Pre-Roll Packaging Box Sizes and Insert Options

- Understanding Pre-Roll Packaging Box Sizes

- Why box size matters for your pre roll packaging box

- Common length and diameter ranges for pre-rolls

- Standard pack counts and box footprint

- Insert Options for Pre-Roll Packaging Box

- Why inserts are essential for pre roll packaging box

- Paperboard and kraft dividers

- Foam inserts (EVA, PU)

- Plastic trays and thermoformed inserts

- Blister and tube inserts for individual protection

- Child-Resistant Options and Compliance

- Integrating child-resistant design into your pre roll packaging box

- Balancing usability and safety

- Materials, Sustainability and Barrier Properties

- Choosing the right material for your pre roll packaging box

- Sustainable options that still protect

- Printing, Finishing and Brand Considerations

- How printing choices affect your pre roll packaging box

- Information hierarchy and regulatory labeling

- Size and Insert Comparison Table

- Quick reference for deciding box size and insert

- Practical Production Considerations

- Minimum order quantities and lead times

- Prototyping and testing

- How Best Pack Supports Your Pre-Roll Packaging Box Needs

- OEM/ODM capabilities and end-to-end service

- Quality, innovation and competitive pricing

- FAQ — Frequently Asked Questions

- What is the best size for a pre roll packaging box for a 1g cone?

- Which insert type is most cost-effective for a multi-pack?

- How do I make a pre roll packaging box child-resistant?

- Can inserts be made from recycled materials?

- What are typical lead times and minimums for custom pre roll packaging box orders?

- How should I present regulatory information on the box without compromising design?

- Who should I contact at Best Pack for a custom pre roll packaging box project?

Understanding Pre-Roll Packaging Box Sizes

Why box size matters for your pre roll packaging box

Choosing the right pre roll packaging box size affects product protection, shelf presence, shipping efficiency and regulatory compliance. A well-sized box reduces movement, prevents damage to tips and filters, and supports accurate branding placement. Whether you sell single 0.5g pre-rolls or multi-packs of king-size cones, box dimensions should match the product geometry and any chosen inserts to keep the consumer experience consistent.

Common length and diameter ranges for pre-rolls

Rather than a one-size-fits-all approach, pre-rolls use common length standards that packaging designers work around. Typical lengths include 70mm (about 2.75), 84mm (about 3.3) and 98–100mm (about 3.86–4) for king-size cones. Diameters vary by cone type: slim cones are around 6–7mm, classic cones 8–9mm, and king-size cones up to 12mm. When planning your pre roll packaging box, allow clearance for the finished cone plus any tip, crutch, or glass tube if used.

Standard pack counts and box footprint

Brands commonly offer these pack counts: single (1), twin (2), three-pack (3), four-pack (4), five-pack (5), and larger bundles (6–10). The footprint of your pre roll packaging box should reflect both the quantity and arrangement: single or tube-style boxes are narrow but longer, while multi-pack tuck boxes and tray boxes require wider footprints and thoughtful internal layout to prevent contact between rolls.

Insert Options for Pre-Roll Packaging Box

Why inserts are essential for pre roll packaging box

Inserts stabilize pre-rolls inside the box, improve presentation and provide child-resistant functions when combined with closures. The right insert reduces breakage, prevents aroma transfer between units, and helps with easy merchandising and unboxing — all critical for converting first-time buyers into repeat customers.

