Eco-Friendly Child Resistant Paper Packaging: Balancing Safety and Sustainability

- Introduction: Why Eco-Friendly Child Resistant Paper Packaging Matters for Cannabis Brands

- Protecting children and the planet while growing Best Pack

- Understanding Regulations and Standards for Child-Resistant Cannabis Packaging

- Regulatory drivers and state-level requirements

- Testing and third-party validation

- Materials: Choosing Sustainable Paperboard and Eco-Friendly Inks

- Paper substrates that balance performance and recyclability

- Low-impact printing and coatings

- Child-Resistant Mechanisms Compatible with Paper Packaging

- Designing effective mechanical features in paper

- Hybrid approaches: minimal plastics, maximum sustainability

- Design & Branding: How Sustainable Child-Resistant Packaging Enhances Marketability

- Branded experiences without compromising recyclability

- User experience: accessibility for adults, resistance for children

- Manufacturing Processes and OEM/ODM Capabilities

- From dielines to finished cartons: scalable production

- Customization and small-batch runs

- Supply Chain and Lifecycle Considerations for Sustainability

- Material sourcing and certifications

- End-of-life pathways: recycling, composting, and reuse

- Cost, ROI, and Commercial Benefits

- Balancing cost and sustainability without sacrificing safety

- Marketing advantages and customer trust

- Real-World Applications: Packaging Types and Case Uses

- Custom cannabis cigarette packaging and cartridge boxes

- Accessories and multipacks

- Implementation Checklist: How Brands Should Evaluate Suppliers

- Key questions to ask potential packaging partners

- Sample and pilot runs

- Best Pack Advantage: OEM/ODM Expertise in Sustainable Cannabis Packaging

- One-stop service from design to handicraft processing

- Attention to detail and real customer cases

- Conclusion: Practical Steps to Adopt Eco-Friendly Child Resistant Paper Packaging

- Start with clear priorities and partner selection

- Contact Best Pack to move from concept to compliance

- Frequently Asked Questions

Introduction: Why Eco-Friendly Child Resistant Paper Packaging Matters for Cannabis Brands

Protecting children and the planet while growing Best Pack

As cannabis products become mainstream, brands face two non-negotiable demands: child safety and environmental responsibility. Eco-friendly child resistant paper packaging answers both, helping companies comply with regulations, reduce environmental impact, and strengthen customer trust. For cannabis cigarette and cartridge packaging, reliable child-resistant mechanisms combined with sustainable paper substrates create a powerful differentiator for brands — especially when delivered through a custom OEM/ODM partner like Best Pack.

Understanding Regulations and Standards for Child-Resistant Cannabis Packaging

Regulatory drivers and state-level requirements

Many jurisdictions require child-resistant packaging for controlled substances and cannabis products. In the United States, federal and state rules — for example, guidance from agencies and state cannabis control boards — typically demand child-resistant closures and tamper-evident features. Manufacturers must design packaging to meet applicable local standards and pass independent child-safety testing where required. For brands, partnering with a packaging supplier experienced in regulatory compliance ensures a smoother route to market.

Testing and third-party validation

Child-resistant packaging should undergo rigorous testing by accredited labs and follow established testing protocols. Independent lab verification provides documented proof of performance and mitigates legal and reputational risk. Manufacturers who offer support for testing and certification lower the compliance barrier for brands and reduce time-to-market.

Materials: Choosing Sustainable Paperboard and Eco-Friendly Inks

Paper substrates that balance performance and recyclability

Paperboard, kraft, and corrugated papers are commonly used for eco-friendly child resistant packaging. Selecting FSC-certified or high post-consumer recycled (PCR) content paper helps reduce environmental impact while maintaining structural strength. For cannabis cigarette packaging, thicker paperboards with appropriate GSM (grams per square meter) deliver rigidity for child-resistant features without resorting to plastic inserts.

Low-impact printing and coatings

Water-based inks, soy-based inks, and UV-free varnishes reduce volatile organic compound (VOC) emissions and enhance recyclability. Avoiding plastic laminates and using biodegradable or water-dispersible coatings preserves the paper’s ability to be recycled. These choices support sustainable credentials and make end-of-life handling simpler for consumers and waste managers.

