Child-Resistant Mechanisms Explained for Pre-Roll Boxes

- Child-Resistant Mechanisms Explained for Pre-Roll Boxes

- Why child-resistant pre roll packaging box matters

- Regulatory landscape and standards for pre-roll boxes

- Common child-resistant mechanisms used in pre-roll boxes

- How push-and-turn and squeeze-and-turn mechanisms work

- Inner sleeve and sliding lock systems for boxes

- Blister inserts, tamper-evident seals, and hybrid options

- Comparing child-resistant mechanisms for pre-roll packaging box

- Design trade-offs: safety, consumers, sustainability

- Testing, documentation, and market acceptance

- Working with a packaging partner: what to ask Best Pack

- Implementation timeline and cost considerations

- FAQ: common questions about child-resistant pre roll packaging box

- Q: Is a sticker or tamper band sufficient to be child-resistant?

- Q: Will child-resistant features harm my brand aesthetic?

- Q: Can a pre-roll box be both child-resistant and recyclable?

- Q: How much does child-resistant packaging increase unit cost?

- Q: How do I prove my packaging is compliant?

- Next steps for brands designing child-resistant pre-roll boxes

Child-Resistant Mechanisms Explained for Pre-Roll Boxes

Why child-resistant pre roll packaging box matters

Child-resistant pre roll packaging box is more than a compliance checkbox — it is a public-safety and brand-protection tool. As cannabis markets expand, accidental pediatric exposures reported to poison control centers have driven regulators and consumers to expect secure, resealable packaging. For cannabis brands, failing to provide reliable child-resistant packaging risks recalls, fines, and reputational damage. Designing a box that keeps children out while remaining accessible to adult consumers is a core requirement for responsible pre-roll packaging.

Regulatory landscape and standards for pre-roll boxes

Understanding regulation is essential when designing child-resistant pre roll packaging box. In the U.S., the Poison Prevention Packaging Act (PPPA) and Consumer Product Safety Commission (CPSC) guidelines are foundational for child-resistant packaging concepts. For products requiring formal testing, ISO 8317 specifies performance requirements and test methods for reclosable child-resistant packaging: typically, no more than 15% of children in the prescribed test group may be able to open the package, and at least 90% of adults must be able to open and reclose it. Many U.S. states with legalized cannabis also require packaging to be child-resistant and tamper-evident; California, Colorado, and others have specific rules for cannabis products, including pre-rolls. Meeting these standards protects consumers and supports market access for your pre roll packaging box.

Common child-resistant mechanisms used in pre-roll boxes

There are several effective mechanisms for making a pre roll packaging box child-resistant. Choices should balance security, cost, user ergonomics, and brand aesthetics. Popular mechanisms include push-and-turn or squeeze-and-turn closures, internal locking sleeves, sliding locks, blister or tube inserts with CR caps, and magnet-with-detent systems that require specific motions. Each mechanism can be adapted to paperboard tuck boxes, rigid boxes, or hybrid solutions combining board and plastic components, depending on the brand vision and unit economics.

How push-and-turn and squeeze-and-turn mechanisms work

Push-and-turn or squeeze-and-turn mechanisms are common on small cylindrical containers and can be incorporated into pre-roll tubes or inside a box as an inner tube. These require simultaneous force and rotation, an action typically too complex for young children. For brands using a pre roll packaging box with an inner CR tube, this approach combines familiar consumer handling with strong resistance. The design preserves shelf appeal while meeting ISO 8317-type expectations when validated by lab testing.

