Regulatory Compliance for Pre-Roll Packaging Boxes (US/EU)

- Regulatory Compliance for Pre-Roll Packaging Boxes (US/EU)

- Why regulatory compliance matters for your pre roll packaging box

- Overview of applicable US requirements for pre roll packaging box

- Overview of applicable EU requirements for pre roll packaging box

- Standards and testing to prove child-resistant performance

- Labeling and content requirements for pre roll packaging box

- Tamper-evident features and traceability

- Material selection and barrier performance for product integrity

- Sustainability and packaging waste compliance

- Design and branding while staying compliant

- Testing, documentation and recordkeeping best practices

- Manufacturing quality control and supply chain compliance

- Common compliance pitfalls for pre roll packaging box

- Quick compliance checklist for pre roll packaging box

- Comparison: US vs EU regulatory considerations

- How to validate a pre roll packaging box before launch

- Costs and timelines for compliance testing and certification

- Working with vendors and contract manufacturers

- Best practices for multi-state or multi-country launches

- Best Pack — strengths and compliant product offerings

- Why Best Pack is a strong partner for compliant pre roll packaging box solutions

- Main products and advantages from Best Pack

- How Best Pack supports compliance and market readiness

- Frequently Asked Questions (FAQs)

- Do I always need child-resistant packaging for pre-rolls?

- Is ISO 8317 required for my pre roll packaging box?

- How do I balance child-resistance with recyclability?

- What labeling elements are universally required?

- How long does it take to certify a new pre roll packaging box design?

- Can Best Pack help with testing and documentation?

- Where can I learn more or request a custom quote?

Regulatory Compliance for Pre-Roll Packaging Boxes (US/EU)

Why regulatory compliance matters for your pre roll packaging box

Meeting regulations for a pre roll packaging box protects children, reduces legal risk, preserves product quality, and helps brands access markets. For cannabis pre-rolls the focus is especially strong on child-resistant closures, tamper evidence, clear potency labeling, and secure barrier packaging that controls odor and moisture. Non-compliant packaging can result in seizures, fines, forced recalls, and lost shelf access.

Overview of applicable US requirements for pre roll packaging box

In the United States there is no single federal cannabis packaging law because cannabis remains federally prohibited. However, several reliable compliance points apply to pre roll packaging box manufacturers and brands: the Poison Prevention Packaging Act (PPPA) governs household substances and influences expectations for child-resistance; state-level cannabis regulators (for example, California, Colorado, Oregon and Washington) routinely require child-resistant and tamper‑evident packaging, potency and ingredient labeling, lot identification, and warnings. Brands must follow the specific packaging, testing and labeling rules of each state where the product is sold.

Overview of applicable EU requirements for pre roll packaging box

In the European Union, cannabis rules vary because recreational cannabis remains illegal in most member states. For products that are legally sold (for example certain medical cannabis products or nicotine/tobacco pre-rolls), general packaging laws apply: the EU Packaging and Packaging Waste Directive (94/62/EC) requires minimization of packaging and attention to recyclability; CLP Regulation (EC) No 1272/2008 covers classification, labeling and packaging of hazardous substances; and the Tobacco Products Directive (2014/40/EU) governs cigarette packaging and health warnings. For medicinal cannabis, member-state medical product rules apply. In short, EU compliance often means adhering to packaging waste rules, proper hazard labeling where relevant, and meeting any national child-resistance or medicinal-product packaging standards.

Standards and testing to prove child-resistant performance

ISO 8317 (reclosable child-resistant packaging) is a widely accepted international standard for testing closures and reclosable systems. It defines test protocols using panels of children and adults to demonstrate that a packaging system is child-resistant and still reasonably accessible to adults. Many regulators and purchasers accept ISO 8317 or equivalent documented testing. For non-reclosable designs, manufacturers often rely on alternative validated testing protocols and laboratory test reports to demonstrate performance.

Labeling and content requirements for pre roll packaging box

A compliant pre roll packaging box must include clear information: product identity (pre-roll, strain if required), net weight, cannabinoid potency (THC/CBD % by weight or mg), batch or lot number, manufacturing and/or expiration date where required, required state or national warning statements, and distributor or manufacturer contact. Avoid medical or therapeutic claims unless approved by regulators. Labels should be durable and legible for the shelf life of the product.

Tamper-evident features and traceability

Tamper‑evident seals, perforated tear strips, or shrink bands are often required or strongly recommended. Tamper evidence protects consumers and supports traceability in case of recalls. Traceability also includes lot/serial numbers and maintaining production records so affected product can be quickly identified and removed from the market.

