Branding Strategies Using Child Resistant Cigarette Boxes

- Why Child Resistant Cigarette Boxes Matter for Branding

- Understand the Legal and Safety Landscape

- Align Brand Values with Safety Features

- Design Principles for Effective Child Resistant Packaging

- Choosing Materials: Durability, Cost, and Sustainability

- Material Comparison for custom cigarette boxes

- Integrate Brand Messaging Without Compromising Safety

- Custom Printing Techniques That Elevate Perception

- Structural Innovations for Usability and Marketing

- Testing and Certification: Building Trust Through Proof

- Case Study: How Custom Cigarette Boxes Boost Retail Performance

- Packaging and E-commerce: Optimizing for Shipping and Unboxing

- Sustainability as a Differentiator in custom cigarette boxes

- Price vs. Perceived Value: Positioning Best Pack

- Collaborating with a Manufacturer: What to Expect

- Why Choose Best Pack for Custom Cigarette Boxes

- Marketing Tactics to Amplify Packaging Investments

- Measuring Success: KPIs for Packaging-Led Branding

- Costing and ROI Considerations

- International Considerations for Global Brands

- Practical Checklist Before Mass Production

- Frequently Asked Questions (FAQ)

- Q2: Can custom cigarette boxes be both child-resistant and eco-friendly?

- Q3: How do child-resistant features affect user experience?

- Q4: What is the typical cost increase for child-resistant custom cigarette boxes?

- Q5: How should brands communicate child safety on packaging?

- Q6: Where can I get prototypes and testing for child resistant boxes?

Why Child Resistant Cigarette Boxes Matter for Branding

Child resistant cigarette boxes are no longer only about compliance; they directly affect brand perception, shelf impact, and customer trust. Consumers increasingly expect safety, sustainability, and High Quality presentation. A well-designed child-resistant pack communicates responsibility and quality, helping your product stand out and reducing risk of accidental access by children.

Understand the Legal and Safety Landscape

Regulatory context drives packaging requirements and influences brand choices. For example, Canada’s Cannabis Act (2018) mandates child-resistant packaging for cannabis products, and many U.S. states require similar protections for cannabis and nicotine products. The Poison Prevention Packaging Act (PPPA) in the U.S. (1970) set the precedent for child-resistant closures for hazardous household substances. Meeting or exceeding these standards is an essential baseline for any brand using custom cigarette boxes.

Align Brand Values with Safety Features

Integrate safety into Best Pack story by treating child resistant features as a value proposition. If sustainability, High Quality craftsmanship, or community responsibility are part of your mission, show how your custom cigarette boxes reflect those values—whether through recyclable materials, child-safe closure innovations, or transparent testing and certification practices.

Design Principles for Effective Child Resistant Packaging

Good design balances usability, security, and brand expression. Use clear hierarchy, tactile cues, and intuitive interactions so adult customers can open and reseal packs easily while children cannot. Incorporate brand colors, typography, and imagery in ways that remain compliant with local plain-packaging or labeling restrictions.

Choosing Materials: Durability, Cost, and Sustainability

Select materials that meet safety tests and reflect Best Pack positioning. Options range from folding cartons with engineered locking tabs to rigid slipcases, metal tins, and laminated boards with child-resistant mechanisms. Prioritize recyclability and certifications where possible to appeal to eco-conscious consumers.

Material Comparison for custom cigarette boxes

Below is a practical comparison of common materials and constructions for child resistant cigarette boxes:

| Material/Construction | Security Level | Cost | Durability | Sustainability |

|---|---|---|---|---|

| Folding carton + engineered child-resistant tab | Moderate (meets many state/country requirements) | Low–Medium | Medium | High (recyclable paperboard) |

| Rigid box with push-and-turn mechanism | High | High | Very High | Medium (depends on materials used) |

| Metal tin with child-resistant insert | High | Medium–High | Very High | Low–Medium (metal recyclable but often mixed materials) |

| Inner blister / sealed pods in box | Very High (adds layers) | Medium–High | High | Variable (plastic vs. recyclable inserts) |

Integrate Brand Messaging Without Compromising Safety

Branding elements such as logos, taglines, and color systems must be balanced against mandatory warnings, child-resistant notices, and plain-label rules where applicable. Use secondary spaces (interiors, under flaps, banding) for storytelling—this keeps the exterior compliant while delivering a High Quality unboxing experience.

Custom Printing Techniques That Elevate Perception

High-quality printing—such as spot UV, soft-touch varnish, debossing, metallic foils, and textured finishes—creates tactile differentiation that signals High Quality value. For custom cigarette boxes, these techniques must be tested to ensure they don’t interfere with child-resistant mechanisms or regulatory labels.

Structural Innovations for Usability and Marketing

Structural design is a brand tool. Consider features that help adult consumers while maintaining child resistance: magnetic closures paired with an internal child-resistant latch, two-step opening actions, or reclosable seals. These elements can become signature interactions that customers remember and recommend.

