How to Choose a Manufacturer for Pre-Roll Boxes

- How to Choose a Manufacturer for Pre-Roll Boxes

- Understand Your Product and Market Needs

- Verify Regulatory Compliance and Child-Resistant Performance

- What to request: documentation and test reports

- Assess Materials and Construction Options

- Material comparison table

- Evaluate Printing and Finishing Capabilities

- Digital vs. Offset: which to pick?

- Review Minimum Order Quantities (MOQs) and Pricing Structure

- Negotiation tips

- Quality Control, Sampling and Production Oversight

- What to include in an agreement

- Check Lead Times, Logistics and Scalability

- Protect Best Pack and Intellectual Property

- Assess Sustainability and Corporate Responsibility

- Compare Suppliers with a Scorecard

- Sample scorecard columns to use

- Red Flags to Watch For

- Negotiating On-Service: Samples, Revisions and Warranties

- Why Best Pack is a Strong Partner for Pre-Roll Packaging Box Needs

- Best Pack core strengths

- Main products and advantages

- Practical Checklist Before You Commit

- FAQs

- Q: What is the typical MOQ for pre roll packaging box orders?

- Q: Do I need child-resistant packaging for pre-rolls?

- Q: How do I balance cost vs. branding for packaging?

- Q: What printing method is best for full-color artwork?

- Q: How long does it take to receive samples?

- Q: What sustainability features should I ask for?

- Sources

How to Choose a Manufacturer for Pre-Roll Boxes

Choosing the right partner for your pre roll packaging box is a commercial decision: it affects compliance, shelf appeal, cost per unit, and the customer experience. This guide walks through the key selection criteria—certifications and testing, materials and finishes, printing capabilities, MOQ and cost structure, quality control, lead times, IP protection, and sustainability—so you can select a manufacturer that fits Best Pack and market strategy.

Understand Your Product and Market Needs

Before contacting suppliers, clarify the product requirements for your pre roll packaging box: how many pre-rolls per pack, whether child-resistant closure is required, local regulatory labeling needs, branding level, and target run sizes. These decisions drive the choice of materials (cardboard sleeve, tuck-end box, rigid carton, or tube), required testing, and the most cost-effective manufacturing method.

Verify Regulatory Compliance and Child-Resistant Performance

If your product requires child-resistant packaging, prioritize manufacturers with experience producing compliant child-resistant and tamper-evident boxes. Ask for evidence of relevant testing and the ability to meet regional regulations—such as requirements enforced under the Poison Prevention Packaging Act (PPPA) in the U.S. and state-level cannabis packaging rules. A reliable supplier should provide test reports, a description of test methods used, and a history of successful certifications.

What to request: documentation and test reports

Request copies of test reports, certificates (for example, ISO 9001 quality systems where applicable), material safety declarations, and any lab reports demonstrating child-resistant performance or tamper-evident properties. Confirm whether the supplier can support periodic re-testing and batch-level traceability.

Assess Materials and Construction Options

Your material choice affects durability, shelf presentation, and cost. Common options for pre roll packaging box designs include SBS (solid bleached sulfate) paperboard for high print quality, kraft or recycled card for a rustic look, and rigid tube/hinge boxes for a High Quality feel. Make sure the manufacturer can advise on material grades, barrier coatings for moisture or terpene resistance, and compatibility with your product (especially essential oils and terpenes in cannabis products which can interact with substrates).

Material comparison table

| Material | Best for | Pros | Cons |

|---|---|---|---|

| SBS Paperboard | High-quality printed pre roll packaging box | Excellent print fidelity; smooth surface; High Quality look | Higher cost; may need barrier coating for aroma-sensitive products |

| Kraft / Recycled Board | Eco-conscious brands; rustic branding | Lower cost; perceived sustainability | Lower print quality for fine detail; variable color |

| Rigid Tubes / Hinge Boxes | High Quality pre roll packaging box | Strong shelf presence; durable; reusable feel | Higher tooling and unit cost |

| Corrugated (micro) | Bulk packs or shipping-friendly boxes | Good protection; cost-effective for larger sizes | Less High Quality finish; thicker profile |

Evaluate Printing and Finishing Capabilities

Best Pack is communicated first via print and finish. Confirm that the manufacturer offers the printing methods you need—digital for short runs and personalization, offset for high-quality long runs, flexo for certain board types, and screen/UV/coating options for special effects. Also ensure they can handle embossing, debossing, hot stamping, matte/gloss laminates, and security features (holograms, tamper seals) if required.