Material selection and barrier performance for product integrity

Pre-rolls are light-sensitive and sensitive to moisture and odor. A compliant pre roll packaging box design considers barrier properties: foil linings, metallized films, and multi-layer laminates provide oxygen, moisture and odor barriers; child-resistant inner components must be compatible with these materials. Choose food‑grade, inert materials to avoid off‑flavors or contamination, and ensure inks and adhesives comply with food-contact and safety rules in each jurisdiction.

Sustainability and packaging waste compliance

Both US states and the EU emphasize packaging reduction and recyclability. In the EU, the Packaging and Packaging Waste Directive sets obligations for design and recovery; many member states have EPR (extended producer responsibility) schemes. In the US, state EPR and recycling laws are expanding. When designing a pre roll packaging box, balance child-resistant mechanics and tamper evidence with recyclable materials, or provide clear consumer recycling guidance on the box.

Design and branding while staying compliant

Pre roll packaging box design must avoid appeal to minors—no cartoons or child‑attractive imagery—and must follow size and color rules where specified. Many jurisdictions also restrict promotional claims and require standardized health warnings for tobacco products. Work with legal counsel or compliance specialists to ensure branding elements do not violate local prohibitions and that mandatory warnings are placed per regulation.

Testing, documentation and recordkeeping best practices

Maintain: (1) child‑resistant testing reports (ISO 8317 or equivalent), (2) material safety data sheets for inks/adhesives, (3) shelf-life and stability test results for barrier performance, (4) lot-level production records, and (5) labeling mockups approved for each market. Regulators commonly request documentation during inspections; keeping organized files speeds approvals and reduces recall risk.

Manufacturing quality control and supply chain compliance

Control the supply chain: audit suppliers for material certifications, ensure consistent print quality for required warnings and batch data, and verify supply traceability. Implement incoming inspection for barrier films and child-resistant components, and use periodic third-party testing to catch drift in performance or materials.

Common compliance pitfalls for pre roll packaging box

Common mistakes include: relying on generic child-resistant claims without test reports; using food-contact unapproved inks or adhesives; missing required potency or warning statements; designing packaging that appeals to minors; and failing to include tamper evidence. Each market’s differences mean a packaging design that’s compliant in one state or country can be non-compliant in another.

Quick compliance checklist for pre roll packaging box

Use this checklist as a starting point before production and market entry:

- Confirm local/regional packaging regulations for the target market.

- Obtain child-resistant test reports (ISO 8317 or accepted alternative).

- Include required labeling: potency, net weight, lot number, warnings.

- Incorporate tamper‑evident features and verify performance.

- Choose barrier materials for odor, moisture and light protection.

- Verify inks/adhesives are compliant with food-contact rules.

- Document supplier certifications and maintain traceability records.

- Consider recyclability and EPR obligations in target markets.

Comparison: US vs EU regulatory considerations

The table below summarizes key differences and similarities for pre roll packaging box compliance in the US and EU.

| Aspect | United States (typical) | European Union (typical) |

|---|---|---|

| Primary regulatory scope | State-level cannabis laws; PPPA influence; FDA not regulating cannabis federally | EU directives (packaging waste), CLP for hazardous substances, national medicinal product rules for medical cannabis |

| Child-resistant requirement | Commonly required by state cannabis regulators; ISO 8317 often accepted | Varies by member state and product type; ISO 8317 widely referenced |

| Labeling requirements | Potency, warnings, batch info, state-specific statements | Health warnings (tobacco), hazard labeling for chemicals, national rules for medicinal products |

| Packaging waste & sustainability | State EPR/recycling evolving; brand-driven sustainability | Packaging and Packaging Waste Directive and EPR schemes in many countries |

| Testing standards | ISO 8317 and state-accepted lab reports | ISO 8317 commonly accepted; national competent authority approvals where relevant |

How to validate a pre roll packaging box before launch

Validation steps: run ISO 8317 or equivalent child-resistance testing; conduct barrier and shelf-life tests for the expected storage conditions; perform label durability tests (rub, fade, solvent exposure); complete tamper-evident tear/peel tests; and assemble a regulatory submission package for the target market including test reports, materials lists, and finished-goods photos.

Costs and timelines for compliance testing and certification

Costs vary: ISO 8317 testing from accredited labs typically ranges from a few hundred to a few thousand USD/EUR depending on the number of samples and the lab. Barrier and stability tests add variable costs and time (often several weeks). Plan 6–12 weeks for testing, iteration and documentation for a new pre roll packaging box design to be validated for one market; multi-market launches require additional time for each jurisdiction.

