Bulk Ordering Guide for Pack Sizes and Case Quantities

- How to Choose Pack Sizes and Case Quantities for Cigarette Boxes

- Assessing demand and turnover

- Matching pack size (5/10/20) to customer preferences

- Cost and storage implications

- Manufacturing, Custom Printing, and Quality Considerations

- Material selection and durability

- Custom logo printing and branding options

- Quality control & compliance

- Logistics, Bulk Ordering, and Cost Optimization

- Case quantities, palletization, and shipping savings

- Inventory management and minimum order quantities (MOQs)

- Sustainability and recyclable options

- Child-Resistant Packaging, Regulations, and Best Practices

- Regulatory considerations and international guidance

- Designing for safety without compromising brand

- Testing, certification and documentation

- Practical Bulk Ordering Checklist for Manufacturers and Brands

- Pre-order checklist

- During-order checklist

- Post-delivery checklist

- FAQ — Frequently Asked Questions

- Q: What is the minimum order quantity for customized cigarette boxes?

- Q: How do I calculate the right number of cases to order?

- Q: Can child-resistant features be added to paperboard cigarette boxes?

- Q: Are there standard case configurations for 5/10/20 pack sizes?

- Q: What lead times should I expect for bulk customized orders?

- Q: How can I reduce per-unit cost without sacrificing quality?

This guide provides a practical, search-optimized summary for businesses sourcing bulk cigarette boxes and pre-roll packaging. It covers how to select pack sizes (5, 10, 20), calculate case quantities, optimize costs and logistics, meet regulatory and child-resistant expectations, and design high-impact custom printing for shelf-ready presentation. The recommendations here are suitable for manufacturers, distributors, dispensaries, and brands looking to scale orders for Factory Customized Printing LOGO Pack 10 20 5 Thick Case Pre Roll Non Tobacco Paper Box Cigarette Boxes while balancing inventory, compliance, and sustainability.

How to Choose Pack Sizes and Case Quantities for Cigarette Boxes

Assessing demand and turnover

Begin by analyzing expected sell-through rate. If a product shelf or dispensary moves 300 units per month and you sell a 10-pack variant, that's 30 retail packs per month. Converting to cases depends on your case configuration (e.g., 12 retail packs per case). Forecasting for 3 months of coverage is a common practice to avoid stockouts. For new SKUs, start with a conservative test order (e.g., one pallet) and scale once velocity is proven.

