How to Test Child-Resistance for Pre-Roll Packaging Boxes

- How to Test Child-Resistance for Pre-Roll Packaging Boxes

- Why child-resistance matters for a pre roll packaging box

- Regulatory landscape: what to consider before testing

- Common standards and how they differ

- Standards comparison

- Design review: the first test step for any pre roll packaging box

- Prototype and engineering testing

- Human-subject testing: child panel and adult panel

- Running the child panel

- Running the adult usability panel

- Lab vs. in-field testing

- Documentation and reporting: what regulators and buyers expect

- Quality control and production monitoring

- Design tips to improve child-resistance without harming usability

- Tamper-evidence: a complementary requirement

- Working with a packaging partner: what to ask

- Case example: integrating testing into development (Best Pack approach)

- Cost, timeline, and common pitfalls

- Ongoing compliance and revalidation

- FAQ — Frequently Asked Questions

- Q: How do I know which child-resistance standard applies to my pre roll packaging box?

- Q: Can a package be both child-resistant and easy for seniors to open?

- Q: Do I need third-party lab testing or can I test in-house?

- Q: How often should I retest production batches?

- Q: What documentation should I keep after testing?

- Q: How does Best Pack support brands testing child-resistance for pre roll packaging box?

How to Test Child-Resistance for Pre-Roll Packaging Boxes

Why child-resistance matters for a pre roll packaging box

Child-resistant packaging is a crucial safety and compliance requirement for cannabis products. A well-tested pre roll packaging box protects children from accidental ingestion, meets regulatory expectations, reduces liability, and strengthens retailer and consumer trust. For manufacturers and brands, robust testing improves product launch speed and avoids costly recalls or fines.

Regulatory landscape: what to consider before testing

Regulations vary by country and region. In the United States, the Poison Prevention Packaging Act (PPPA), enforced by the Consumer Product Safety Commission (CPSC), sets expectations for child-resistant packaging in many product categories. In addition, several states with legal cannabis markets (for example California, Colorado, and Washington) require cannabis packaging to be child-resistant and tamper-evident. Internationally, ISO 8317 is a recognized standard for reclosable child-resistant packages. Before testing, identify the jurisdiction(s) where you will sell your pre roll packaging box and confirm the applicable standards and state-level cannabis rules.

Common standards and how they differ

Most widely referenced standards and regulations fall into three categories: national regulations (e.g., PPPA/CPSC), international standards (e.g., ISO 8317 for reclosable packaging), and industry/state-specific cannabis rules. Each focuses on similar goals—preventing child access while allowing intended users to open the package—but differ in testing protocols, sample sizes, and documentation requirements.

Standards comparison

| Type | Typical focus | Notes |

|---|---|---|

| National regulations (PPPA/CPSC) | Legal enforceability, general child-safety requirements | Enforced in the U.S.; check for specific product categories and exemptions |

| ISO 8317 | Reclosable child-resistant packaging test methods | Widely accepted internationally; useful benchmark for pre-roll boxes with reclosable features |

| State cannabis rules | Specific cannabis packaging requirements (child-resistance, tamper-evidence, labeling) | Varies by state—always review local law before sale |

Design review: the first test step for any pre roll packaging box

Start with a design review to identify potential child-attractive elements (bright colors, cartoon imagery, toy-like shapes) and ease-of-opening. Consider materials, closure type (hinge, friction fit, snap, screw), and any secondary features like inner trays or glass tubes. A well-designed pre roll packaging box minimizes attractive elements and uses tested closure mechanisms without compromising adult usability.

Prototype and engineering testing

Before human-subject testing, perform engineering tests to measure mechanical opening forces, hinge/lid durability, and tamper-evidence performance. Use instrumented tests to record force-to-open, cycle life (open/close cycles), and how the package behaves when dropped or compressed. These metrics help optimize the design and reduce the number of human-panel test iterations needed.

Human-subject testing: child panel and adult panel

Human testing typically involves two panels: a child panel to verify the package resists access by young children, and an adult panel to ensure intended users (including older adults) can open it reasonably. The exact sample sizes and age ranges are dictated by the chosen standard or local regulation—refer to the applicable protocol. Use an independent testing lab experienced in child-resistant testing to run these panels under controlled conditions.

