco pre-roll boxes

Many jurisdictions require child-resistant packaging, especially for products containing cannabinoids. Confirm whether your market demands such features, then test accordingly:

- Mechanical child-resistant closures: validate with standardized opening tests (consult local rules: CPSC/PPPA for the U.S., state cannabis packaging rules where applicable).

- Labeling and warning legibility: ensure mandated warnings meet size and contrast standards.

- Tamper-evident features: verify seals or perforations function as intended.

Document test results and keep records for regulatory audits. In the U.S., the Consumer Product Safety Commission (CPSC) oversees child-resistant packaging under the Poison Prevention Packaging Act. Cannabis packaging rules vary by state, so verify state-level guidance where your product will be sold.

Environmental and chemical safety checks

For consumer safety and brand reputation, test chemical safety of inks, coatings and adhesives. Verify compliance with restricted-substance lists (e.g., heavy metals, phthalates, formaldehyde). If marketing as recyclable or compostable, ensure materials and adhesives are certified and that recycling codes align with local sorting systems. Use supplier declarations and lab testing for claims like FSC-certified.

Production process controls and inline quality checks

Apply statistical process control (SPC) during runs: monitor key variables (print density, registration, board caliper, glue strength) at defined intervals. Use in-line cameras or manual checkpoints at start, middle and end of batches. Hold suspect lots and quarantine until cleared. Keep shift logs and operator sign-offs to maintain traceability.

Sampling plans and acceptance criteria

Full inspection is costly; use acceptance sampling to balance risk and cost. Common standards like ANSI/ASQ Z1.4 (formerly MIL-STD-105E) guide lot acceptance by AQL (acceptable quality level). For High Quality custom cigarette box lines, a tighter AQL (e.g., 0.65 or 1.0) may be appropriate for critical visual defects.

Final inspection, labeling, and shipment readiness for your custom cigarette box

Before shipping, perform a final 100% visual check of critical items (branding, warnings, batch codes). Verify correct quantity per outer carton, secure inner packaging to prevent movement, and ensure shipping marks and barcodes are legible. Generate a Certificate of Conformity that includes production date, lot number, test results summary, and material certificates.

Quality checklist table (practical at-a-glance view)

| Item | What to check | Acceptance criteria | Frequency |

|---|---|---|---|

| Board thickness & moisture | Caliper & %MC | Within spec ± tolerance; MC 4–8% (example) | Each incoming roll/sheet |

| Print color & registration | Pantone/Delta E, alignment | Delta E < 3; registration within 0.5 mm | First-article and hourly checks |

| Finish adhesion | Lamination/varnish adhesion | No lifting, peel < 5 mm | Every shift |

| Structural fit | Pack fit (5/10/20) | Product fits snug but removable | Sample per lot |

| Child-resistant function | Opening test, tamper evidence | Pass required test protocol | Per production run (if required) |

| Final visual | Logo, warnings, defects | No critical or major defects per AQL | 100% for critical items or sampling |

Record-keeping, traceability and corrective actions

Maintain QC records (inspections, certificates, SPC charts) for each lot. If defects appear, perform root cause analysis (5 Whys, fishbone) and document corrective and preventive actions (CAPA). Update production and inspection checklists after major changes to prevent recurrence.

How to root the QC checklist in supplier contracts

Embed QC checkpoints, sampling plans, rejection terms, rework allowances, and remedies into supplier agreements. Include right-to-audit clauses and require hard-copy or digital evidence (photos, test results). Stipulate pre-production sample approval and define who bears shipping costs for rejected batches.

Brand advantages: why choose our factory for your custom cigarette box

When you select our Factory Customized Printing LOGO Pack 10 20 5 Thick Case Pre Roll Non Tobacco Paper Box Cigarette Boxes, you get factory-direct control and several quality advantages:

- Direct factory oversight reduces lead times and cost markup.

- Thick, durable paperboard chosen for protection and High Quality feel.

- Full printing customization (logos, Pantone matching, special finishes) with strict color control.

- Built-in QA process with sampling plans and final inspection documentation.

- Experience manufacturing packaging for non-tobacco and cannabinoid products with guidance on child-resistant and labeling requirements.

- Sustainability options with certified materials and transparent supplier documentation.

Frequently Asked Questions (FAQ)

Q: What is the typical lead time for a custom cigarette box order?

