The Role of Custom Cigarette Boxes in Enhancing Product Protection

- Introduction: Why The Role of Custom Cigarette Boxes in Enhancing Product Protection Matters

- Understanding the Behind the Keyword

- How Custom Packaging Protects Physical Integrity

- Structural design: cushioning, stacking, and shipping resilience

- Barrier materials: moisture, oxygen, and light protection

- Safety and Compliance: Child-Resistant and Tamper-Evident Features

- Child-resistant packaging (CRP): requirements and best practices

- Tamper-evidence and anti-counterfeiting

- Material Choices That Enhance Protection

- Paperboard and composite constructions

- Flexible pouches and inner liners

- Testing and Validation: Ensuring the Packaging Works in the Real World

- Transport and handling tests

- Performance testing for child resistance

- Environmental Considerations: Protection Without Waste

- Balancing protection and sustainability

- Design for recyclability and circularity

- Branding and Commercial Impact of Protective Custom Packaging

- Protection that supports shelf appeal and conversion

- Using packaging to communicate safety and compliance

- Smart Packaging: Adding Data-Driven Protection

- Temperature and humidity indicators

- QR codes and serialization for traceability

- How Best Pack Delivers Protective Custom Cigarette Boxes

- End-to-end OEM/ODM services

- Real-world case examples and quality focus

- Practical Steps for Brands: Implementing Protective Custom Packaging

- Step 1 — Conduct a risk assessment

- Step 2 — Choose materials and features aligned with risks

- Step 3 — Prototype and test

- Step 4 — Integrate branding and sustainability

- Conclusion: The Business Case for Protective Custom Cigarette Boxes

- Frequently Asked Questions

Introduction: Why The Role of Custom Cigarette Boxes in Enhancing Product Protection Matters

Consumers and regulators increasingly expect cigarette and cannabis cigarette packaging to do more than look good: it must protect product integrity, ensure safety, and meet compliance requirements. The role of custom cigarette boxes in enhancing product protection is central to reducing product damage, preventing contamination, deterring tampering, and ensuring child safety. This article explains practical strategies manufacturers and brands can use to optimize protective packaging, and how Best Pack supports customers from design to finished protective boxes.

Understanding the Behind the Keyword

When users search The Role of Custom Cigarette Boxes in Enhancing Product Protection, they are typically looking for:

- How custom packaging reduces physical, chemical, and biological risks to products.

- Which materials and design features deliver reliable protection.

- Compliance and safety considerations, especially around child resistance and tamper evidence.

- Practical OEM/ODM solutions and real-world case examples for cannabis cigarette packaging.

This article answers those needs with actionable guidance and examples relevant to brands and packaging professionals.

How Custom Packaging Protects Physical Integrity

Structural design: cushioning, stacking, and shipping resilience

Custom cigarette boxes can be engineered to resist mechanical damage during handling and transit. Properly selected board grades (from sturdy SBS paperboard to lightweight folding carton stock with lamination) and internal supports (inserts, trays, or partitions) reduce crushing, tearing, and deformation. For multi-unit shipments, reinforced tuck ends, glued locks, and corrugated outer cartons protect against stacking pressure and pallet loads.

Barrier materials: moisture, oxygen, and light protection

Many cigarette products are highly sensitive to humidity, oxygen, and UV light. Custom cigarette boxes often incorporate barrier layers or lining options—such as foil laminates, metallized films, or barrier coatings—that dramatically reduce moisture and oxygen transmission. Adding an inner foil pouch or heat-sealed liner extends shelf life and preserves flavor and potency for cannabis cigarettes, which can be especially susceptible to degradation from humidity.

Safety and Compliance: Child-Resistant and Tamper-Evident Features

Child-resistant packaging (CRP): requirements and best practices

Across many markets, cannabis products are subject to child-resistant packaging requirements. While rules vary by jurisdiction, the core objective is universal: prevent young children from opening packages and accessing harmful products. Child-resistant mechanisms include push-and-slide closures, multi-step unlocking, blister packs, and independently tested closures that meet recognized protocols. Brands should work with manufacturers experienced in testing CRP to ensure designs pass required performance standards.

Tamper-evidence and anti-counterfeiting

Tamper-evident features — shrink bands, security seals, perforated tear strips, and destructible labels — reassure consumers that the product has not been interfered with. For higher-value or regulated products, adding overt and covert security elements (holograms, micro-text, QR codes linked to batch records, and serialized numbering) both deters counterfeiters and enables traceability through the supply chain.

Material Choices That Enhance Protection

Paperboard and composite constructions

Paperboard remains the dominant choice for retail cigarette boxes due to printability and sustainability. High-density SBS paperboard with aqueous or UV coatings offers balanced protection and aesthetics. Composite builds—paperboard with laminated film or foil—add barrier performance without sacrificing brand presentation.

Flexible pouches and inner liners

Inner flexible pouches (aluminum or multilayer laminates) are commonly used for moisture-sensitive or aroma-driven products. These pouches can be heat-sealed and paired with desiccant packets to control humidity. For cannabis cigarettes, such lining systems help preserve terpene profiles and prevent mold growth.