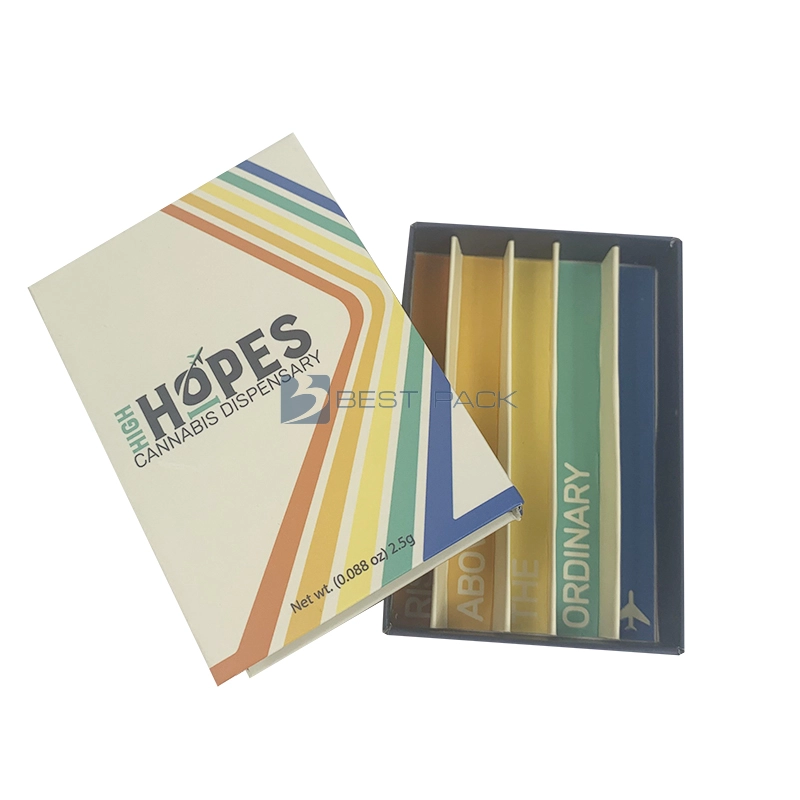

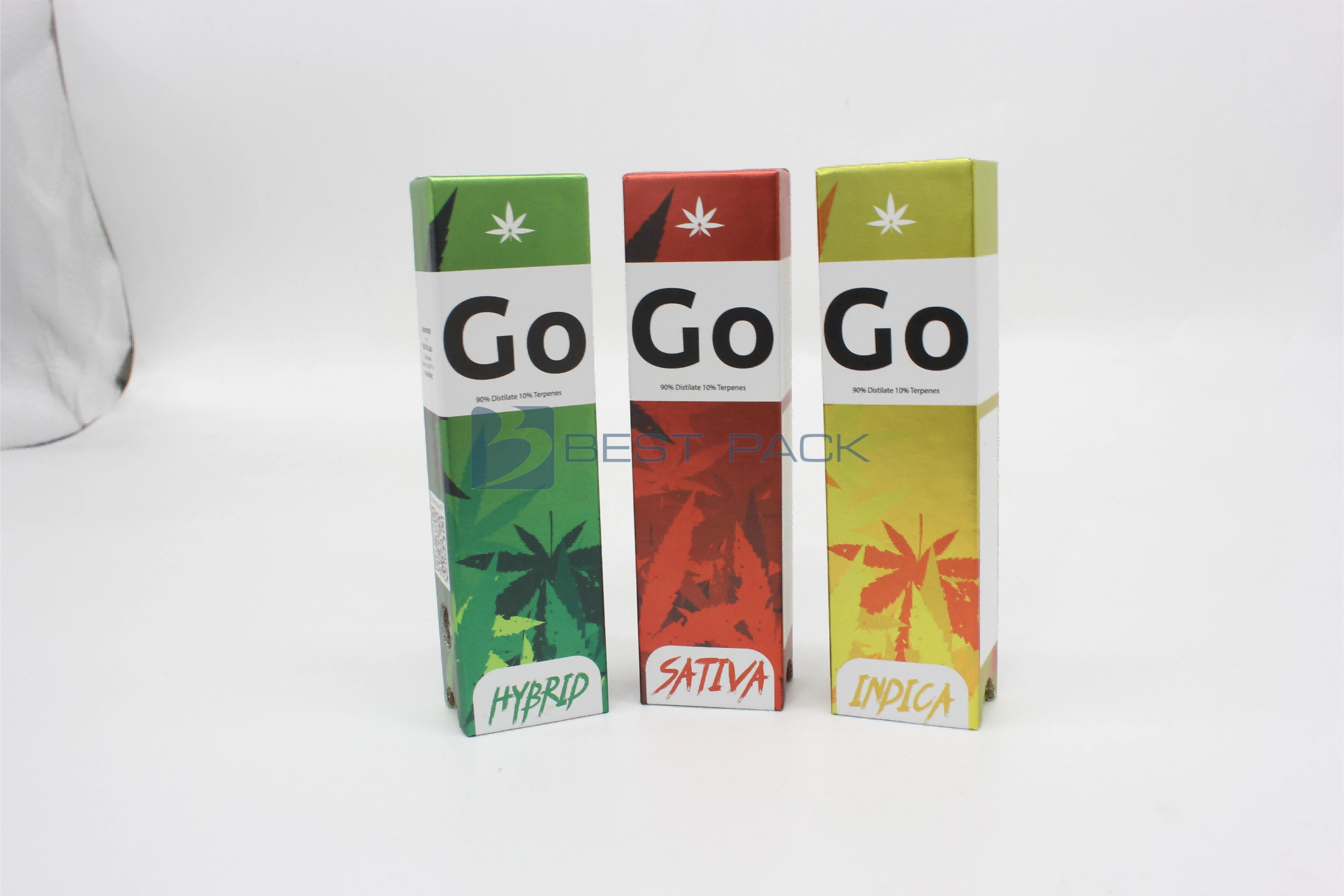

Matching pack size (5/10/20) to customer preferences

Different markets prefer different pack sizes. A 5-pack is attractive for trial buyers and High Quality single-use consumers; a 10-pack balances value and price; a 20-pack aligns with traditional cigarette pack expectations and high-frequency users. Choose pack sizes that reflect your target customer behavior and price elasticity to reduce returns and overstock.