Digital vs. Offset: which to pick?

Digital printing is cost-effective for small runs, rapid prototyping, and variable data. Offset printing delivers superior color consistency and lower unit cost for larger volumes. Talk to the supplier about minimums and how they price color deviations and spot colors.

Review Minimum Order Quantities (MOQs) and Pricing Structure

MOQs vary widely between suppliers and depend on material, printing method, and tooling needs. Request full quotes that separate tooling/die costs, unit price tiers by volume, sampling fees, and shipping. A clear pricing matrix helps you calculate landed cost per pre roll packaging box at different production volumes and supports sound inventory planning.

Negotiation tips

Ask about price breaks at volume tiers, amortization of tooling costs across multiple orders, and potential discounts for recurring contracts. If your initial demand is low, consider a mix of short-run digital samples and a later larger offset run once demand stabilizes.

Quality Control, Sampling and Production Oversight

Quality consistency is critical. A trustworthy manufacturer provides pre-production samples, digital proofs, and pre-shipment inspections. Look for factories that perform in-line quality checks, final inspections (AQL standards where applicable), and can share inspection reports and photos. Ask how they handle defects: acceptable defect rates, rework policies, and replacement timelines.

What to include in an agreement

Include acceptance criteria, sample sign-off process, production milestones, and remedies for non-conforming goods in your contract. If your pre roll packaging box is regulated, require batch traceability and document retention for audits.

Check Lead Times, Logistics and Scalability

Lead time affects product launch planning. Confirm typical turnaround for samples, pilot runs and full production. Ask about factory capacity, peak-season impacts, and their ability to scale with you as demand grows. Confirm shipping options, customs experience, and the supplier’s preferred freight forwarders if exporting.

Protect Best Pack and Intellectual Property

Work with manufacturers that respect IP. Ask for NDAs before sharing designs, confirm die and plate ownership, and clarify who retains artwork and tool files after production. Check for watermarking/samples policy to avoid unauthorized re-use. If you have patented mechanisms or unique child-resistant constructions, ensure the supplier signs to protect proprietary information.

Assess Sustainability and Corporate Responsibility

Sustainability is increasingly important for customers and retailers. Ask your manufacturer about recycled content, FSC certification, recyclable inks, and end-of-life guidance for your pre roll packaging box. Also evaluate labor standards and whether the factory adheres to recognized social compliance programs (e.g., Sedex, BSCI) if that matters to Best Pack.

Compare Suppliers with a Scorecard

Create a supplier scorecard to objectively compare candidates. Common criteria: compliance and certifications (20%), material and printing quality (20%), price and MOQ flexibility (15%), lead time and capacity (15%), QC process and testing (15%), IP protection and communication (10%), sustainability (5%). Weight the categories based on your priorities and score each supplier during evaluation.

Sample scorecard columns to use

Supplier name, certifications, sample quality score, lead time, unit price at x quantity, tooling cost, MOQ, AQL pass rate, communication responsiveness, sustainability credentials.

Red Flags to Watch For

Be cautious if a prospective manufacturer refuses to share test reports or references, cannot provide samples, has inconsistent communication, or pushes unusually low MOQ without clarifying how quality is maintained. Unclear pricing, no traceability, and missing proof of regulatory compliance are also major red flags.

Negotiating On-Service: Samples, Revisions and Warranties

Agree on a clear sample review and revision process. Define how many revision cycles are included, the cost and lead time for additional revisions, and whether the supplier offers warranties for manufacturing defects. If the product is seasonally sensitive, consider clauses for expedited production or priority scheduling.