Inner sleeve and sliding lock systems for boxes

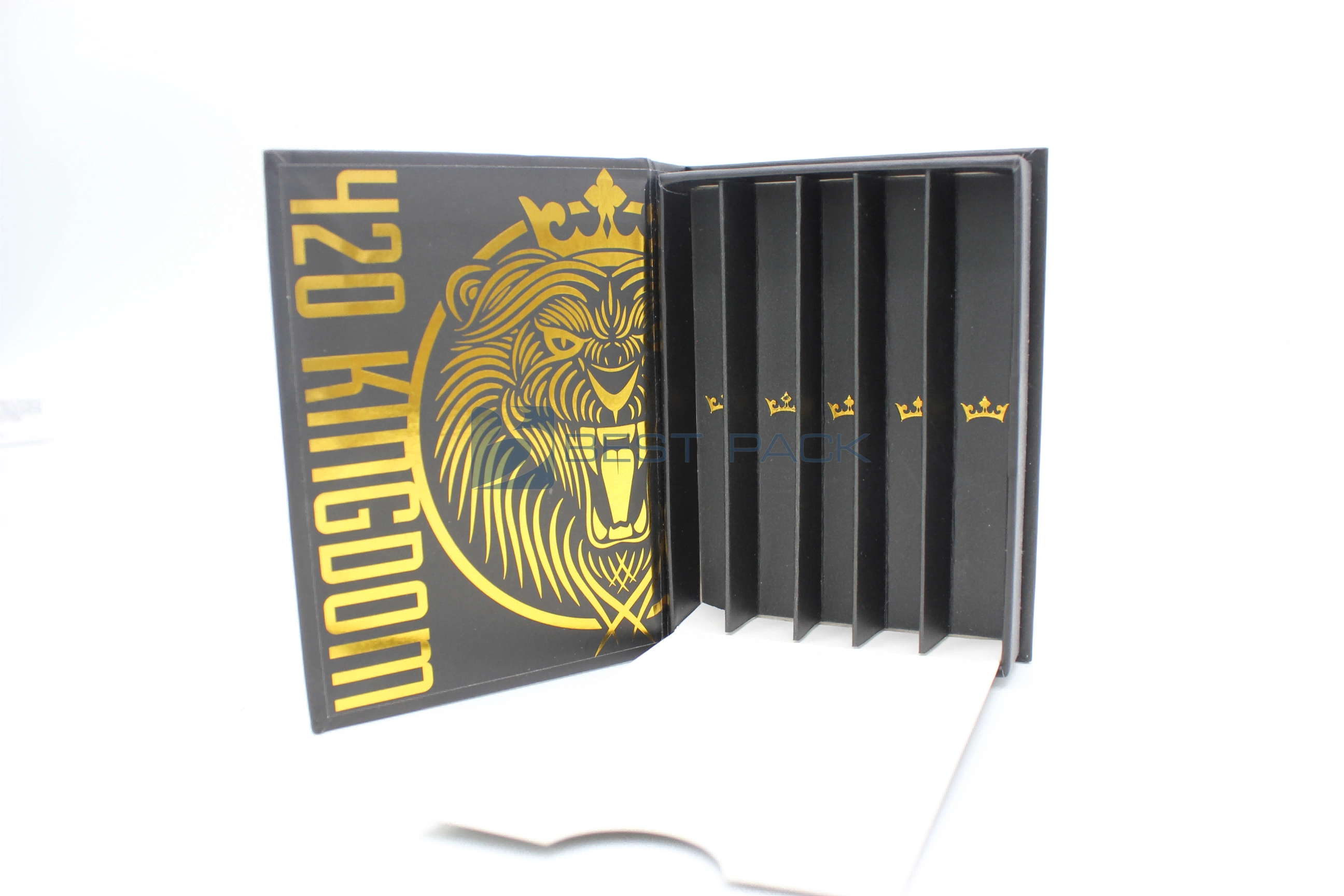

Inner sleeves and sliding locks are popular for paperboard pre roll packaging box designs. An inner sleeve that must be slid out or twisted to access the product adds a layer of complexity. Sliding locks that require pressing or aligning hidden tabs can be integrated into tuck-top or rigid-box designs. These mechanisms allow attractive printing and finishing on the external box while keeping the functional CR element concealed, preserving both child safety and high-end brand presentation.