Cost and storage implications

Bulk ordering saves per-unit cost but increases storage needs. When comparing a 5-pack vs 20-pack, the per-unit material cost may drop for larger packs due to fewer total closure mechanisms and less relative printing per product. However, case volume and weight increase shipping costs. Use cost-per-retail-unit and cubic-foot storage metrics to compare scenarios.

Manufacturing, Custom Printing, and Quality Considerations

Material selection and durability

Your Factory Customized Printing LOGO Pack 10 20 5 Thick Case Pre Roll Non Tobacco Paper Box Cigarette Boxes are made from thick paperboard to protect non-tobacco herbal pre-rolls, CBD/THC joints, and cigarettes during transport and retail handling. Choose board caliper and coatings (matte, gloss, aqueous, or soft-touch) based on desired shelf appeal and durability. Thicker board reduces crushing risk during pallet stacking but increases material cost.

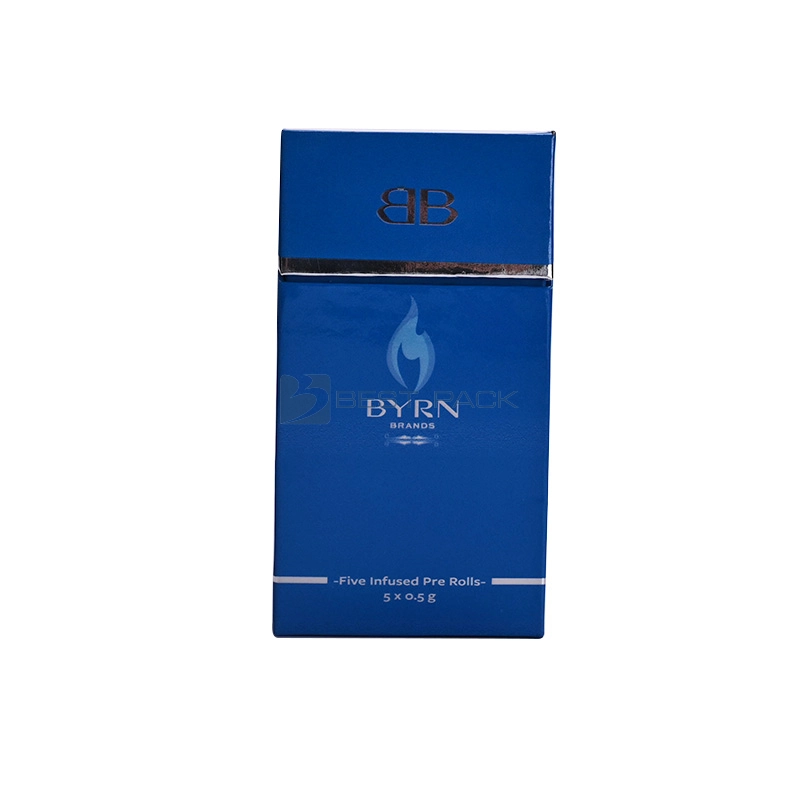

Custom logo printing and branding options

Full-surface custom printing raises perceived value and improves brand recall. Options include CMYK process printing, spot UV, foil stamping, embossing, and die-cut windows. When ordering in bulk, negotiate plate or dieline reuse terms for future reprints. Factory-direct customized printing minimizes intermediaries and keeps lead times and per-unit costs competitive.

Quality control & compliance

Inspect pre-production samples and run first-article approvals. Establish quality acceptance criteria: print color match, board integrity, adhesive strength, and closure functionality. For safety-related packaging like child-resistant designs, follow testing protocols and documented acceptance criteria. Refer to authoritative guidance from the U.S. Consumer Product Safety Commission (Poison Prevention Packaging Act) for child-resistant expectations: CPSC — PPPA. For general background on child-resistant packaging design, see the overview on Wikipedia: Child-resistant packaging — Wikipedia.