Child-Resistant Mechanisms Compatible with Paper Packaging

Designing effective mechanical features in paper

Child-resistant mechanisms for paper packaging include tuck-and-lock flaps, slide-and-lock inner trays, tab-locking systems, and multi-step opening sequences that require coordinated actions. These can be engineered using die-cutting, reinforced flaps, and internal locking tabs without relying heavily on plastics. Selecting the right mechanism depends on product form (cigarettes, cartridges, or accessories), desired user experience, and compliance requirements.

Hybrid approaches: minimal plastics, maximum sustainability

Where necessary, small, recyclable plastic components or biodegradable polymer liners can be integrated to achieve certified child resistance while keeping plastic usage minimal. Hybrid solutions combine the structural and printing benefits of paper with targeted functional elements to meet both safety and sustainability goals.

Design & Branding: How Sustainable Child-Resistant Packaging Enhances Marketability

Branded experiences without compromising recyclability

Eco-friendly child resistant paper packaging allows rich branding through high-quality printing, embossing, debossing, and hot-stamping using sustainable foils. Thoughtful design communicates both High Quality quality and environmental responsibility. Brands that highlight eco-credentials on-pack (e.g., recycled content, recyclability symbols, and FSC certification) can improve purchase consideration among eco-conscious consumers.

User experience: accessibility for adults, resistance for children

Balancing safety with convenience is essential. Packaging should be intuitive for adults while resisting child access. Clear instructions, ergonomic openings, and resealability enhance adult usability. A user-focused design reduces customer frustration and returns while preserving safety performance.

Manufacturing Processes and OEM/ODM Capabilities

From dielines to finished cartons: scalable production

Producing reliable child resistant paper packaging requires precision die-cutting, skilled folding and gluing, and quality control systems. OEM/ODM suppliers with in-house prepress, printing, and handicraft processing capabilities — like Best Pack — offer end-to-end production: concept, structural design, prototyping, printing, finishing, and assembly. This reduces complexity for brands and ensures consistent quality at scale.

Customization and small-batch runs

Market testing and limited-edition product lines benefit from suppliers who can handle small-batch production economically. Flexible tooling, digital printing, and modular designs allow brands to experiment with messaging and sustainable finishes without large upfront tooling costs.

Supply Chain and Lifecycle Considerations for Sustainability

Material sourcing and certifications

Work with suppliers that can document responsible sourcing — for example, FSC or PEFC chain-of-custody certificates — and provide transparency on recycled content. Local sourcing reduces transportation emissions and shortens lead times, helping brands meet sustainability goals and improve responsiveness.

End-of-life pathways: recycling, composting, and reuse

Design packaging to align with existing recycling streams. Avoid mixed-material laminates that confound recyclers; instead, opt for mono-material designs or easily separable components. Clear on-pack instructions help consumers dispose of packaging correctly, increasing the likelihood of recycling or composting.

Cost, ROI, and Commercial Benefits

Balancing cost and sustainability without sacrificing safety

Eco-friendly child resistant paper packaging can be cost-competitive when designs optimize material use and manufacturing efficiency. Lightweighting, standardized dielines, and smart folding techniques reduce material costs. While some sustainable finishes or third-party certifications add expense, they can be offset by higher perceived value and stronger brand loyalty.

Marketing advantages and customer trust

Consumers increasingly prefer brands that demonstrate environmental responsibility. Sustainable child resistant packaging signals corporate responsibility and concern for community safety, improving brand reputation and supporting High Quality pricing strategies. For cannabis brands, this can translate into higher shelf visibility and stronger word-of-mouth.