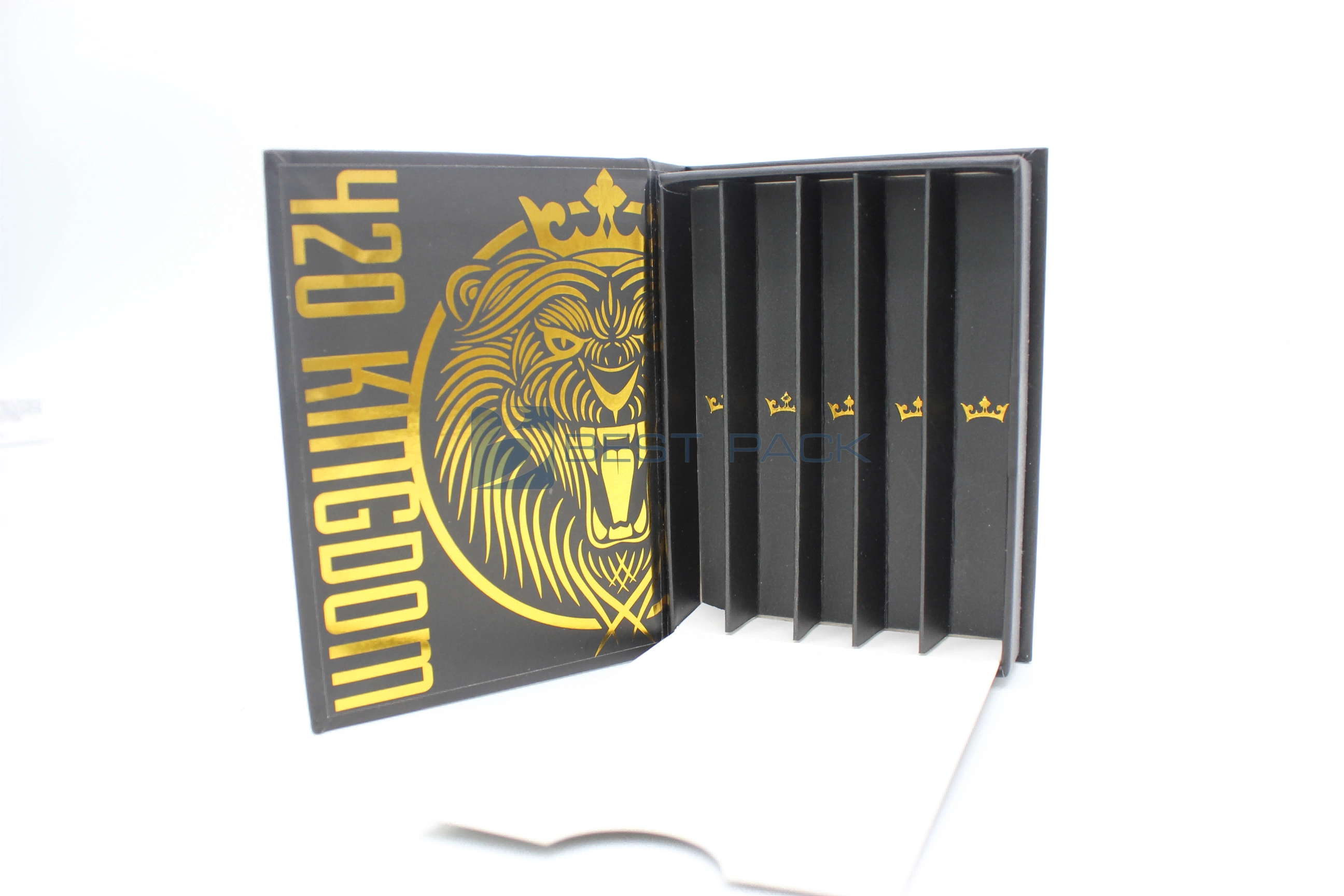

Paperboard and kraft dividers

Paperboard dividers (SBS or kraft) are economical, recyclable, and customizable. They separate units and can be die-cut to cradle cones of different diameters. For brands prioritizing sustainability and cost, paper inserts can achieve excellent performance, especially with snug tolerances and protective tips on the cones.

Foam inserts (EVA, PU)

Foam inserts offer cushioning and are excellent when you need to protect delicate tips or glass tubes. Closed-cell foams resist moisture and provide shock absorption during transit. Foam can be die-cut or CNC-shaped to match cone geometry. Note that recycled or compostable foam options are limited; choose materials aligned with your sustainability messaging if needed.

Plastic trays and thermoformed inserts

Rigid PET or RPET trays provide consistent positioning and a High Quality look. Thermoformed cavities ensure each pre-roll sits securely, and RPET offers a recycled-content option. Plastic trays are ideal for high-volume, repeatable packaging where presentation and stacking stability matter, but check local recycling capabilities and labeling requirements.

Blister and tube inserts for individual protection

For single pre-rolls or high-end cones, blister packs or individual tubes (glass, aluminum, or high-barrier plastic) provide maximum protection and aroma control. Tubes can be paired with a molded insert inside the outer box for an upscale unboxing while also supporting child-resistant cap mechanisms.

Child-Resistant Options and Compliance

Integrating child-resistant design into your pre roll packaging box

Child-resistant (CR) packaging for cannabis products is often required by regulation. Common CR mechanisms used with pre roll packaging box designs include push-and-slide tuck closures, screw caps with push-and-turn action for tubes, and hinged-lid boxes with locking tabs. Many brands pair an internal insert that holds the cone securely with an outer CR closure to meet both safety and display needs.

