Quality Control: Testing Standards for Child-Resistant Packs

- Quality Control: Testing Standards for Child-Resistant Packs for Cigarette Pack Products

- Why child-resistant testing matters for your cigarette pack

- Key regulatory frameworks: PPPA (U.S.) and ISO standards

- U.S. Poison Prevention Packaging Act (PPPA) — 16 CFR Part 1700

- ISO 8317 — Reclosable child-resistant packaging

- How tests are performed: child panel and adult-use testing

- Typical test protocol steps

- Design strategies to make a cigarette pack child-resistant while preserving branding

- Practical design tips

- Quality control steps during manufacturing for consistent child-resistant performance

- Recommended QC checklist for cigarette pack runs

- Testing lab selection: what to look for

- Questions to ask prospective labs

- Comparative overview of common tests and their purposes

- How Factory Customized Printing LOGO Pack 10 20 5 Thick Case Pre Roll Non Tobacco Paper Box Cigarette Boxes fits into compliance strategies

- Compliance-friendly customization options

- Common pitfalls and how to avoid them

- Checklist to reduce failure risk

- Cost considerations and timeframes for certification

- FAQ — Child-resistant testing for cigarette pack products

- Q: Are paperboard cigarette boxes capable of being child-resistant?

- Q: Which standard should I target: PPPA or ISO 8317?

- Q: How many units should I submit for testing?

- Q: Can you make the Factory Customized Printing LOGO Pack 10 20 5 Thick Case Pre Roll Non Tobacco Paper Box Cigarette Boxes child-resistant?

- Q: What documentation will I receive after testing?

- Brand advantages and why choose our factory-direct solution

- Contact us / View product

- Authority references

Quality Control: Testing Standards for Child-Resistant Packs for Cigarette Pack Products

Why child-resistant testing matters for your cigarette pack

Child-resistant packaging is not just a regulatory checkbox — it protects children from accidental ingestion and reduces liability for manufacturers and brand owners. For a cigarette pack or non-tobacco pre-roll box, demonstrating reliable child resistance through standardized testing builds trust with retailers, regulators, and consumers. When you manufacture or source items like the Factory Customized Printing LOGO Pack 10 20 5 Thick Case Pre Roll Non Tobacco Paper Box Cigarette Boxes, understanding test requirements and quality-control steps ensures your product performs as promised in the real world. After validating safety and performance, attention turns back to shelf impact with practical design tips for effective logo printing on cigarette boxes.

Key regulatory frameworks: PPPA (U.S.) and ISO standards

Two of the most important references for child-resistant packaging are national regulations such as the U.S. Poison Prevention Packaging Act (PPPA) and international standards like ISO 8317 (for reclosable packages). These frameworks describe test protocols, participant selection, pass/fail criteria, and documentation expectations. For manufacturers of cigarette pack style boxes intended for herbal pre-rolls or CBD/THC products, aligning design and testing with these standards is the baseline for market access in many jurisdictions.

U.S. Poison Prevention Packaging Act (PPPA) — 16 CFR Part 1700

The PPPA defines child-resistant packaging and provides testing methodology commonly used in the United States. It sets forth the requirement that a package must be difficult for children under five years of age to open, while being reasonably accessible to most adults. The Consumer Product Safety Commission (CPSC) oversees application of the PPPA. If your product is sold in the U.S. market and contains substances that trigger PPPA requirements (including certain cannabis products in some states), you must consider these regulations.

ISO 8317 — Reclosable child-resistant packaging

ISO 8317:2015 specifies test methods and performance criteria for reclosable packages designed to be child-resistant yet usable by adults. The standard is widely adopted by international manufacturers and is appropriate for cigarette pack formats that use reclosable mechanisms (for example, tuck-and-lock systems with a child-resistant inner feature). ISO 8317 focuses on both the ability of children to open the package and the ability of adults to use it.

How tests are performed: child panel and adult-use testing

Testing generally includes two complementary panels: a child panel and an adult panel. The child panel consists of children within a specified age bracket (commonly 42-51 months for PPPA/ISO 8317) attempting to open the package under supervised, standardized conditions. The adult panel consists of adults (often ages 50–70 in PPPA tests) who must be able to open the package and then reclose it as intended. Statistical pass/fail thresholds are applied to both panels.