Running the child panel

Child testing is conducted in a controlled environment with professional supervision and ethical safeguards. Children are observed trying to open the package for a specified time period; any successful opening is recorded. The goal is to verify that the package is difficult for the defined child age group to open without adult assistance. Always follow the approved protocol for recruitment, consent, and safety when using child panels.

Running the adult usability panel

Adult usability verifies that the package is reasonably accessible to intended users, including older adults or those with limited dexterity. Tests often include an initial demonstration of the opening method followed by unassisted attempts, plus a second round after a delay to simulate real-world use. Record success rates, time-to-open, and subjective feedback on ease-of-use. Balancing child resistance with adult accessibility is essential for compliance and customer satisfaction.

Lab vs. in-field testing

Laboratory testing offers controlled, repeatable results and is necessary for certification and documentation. Field testing—small-scale pilot releases or retailer feedback—can highlight real-world use issues not visible in labs, such as opening with gloves or under low light. Combine both approaches: use lab testing for certification and targeted field trials to fine-tune the user experience.

Documentation and reporting: what regulators and buyers expect

Maintain detailed test reports including test methods, sample IDs, environmental conditions, participant demographics, pass/fail results, and photos/videos of failures. Keep engineering test data (force metrics, cycle life) and user-panel reports. For cannabis brands, regulators and retailers often request proof of child-resistant testing and ongoing quality control records before accepting new lines of pre roll packaging box products.

Quality control and production monitoring

Child-resistance must be ensured across production runs. Implement incoming material checks, production spot checks, and periodic sample testing. Where feasible, perform batch-level mechanical checks (e.g., opening force, closure integrity) to detect manufacturing drift. Document corrective actions and re-testing when deviations occur.

Design tips to improve child-resistance without harming usability

Use multi-step opens (push-and-turn, squeeze-and-lift) or hidden release mechanisms that are intuitive after demonstration but difficult for young children. Avoid toy-like graphics and scented coatings. For pre roll packaging box designs, incorporate internal tubes or sealed inserts for the product to add another barrier. Durable materials and robust hinges reduce accidental openings during transport and retail handling.

Tamper-evidence: a complementary requirement

Many jurisdictions require tamper-evident features in addition to child-resistance. Consider tear strips, breakaway seals, or visible indicators of prior opening. Tamper-evidence helps maintain product integrity and increases consumer confidence; it also tends to discourage casual tampering that could make a package easier for a child to open.

Working with a packaging partner: what to ask

When selecting a vendor for a pre roll packaging box, ask whether they: have experience with cannabis-specific child-resistance testing; use independent accredited labs; maintain comprehensive documentation; and offer design-for-test (DFT) services. A vendor that understands regulatory nuance and provides turnkey OEM/ODM support speeds path-to-market. Best Pack (https://www.gzbestpack.com/) offers end-to-end services including design, printing, prototyping, and test-aware production for cannabis protective packaging and cartridge box packaging.