Balancing usability and safety

While CR features are essential, usability for adult consumers is also important. Consider a two-step opening that is still intuitive for adults: for example, a push-tab to release the latch combined with a smooth second pull to slide out an inner tray. Testing with representative users helps ensure compliance and customer satisfaction.

Materials, Sustainability and Barrier Properties

Choosing the right material for your pre roll packaging box

SBS (solid bleached sulfate) paperboard, kraft, and chipboard are common for printed boxes because they balance print quality and cost. For better barrier properties (odor and moisture), combine paperboard with an inner barrier layer (foil, metallized film) or place product inside a sealed tube or pouch. Rigid boxes, mailer boxes and hybrid designs can use a combination of materials to achieve a High Quality feel and functional protection.

Sustainable options that still protect

Sustainable choices include recycled-content paperboards, mono-material structures for recyclability, and compostable inner sleeves. If aroma and moisture control are vital, consider compostable barrier coatings or certified recyclable metallized films. Communicate material choices clearly on your packaging to support brand claims and reduce consumer confusion at disposal.

Printing, Finishing and Brand Considerations

How printing choices affect your pre roll packaging box

High-quality printing transfers brand equity directly to shelves. Offset litho and digital printing both deliver excellent results; digital is often better for short runs and variable data (batch codes, terpene info), while offset is cost-effective for larger runs. Add finishing touches—spot UV, soft-touch lamination, foil stamping—to highlight logos and High Quality cues. Always ensure finishes don’t interfere with child-resistant features.

Information hierarchy and regulatory labeling

Your pre roll packaging box must clearly present required regulatory information: cannabinoid content, net weight, warnings, batch and lot numbers, and manufacturer info. Design the artwork so mandatory labels do not obscure branding. Use visual hierarchy—primary brand mark, product name, strain/THC/CBD levels and required warnings—so shoppers can quickly identify product attributes.

Size and Insert Comparison Table

Quick reference for deciding box size and insert

The table below summarizes common pre roll packaging box sizes, typical capacities, and suitable insert options.

| Box Type | Typical External Dimensions (L × W × H) | Common Pack Counts | Suitable Inserts | Best Use Case |

|---|---|---|---|---|

| Tube Box | 90–110mm × 18–25mm × 18–25mm | 1 | Foam cradle, blister sleeve, paper plug | Single High Quality pre-roll, aroma control |

| Single Flat Tuck | 100–120mm × 25–35mm × 10–20mm | 1 | Paperboard insert, molded pulp | Retail singles, low-cost presentation |

| Multi-Row Tray Box | 100–140mm × 60–100mm × 18–30mm | 2–6 | Thermoformed tray, die-cut dividers, foam | Twin to 6-pack retail displays |

| Rigid/Drawer Box | 120–200mm × 60–120mm × 20–40mm | 1–6 | Foam insert, molded pulp, tube cradles | High Quality gifting & limited editions |

| Pallet/Multi-Bulk Box | Custom | 10–50+ | Partitioned trays, corrugated dividers | Wholesale and sample kits |

Practical Production Considerations

Minimum order quantities and lead times

Custom pre roll packaging box orders commonly have MOQs ranging from a few hundred to several thousand units depending on the complexity and materials. Digital printing allows lower MOQs (often 250–500 units), while offset runs usually start at 1,000+ units to be cost-effective. Typical production lead times vary: 2–3 weeks for simple digital jobs, and 4–8 weeks for custom offset + specialty finishes. Always factor in artwork approvals, prototyping, and shipping time.

Prototyping and testing

Invest in prototypes to validate fit, child-resistance, and assembly. Mockups let you verify insert tolerances and ensure cones remain undamaged when the box is handled. Perform simple drop and vibration tests representative of transit conditions, and gather feedback from staff and a small consumer group to refine usability.

How Best Pack Supports Your Pre-Roll Packaging Box Needs

OEM/ODM capabilities and end-to-end service

Best Pack is a custom cannabis cigarette packaging company offering one-stop services from design and printing to handicraft processing. We provide tailored pre roll packaging box solutions across protective packaging, cartridge boxes and High Quality gift sets. With proven OEM/ODM capabilities, Best Pack manages artwork, prototyping, materials selection and finishing to deliver packaging that protects product and elevates brand experience.