Testing and Validation: Ensuring the Packaging Works in the Real World

Transport and handling tests

Effective protective design requires validation: drop tests, vibration tests, and compression tests simulate actual logistics stresses. Brands should validate custom cigarette boxes under expected transit and retail handling scenarios to quantify damage rates and make iterative improvements.

Performance testing for child resistance

Child-resistant designs should be validated using recognized protocols. Independent labs can run child and adult use tests to confirm that packaging is difficult for young children to open while remaining accessible for adults. Documented testing helps satisfy regulators and retailers.

Environmental Considerations: Protection Without Waste

Balancing protection and sustainability

Consumers and regulators increasingly prioritize sustainable packaging. Brands can choose recyclable paperboard, mono-material constructions, and minimal-but-effective protective inserts to reduce material use while maintaining product safety. Sustainable adhesives, water-based coatings, and post-consumer recycled content are additional strategies that reduce environmental impact without compromising protection.

Design for recyclability and circularity

Designing custom cigarette boxes with an eye toward recycling (avoiding mixed materials that are hard to separate) improves end-of-life outcomes. Where barrier performance requires laminates, consider recyclable barrier options or clearly label disposal instructions to help consumers recycle properly.

Branding and Commercial Impact of Protective Custom Packaging

Protection that supports shelf appeal and conversion

Protective packaging should never be at odds with branding. High-quality custom cigarette boxes enhance perceived product value, increase shelf presence, and can drive purchasing decisions. Packaging that preserves product freshness and arrives undamaged increases repeat purchase rates and reduces returns.

Using packaging to communicate safety and compliance

Clear labeling about child-resistant features, tamper seals, batch numbers, and authenticity information builds consumer trust. For regulated categories like cannabis, accurate labeling (ingredients, potency, warnings, and disposal instructions) must be integrated into the box design while maintaining readability and compliance.

Smart Packaging: Adding Data-Driven Protection

Temperature and humidity indicators

Smart labels — such as time-temperature indicators or humidity-sensitive inks — alert manufacturers, retailers, and consumers about exposure that could affect product quality. For cannabis cigarettes, monitoring storage conditions can be crucial to maintain potency and minimize mold risk.

QR codes and serialization for traceability

Integrating QR codes or unique identifiers onto custom cigarette boxes enables verification of origin and batch-level traceability. Consumers can scan codes to confirm authenticity, view lab test results, and access product handling instructions—adding transparency and reducing counterfeit risk.

How Best Pack Delivers Protective Custom Cigarette Boxes

End-to-end OEM/ODM services

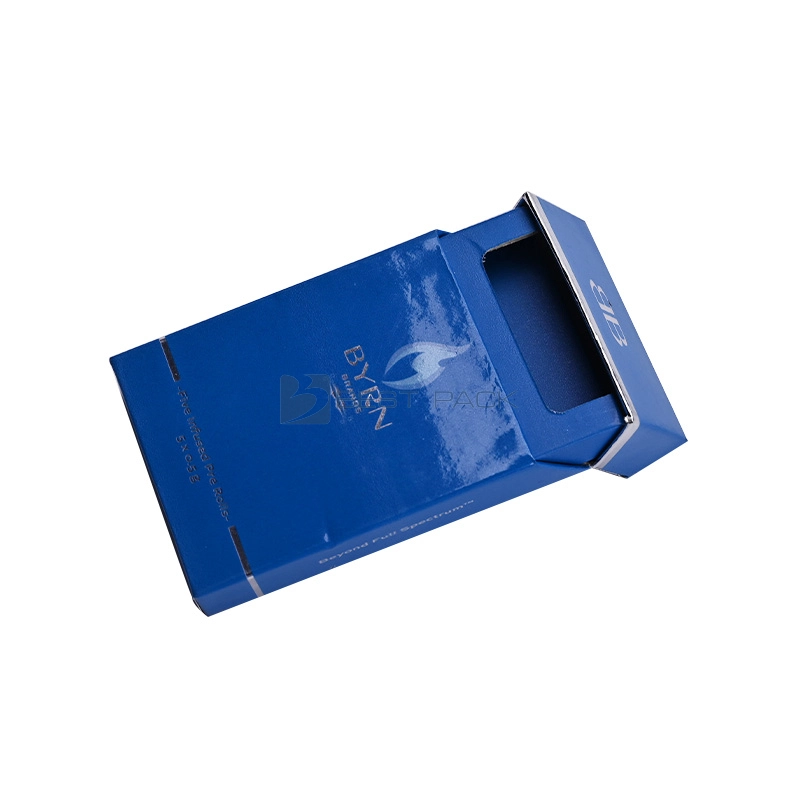

Best Pack (https://www.gzbestpack.com/) offers one-stop services from concept and structural design to printing and handicraft processing. Our approach begins with product analysis—understanding sensitivity to moisture, light, and mechanical stress—then selecting materials and design features that address those vulnerabilities.

