Everything You Need to Know About cigarette box factory

- Everything You Need to Know About Cigarette Box Factory

- What is a Cigarette Box Factory?

- Key Processes in a Cigarette Box Factory

- The Importance of Custom Packaging in the Cannabis Industry

- Materials Commonly Used in Cigarette Box Manufacturing

- OEM/ODM Capabilities in Cigarette Box Factories

- Child-Resistant Packaging and Safety Regulations

- How Technology Enhances Production Efficiency

- Environmental Considerations in the Cigarette Box Industry

- Choosing the Right Cigarette Box Factory Partner

- Conclusion

- FAQ

Everything You Need to Know About Cigarette Box Factory

The cigarette box factory plays a vital role in producing packaging that not only protects the product but also enhances brand identity and appeals to consumers. In industries like cannabis cigarette packaging, where customization, protection, and compliance are crucial, understanding what goes on inside a cigarette box factory is essential for businesses looking to elevate their packaging solutions.

What is a Cigarette Box Factory?

A cigarette box factory is a manufacturing facility specializing in producing cigarette packaging boxes. These factories offer everything from design consultation to printing, cutting, folding, and final packaging assembly. Particularly for custom cannabis cigarette packaging, factories must incorporate advanced printing technologies and quality control systems to meet strict industry standards.

Key Processes in a Cigarette Box Factory

The production flow within a cigarette box factory generally involves several stages:

- Design and Prototyping: Using sophisticated design software, the packaging layout and artwork are created to ensure perfect alignment with brand identity.

- Printing: High-quality printing techniques such as offset printing, digital printing, and UV coating are applied to enhance visual appeal.

- Cutting and Folding: Precision die-cutting machines shape the boxes, followed by folding and gluing to form the final structure.

- Handicraft Processing: Additional features such as embossing, debossing, foil stamping, and lamination require artisanal skills.

- Quality Control: Each batch undergoes stringent checks for color fidelity, material strength, and functional integrity.