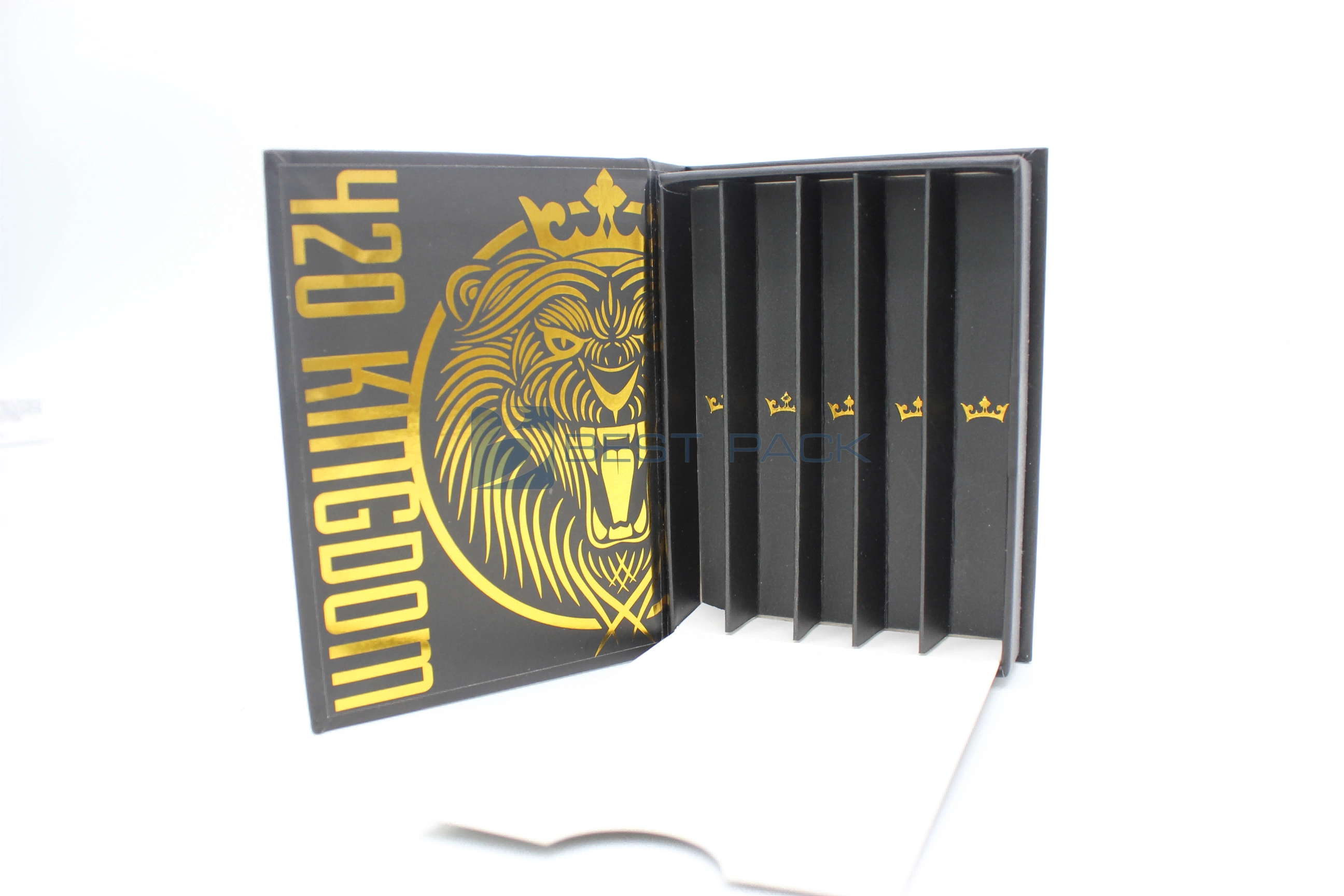

Case example: integrating testing into development (Best Pack approach)

Best Pack approaches child-resistance by combining design reviews, engineering tests, third-party human-panel testing, and production quality controls. This structured workflow reduces iterations, ensures compliance with client target markets, and preserves brand aesthetics. Their OEM/ODM capabilities allow brands to scale from a tested prototype into mass production while maintaining testable consistency for each batch.

Cost, timeline, and common pitfalls

Testing costs vary by scope—engineering tests, independent lab child/adult panels, and certification each carry separate fees. Timelines typically range from weeks for engineering validation to months for full certification and repeated state approvals. Common pitfalls include: skipping engineering validation and failing human panels; ignoring state-specific cannabis rules; and inadequate production-level QA that causes post-launch failures.

Ongoing compliance and revalidation

Regulations and market expectations change. Revalidate designs if you change materials, tooling, or closure mechanisms. Periodic re-testing and batch checks ensure continuing compliance and reduce the risk of recalls. Keep records organized and accessible for audits by regulators or supply-chain partners.

FAQ — Frequently Asked Questions

Q: How do I know which child-resistance standard applies to my pre roll packaging box?

A: Identify the jurisdictions where you will sell. For U.S. markets, review federal PPPA requirements (CPSC) and state cannabis rules. For international sales, consider ISO 8317 for reclosable packaging. When in doubt, consult a testing lab or regulatory expert to map standards to your specific product.

Q: Can a package be both child-resistant and easy for seniors to open?

A: Yes. The goal of child-resistant design is to require a level of coordination or sequence that children cannot generally perform, while still allowing older adults to open after a demonstration or with reasonable effort. Adult usability testing that includes older participants is essential to confirm accessibility.

Q: Do I need third-party lab testing or can I test in-house?

A: Initial engineering and mechanical testing can be done in-house to refine design. For certification or for retailer/regulator acceptance, third-party testing is strongly recommended or required. Accredited labs provide defensible, standardized reports.

Q: How often should I retest production batches?

A: Frequency depends on risk and production variability. Many manufacturers perform incoming material checks and periodic batch sampling (e.g., monthly or per production run). If tooling changes, supplier changes, or failure trends arise, increase retesting frequency immediately.