Why Best Pack is a Strong Partner for Pre-Roll Packaging Box Needs

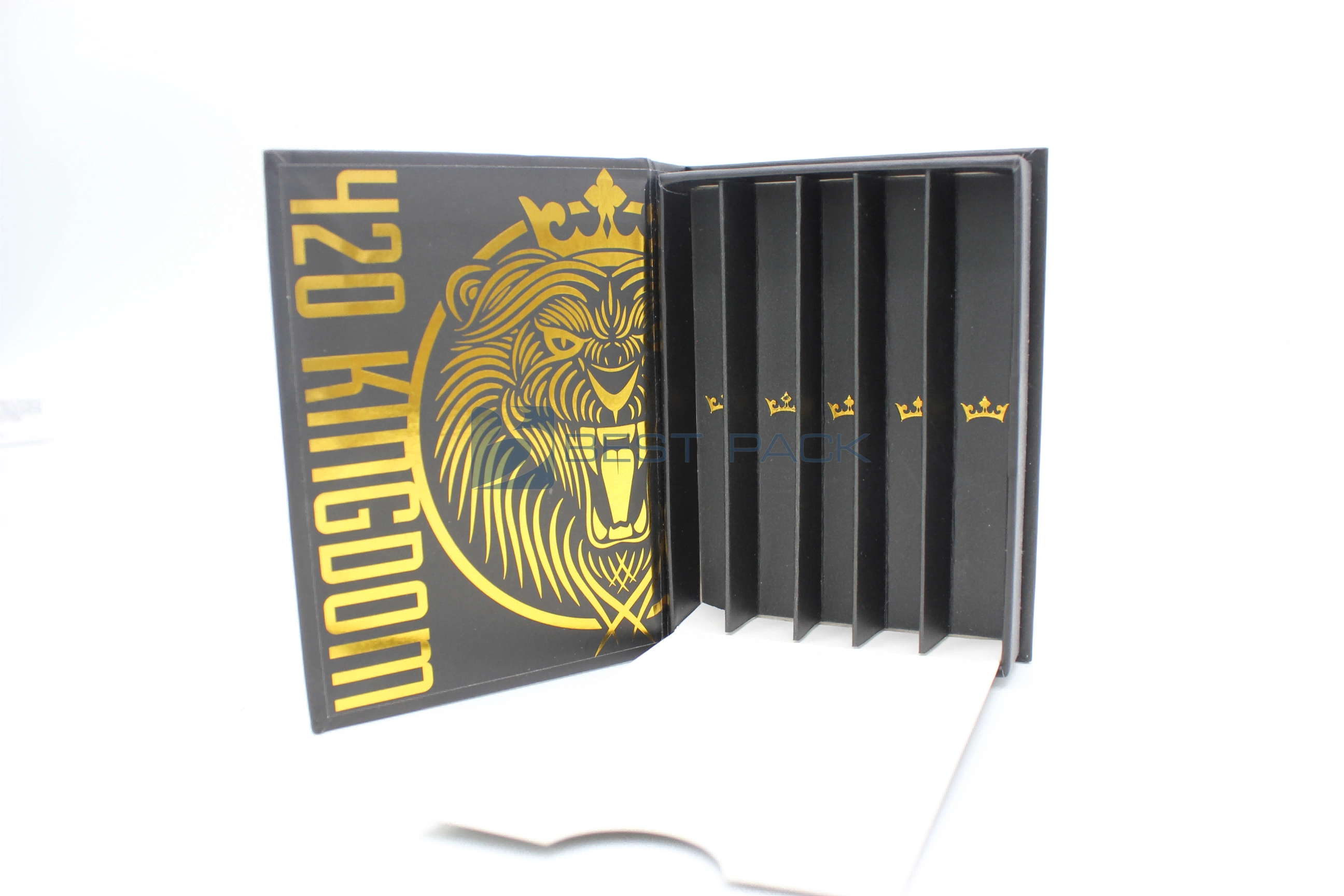

Best Pack positions itself as a one-stop custom packaging provider capable of handling design, printing, and handicraft processing for cannabis and cigarette packaging needs. They emphasize quality, competitive pricing, and continuous innovation. For brands looking for OEM/ODM services, Best Pack highlights real customer cases that show their ability to produce child resistant packaging box solutions, cannabis protective packaging, vape packaging, and custom cigarette packaging boxes.

Best Pack core strengths

Best Pack emphasizes integrated capabilities—from concept and dielines to printing, finishing and assembly—enabling consistent brand presentation. Their services include custom vape cartridge boxes, cannabis packaging boxes, and child resistant packaging box options. The company markets its strengths as attention to detail, quality control processes, and the ability to elevate brand value through tailored packaging that supports promotions and customer feedback.

Main products and advantages

Best Pack’s product range relevant to pre roll packaging box buyers includes:

- Child Resistant Packaging Box — designed to meet child-safety requirements while maintaining a branded appearance.

- Cannabis Protective Packaging — materials and constructions that protect aroma and product integrity during storage and transport.

- Vape Packaging — cartridge boxes and accessories with secure inserts and tamper-evident features.

- Cigarette Packaging Box — custom cigarette packaging solutions for branding and protection.