Real-world case examples and quality focus

From cannabis protective packaging to cartridge box packaging, Best Pack showcases OEM/ODM capabilities and attention to detail through customer case studies. We include barrier liners, child-resistant closures, tamper-evident seals, and serialization where required. Our team emphasizes quality control at each production stage to ensure packaging performs under real-world conditions.

Practical Steps for Brands: Implementing Protective Custom Packaging

Step 1 — Conduct a risk assessment

Identify the product’s vulnerabilities: moisture, light, aroma loss, mechanical stress, or regulatory risks. Rank these risks to prioritize design choices.

Step 2 — Choose materials and features aligned with risks

Select board grades, barrier liners, closures, and tamper-evident elements matched to the product’s profile. For cannabis cigarettes, consider foil-lined pouches, desiccants, and multi-step child-resistant closures.

Step 3 — Prototype and test

Build prototypes and run transit, compression, and child-resistance tests. Adjust designs based on test outcomes before scaling production.

Step 4 — Integrate branding and sustainability

Ensure the protective features work hand-in-hand with visual design and recyclability goals. Use printing and finishing techniques that communicate quality and compliance.

Conclusion: The Business Case for Protective Custom Cigarette Boxes

The role of custom cigarette boxes in enhancing product protection is both practical and commercial. Well-designed packaging reduces damage and waste, supports regulatory compliance, protects consumers (especially children), and strengthens brand trust. For cannabis cigarette brands in particular, protective packaging is essential to preserve product integrity, meet jurisdictional rules, and build market credibility. As a full-service OEM/ODM partner, Best Pack helps brands translate protection needs into manufacturable, scalable box solutions that elevate brand value and minimize risk.

Frequently Asked Questions

Q: What is the most important protective feature in custom cigarette boxes?A: The most important feature depends on the product risks—moisture and oxygen barriers are critical for freshness, while child-resistant closures and tamper-evident seals address safety and compliance. A combined approach tailored to product sensitivity is best.

Q: Are child-resistant cigarette boxes legally required?A: Requirements vary by jurisdiction. Many regions require child-resistant packaging for cannabis products and certain regulated goods. Brands should consult local regulations and test packaging to recognized protocols where required.

Q: Can protective packaging be sustainable?A: Yes. Brands can use recyclable paperboard, mono-material constructions, recyclable barriers, and minimal inserts to balance protection and environmental goals. Clearly labeling disposal instructions helps improve recycling outcomes.

Q: How does Best Pack help with testing and compliance?A: Best Pack supports structural and materials design and partners with testing facilities to validate transport robustness and child-resistance where needed. We document test results to help customers meet regulatory and retailer expectations.

Q: What smart packaging options improve product protection?A: Smart options include temperature/humidity indicators, QR codes for traceability and lab data access, serialized numbering, and authentication features like holograms. These tools add monitoring and anti-counterfeit capabilities.

Q: How do I get started with a custom protective cigarette box project?A: Begin by assessing product vulnerabilities and compliance needs, then contact an experienced OEM/ODM like Best Pack to discuss materials, prototyping, and testing. The process typically moves from concept to prototype to validation and production.

Compliance Checklist for Pre-Roll Non-Tobacco Paper Packaging

Vintage Cigar Box Design Trends for Child Resistant Packaging

Regulatory Changes for Cigarette Box CR Packaging in 2026

Top pre roll box packaging Manufacturers and Suppliers in China

About us

How many kinds the printing process you have?

We can make Silk screen printing, offset printing, and also hot silver stamping

Are you able to do design for my products?

Yes, just send us your logo artwork in Vector file, such as AI or PDF format,and text information you want to print ,we can put it on box to make the design to let you check. Once you say ok, then we go on to make samples or production.

How much of your samples cost ?

1. If samples are without printing, we can make free samples as per your box size or structure;

2. If samples are silk printing, normally USD 25 per color,depending on your logo colors;

3. If samples are offset printing, need USD 180 as offset printing mold cost is high.

FAQs

What services do you provide?

We offer one-stop packaging solutions, including design, printing, and handicraft processing for electronic boxes, plastic boxes, paper boxes, paper bags, and book printing.

How do you ensure product quality?

We maintain strict quality control at every stage, from material selection to final production, ensuring high-quality standards.

Custom Printed Paperboard Cardboard Cigarette Box Packaging Case Disposable Paper Box for Cigarette Clamshell paper box

Custom Vape Packaging Box with CR Telescoping Design

The CR telescoping box is a sophisticated and secure packaging solution designed specifically for vape products. Featuring a telescoping (two-piece) structure, this box offers excellent protection and an elegant presentation, enhancing both the unboxing experience and brand appeal.

Custom Logo Child-Resistant Pre-Roll Box Packaging Biodegradable Handmade Luxury 5 Pack Embossing Childproof Pre Roll Package

Custom CR Vape Packaging Cardboard Boxes with Child-Resistant Design

CR custom vape packaging cardboard boxes are specially designed child-resistant packaging solutions crafted to ensure safety, protection, and premium presentation for vape products. Made from sturdy cardboard materials, these boxes balance regulatory compliance with brand aesthetics.

Best pack

Best pack

Best pack