Typical test protocol steps

- Sample selection: Random, production-equivalent units are selected to ensure representative performance.

- Pre-test conditioning: Packages may be conditioned (temperature/humidity cycles) to simulate storage conditions.

- Child panel attempts: Children attempt to open samples for a defined period; success rates are recorded.

- Adult-use testing: Adults must be able to open and reclose the package within a reasonable time and without undue difficulty.

- Documentation: All observations, times, and assistance levels are recorded to produce a compliance report.

Design strategies to make a cigarette pack child-resistant while preserving branding

Designing child-resistant cigarette pack style boxes like the Factory Customized Printing LOGO Pack 10 20 5 Thick Case Pre Roll Non Tobacco Paper Box Cigarette Boxes requires balancing security, usability, and brand presentation. For paperboard boxes, common approaches include: integrating tested child-resistant inserts, using multi-step opening mechanisms (e.g., push-and-slide inner tray), adding sealed blister liners, or pairing the outer box with a certified child-resistant inner container.

Practical design tips

- Use multi-layer structures: A rigid outer sleeve with an inner child-resistant tray keeps printed branding on the outer surface while the inner mechanism provides tested protection.

- Design for adult ergonomics: Provide clear cues (tactile or printed) to guide intended adult users so the package is accessible without instruction.

- Test early and iterate: Rapid-prototype multiple mechanisms and run small-scale child/adult usability tests before full certification testing.

- Labeling and instructions: Clear adult-use instructions improve pass rates in adult panels and support compliance across markets.

Quality control steps during manufacturing for consistent child-resistant performance

Child-resistant performance must be repeatable across production batches. Key QA steps include incoming material inspection (paperboard strength, coating adhesion), in-line dimensional checks (tolerances for locking components), finishing checks (glue application, die-cut accuracy), and final sample testing (open/close cycles, random functional checks). Maintain traceability for each batch so issues can be isolated quickly.

Recommended QC checklist for cigarette pack runs

- Pre-production: Approve a certified sample with test report from an accredited lab.

- Incoming material control: Verify GSM, stiffness, and moisture content of paperboard every lot.

- Process control: Monitor die-cut alignment, glue strength, and assembly torque for mechanical components.

- On-line sampling: Functional open/close tests on randomly selected units every shift.

- Post-production: Store retention samples under controlled conditions for future reference.

Testing lab selection: what to look for

Choose an accredited laboratory experienced with child-resistant protocols and with accreditations such as ISO/IEC 17025. Labs should be able to run both the child and adult panels per the required standard (PPPA/ISO 8317) and provide a comprehensive report that includes raw data, test environment, sample conditioning, and photographic evidence. For global sales, confirm the lab's test reports are recognized by your target markets.

Questions to ask prospective labs

- Are you ISO/IEC 17025 accredited for child-resistance testing?

- Can you conduct PPPA (16 CFR 1700) and ISO 8317 protocols?

- Do you provide participant demographics and raw data with each report?

- Can you offer pre-compliance testing (child/adult usability) to reduce full-test failure risk?

Comparative overview of common tests and their purposes

The following table summarizes typical tests, their purpose, general method, and the most relevant standard.

| Test Type | Purpose | Typical Method | Relevant Standard/Notes |

|---|---|---|---|

| Child Panel Opening Test | Measure difficulty for young children to open | Panel of children attempts to open within set time; success rates recorded | PPPA (16 CFR 1700), ISO 8317 |

| Adult Usability Test | Ensure adults can open and reclose packaging | Adult panel times and observes opening/reclosing | PPPA, ISO 8317 |

| Durability & Cycle Testing | Verify mechanism holds up to repeated use | Open/close cycles (e.g., 100–500 cycles), humidity/temperature conditioning | ASTM / in-house protocols |

| Material Strength Tests | Confirm paperboard and adhesives meet mechanical requirements | Tensile, tear, and adhesive bond testing | ASTM standards for paper and adhesives |

| Drop & Transit Simulation | Ensure child-resistant feature not compromised in shipping | Package subjected to drops, vibration, compression | ISTA / ASTM transit tests |