Blister inserts, tamper-evident seals, and hybrid options

Blister inserts and tamper-evident seals provide both child resistance and product integrity. A blister or molded insert secured inside a pre roll packaging box can require a deliberate action to remove a pre-roll, such as tearing a sealed blister or using a built-in press-and-release tab. Hybrid solutions—paperboard boxes with a molded or plastic internal component—let brands combine sustainable outer materials with a robust CR mechanism inside.

Comparing child-resistant mechanisms for pre-roll packaging box

Below is a concise comparison to help you select an appropriate mechanism for your pre-roll boxes.

| Mechanism | How it works | Pros | Cons | Best for |

|---|---|---|---|---|

| Push-and-turn (inner tube) | Press and rotate cap or inner tube to open | High effectiveness; familiar to adults | Requires plastic parts; higher unit cost | Cylindrical pre-roll tubes within a box |

| Squeeze-and-turn | Compress two sides while turning to release | Good CR performance; tactile | Challenging for users with limited dexterity | Small-form factor boxes and tubes |

| Inner sleeve / hidden tab | Slide or lift hidden sleeve to access product | Maintains external branding; customizable | Moderate complexity; testing required | Tuck-top and rigid pre roll packaging box |

| Sliding lock (tab/press) | Align/press tabs to slide lock open | Low-profile; preserves box look | May need precise tolerances in production | High Quality boxes where aesthetics matter |

| Blister insert / tear seal | Tear or press to release single-use blister | Strong tamper evidence; single-use control | Less sustainable if plastic-heavy | Disposable single pre-roll or multi-pack |

| Magnetic detent locks | Specific motion to overcome magnetic hold | Sleek; High Quality feel | Higher cost; magnets complicate recycling | High-end limited editions |

Design trade-offs: safety, consumers, sustainability

When selecting a child-resistant approach, weigh adult usability against child-safety performance. ISO 8317 requires that the package be usable by most adults while resisting children. Consider senior users and those with limited hand strength—offer clear instructions, tactile cues, and accessible reclosure. Sustainability is an increasing demand: brands are choosing recyclable paperboard exteriors with a small, removable CR insert so the outer box can be recycled. Communicate these choices on your pre roll packaging box to meet consumer expectations and regulatory scrutiny.

Testing, documentation, and market acceptance

Validating your pre roll packaging box through accredited child-resistance testing labs is essential. ISO 8317-style testing uses representative groups of children and adults to measure ease of opening and reclosing. The common pass thresholds are no more than 15% of children succeeding and at least 90% of adults able to open and reclose. Keep test reports, production drawings, and quality control records on file—many regulators and distributors will request documentation before permitting market entry. Regular production audits help ensure compliant performance once you scale up.

Working with a packaging partner: what to ask Best Pack

Choosing a supplier with cannabis packaging experience reduces risk. Ask your manufacturer whether they offer prototyping, CR mechanism integration, and assistance with third-party testing. Best Pack is a custom cannabis cigarette packaging company providing one-stop services from design and printing to handicraft processing. Our OEM/ODM capabilities include protective packaging and cartridge box packaging, where we focus on quality, innovation, and meeting regulatory needs. For pre-roll customers, we help balance brand presentation with child-resistant function while offering competitive pricing and production scalability. Visit https://www.gzbestpack.com/ to explore solutions for your pre roll packaging box.

Implementation timeline and cost considerations

Development timelines vary: concept to prototype commonly takes 4–8 weeks, including sample tooling and iterations for mechanism fit. Third-party testing may add 2–4 weeks. Cost increases depend on complexity: simple inner sleeves or sliding tabs add modest per-unit costs; engineered plastic caps or magnets increase tooling and per-unit expense. Factor in minimum order quantities, decoration costs, and potential retooling if you pivot between materials. Partner with a provider experienced in cannabis packaging to optimize cost-performance trade-offs while ensuring your pre roll packaging box meets market expectations.