Testing and Certification: Building Trust Through Proof

Demonstrating compliance through third-party testing and certification is a powerful trust signal. Child resistance is often validated with standardized tests (e.g., consumer product safety tests). Share test summaries, certificates, or QR codes linking to test reports on your website to support claims and improve conversion.

Case Study: How Custom Cigarette Boxes Boost Retail Performance

A well-executed child-resistant pack can improve on-shelf attention and reduce shrinkage from accidental spills. Retailers prefer products that protect children and reduce liability. Use POS displays and packaging-led merchandising that highlight safety and brand story—this can improve buy-in from retail partners and e-commerce platforms.

Packaging and E-commerce: Optimizing for Shipping and Unboxing

For online sales, packaging must survive transit while delivering an unboxing experience. Use protective mailer systems or double-boxing where necessary. Communicate child safety and tamper-evidence on fulfillment packaging in a way that doesn't inadvertently become a barrier for legitimate adult customers.

Sustainability as a Differentiator in custom cigarette boxes

Many consumers equate responsible packaging with brand ethics. Choose recyclable paperboards, mono-material laminates, or compostable inserts when possible. If plastics are necessary for child-resistant mechanisms, explain recycling instructions and use post-consumer recycled content to reduce environmental impact.

Price vs. Perceived Value: Positioning Best Pack

Invest in packaging where it supports higher margins or strategic positioning. High Quality construction and printing justify higher price points for boutique and craft brands. For value brands, focus on efficient child-resistant engineering that keeps costs low while delivering required safety.

Collaborating with a Manufacturer: What to Expect

Work with packaging partners who understand both compliance and branding. A reliable manufacturer will offer prototyping, child-resistant engineering expertise, printing capabilities, and quality control processes. Communicate required certifications, target price, sustainability goals, and desired shelf presence up front.

Why Choose Best Pack for Custom Cigarette Boxes

Best Pack is a custom cannabis cigarette packaging company that provides one-stop services from design and printing to handicraft processing. We constantly insist on offering products of the best quality, excellent services and competitive prices to our customers. At the same time, the company persists in its team-working spirit and develops innovation continually to meet the chance and challenge brought by the Information Technology Age. From cannabis protective packaging to cartridge box packaging, our real customer cases showcase our OEM/ODM capabilities, attention to detail, and commitment to quality. Our custom packaging not only enhances Best Pack image but also provides high-quality, tailor-made packaging solutions that elevate brand value, driving more purchasing decisions through promotions and customer feedback. Our vision is to become the world's leading cannabis and cigarette packaging box manufacturer. Visit https://www.gzbestpack.com/ to review capabilities and request samples.

Marketing Tactics to Amplify Packaging Investments

Promote your child-resistant custom cigarette boxes through product photography, unboxing videos, and educational content that explains safety and sustainability features. Use targeted ads highlighting safety and compliance to reach adult buyers and retailers. Leverage customer reviews that mention packaging to boost social proof.

Measuring Success: KPIs for Packaging-Led Branding

Track metrics such as conversion rate lift after packaging changes, retail reorder frequency, average order value, and customer feedback regarding unboxing and usability. Monitor return rates and product damage to ensure packaging performs in logistics. Use A/B tests with different pack variants to quantify impact.

Costing and ROI Considerations

Packaging upgrades should be evaluated for return on investment: higher price tolerance, improved shelf performance, reduced returns, and stronger retailer relationships. Use a simple ROI model: incremental margin from price or volume increases minus additional packaging cost, divided by packaging investment. Iterative prototyping reduces costly mistakes.

International Considerations for Global Brands

When selling across borders, adapt custom cigarette boxes to local regulations (language, warning size, child-resistant standards) and cultural perceptions. Localize artwork and ensure supply chain certifications meet import requirements. Using a manufacturer with global shipping and compliance experience simplifies rollout.

Practical Checklist Before Mass Production

Finalize child-resistant mechanism testing, confirm label and warning compliance for target markets, approve physical prototypes, validate print proofs, review sustainability claims, and secure testing certifications. Confirm lead times and minimum order quantities with your supplier before committing to large runs.

Frequently Asked Questions (FAQ)

Q1: Are child resistant cigarette boxes legally required?

A1: Requirements vary by country and product. Many jurisdictions mandate child-resistant packaging for cannabis products and certain nicotine forms. Check local regulations like Canada’s Cannabis Act and state-level cannabis rules in the U.S.

Q2: Can custom cigarette boxes be both child-resistant and eco-friendly?

A2: Yes. Many manufacturers combine recyclable paperboard with engineered locking tabs or use mono-material constructions. When plastic elements are necessary, choose recycled content and provide clear recycling guidance.

Q3: How do child-resistant features affect user experience?

A3: Properly designed mechanisms are intuitive for adults and preserve positive unboxing. Prioritize usability testing with adults during prototyping to ensure ease of access without compromising safety.

Q4: What is the typical cost increase for child-resistant custom cigarette boxes?