How Factory Customized Printing LOGO Pack 10 20 5 Thick Case Pre Roll Non Tobacco Paper Box Cigarette Boxes fits into compliance strategies

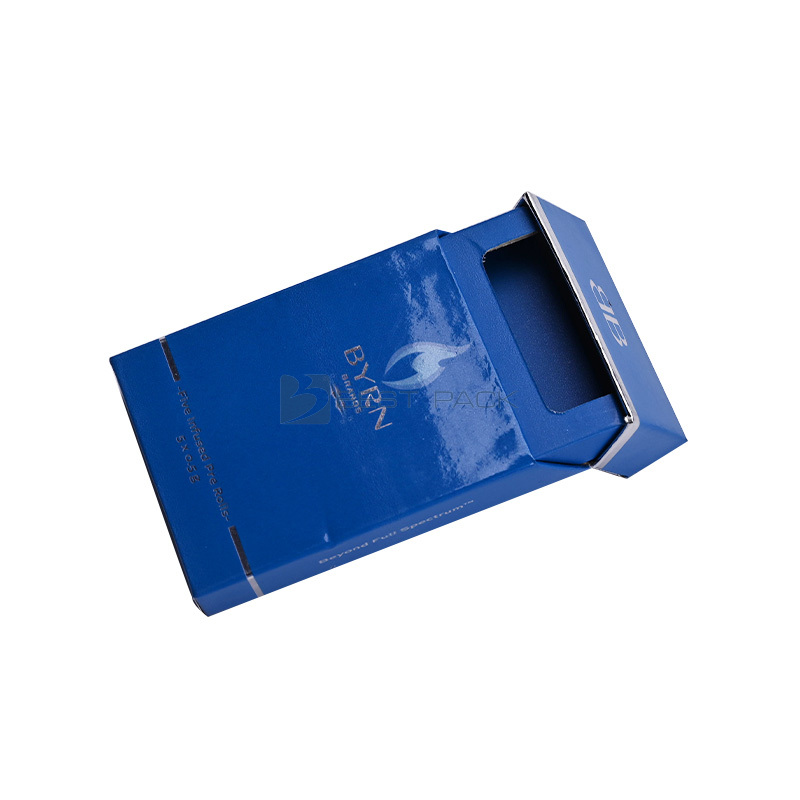

Our Factory Customized Printing LOGO Pack 10 20 5 Thick Case Pre Roll Non Tobacco Paper Box Cigarette Boxes are manufactured to combine High Quality branding with options to integrate child-resistant solutions. The thick case paperboard provides structural integrity for mechanical CR inserts or blister liners. Because these boxes are factory-direct and customizable, it’s possible to include design elements that facilitate compliance testing from the earliest sample stage.

Product brief:

Our factory-direct custom pre-roll and cigarette paper boxes are designed for High Quality presentation, protection, and branding. Made with thick, durable paperboard, these boxes are ideal for non-tobacco herbal pre-rolls, cigarettes, or CBD/THC joints. Available in various capacities (5-pack, 10-pack, 20-pack) and fully customizable with your logo and design.

Compliance-friendly customization options

- Option to include a certified child-resistant inner tray or blister.

- Printed adult-use instructions and tamper-evident seals to support regulatory expectations.

- Choice of coatings and lamination to improve durability during transit and use.

- Batch traceability via printed lot codes for QC and recall management.

Common pitfalls and how to avoid them

Manufacturers and brand owners often underinvest in pre-compliance testing and then fail full certification. Typical pitfalls include relying solely on an outer box design for CR without a certified inner mechanism, inadequate material testing that leads to failure under humidity or repeated use, and poor adult usability that results in customer complaints. Avoid these by conducting staged testing (prototype usability, small-scale child panel, then full certification) and partnering with accredited labs early in development.

Checklist to reduce failure risk

- Prototype and pre-test before ordering full production runs.

- Require a certified sample and lab report as part of supplier approval.

- Run environmental conditioning and cycle tests representative of real-world use.

- Document and store retention samples from each production batch.

Cost considerations and timeframes for certification

Costs vary by the complexity of the mechanism and the lab, with a full certification test involving both child and adult panels usually taking several weeks and several thousand dollars. Pre-compliance usability testing is less expensive and shortens time-to-market risk. Factor in design iteration time, shipping of samples to labs, and any rework if a test is not passed. Planning and early investment typically reduce overall cost by avoiding costly re-runs.