Real-World Applications: Packaging Types and Case Uses

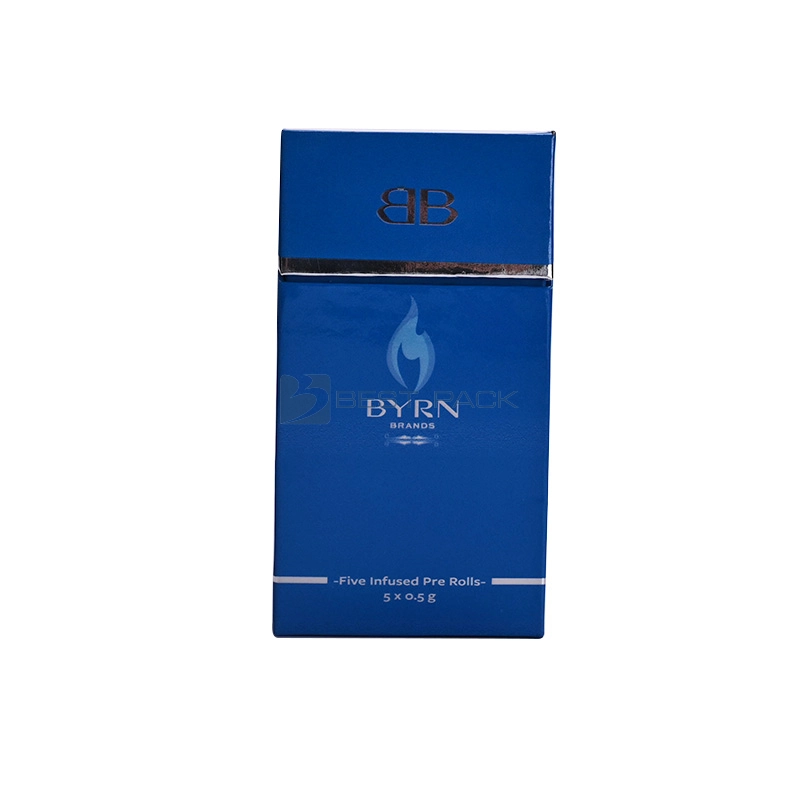

Custom cannabis cigarette packaging and cartridge boxes

Paper-based slide boxes, tuck-top cartons, and folding cartons with integrated child-resistant features work well for cigarettes and cartridges. Best Pack’s OEM/ODM services produce protective packaging that secures products during transport, supports retail display, and integrates child safety and tamper-evidence.

Accessories and multipacks

Multipacks, accessory boxes, and promotional sleeves can also be designed to meet child-safety standards. Sustainable materials and clear brand messaging across multipack solutions increase cross-sell opportunities and enhance perceived value.

Implementation Checklist: How Brands Should Evaluate Suppliers

Key questions to ask potential packaging partners

When selecting a supplier, request evidence of regulatory compliance support, child-safety testing experience, material certifications, and OEM/ODM capabilities. Ask for case studies relevant to cannabis packaging, sample production timelines, minimum order quantities, and options for eco-friendly inks and coatings.

Sample and pilot runs

Pilot runs and functional prototypes allow brands to validate child resistance, user experience, and shelf appeal. Suppliers that provide iterative prototyping and testing reduce risk and accelerate approvals.

Best Pack Advantage: OEM/ODM Expertise in Sustainable Cannabis Packaging

One-stop service from design to handicraft processing

Best Pack specializes in custom cannabis cigarette and cartridge packaging with full-service capabilities: structural design, printing, finishing, and handicraft processing. Our team emphasizes quality, competitive pricing, and continuous innovation, enabling brands to launch compliant, sustainable, and market-ready packaging quickly.

Attention to detail and real customer cases

Our portfolio spans protective packaging, cartridge boxes, and tailor-made solutions that emphasize brand elevation while meeting safety needs. Best Pack’s OEM/ODM approach supports brands through regulatory complexities and market demands, delivering packaging that drives purchasing decisions through strong design and reliable functionality.

Conclusion: Practical Steps to Adopt Eco-Friendly Child Resistant Paper Packaging

Start with clear priorities and partner selection

Balancing child safety and sustainability requires purposeful design choices, validated testing, and experienced manufacturing partners. Begin by defining compliance needs, brand goals, and sustainability targets. Work with an OEM/ODM partner that can provide certified materials, testing support, sample prototyping, and scalable production. By doing so, brands can protect consumers, reduce environmental impact, and strengthen market position.