The Importance of Custom Packaging in the Cannabis Industry

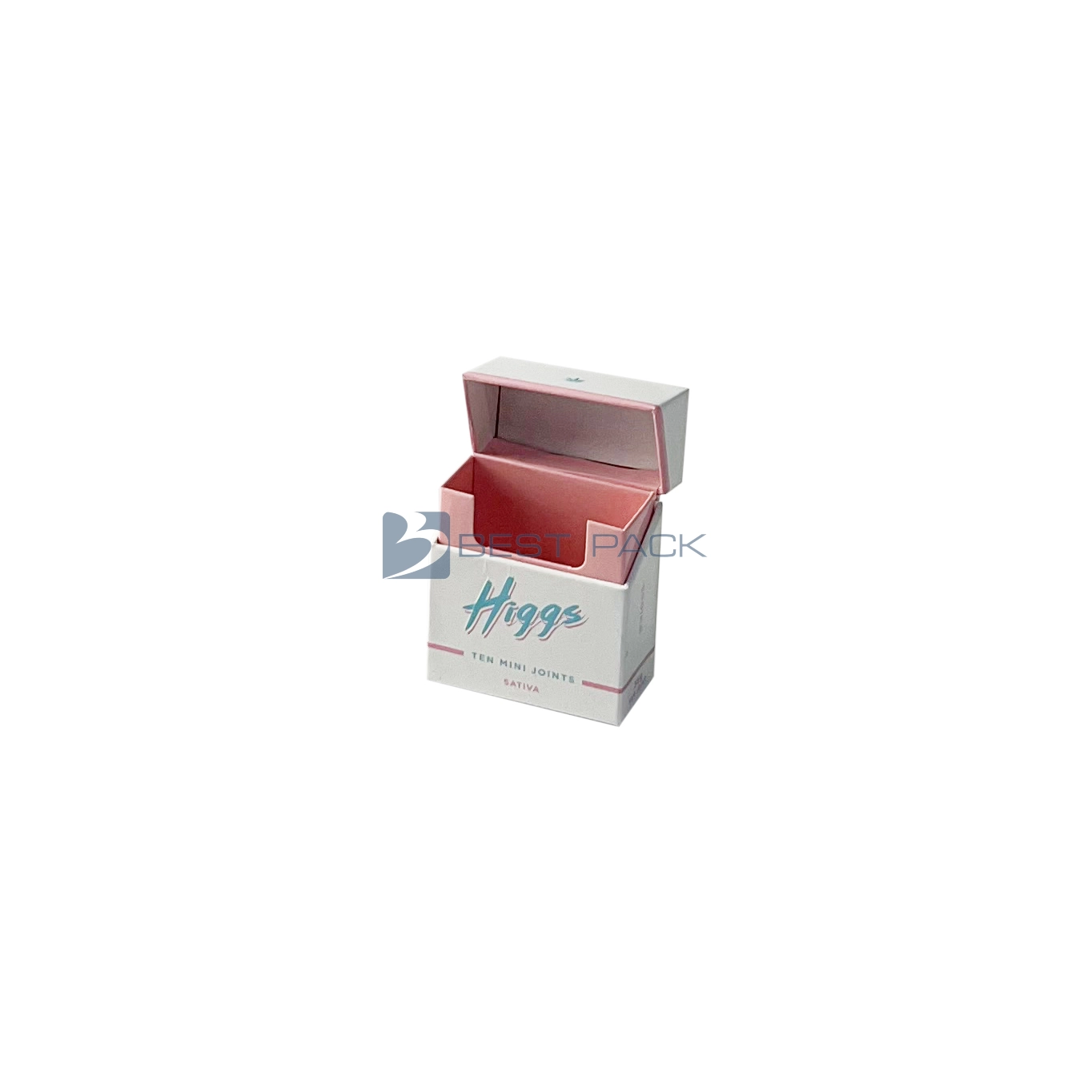

With cannabis products becoming mainstream, custom cigarette box factories have adapted to cater to the unique needs of this market. Packaging must be child-resistant, comply with regulatory requirements, and provide protection against odor and contamination.

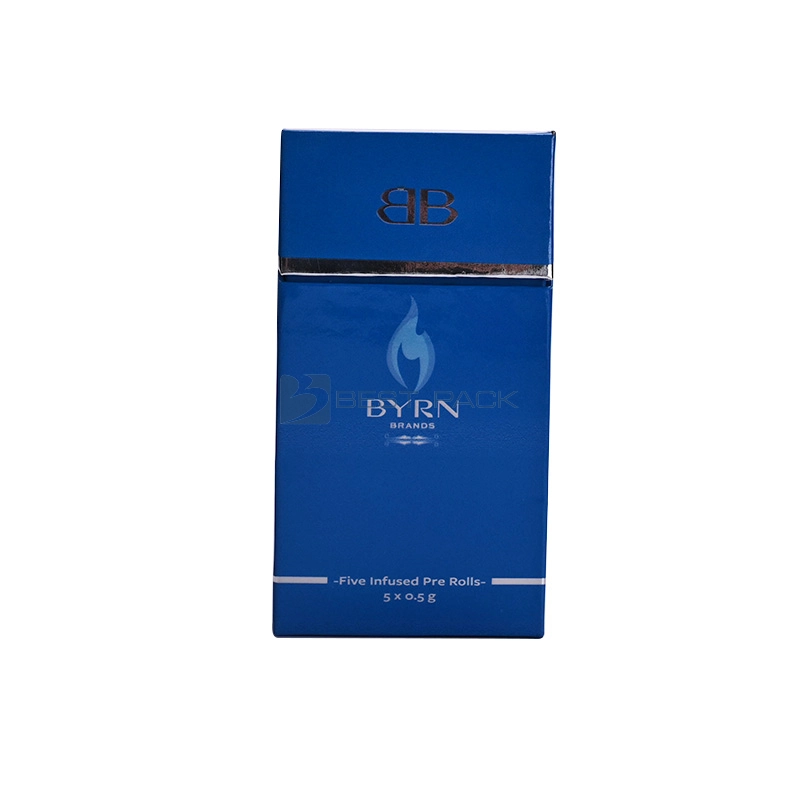

Best Pack specializes in custom cannabis cigarette packaging that combines safety features with aesthetic customization. Our factory’s one-stop service from design to handicraft processing ensures tailored solutions that drive brand loyalty and regulatory compliance.

Materials Commonly Used in Cigarette Box Manufacturing

Material selection impacts durability, customer experience, and environmental footprint:

- Kraft Paperboard: Eco-friendly and sturdy, ideal for High Quality packaging.

- Coated Paperboard: Provides a smooth finish with enhanced print quality.

- Plastic Components: Used in child-resistant locks and tamper-evident seals.

- Recycled Materials: Increasingly used due to sustainability trends.

OEM/ODM Capabilities in Cigarette Box Factories

OEM (Original Equipment Manufacturing) and ODM (Original Design Manufacturing) services allow brands to customize product packaging extensively. Best Pack’s expertise reflects in delivering innovative designs while maintaining cost efficiency and compliance standards. Our real customer cases demonstrate a commitment to detail, quality, and on-time delivery.

Child-Resistant Packaging and Safety Regulations

Child-resistant packaging is a legal requirement in many jurisdictions for cannabis cigarettes. Factories like Best Pack employ tested locking mechanisms and materials to ensure compliance with laws such as the Poison Prevention Packaging Act (PPPA) in the U.S. and equivalent global regulations.

