Leveraging Child-Safe Packaging in Your Marketing Strategy: A Guide for Cannabis Brands

- Introduction: Why Child-Safe Packaging Matters for Cannabis Brands

- Understanding Regulations: Compliance as a Marketing Foundation

- Standards and Testing: Proving Safety to Regulators and Consumers

- Design Strategies: Combining Safety With Brand Appeal

- Materials & Sustainability: Marketing the Responsible Choice

- Retail & Shelf Impact: Using Safety to Win Placement

- Brand Trust & Consumer Experience: Turn Safety into Storytelling

- Digital Marketing: Content and SEO Opportunities Around Safety

- Pricing & Positioning: Monetizing Safety Features

- Case Study Snapshot: From Protective Packaging to Cartridge Boxes

- Supply Chain & Production: Ensuring Consistency and Compliance

- Measurement & KPIs: Tracking the Impact of Child-Safe Packaging

- Action Plan: Implementing Child-Safe Packaging in Your Marketing Mix

- Conclusion: Safety as a Competitive Advantage

- Frequently Asked Questions

Introduction: Why Child-Safe Packaging Matters for Cannabis Brands

As regulated cannabis markets expand, leveraging child-safe packaging in your marketing strategy is no longer just a compliance checkbox—it’s a strategic advantage. Child-resistant (CR) packaging protects consumers and children, reduces liability, and signals responsibility. For cannabis brands, combining safety with on-brand design can increase consumer trust and create distinct retail presence. Best Pack, a custom cannabis cigarette packaging company, brings one-stop services—from design and printing to handicraft processing—helping brands turn safety requirements into marketing opportunities.

Understanding Regulations: Compliance as a Marketing Foundation

Regulatory compliance and marketing alignment

Child-resistant packaging requirements stem from public safety laws such as the U.S. Poison Prevention Packaging Act (PPPA) of 1970 and state-level cannabis packaging rules. Many jurisdictions (including major U.S. states and EU member states) require CR closures, tamper-evident features, and clear labeling for cannabis products. Using compliant packaging is essential to market access: non-compliant packaging can lead to fines, product recalls, and loss of shelf space. Positioning compliance as part of Best Pack story—safety-first, regulated & tested—builds consumer confidence and retailer trust.

Standards and Testing: Proving Safety to Regulators and Consumers

Standards and testing you should know

To legitimately claim child-safe properties, packaging must pass recognized testing standards. ISO 8317 covers reclosable child-resistant packaging testing methods and acceptance criteria. In the U.S., child-resistant packaging typically follows test protocols defined under the PPPA and the Consumer Product Safety Commission (CPSC). Documented testing, third-party certification, and clear labeling reinforce credibility—these elements should be highlighted in product literature and marketing materials to show proof and transparency.

Design Strategies: Combining Safety With Brand Appeal

Design techniques that balance CR functionality and visual impact

Designing child-safe packaging does not mean sacrificing brand aesthetics. Brands can incorporate CR mechanisms—push-and-turn closures, squeeze-and-turn lids, inner child-resistant trays, or blister cards—while preserving High Quality finishes, color palettes, and graphics. Structural solutions such as an internal CR capsule or nested inner drawer (used for cartridge box packaging and pre-rolls) let the external box maintain high-impact printing and embossing. Best Pack’s OEM/ODM capabilities let clients specify materials, finishes, and structural CR options to achieve both safety and shelf differentiation.

Materials & Sustainability: Marketing the Responsible Choice

Material selection that supports safety and environmental messaging

Consumers increasingly expect sustainability. Choosing recyclable or responsibly sourced materials for child-safe packaging can be a strong marketing message—if done without compromising CR integrity. Options include recyclable paperboard with an inner CR liner, glass or high-density polyethylene (HDPE) containers with tested CR caps, and biodegradable outer sleeves combined with certified CR inserts. Communicating your material choices (e.g., FSC-certified board, PCR content) and how they meet safety requirements helps align Best Pack with responsible consumption trends.

Retail & Shelf Impact: Using Safety to Win Placement

How CR packaging improves retail relationships and shelf performance

Retailers prioritize compliance and products that sell. Child-safe packaging that also presents High Quality branding can improve retailer confidence and speed shelf approvals. Packaging designed to fit standard shelving, display easily, and include tamper-evident seals helps operations teams. Marketing collateral for buyers—compliance documentation, third-party testing certificates, and retailer-friendly pack configurations—helps secure distribution. Best Pack’s portfolio, ranging from protective packaging to cartridge box packaging, provides real customer cases demonstrating shelf-ready, compliant packaging solutions.

Brand Trust & Consumer Experience: Turn Safety into Storytelling

Messaging and packaging cues that communicate safety and quality

Packaging is a direct touchpoint with consumers. Clearly communicating child-safe features, instructions, and safety icons on the outer pack reassures customers. Use storytelling elements—tested for child safety, tamper-evident seal, and quality-controlled production—to create trust. Unboxing experience is important: include concise safety copy on inner panels, QR codes linking to testing reports or safe-use videos, and discreet branding to respect consumer privacy. Highlighting these features in product pages, social media, and email marketing supports brand positioning as responsible and High Quality.