Working with vendors and contract manufacturers

Choose vendors experienced with child-resistant solutions and with established QA and documentation processes. Ensure vendors can produce compliant printing (correct warnings, barcodes, batch variable data), and that they allow for pre-production proofs and pilot batches for testing. Insist on written material certifications and capability to support audits.

Best practices for multi-state or multi-country launches

Standardize core packaging to the most stringent requirements you must meet (for example the strictest child-resistance and labeling specs), then use secondary sleeves, stickers or market-specific inserts to meet local labeling differences. Maintain modular artwork files so you can quickly adapt warnings, languages and compliance statements per market.

Best Pack — strengths and compliant product offerings

Why Best Pack is a strong partner for compliant pre roll packaging box solutions

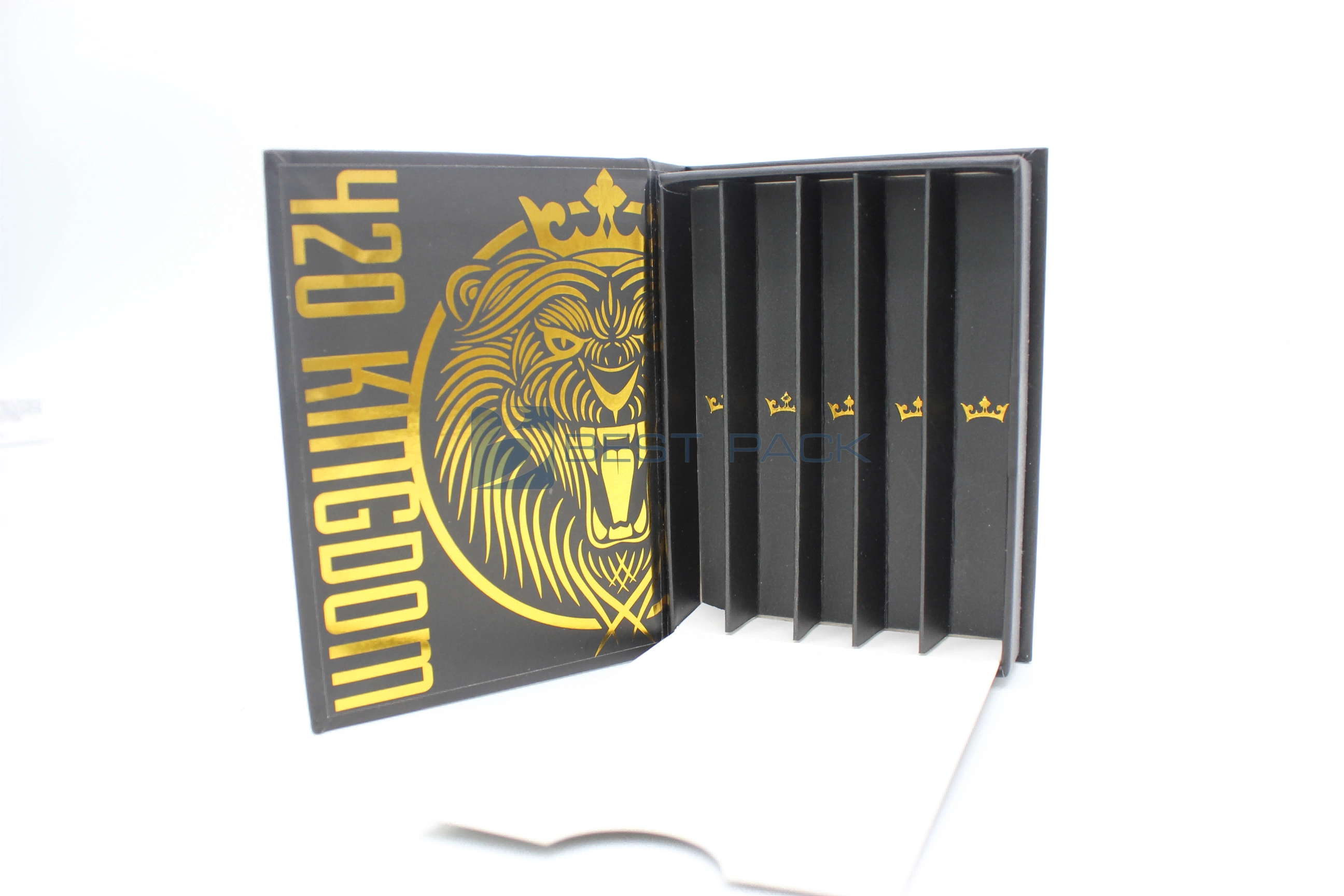

Best Pack is a custom cannabis cigarette packaging company offering one-stop services from design and printing to handicraft processing. The company emphasizes high quality, competitive pricing, and continuous innovation. Best Pack’s OEM/ODM capabilities and focus on detail help brands meet child-resistant, tamper-evident and labeling requirements while providing attractive, functional pre roll packaging box solutions that support brand positioning and drive purchases.