Logistics, Bulk Ordering, and Cost Optimization

Case quantities, palletization, and shipping savings

Optimizing case quantities reduces handling and freight cost. Common case unitization patterns for cigarette boxes can be 6, 12, or 24 retail packs per case depending on pack size and case dimensions. Bulk shipping discounts often apply at pallet quantities (e.g., full pallet or half pallet). When planning orders, evaluate the break-even point where lower per-unit cost offsets increased inventory and handling.

Inventory management and minimum order quantities (MOQs)

Factories typically set MOQs to make production runs efficient. For customized printed cigarette boxes, MOQs might be higher than for plain stock. Plan SKUs and SKUs variants (colorways, logos) to consolidate art files and reduce MOQs. Use inventory models (reorder point, safety stock) to ensure cases arrive before safety stock depletion, minimizing expedited freight costs.

Sustainability and recyclable options

Eco-conscious consumers favor recyclable and FSC-certified paperboard. Select uncoated or recyclable coatings and avoid laminates that complicate recycling. Factories can often supply recycled-content board or provide certifications—confirm these during supplier selection. Sustainable choices can also become marketing points on the cigarette boxes themselves.

| Pack Size | Retail Units per Case (example) | Recommended Bulk Order (cases) | Best For |

|---|---|---|---|

| 5-pack | 24 | 200 - 1,000 | Trials, High Quality small-format |

| 10-pack | 12 | 100 - 500 | Balanced value, dispensaries |

| 20-pack | 10 | 50 - 300 | High-velocity retail channels |

Child-Resistant Packaging, Regulations, and Best Practices

Regulatory considerations and international guidance

Even for non-tobacco herbal pre-rolls or CBD products, some jurisdictions require child-resistant packaging. In the U.S., the Poison Prevention Packaging Act (PPPA) administered by the CPSC sets direction for child-resistant closures for certain hazardous household substances and provides important context: CPSC — PPPA. For tobacco-specific labeling, see the FDA’s guidance on tobacco products: FDA — Tobacco Products. Internationally, the World Health Organization's Framework Convention on Tobacco Control provides policy context for packaging and labeling: WHO — Tobacco Control.

Designing for safety without compromising brand

Child-resistant mechanisms can be integrated into paperboard solutions via locking tabs, tuck-and-lock designs requiring a two-step motion, or slip-sleeve constructions. The goal is to make everyday adult use intuitive while preventing child access. Work with packaging engineers to prototype mechanisms and maintain the brand's visual identity via printing and finishing. Consider clear labeling that shows adults how to open and close the pack safely.

Testing, certification and documentation

Certified testing ensures your cigarette boxes meet child-resistant criteria. Use accredited laboratories that follow protocols recognized by regulators. Keep documentation of design iterations, testing reports, and quality checks—these support compliance and can be requested by retailers or regulators. For industry perspective on packaging best practices, consult the Institute of Packaging Professionals: IoPP.

Practical Bulk Ordering Checklist for Manufacturers and Brands

Pre-order checklist

- Confirm pack sizes to be produced (5, 10, 20) and the preferred retail presentation.

- Order pre-production samples and approve artwork/color proofs.

- Verify material specs (board caliper, coating, recyclability) and child-resistant mechanism if required.

During-order checklist

- Negotiate MOQ, tooling, and plate reuse terms with factory.

- Specify packing plan: retail units per case, cases per pallet, and labeling for shipment.

- Arrange third-party inspection or request factory inspection reports.

Post-delivery checklist

- Confirm received quantities vs. packing list and inspect for damage.

- Rotate inventory by production date and monitor sell-through to adjust future case quantity choices.

- Collect customer feedback on pack usability and branding impact.

FAQ — Frequently Asked Questions

Q: What is the minimum order quantity for customized cigarette boxes?

A: MOQ varies by factory and customization level. For fully customized printing and special finishes, MOQs commonly range from a few thousand to tens of thousands of retail packs. Consolidate SKUs and re-use artwork templates to lower MOQs. Ask your supplier for sample or pilot run options.

Q: How do I calculate the right number of cases to order?