Digital Marketing: Content and SEO Opportunities Around Safety

SEO and content strategies using child-safety as a conversion driver

Leveraging child-safe packaging in your marketing strategy also plays well in digital channels. Create content that targets queries from consumers and retailers—topics like child-safe cannabis packaging, how to choose CR packaging, and compliance for cannabis packaging—to capture commercial intent traffic. Publish case studies showcasing Best Pack’s OEM/ODM projects and results, and use long-form guides, FAQs, and downloadable compliance kits. Optimize product pages with structured data (product, certification) and rich snippets to increase visibility in search results. Link-building opportunities include safety organizations, trade associations, and regulatory resources.

Pricing & Positioning: Monetizing Safety Features

How to justify High Quality pricing through safety and compliance

Child-safe packaging can be positioned as a value-added feature that justifies a price High Quality. Emphasize the cost-savings of reduced returns, fewer regulatory issues, and improved retailer relationships. For B2B buyers (dispensaries and distributors), create tiered packaging options—basic compliance, enhanced CR with High Quality finishes, and fully bespoke solutions. Best Pack’s flexible production, competitive pricing, and commitment to quality allow brands to scale packaging across tiers while maintaining costs and brand integrity.

Case Study Snapshot: From Protective Packaging to Cartridge Boxes

Practical examples that demonstrate OEM/ODM strengths and marketing results

Best Pack has delivered projects across the cannabis packaging spectrum—from protective inner trays for pre-rolls to customized cartridge box packaging with CR liners and tamper-evident seals. These OEM/ODM case examples highlight attention to detail: exact dielines, compliant labeling, spot UV and matte finishes for shelf standout, and efficient production runs that meet launch timelines. Use case studies in marketing to show retailers and consumers tangible results: better shelf presence, compliance documentation, and improved unboxing experiences.

Supply Chain & Production: Ensuring Consistency and Compliance

Operational steps to maintain CR integrity at scale

Maintaining CR performance requires end-to-end quality control. From material sourcing and tooling to assembly and final testing, establish checkpoints to verify CR function and labeling accuracy. Work with packaging partners who offer one-stop services—design, printing, finishing, and CR assembly—to minimize errors and speed time-to-market. Best Pack’s integrated approach reduces handoffs and helps maintain consistent quality across production runs, which is essential for regulatory audits and long-term brand reputation.

Measurement & KPIs: Tracking the Impact of Child-Safe Packaging

Key metrics to prove ROI of safety-driven packaging investments

Measure the impact of CR packaging with both commercial and safety KPIs: retail acceptance rates, sell-through and conversion lift, return rates, compliance incident reductions, and customer satisfaction scores. Track online engagement for safety-related content—click-through rates on safety product pages, downloads of compliance documents, and search impressions for child-safe keywords. These metrics help quantify the business value of CR packaging and guide future iterations.

Action Plan: Implementing Child-Safe Packaging in Your Marketing Mix

Step-by-step implementation checklist for brands

Start with a compliance audit of existing packaging. Define safety and brand objectives—what CR features are necessary and how they should look. Partner with an OEM/ODM like Best Pack to design, prototype, and test CR solutions. Prepare marketing assets: product pages, certifications, retail sell sheets, and social content. Launch with retailer education and targeted PR highlighting your safety-first approach. Monitor KPIs and iterate based on feedback. This structured approach turns a regulatory requirement into a competitive marketing tool.

Conclusion: Safety as a Competitive Advantage

Final thoughts on integrating child-safe packaging into strategic marketing

Leveraging child-safe packaging in your marketing strategy aligns safety, compliance, and brand differentiation. For cannabis brands, this integration builds trust with consumers and retailers, reduces regulatory risk, and creates new opportunities to command High Quality positioning. Best Pack’s one-stop OEM/ODM services—from design and printing to handicraft processing—help brands produce compliant, attractive, and market-ready packaging solutions. By treating child safety as a core part of Best Pack story, you protect customers and unlock measurable commercial benefits.

Frequently Asked Questions

What is child-resistant packaging and why is it required for cannabis products?Child-resistant packaging uses design features (e.g., push-and-turn caps, inner CR trays, reclosable closures) to make it difficult for children to open containers. It’s required by many jurisdictions to prevent accidental ingestion and to meet public safety laws such as the U.S. Poison Prevention Packaging Act (PPPA) and state cannabis packaging regulations.

How can child-safe packaging be both functional and visually appealing?Brands can use internal CR mechanisms while keeping the external box high-impact with High Quality printing, embossing, and finishes. Structural solutions (inner drawers, nested trays) let the consumer experience High Quality unboxing without exposing the CR hardware on the outside.