Main products and advantages from Best Pack

Best Pack’s product strengths include:

- Child Resistant Packaging Box — engineered closures and component solutions that meet child safety expectations and support certification testing.

- Cannabis Protective Packaging — barrier laminates and odor-control constructions to extend shelf life and preserve product integrity.

- Vape Packaging and Custom Vape Cartridge Boxes — tamper-evident designs and printed guidance for safe use and compliance with market labeling rules.

- Cigarette Packaging Box and Custom Cigarette Packaging — compliant printing, health-warning integration, and high‑quality finishing.

- Custom Cannabis Packaging and Cannabis Packaging Boxes — end-to-end design, prototyping, and production with attention to regulatory labeling, batch printing and material safety.

These offerings are supported by Best Pack’s production control, attention to finish and ability to deliver OEM/ODM projects that align with regulatory and market demands.

How Best Pack supports compliance and market readiness

Best Pack provides design-for-compliance services (label placement, child‑resistant mechanism integration), prototyping for ISO 8317 testing, full-color printing aligned with required warnings, and options for barrier or sustainable materials. Their one-stop approach reduces coordination delays between design and production and helps brands get compliant pre roll packaging box products to market faster.

Frequently Asked Questions (FAQs)

Do I always need child-resistant packaging for pre-rolls?

Most U.S. states that legalize cannabis require child-resistant packaging for pre-rolls. In the EU it depends on product type and national rules. Always check the specific regulator requirements for each market where you sell.

Is ISO 8317 required for my pre roll packaging box?

ISO 8317 is widely accepted as the standard test for reclosable child-resistant packaging. Some regulators or purchasers require ISO 8317 testing; others accept equivalent accredited test reports. Using ISO 8317 testing makes market acceptance easier.

How do I balance child-resistance with recyclability?

Use mono-material constructions where possible, design separable components (for example a recyclable outer box with a tested child-resistant insert), and clearly label recycling instructions. Engage suppliers early to select materials that meet both safety and sustainability goals.

What labeling elements are universally required?

Common elements include product identity, net weight, potency (THC/CBD), batch/lot number, manufacturer/distributor info, and any mandated warnings. Local regulators will specify wording, fonts and placement, so verify for each market.

How long does it take to certify a new pre roll packaging box design?

Typical timelines for testing and documentation range from 6–12 weeks for one market, depending on test scheduling, iterations and lab availability. Multi-market certification takes longer.

Can Best Pack help with testing and documentation?

Yes. Best Pack supports prototyping, coordinates with testing labs for child-resistance and barrier tests, and helps assemble documentation packages for market submissions. They provide OEM/ODM services that integrate compliance into the design and production process.

Where can I learn more or request a custom quote?

Visit Best Pack’s website at https://www.gzbestpack.com/ to view product examples and contact the team for custom pre roll packaging box designs, testing support, and pricing.

The latest trends for cigarette packaging box

Child resistant pre roll packaging: compliance and design

How to Procure Custom Printed Paperboard Cigarette Boxes in Bulk

Where to Buy smoking paper box in Guangzhou

About us

How much of your samples cost ?

1. If samples are without printing, we can make free samples as per your box size or structure;

2. If samples are silk printing, normally USD 25 per color,depending on your logo colors;

3. If samples are offset printing, need USD 180 as offset printing mold cost is high.

Leading time for samples production?

Normally we need 3-7 days for samples making, 10-12 days to complete your orders,but the delivery time more depends on the order QTY.

How many kinds the printing process you have?

We can make Silk screen printing, offset printing, and also hot silver stamping

FAQs

Do you support custom designs?

Yes, we provide custom packaging designs tailored to your brand and product needs.

What services do you provide?

We offer one-stop packaging solutions, including design, printing, and handicraft processing for electronic boxes, plastic boxes, paper boxes, paper bags, and book printing.

Custom Pre Cone 5 Pack Magnetic Paper Cigarettes Box Pre Roll Packaging Box

Custom Printed Paperboard Cardboard Cigarette Box Packaging Case Disposable Paper Box for Cigarette Clamshell paper box

Custom Vape Packaging Box with CR Telescoping Design

The CR telescoping box is a sophisticated and secure packaging solution designed specifically for vape products. Featuring a telescoping (two-piece) structure, this box offers excellent protection and an elegant presentation, enhancing both the unboxing experience and brand appeal.

Best pack

Best pack

Best pack