A: Lead time depends on complexity, quantity and approvals. Typical production runs take 10–25 business days after sample approval. Child-resistant or specialty finishes can add time. Confirm with your supplier for a precise schedule.

Q: Do you offer child-resistant options for non-tobacco pre-roll boxes?

A: Yes. We can implement mechanical closures or tamper-evident seals to meet jurisdictional requirements. Testing and certification may be required depending on the market.

Q: What minimum order quantities (MOQs) apply for customized boxes?

A: MOQs vary by material and print setup. Typical MOQs for full-color printed custom cigarette box runs range from a few thousand to tens of thousands. Contact us with your specifications to get an accurate MOQ and price.

Q: How do you ensure consistent color across multiple production runs?

A: We use approved press proofs, Pantone matching, spectrophotometer (Delta E) checks, and maintain standardized color profiles. We also keep print plates/digital files and process logs to replicate runs accurately.

Q: What environmental options are available?

A: We offer recycled boards, FSC-certified materials, soy-based inks, and recyclable-compatible adhesives. Provide local recycling guidelines and we’ll recommend the best material options.

Contact and product CTA

Ready to implement a robust QC plan for your custom cigarette box or to request a quote? Contact our customer service team or view the product: Factory Customized Printing LOGO Pack 10 20 5 Thick Case Pre Roll Non Tobacco Paper Box Cigarette Boxes. We’ll provide a tailored QC checklist, sample timeline, and pricing for your specifications.

Authority references

- U.S. Consumer Product Safety Commission (CPSC) — Poison Prevention Packaging Act (PPPA): https://www.cpsc.gov/Regulations-Laws--Standards/Statutes/Poison-Prevention-Packaging-Act

- Food and Drug Administration (FDA) — Packaging and Food Safety Guidance: https://www.fda.gov/food

- FSC — Forest Stewardship Council certification: https://fsc.org/

- ISO standards relevant to packaging (overview): https://www.iso.org/ics/55.080/x/

- Wikipedia — Packaging: https://en.wikipedia.org/wiki/Packaging

- ANSI/ASQ Z1.4 Sampling Procedures and Tables for Inspection by Attributes: https://asq.org/

Document revision: QC checklist compiled to meet E-E-A-T guidance and best industry practices for factory-customized cigarette boxes. Keep this checklist as a living document and update it when regulations or supplier processes change.

Top child resistant paper box Manufacturers and Suppliers in China

Cost Factors to Consider When Ordering Child Resistant Paper Boxes in Bulk

Packaging Materials Compatible with Vintage Cigar Boxes

Sustainable Materials for Cardboard Cigarette Box Packaging

FAQs

Do you support custom designs?

Yes, we provide custom packaging designs tailored to your brand and product needs.

What services do you provide?

We offer one-stop packaging solutions, including design, printing, and handicraft processing for electronic boxes, plastic boxes, paper boxes, paper bags, and book printing.

Can you ship internationally?

Yes, we export worldwide and work with reliable logistics partners for timely delivery.

About us

When can I get the quotation?

1. The quotation will be offered within 24 hours after getting your detailed request.

2. If you get the urgent inquiry, please call us or mark it via E-mail, then we could make it into priority list.

The process of your packaging box production?

1. Make knife mold as per box size and structure

2. order material as per mold

3. make printing on material if need to print

4. suppress and cut material

5. Makeboxes with glue edge in machine

6. Package boxes into cartons

Custom Printed Paperboard Cardboard Cigarette Box Packaging Case Disposable Paper Box for Cigarette Clamshell paper box

Custom Vape Packaging Box with CR Telescoping Design

The CR telescoping box is a sophisticated and secure packaging solution designed specifically for vape products. Featuring a telescoping (two-piece) structure, this box offers excellent protection and an elegant presentation, enhancing both the unboxing experience and brand appeal.

Custom Logo Child-Resistant Pre-Roll Box Packaging Biodegradable Handmade Luxury 5 Pack Embossing Childproof Pre Roll Package

Custom CR Vape Packaging Cardboard Boxes with Child-Resistant Design

CR custom vape packaging cardboard boxes are specially designed child-resistant packaging solutions crafted to ensure safety, protection, and premium presentation for vape products. Made from sturdy cardboard materials, these boxes balance regulatory compliance with brand aesthetics.

Best pack

Best pack

Best pack