Quality control checklist for factory-customized pre rolls

- Quality control checklist for factory-customized pre rolls: essential steps for reliable pre roll packaging

- Why a dedicated QC approach matters for pre roll packaging

- Product overview and QC implications for Factory Customized Printing LOGO Pack 10 20 5 Thick Case Pre Roll Non Tobacco Paper Box Cigarette Boxes

- High-level QC framework: align to ISO 9001 principles

- Incoming materials inspection (pre press and board) — pre roll packaging essentials

- Artwork & printing QA for pre roll packaging

- Structural integrity and dimensional checks for pre roll packaging

- Sealing, closure and tamper evidence

- Child-resistant and regulatory compliance checks (where applicable)

- Functional performance testing: drop, vibration, humidity, and shelf life

- Labeling, legal content and barcode verification for pre roll packaging

- Batch control, traceability and documentation

- Supplier audits and continuous improvement

- Implementing the checklist on the factory floor

- Cost vs. quality—finding the right balance for pre roll packaging

- Brand advantages: why our factory-customized pre roll packaging stands out

- FAQ — Frequently asked questions about QC for pre roll packaging

- Contact us / view product

- References and sources

Quality control checklist for factory-customized pre rolls: essential steps for reliable pre roll packaging

Why a dedicated QC approach matters for pre roll packaging

Pre roll packaging is not just a box — it is the final brand touchpoint, a product protection system, and in many jurisdictions a regulated container. For the product Factory Customized Printing LOGO Pack 10 20 5 Thick Case Pre Roll Non Tobacco Paper Box Cigarette Boxes, consistent quality control at the factory level ensures that every 5-pack, 10-pack, or 20-pack meets Best Pack promise, protects contents, and complies with buyer expectations. Poorly controlled production leads to complaints, returns, lost shelf presence, and possible legal exposure where child-resistant or labeling rules apply. Once your pre-rolls are factory-customized, shipping and protection: thick case solutions for pre-rolls become a priority. Using durable, secure packaging ensures that your products arrive safely and in pristine condition for your customers.

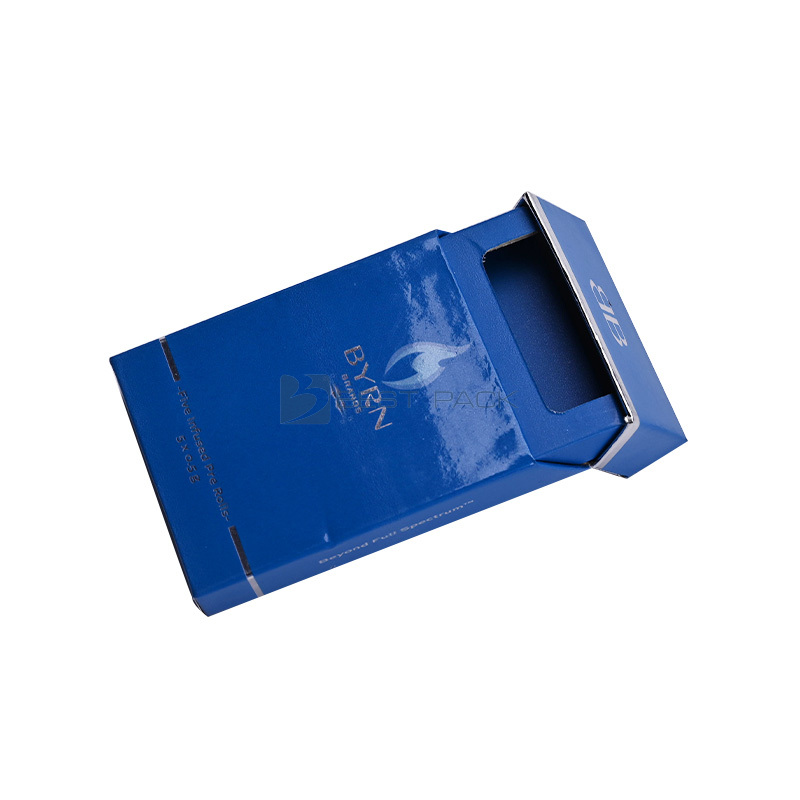

Product overview and QC implications for Factory Customized Printing LOGO Pack 10 20 5 Thick Case Pre Roll Non Tobacco Paper Box Cigarette Boxes

Our factory-direct custom pre-roll and cigarette paper boxes are designed for High Quality presentation, protection, and branding. Made with thick, durable paperboard, these boxes are ideal for non-tobacco herbal pre-rolls, cigarettes, or CBD/THC joints. Available in various capacities (5-pack, 10-pack, 20-pack) and fully customizable with your logo and design.

This product positioning implies QC priorities: High Quality print quality, tight dimensional tolerances for fit of pre-rolls, durable materials to prevent crushing or moisture ingress, and reliable finishing (glue, tuck, or magnetic closures). If marketing or regulations call for child-resistant features, these must be validated separately.

High-level QC framework: align to ISO 9001 principles

Implementing a checklist is most effective when embedded in a quality management framework. Use simple ISO 9001-inspired principles: define requirements, inspect incoming materials, control the process, test the output, document results, and continuously improve. This approach helps ensure the pre roll packaging you produce aligns with customer specifications and regulatory expectations.