- Custom Vape Cartridge Boxes & Custom Cannabis Packaging — full OEM/ODM services to create tailored solutions.

These product lines support different price and branding tiers, from economical printed cartons to High Quality rigid boxes and fully customized child-resistant closures. Best Pack states a vision to become a leading global cannabis and cigarette packaging box manufacturer and emphasizes team collaboration, innovation, and a focus on quality and competitive pricing. Their website (https://www.gzbestpack.com/) provides more detail and customer case studies.

Practical Checklist Before You Commit

Before signing a manufacturing contract for your pre roll packaging box, use this short checklist: request samples and test reports; confirm MOQs and full-cost breakdown; verify lead times and inventory terms; secure IP protection (NDA and ownership clauses); confirm QC processes and remedies; and review sustainability and labor compliance credentials.

FAQs

Q: What is the typical MOQ for pre roll packaging box orders?

A: MOQs vary widely depending on material and printing method—digital short runs can be a few hundred to a few thousand units, while offset or rigid box runs often require several thousand units. Ask suppliers for tiered pricing so you can model your cost per unit at different volumes.

Q: Do I need child-resistant packaging for pre-rolls?

A: Requirements depend on jurisdiction and product category. Many regions require child-resistant features for cannabis products. Work with a manufacturer experienced in compliant child resistant packaging box designs and request documentation of testing and past approvals.

Q: How do I balance cost vs. branding for packaging?

A: Consider a two-phase approach: start with a cost-effective printed pre roll packaging box for market entry (digital or small offset run) and invest in High Quality materials and finishes for higher-margin SKUs once demand is proven. Factor in tooling amortization and storage costs.

Q: What printing method is best for full-color artwork?

A: Offset printing generally delivers the highest color consistency and is cost-effective for larger runs. Digital printing is best for short runs, fast turnarounds, and variable-data customization. Choose based on run size, color fidelity, and budget.

Q: How long does it take to receive samples?

A: Sample timelines vary: digital mockups and printed proofs can be available within days, while physical pre-production samples for custom tooling can take 1–3 weeks depending on complexity. Confirm timelines in advance.

Q: What sustainability features should I ask for?

A: Ask about recycled content, FSC-certified paperboard, recyclable coatings and inks, minimal plastic use, and guidance on end-of-life disposal. Also inquire about sustainable sourcing and factory practices if that matters to Best Pack.

Sources

U.S. Consumer Product Safety Commission (CPSC) — Poison Prevention Packaging Act; industry best practices for packaging materials, printing methods and quality systems (ISO 9001); brand and regulatory guidance from state-level cannabis packaging regulations; packaging industry knowledge about digital vs. offset printing and common material properties.

How to create child-resistant prototypes for cigarette boxes

Sustainable Options for Child-Resistant Pre-Roll Packaging

Top eco-friendly materials for custom cigarette boxes

Artwork preparation guide for pre roll logo printing

About us

When can I get the quotation?

1. The quotation will be offered within 24 hours after getting your detailed request.

2. If you get the urgent inquiry, please call us or mark it via E-mail, then we could make it into priority list.

The process of your packaging box production?

1. Make knife mold as per box size and structure

2. order material as per mold

3. make printing on material if need to print

4. suppress and cut material

5. Makeboxes with glue edge in machine

6. Package boxes into cartons

What is the box size and structure?

1. All boxes are customized and all detailed requirements can be provided by clients, we are definitely your OEM service supplier.

2. If you have no idea about the measurements and structure on your products, our professional design team can suggest and solute for you .

Are you able to do design for my products?

Yes, just send us your logo artwork in Vector file, such as AI or PDF format,and text information you want to print ,we can put it on box to make the design to let you check. Once you say ok, then we go on to make samples or production.

FAQs

How do you ensure product quality?

We maintain strict quality control at every stage, from material selection to final production, ensuring high-quality standards.

Custom Pre Cone 5 Pack Magnetic Paper Cigarettes Box Pre Roll Packaging Box

Custom Printed Paperboard Cardboard Cigarette Box Packaging Case Disposable Paper Box for Cigarette Clamshell paper box

Custom Vape Packaging Box with CR Telescoping Design

The CR telescoping box is a sophisticated and secure packaging solution designed specifically for vape products. Featuring a telescoping (two-piece) structure, this box offers excellent protection and an elegant presentation, enhancing both the unboxing experience and brand appeal.

Best pack

Best pack

Best pack