Contact Best Pack to move from concept to compliance

If you’re exploring eco-friendly child resistant paper packaging for cannabis cigarettes, cartridges, or accessories, Best Pack can help. We combine design expertise, sustainable material sourcing, and full-service production to deliver packaging that meets safety regulations and resonates with consumers. Reach out to discuss your project and request prototypes tailored to Best Pack needs.

Frequently Asked Questions

What makes paper packaging child resistant?A child-resistant paper package combines mechanical features — such as multi-step openings, locking tabs, and reinforced flaps — with design principles that require dexterity or coordination beyond a young child’s ability. These mechanisms are engineered and tested to meet applicable child-safety requirements while using primarily paper materials.

Can paper child-resistant packaging be certified or tested?Yes. Child-resistant paper packaging can undergo independent laboratory testing and third-party validation. Certifications and test reports demonstrate compliance with local regulations and provide documented evidence for regulators and retailers.

Is eco-friendly child-resistant packaging more expensive?Initial costs can be slightly higher if specialized coatings, certifications, or novel mechanisms are required. However, smart design, material optimization, and economies of scale often make sustainable solutions cost-competitive. Additionally, the marketing and brand benefits can improve ROI.

How recyclable is paper-based child-resistant packaging?Paper-based designs that avoid mixed-material laminates, metal foils, or unrecyclable adhesives are generally recyclable in standard paper streams. Including clear disposal instructions on-pack improves correct consumer behavior and increases recycling rates.

Can Best Pack handle small-batch and large-scale orders?Yes. Best Pack provides flexible OEM/ODM services that support both small pilot runs and large-scale manufacturing. We offer prototyping, sample approval, and scalable production to meet diverse client needs.

How do hybrid solutions reduce plastic without compromising safety?Hybrid designs use minimal, targeted plastic components only where necessary for certified child resistance, while keeping the majority of the structure paper-based. This approach reduces overall plastic usage and simplifies recycling compared to all-plastic solutions.

What information should I prepare before contacting a packaging supplier?Prepare product dimensions, regulatory markets, expected order volumes, desired sustainability certifications, branding artwork (if available), and any required child-resistance testing parameters. This information speeds up technical discussions and prototype timelines.

Sustainable Child Resistant Custom Cigarette Box Solutions

Tips for buy paper cigarette box

Anti-counterfeit features for premium pre roll boxes

Minimizing waste in pre roll packaging production

About us

Leading time for samples production?

Normally we need 3-7 days for samples making, 10-12 days to complete your orders,but the delivery time more depends on the order QTY.

What is the box size and structure?

1. All boxes are customized and all detailed requirements can be provided by clients, we are definitely your OEM service supplier.

2. If you have no idea about the measurements and structure on your products, our professional design team can suggest and solute for you .

FAQs

What services do you provide?

We offer one-stop packaging solutions, including design, printing, and handicraft processing for electronic boxes, plastic boxes, paper boxes, paper bags, and book printing.

How do you ensure product quality?

We maintain strict quality control at every stage, from material selection to final production, ensuring high-quality standards.

Do you support custom designs?

Yes, we provide custom packaging designs tailored to your brand and product needs.

Custom Printed Paperboard Cardboard Cigarette Box Packaging Case Disposable Paper Box for Cigarette Clamshell paper box

Custom Vape Packaging Box with CR Telescoping Design

The CR telescoping box is a sophisticated and secure packaging solution designed specifically for vape products. Featuring a telescoping (two-piece) structure, this box offers excellent protection and an elegant presentation, enhancing both the unboxing experience and brand appeal.

Custom Logo Child-Resistant Pre-Roll Box Packaging Biodegradable Handmade Luxury 5 Pack Embossing Childproof Pre Roll Package

Custom CR Vape Packaging Cardboard Boxes with Child-Resistant Design

CR custom vape packaging cardboard boxes are specially designed child-resistant packaging solutions crafted to ensure safety, protection, and premium presentation for vape products. Made from sturdy cardboard materials, these boxes balance regulatory compliance with brand aesthetics.

Best pack

Best pack

Best pack