These safety features help minimize accidental ingestion by children while maintaining ease of access for adult consumers, balancing safety with usability.

How Technology Enhances Production Efficiency

The integration of Information Technology in cigarette box factories allows real-time monitoring of production lines, quality assurance, and supply chain management. Best Pack continuously innovates its manufacturing processes using Automation and AI-powered inspection tools to uphold product consistency and shorter lead times.

Environmental Considerations in the Cigarette Box Industry

Eco-conscious production is increasingly demanded by consumers and regulators alike. Sustainable sourcing of raw materials and the reduction of waste during manufacturing are vital. Best Pack advocates green packaging solutions and maintains certifications for environmental management to future-proof our offerings.

Choosing the Right Cigarette Box Factory Partner

When selecting a cigarette box factory, consider factors such as production capacity, customization abilities, quality control, compliance knowledge, and customer service. Partnering with a reputable company like Best Pack guarantees access to cutting-edge technologies and a team-driven innovation mindset.

Conclusion

Cigarette box factories are pivotal in delivering high-quality, compliant, and visually appealing packaging that enhances brand value and safeguards the product. Best Pack leads the way in custom cannabis cigarette packaging, providing end-to-end services that combine quality, innovation, and competitive pricing.

By understanding the nuances of cigarette box manufacturing, from material selection to printing and regulatory compliance, businesses can make informed decisions to boost their brand’s market presence effectively.

For more information on how to customize your cigarette packaging to meet evolving market and safety demands, visit Best Pack’s website and discover our extensive portfolio and tailored solutions.

FAQ

What services does a cigarette box factory provide?They provide comprehensive packaging solutions, including design, printing, cutting, folding, handicraft processes, and quality control.

Why is custom packaging important in the cannabis cigarette market?Custom packaging ensures compliance with safety regulations, enhances brand recognition, and meets unique protection requirements.

How does Best Pack ensure child-resistant packaging?Best Pack incorporates tested locking mechanisms and materials that comply with global child-resistant regulations.

What materials are commonly used in cigarette box manufacturing?Kraft paperboard, coated paperboard, plastic components for safety features, and recycled materials are commonly used.

Can Best Pack handle OEM and ODM cigarette box orders?Yes, Best Pack specializes in OEM/ODM services, providing customized solutions that meet client specifications and regulatory standards.

Everything You Need to Know About green cigarette box

Non tobacco paper boxes: safe options for pre rolls

Sustainable Materials for Cardboard Cigarette Box Packaging

The latest trends for pre roll cigarette box packaging

About us

When can I get the quotation?

1. The quotation will be offered within 24 hours after getting your detailed request.

2. If you get the urgent inquiry, please call us or mark it via E-mail, then we could make it into priority list.

How much of your samples cost ?

1. If samples are without printing, we can make free samples as per your box size or structure;

2. If samples are silk printing, normally USD 25 per color,depending on your logo colors;

3. If samples are offset printing, need USD 180 as offset printing mold cost is high.

Are you able to do design for my products?

Yes, just send us your logo artwork in Vector file, such as AI or PDF format,and text information you want to print ,we can put it on box to make the design to let you check. Once you say ok, then we go on to make samples or production.

What is the box size and structure?

1. All boxes are customized and all detailed requirements can be provided by clients, we are definitely your OEM service supplier.

2. If you have no idea about the measurements and structure on your products, our professional design team can suggest and solute for you .

FAQs

How do you ensure product quality?

We maintain strict quality control at every stage, from material selection to final production, ensuring high-quality standards.

Custom CR Vape Packaging Cardboard Boxes with Child-Resistant Design

CR custom vape packaging cardboard boxes are specially designed child-resistant packaging solutions crafted to ensure safety, protection, and premium presentation for vape products. Made from sturdy cardboard materials, these boxes balance regulatory compliance with brand aesthetics.

Custom Luxury Pre Roll Packaging Boxes with Child-Resistant Paper Tray

Our luxury pre-roll packaging boxes are designed to combine elegant presentation with top-tier safety features. Featuring a child-resistant mechanism and a custom paper tray insert, these boxes ensure secure storage while delivering a premium unboxing experience for pre-roll products.

Custom Child-Lock Pre-Roll 5-Pack Packaging Boxes

Our custom child-lock packaging for pre-roll 5-packs is purposefully engineered to combine premium design with certified safety. This packaging solution ensures that five pre-rolls are securely housed in a compact, stylish, and child-resistant format—ideal for compliant cannabis brands that value both form and function.

Best pack

Best pack

Best pack