Quality, innovation and competitive pricing

Best Pack emphasizes quality control, continuous innovation and competitive pricing. Our real customer cases demonstrate attention to detail and capacity to produce both compliant child-resistant designs and high-end presentation boxes. Whether you need sustainable paperboard inserts or precision thermoformed trays, Best Pack helps you choose the best insert option for your product goals. Visit https://www.gzbestpack.com/ to explore samples and request a consultation.

FAQ — Frequently Asked Questions

What is the best size for a pre roll packaging box for a 1g cone?

For a standard 1g cone (approximately 84–98mm long depending on cone style), consider an internal length of 5–10mm more than the cone length to account for tips and crutches. External box lengths of ~100–120mm are common for single or tube-style packaging. Ensure internal inserts hold the cone securely to prevent movement.

Which insert type is most cost-effective for a multi-pack?

Die-cut paperboard or kraft dividers are generally the most cost-effective for multi-packs. They are recyclable, lightweight and provide adequate separation when designed with snug cavities. For added protection without large cost increases, consider molded pulp or a minimal foam strip at critical contact points.

How do I make a pre roll packaging box child-resistant?

Combine a secure closure (push-and-slide, tuck with latch, or CR screw cap for tubes) with an inner insert that prevents easy removal. Child-resistant performance often depends on both the outer mechanism and the internal fit. Work with packaging engineers to meet local regulatory definitions and perform usability testing with representative adults.

Can inserts be made from recycled materials?

Yes. Paperboard dividers, molded pulp and some foam alternatives can include recycled content. RPET thermoformed trays offer a recycled plastic option. Evaluate recyclability and local waste streams to ensure your chosen materials deliver real environmental benefits.

What are typical lead times and minimums for custom pre roll packaging box orders?

Typical lead times are 2–3 weeks for digital short runs and 4–8 weeks for offset production with specialty finishes. MOQs depend on printing method and complexity; digital may start around 250–500 units, while offset commonly starts at 1,000 units or more. Confirm specifics with your supplier (Best Pack can provide detailed quotes and timelines).

How should I present regulatory information on the box without compromising design?

Reserve a clean panel for mandatory labels and use consistent typography and contrast to ensure legibility. Keep branding on the primary visible faces, and place required warnings and content facts on a side or back panel. Use a clear visual hierarchy so consumers see brand and strain info first and regulatory details second.

Who should I contact at Best Pack for a custom pre roll packaging box project?

Visit Best Pack’s website at https://www.gzbestpack.com/ to review product examples and contact the sales or design team. They can guide material selection, child-resistant options, insert design and prototyping to match Best Pack needs.

Materials That Preserve Vintage Cigar Box Aesthetics

Tamper-evident seals for pre roll non tobacco boxes

Top pre roll box packaging Manufacturers and Suppliers in China

Best custom cigarette box liners and inserts for protection

FAQs

Can you ship internationally?

Yes, we export worldwide and work with reliable logistics partners for timely delivery.

How do you ensure product quality?

We maintain strict quality control at every stage, from material selection to final production, ensuring high-quality standards.

About us

The process of your packaging box production?

1. Make knife mold as per box size and structure

2. order material as per mold

3. make printing on material if need to print

4. suppress and cut material

5. Makeboxes with glue edge in machine

6. Package boxes into cartons

How much of your samples cost ?

1. If samples are without printing, we can make free samples as per your box size or structure;

2. If samples are silk printing, normally USD 25 per color,depending on your logo colors;

3. If samples are offset printing, need USD 180 as offset printing mold cost is high.

Are you able to do design for my products?

Yes, just send us your logo artwork in Vector file, such as AI or PDF format,and text information you want to print ,we can put it on box to make the design to let you check. Once you say ok, then we go on to make samples or production.

Custom Pre Cone 5 Pack Magnetic Paper Cigarettes Box Pre Roll Packaging Box

Custom Printed Paperboard Cardboard Cigarette Box Packaging Case Disposable Paper Box for Cigarette Clamshell paper box

Custom Vape Packaging Box with CR Telescoping Design

The CR telescoping box is a sophisticated and secure packaging solution designed specifically for vape products. Featuring a telescoping (two-piece) structure, this box offers excellent protection and an elegant presentation, enhancing both the unboxing experience and brand appeal.

Best pack

Best pack

Best pack