FAQ: common questions about child-resistant pre roll packaging box

Q: Is a sticker or tamper band sufficient to be child-resistant?

A: No. A tamper band or sticker only shows product integrity and does not provide child resistance. Regulators and safety standards require purposeful CR designs tested to standards like ISO 8317 for reclosable packages.

Q: Will child-resistant features harm my brand aesthetic?

A: Not necessarily. Many mechanisms can be hidden or integrated so the external artwork and finish remain High Quality. Inner sleeves, concealed tabs, and custom inserts allow high-quality printing and finishing on the outer pre roll packaging box while meeting CR requirements.

Q: Can a pre-roll box be both child-resistant and recyclable?

A: Yes. Common approaches include using recyclable paperboard for the outer box and a small, removable plastic insert for the CR function. Clearly label recycling instructions so consumers can separate components for proper disposal.

Q: How much does child-resistant packaging increase unit cost?

A: Costs vary widely. The simplest modifications (tabs, sleeve adjustments) add a small percentage to unit cost; engineered plastic caps, magnets, or molded inserts increase tooling and per-unit costs more substantially. Request quotes for target volumes to get accurate pricing for your pre roll packaging box.

Q: How do I prove my packaging is compliant?

A: Work with an accredited testing lab to perform child and adult opening tests per relevant standards. Maintain test reports and quality-control documentation. For cannabis markets, also confirm compliance with state-specific packaging rules where you sell products.

Next steps for brands designing child-resistant pre-roll boxes

If you are developing or upgrading your pre roll packaging box, start with a risk assessment, select candidate mechanisms, and order prototypes for user testing. Engage a packaging supplier with cannabis experience to iterate quickly and manage third-party testing. Best Pack offers end-to-end design, printing, and manufacturing for cannabis protective packaging and cartridge box packaging, delivering OEM/ODM solutions that combine compliance, quality, and brand impact. Contact us via https://www.gzbestpack.com/ to discuss child-resistant options for your next pre-roll release.

Tips for buy pre roll cone packaging

How barcode and serialization work on custom cigarette boxes

How to Procure Custom Printed Paperboard Cigarette Boxes in Bulk

Sustainable Options for Child-Resistant Pre-Roll Packaging

About us

How much of your samples cost ?

1. If samples are without printing, we can make free samples as per your box size or structure;

2. If samples are silk printing, normally USD 25 per color,depending on your logo colors;

3. If samples are offset printing, need USD 180 as offset printing mold cost is high.

Leading time for samples production?

Normally we need 3-7 days for samples making, 10-12 days to complete your orders,but the delivery time more depends on the order QTY.

Are you able to do design for my products?

Yes, just send us your logo artwork in Vector file, such as AI or PDF format,and text information you want to print ,we can put it on box to make the design to let you check. Once you say ok, then we go on to make samples or production.

When can I get the quotation?

1. The quotation will be offered within 24 hours after getting your detailed request.

2. If you get the urgent inquiry, please call us or mark it via E-mail, then we could make it into priority list.

What is the box size and structure?

1. All boxes are customized and all detailed requirements can be provided by clients, we are definitely your OEM service supplier.

2. If you have no idea about the measurements and structure on your products, our professional design team can suggest and solute for you .

Custom Pre Cone 5 Pack Magnetic Paper Cigarettes Box Pre Roll Packaging Box

Custom Printed Paperboard Cardboard Cigarette Box Packaging Case Disposable Paper Box for Cigarette Clamshell paper box

Custom Vape Packaging Box with CR Telescoping Design

The CR telescoping box is a sophisticated and secure packaging solution designed specifically for vape products. Featuring a telescoping (two-piece) structure, this box offers excellent protection and an elegant presentation, enhancing both the unboxing experience and brand appeal.

Best pack

Best pack

Best pack