Incoming materials inspection (pre press and board) — pre roll packaging essentials

Start quality control at the source. Incoming material checks prevent downstream defects and wasted production runs. Key checkpoints:

- Paperboard grade and GSM/pt verification: Confirm the board meets the specified thickness and stiffness (e.g., 300–600 gsm range typical for thick retail boxes). Reject visible delamination, water damage, or size deviations.

- Color proof and ink compatibility tests: Ensure coatings and inks are compatible with the selected board and finishing (lamination, varnish). Request material safety data sheets (MSDS) where applicable.

- Adhesive and closure materials: Verify glue type, tack strength, and cure behavior. For tuck or glued boxes ensure adhesive lot traceability.

Artwork & printing QA for pre roll packaging

Printing errors are one of the fastest ways to damage brand image. A robust printing QA should include:

- Pre-production approval: Sign-off on press proofs and digital mockups with color swatches (Pantone or CMYK targets).

- Registration and color consistency checks: Use spectrophotometer readings for critical colors; measure Delta E values against approved proof (typical tolerance Delta E < 3 for brand-critical colors).

- Text and regulatory label verification: Confirm ingredient statements, warnings, barcodes, and logos match the approved artwork and local legal requirements.

Structural integrity and dimensional checks for pre roll packaging

Structural failures (crushed sides, misfolds, weak seams) impact protection and shelf presence. Key dimensional and structural checks:

- Dimensional tolerance: Measure box internal width/height/depth; ensure the pre-rolls fit without excessive movement. Typical tolerance: ±1–2 mm depending on size.

- Corner and fold inspection: Check for consistent crease depth and no tearing along fold lines.

- Compression resistance: Spot-check samples for crush resistance per expected storage/transport loads.

Sealing, closure and tamper evidence

Closures must be consistent to protect contents and prevent accidental opening. For the Factory Customized Printing LOGO Pack 10 20 5 Thick Case Pre Roll Non Tobacco Paper Box Cigarette Boxes, evaluate:

- Glue seam strength: Test peel strength on glued seams to ensure permanent closure where required.

- Tuck closure fit: Tuck flaps should hold without popping open; measure retention force.

- Tamper evidence: If needed, verify tamper tapes or seals apply cleanly and show clear evidence when opened.

Child-resistant and regulatory compliance checks (where applicable)

If your product line requires child-resistant packaging (e.g., certain cannabis products), validate against the applicable regulation. QC should include:

- Design verification: Confirm mechanical or multi-step opening performs as intended in prototype testing.

- Compliance testing: Arrange certified testing (CPSC or state-authorized labs in the U.S.) to validate child-resistant performance.

- Label and warning verification: Ensure required child-resistance notices and safety warnings are printed in the right language and format.

Functional performance testing: drop, vibration, humidity, and shelf life

Simulate real-world conditions to verify protection:

| Test | Method | Acceptance Criteria | Frequency |

|---|---|---|---|

| Drop test | Controlled single-box drop from 1 m to concrete or standard surface | No severe crush or content damage; closure intact | Per lot, 3–5 samples |

| Vibration/transport simulation | 2–4 hr vibration table simulating truck transport | No label abrasion; closures remain secured | Per product launch and quarterly |

| Humidity aging | 72-hour 85% RH at 40°C exposure for board/print stability | No ink bleed, warping, or delamination | Sample-based during qualification |

Sources: industry-standard transport simulation protocols and accepted packaging test practices (see references).

Labeling, legal content and barcode verification for pre roll packaging

Labels are crucial for both sales and compliance. Checklist items:

- Legal copy: Verify ingredient lists, net weight, health warnings, and jurisdictional statements.

- Barcode and QR code readability: Scan at multiple angles using standard scanners and mobile devices.

- Language and font legibility: Confirm minimum font sizes per market rules and ensure contrast for readability.

Batch control, traceability and documentation

Good documentation reduces recall risk and improves root cause analysis. Implement:

- Batch numbering and production records: Every lot should record material lot numbers, press parameters, operator, and inspection results.

- Incoming and final QC checklists: Store signed inspection records for at least the customer-required retention period.

- Non-conformance handling: Define hold, rework, and reject flows and documentation for disposition.

Supplier audits and continuous improvement

Even if packaging is made in-house, raw material suppliers matter. Audit suppliers for consistency, environmental controls, and certification (FSC, recycled content claims). Regularly review defect rates and implement corrective action requests (CARs) with clear timelines.

Implementing the checklist on the factory floor

Make the checklist actionable: create walk sheets and a digital inspection form that operators and quality technicians complete in real time. Use simple pass/fail and comment fields, include photos for defects, and escalate critical failures automatically to management. Train production and QC teams on the checklist and re-train quarterly.

Cost vs. quality—finding the right balance for pre roll packaging

Quality improvements often add cost. Prioritize checks that prevent the most impactful failures: wrong artwork, structural collapse, or non-compliant labeling. Use sampling plans based on AQL standards for large runs to balance inspection cost and risk. For High Quality products like the Factory Customized Printing LOGO Pack 10 20 5 Thick Case Pre Roll Non Tobacco Paper Box Cigarette Boxes, invest more in print and material quality to protect brand value.