Q: What documentation should I keep after testing?

A: Keep complete test reports (engineering and human-panel), certificates from third-party labs, quality control logs, sample IDs, production run records, and any corrective action reports. Organized documentation simplifies audits and retailer approvals.

Q: How does Best Pack support brands testing child-resistance for pre roll packaging box?

A: Best Pack provides design-for-test services, prototyping, and coordinates third-party testing where needed. Their one-stop service includes printing, handicraft processing, and production QA to ensure the delivered pre roll packaging box meets design and compliance goals. Visit https://www.gzbestpack.com/ for case studies and contact details.

Integrating Security Features into Custom Cigarette Packaging

How to Choose the custom cigarette boxes manufacturer and supplier ?

What are the application scenarios of child resistant paper box?

Anti-Tamper Options for Vintage Style Packaging

About us

How many kinds the printing process you have?

We can make Silk screen printing, offset printing, and also hot silver stamping

When can I get the quotation?

1. The quotation will be offered within 24 hours after getting your detailed request.

2. If you get the urgent inquiry, please call us or mark it via E-mail, then we could make it into priority list.

How much of your samples cost ?

1. If samples are without printing, we can make free samples as per your box size or structure;

2. If samples are silk printing, normally USD 25 per color,depending on your logo colors;

3. If samples are offset printing, need USD 180 as offset printing mold cost is high.

FAQs

Can you ship internationally?

Yes, we export worldwide and work with reliable logistics partners for timely delivery.

What services do you provide?

We offer one-stop packaging solutions, including design, printing, and handicraft processing for electronic boxes, plastic boxes, paper boxes, paper bags, and book printing.

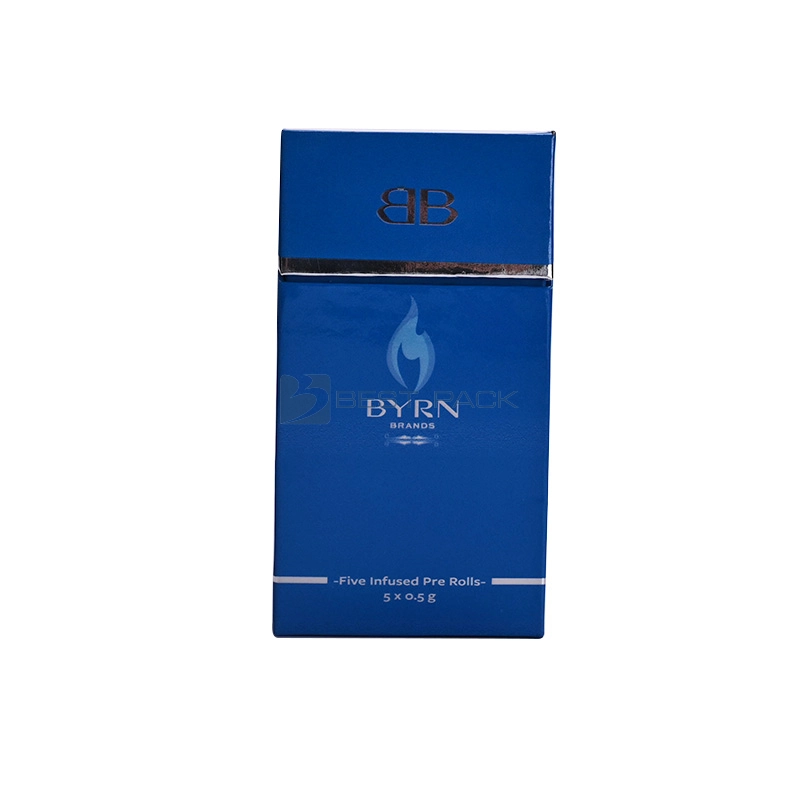

Custom Pre Cone 5 Pack Magnetic Paper Cigarettes Box Pre Roll Packaging Box

Custom Printed Paperboard Cardboard Cigarette Box Packaging Case Disposable Paper Box for Cigarette Clamshell paper box

Custom Vape Packaging Box with CR Telescoping Design

The CR telescoping box is a sophisticated and secure packaging solution designed specifically for vape products. Featuring a telescoping (two-piece) structure, this box offers excellent protection and an elegant presentation, enhancing both the unboxing experience and brand appeal.

Best pack

Best pack

Best pack