A4: Costs depend on mechanism complexity, materials, and print finishes. Simple child-resistant tabs on folding cartons add modest cost; rigid boxes or multi-component solutions increase unit price. Work with suppliers to model cost at different MOQ levels.

Q5: How should brands communicate child safety on packaging?

A5: Use clear labeling required by law, and supplement with consumer-facing messaging (interior panels, hangtags, website content) that explains testing and safe handling. Transparency builds trust without diluting brand aesthetics.

Q6: Where can I get prototypes and testing for child resistant boxes?

A6: Partner with experienced packaging manufacturers that offer prototyping and testing coordination. Ask for references, sample portfolios, and any existing compliance test reports. Best Pack provides OEM/ODM prototyping and can assist with third-party testing coordination.

The latest trends for cigar box custom

Labeling and regulatory tips for pre roll packaging

Everything You Need to Know About personalized cigar box

What are the application scenarios of personalized cigarette box?

About us

Are you able to do design for my products?

Yes, just send us your logo artwork in Vector file, such as AI or PDF format,and text information you want to print ,we can put it on box to make the design to let you check. Once you say ok, then we go on to make samples or production.

The process of your packaging box production?

1. Make knife mold as per box size and structure

2. order material as per mold

3. make printing on material if need to print

4. suppress and cut material

5. Makeboxes with glue edge in machine

6. Package boxes into cartons

What is the box size and structure?

1. All boxes are customized and all detailed requirements can be provided by clients, we are definitely your OEM service supplier.

2. If you have no idea about the measurements and structure on your products, our professional design team can suggest and solute for you .

FAQs

What services do you provide?

We offer one-stop packaging solutions, including design, printing, and handicraft processing for electronic boxes, plastic boxes, paper boxes, paper bags, and book printing.

Can you ship internationally?

Yes, we export worldwide and work with reliable logistics partners for timely delivery.

Custom Printed Paperboard Cardboard Cigarette Box Packaging Case Disposable Paper Box for Cigarette Clamshell paper box

Custom Vape Packaging Box with CR Telescoping Design

The CR telescoping box is a sophisticated and secure packaging solution designed specifically for vape products. Featuring a telescoping (two-piece) structure, this box offers excellent protection and an elegant presentation, enhancing both the unboxing experience and brand appeal.

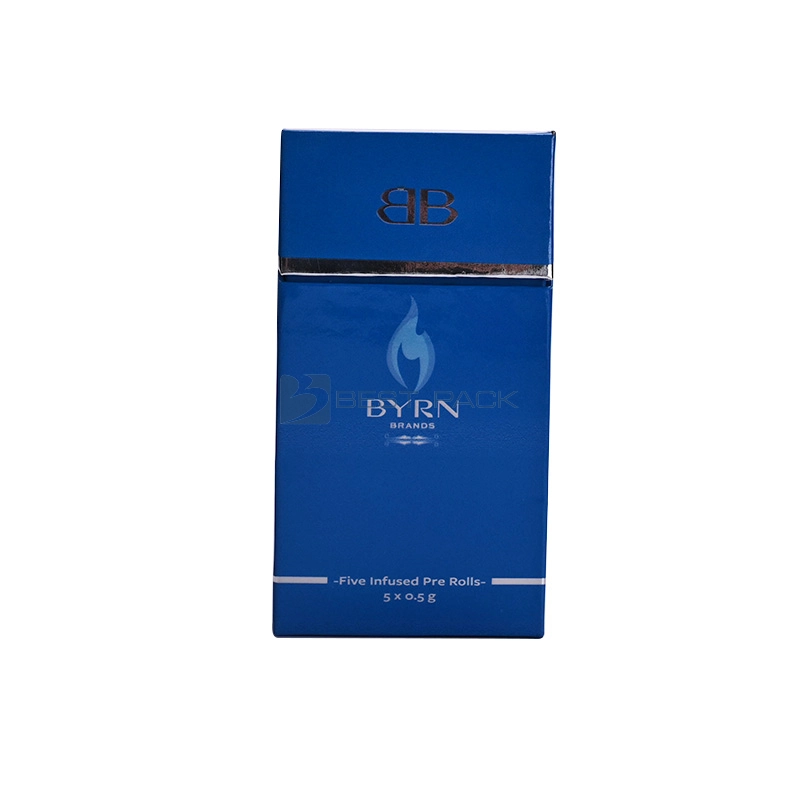

Custom Logo Child-Resistant Pre-Roll Box Packaging Biodegradable Handmade Luxury 5 Pack Embossing Childproof Pre Roll Package

Custom CR Vape Packaging Cardboard Boxes with Child-Resistant Design

CR custom vape packaging cardboard boxes are specially designed child-resistant packaging solutions crafted to ensure safety, protection, and premium presentation for vape products. Made from sturdy cardboard materials, these boxes balance regulatory compliance with brand aesthetics.

Best pack

Best pack

Best pack