Brand advantages: why our factory-customized pre roll packaging stands out

When you select our Factory Customized Printing LOGO Pack 10 20 5 Thick Case Pre Roll Non Tobacco Paper Box Cigarette Boxes, you benefit from:

- Factory-direct control: Reduced intermediaries mean tighter QC, faster changeovers, and clearer traceability.

- High Quality materials and finishes: Thick paperboard and advanced finishing options deliver better durability and shelf presence.

- Custom printing expertise: We handle color-critical branding with spectrophotometer checks and pre-press approvals.

- Regulatory and compliance support: We design for labeling requirements and help coordinate child-resistant testing where required.

- Scalable production: From small boutique runs to larger retail quantities with consistent quality.

FAQ — Frequently asked questions about QC for pre roll packaging

Q1: How many samples should I inspect per production run?

A: Use a risk-based approach. For high-volume, low-risk products an AQL sampling plan (e.g., ISO 2859) is suitable. For new artwork or High Quality lines, inspect 100% for critical elements (artwork, color, dimensions) during the first runs.

Q2: Do I need child-resistant packaging for non-tobacco pre-rolls?

A: It depends on jurisdiction and product content (e.g., THC products often require child-resistant packaging). Confirm with local regulations; if child-resistance is required, include certified testing in your QC plan.

Q3: What are common failure modes we should track?

A: Common issues include color mismatch, misprints, board warp, weak glue seals, wrong dimensions causing fit issues, and unreadable barcodes.

Q4: How should we document non-conformances?

A: Log every NC with a unique ID, describe the defect, include photos, record affected quantities, assign root cause, corrective action, and verify closure.

Q5: Can environmental exposure affect printed pre roll packaging?

A: Yes. High humidity and extreme temperatures can warp board and cause ink migration. Include humidity aging tests if packaging will be stored or shipped in variable climates.

Contact us / view product

To discuss how we implement this quality control checklist on your custom orders or to request samples of our Factory Customized Printing LOGO Pack 10 20 5 Thick Case Pre Roll Non Tobacco Paper Box Cigarette Boxes, contact our customer service team or view product details on our catalog page. Email: sales@example.com | Phone: +1-800-555-0123.

References and sources

- U.S. Consumer Product Safety Commission (CPSC) — Poison Prevention Packaging Act (PPPA) information: https://www.cpsc.gov/Regulations-Laws--Standards/Statutes/Poison-Preventive-Packaging-Act

- ISO — Quality management systems (ISO 9001) overview: https://www.iso.org/iso-9001-quality-management.

- Paperboard Packaging Council — guidance on board grades and specifications: https://www.paperbox.org/ (industry reference for paperboard types)

- Packaging testing guidance — general industry practices for drop and vibration testing; e.g., ISTA test procedures: https://www.ista.org/

Note: Specific legal or regulatory requirements vary by market and product content (especially for CBD/THC products). Always consult local regulatory authorities or legal counsel for compliance decisions.

Best Labeling Practices for Child-Resistant Cigarette Box 2026

The latest trends for customized cigar box

Choosing paper types for non tobacco pre roll boxes

How Child Resistant Custom Cigarette Boxes Protect Families

About us

When can I get the quotation?

1. The quotation will be offered within 24 hours after getting your detailed request.

2. If you get the urgent inquiry, please call us or mark it via E-mail, then we could make it into priority list.

What is the box size and structure?

1. All boxes are customized and all detailed requirements can be provided by clients, we are definitely your OEM service supplier.

2. If you have no idea about the measurements and structure on your products, our professional design team can suggest and solute for you .

How many kinds the printing process you have?

We can make Silk screen printing, offset printing, and also hot silver stamping

FAQs

Do you support custom designs?

Yes, we provide custom packaging designs tailored to your brand and product needs.

What services do you provide?

We offer one-stop packaging solutions, including design, printing, and handicraft processing for electronic boxes, plastic boxes, paper boxes, paper bags, and book printing.

Custom CR Vape Packaging Cardboard Boxes with Child-Resistant Design

CR custom vape packaging cardboard boxes are specially designed child-resistant packaging solutions crafted to ensure safety, protection, and premium presentation for vape products. Made from sturdy cardboard materials, these boxes balance regulatory compliance with brand aesthetics.

Custom Luxury Pre Roll Packaging Boxes with Child-Resistant Paper Tray

Our luxury pre-roll packaging boxes are designed to combine elegant presentation with top-tier safety features. Featuring a child-resistant mechanism and a custom paper tray insert, these boxes ensure secure storage while delivering a premium unboxing experience for pre-roll products.

Custom Child-Lock Pre-Roll 5-Pack Packaging Boxes

Our custom child-lock packaging for pre-roll 5-packs is purposefully engineered to combine premium design with certified safety. This packaging solution ensures that five pre-rolls are securely housed in a compact, stylish, and child-resistant format—ideal for compliant cannabis brands that value both form and function.

Best pack

Best pack

Best pack