A: Forecast demand (units per period), determine desired coverage period (e.g., 3 months), and divide by retail units per case. Add safety stock to account for lead time variability. Example: forecast 3,000 retail packs for 3 months ÷ 12 retail packs per case = 250 cases, plus safety stock (e.g., 10%) = 275 cases.

Q: Can child-resistant features be added to paperboard cigarette boxes?

A: Yes. Child-resistant mechanisms can be integrated into paperboard via two-step closures, locking tabs, or sleeves. These should be prototype-tested and validated by accredited labs. Always check local regulations to ensure compliance.

Q: Are there standard case configurations for 5/10/20 pack sizes?

A: Case configurations vary. Typical patterns include 24 units per case for 5-packs, 12 units per case for 10-packs, and 10 units per case for 20-packs, but these are examples. Confirm exact case sizes with your supplier for palletization and freight planning.

Q: What lead times should I expect for bulk customized orders?

A: Lead times depend on factory schedule, complexity of printing/finishing, and testing requirements. Typical lead times for custom printed cigarette boxes range from 4–8 weeks after artwork approval; longer if child-resistant testing or special coatings are required.

Q: How can I reduce per-unit cost without sacrificing quality?

A: Increase order volume to leverage economies of scale, simplify finishes (avoid multiple spot coatings), consolidate SKUs, and reuse printing plates where possible. Negotiate better freight terms by optimizing case per pallet packing and agreeing to factory-standard palletization.

Need help choosing the right pack sizes or placing a bulk order for Factory Customized Printing LOGO Pack 10 20 5 Thick Case Pre Roll Non Tobacco Paper Box Cigarette Boxes? Contact our sales team for a tailored quote, sample request, or regulatory guidance. View the product details and request a sample here: View Product — Factory Customized Pre-Roll & Cigarette Paper Boxes. For direct assistance, email our packaging specialists or request a consultation.

References and further reading: Child-resistant packaging — Wikipedia, CPSC — Poison Prevention Packaging Act (PPPA), FDA — Tobacco Products, WHO — Tobacco Control, Institute of Packaging Professionals (IoPP).

Comparing Printing Options for Branded Cigarette Packaging

Cost-Saving Strategies for Buying Cardboard Childproof Paper Tubes

Custom print finishes that elevate pre roll packaging

Choosing Biodegradable 5-Pack Pre-Roll Boxes with Custom Logos

About us

What is the box size and structure?

1. All boxes are customized and all detailed requirements can be provided by clients, we are definitely your OEM service supplier.

2. If you have no idea about the measurements and structure on your products, our professional design team can suggest and solute for you .

Are you able to do design for my products?

Yes, just send us your logo artwork in Vector file, such as AI or PDF format,and text information you want to print ,we can put it on box to make the design to let you check. Once you say ok, then we go on to make samples or production.

The process of your packaging box production?

1. Make knife mold as per box size and structure

2. order material as per mold

3. make printing on material if need to print

4. suppress and cut material

5. Makeboxes with glue edge in machine

6. Package boxes into cartons

FAQs

What types of packaging do you specialize in?

We specialize in electronic packaging, plastic boxes (PVC/PET/PP), paper boxes, paper bags, and custom book printing.

How do you ensure product quality?

We maintain strict quality control at every stage, from material selection to final production, ensuring high-quality standards.

Manufacture Personalized Blank Cigarette Boxes Custom Pre Roll Box Child Resistant Drawer Cardboard Childproof Box

Various Style Design Drawer-Style Packaging Paper Cigarette Boxes Flip Top Closure Pre Rolled Cones Box With Dividers With Child Resistant.

Factory Paperboard Child Resist Childproof Button Box Drawer Craft Packing Box Cigarette Box for Cigarettes

Discover Best Pack’s Factory Paperboard Child-Resistant Childproof Button Box—an ideal cigarette packing box featuring a secure drawer craft packing design. Engineered for safety and style, this childproof button box ensures reliable child resistance while enhancing your cigarette storage experience.

Custom CR Vape Packaging Cardboard Boxes with Child-Resistant Design

CR custom vape packaging cardboard boxes are specially designed child-resistant packaging solutions crafted to ensure safety, protection, and premium presentation for vape products. Made from sturdy cardboard materials, these boxes balance regulatory compliance with brand aesthetics.

Best pack

Best pack

Best pack