Which standards and tests prove child-resistant performance?Reclosable child-resistant packaging commonly follows ISO 8317 testing protocols; in the U.S., the PPPA/CPSC testing methods are often used for compliance. Third-party testing and certification are recommended for validation and marketing credibility.

Can child-safe packaging be sustainable?Yes. Designers can combine recyclable or responsibly sourced outer materials with tested CR inserts. Communicate material certifications (FSC, PCR content) and recycling guidance to consumers to avoid greenwashing claims.

How does Best Pack support brands in leveraging CR packaging for marketing?Best Pack provides end-to-end services—custom design, printing, handicraft processing, and CR assembly. We help brands create compliant, attractive packaging (from protective packaging to cartridge box packaging), supply testing documentation where needed, and produce scalable OEM/ODM solutions that support launch timelines and retail requirements.

Custom Branding on Vintage Cigar Boxes for Retail Buyers

Ultimate Guide to Child Resistant Paper Boxes

Integrating Security Features into Custom Cigarette Packaging

Reducing Costs with Efficient Custom Cigarette Box Sourcing

FAQs

Can you ship internationally?

Yes, we export worldwide and work with reliable logistics partners for timely delivery.

Do you support custom designs?

Yes, we provide custom packaging designs tailored to your brand and product needs.

What services do you provide?

We offer one-stop packaging solutions, including design, printing, and handicraft processing for electronic boxes, plastic boxes, paper boxes, paper bags, and book printing.

How do you ensure product quality?

We maintain strict quality control at every stage, from material selection to final production, ensuring high-quality standards.

About us

Are you able to do design for my products?

Yes, just send us your logo artwork in Vector file, such as AI or PDF format,and text information you want to print ,we can put it on box to make the design to let you check. Once you say ok, then we go on to make samples or production.

Custom Printed Paperboard Cardboard Cigarette Box Packaging Case Disposable Paper Box for Cigarette Clamshell paper box

Custom Vape Packaging Box with CR Telescoping Design

The CR telescoping box is a sophisticated and secure packaging solution designed specifically for vape products. Featuring a telescoping (two-piece) structure, this box offers excellent protection and an elegant presentation, enhancing both the unboxing experience and brand appeal.

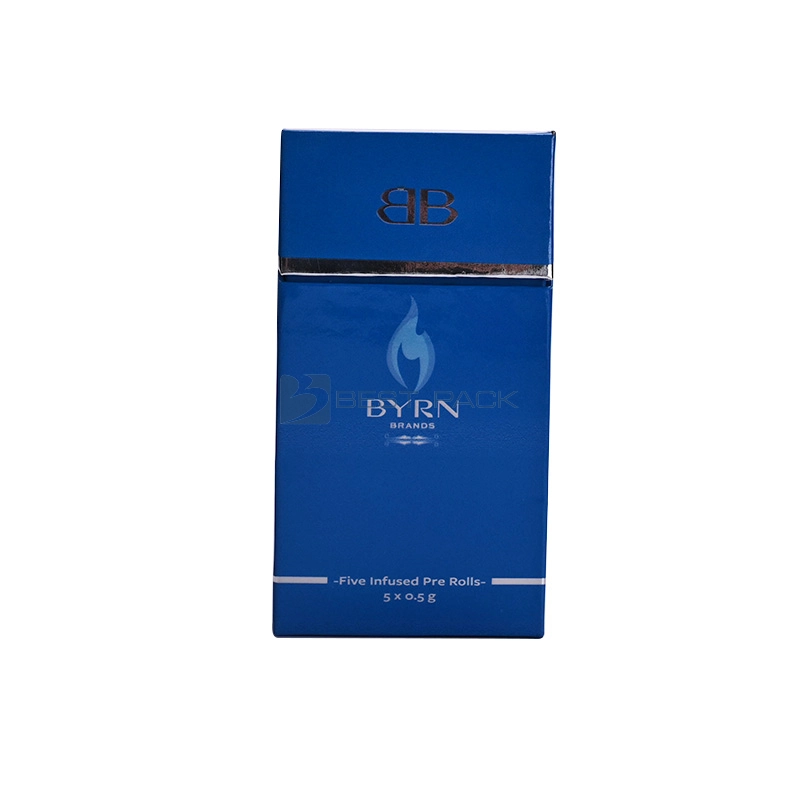

Custom Logo Child-Resistant Pre-Roll Box Packaging Biodegradable Handmade Luxury 5 Pack Embossing Childproof Pre Roll Package

Custom CR Vape Packaging Cardboard Boxes with Child-Resistant Design

CR custom vape packaging cardboard boxes are specially designed child-resistant packaging solutions crafted to ensure safety, protection, and premium presentation for vape products. Made from sturdy cardboard materials, these boxes balance regulatory compliance with brand aesthetics.

Best pack

Best pack

Best pack