FAQ — Child-resistant testing for cigarette pack products

Q: Are paperboard cigarette boxes capable of being child-resistant?

A: Yes. Paperboard outer boxes can be designed around certified child-resistant inner mechanisms (trays, blister inserts, or certified screw/closure systems). Achieving certification typically requires integrating a tested inner feature because paperboard alone is rarely sufficient for multi-step CR opening criteria.

Q: Which standard should I target: PPPA or ISO 8317?

A: It depends on your target market. For the U.S., PPPA requirements administered by CPSC are essential. For international markets, ISO 8317 is widely recognized. Many manufacturers aim to meet both sets of criteria when selling globally.

Q: How many units should I submit for testing?

A: Labs will specify sample counts based on the standard and protocol. Typical child/adult panel tests require multiple units to account for multiple participants and potential retesting. Work with your chosen lab early to confirm the exact quantity.

Q: Can you make the Factory Customized Printing LOGO Pack 10 20 5 Thick Case Pre Roll Non Tobacco Paper Box Cigarette Boxes child-resistant?

A: Yes. We can integrate certified inner child-resistant solutions or design the box to accept a tested insert. We recommend pre-testing prototypes with a certified lab to ensure compliance before full production.

Q: What documentation will I receive after testing?

A: Accredited labs provide a detailed test report that includes methods used, participant demographics, raw data, pass/fail metrics, photographs, environmental conditions, and a conclusion of compliance status.

Brand advantages and why choose our factory-direct solution

Choosing our Factory Customized Printing LOGO Pack 10 20 5 Thick Case Pre Roll Non Tobacco Paper Box Cigarette Boxes offers several advantages: factory-direct pricing reduces cost-per-unit; direct customization allows CR-friendly design features to be incorporated from the prototype stage; thick, durable paperboard enhances mechanical reliability; and we can coordinate with accredited labs and provide certified sample units for your regulatory submissions. This integrated approach reduces time-to-market and lowers the risk of costly design rework.

Contact us / View product

If you want a compliance-ready cigarette pack or pre-roll box, contact our sales team to request a certified sample, ask about child-resistant inner options, or receive a custom quote. Click here to view product details and request a sample: .

Authority references

- Poison Prevention Packaging Act (PPPA) — U.S. Consumer Product Safety Commission

- ISO 8317:2015 — Child-resistant packaging — Reclosable packages

- CPSC Testing & Certification overview

- ASTM International — Standards relevant to packaging materials and transit tests

For personalized guidance on designing a child-resistant cigarette pack and to arrange testing or certified samples, contact our team today.

Ultimate Guide to Child Resistant Paper Boxes

Child resistant pre roll packaging: compliance and design

Where to Buy pre roll packaging box in Guangzhou

How to reduce tampering with a custom cigarette box

About us

The process of your packaging box production?

1. Make knife mold as per box size and structure

2. order material as per mold

3. make printing on material if need to print

4. suppress and cut material

5. Makeboxes with glue edge in machine

6. Package boxes into cartons

How many kinds the printing process you have?

We can make Silk screen printing, offset printing, and also hot silver stamping

FAQs

What services do you provide?

We offer one-stop packaging solutions, including design, printing, and handicraft processing for electronic boxes, plastic boxes, paper boxes, paper bags, and book printing.

How do you ensure product quality?

We maintain strict quality control at every stage, from material selection to final production, ensuring high-quality standards.

Do you support custom designs?

Yes, we provide custom packaging designs tailored to your brand and product needs.

Custom Printed Paperboard Cardboard Cigarette Box Packaging Case Disposable Paper Box for Cigarette Clamshell paper box

Custom Vape Packaging Box with CR Telescoping Design

The CR telescoping box is a sophisticated and secure packaging solution designed specifically for vape products. Featuring a telescoping (two-piece) structure, this box offers excellent protection and an elegant presentation, enhancing both the unboxing experience and brand appeal.

Custom Logo Child-Resistant Pre-Roll Box Packaging Biodegradable Handmade Luxury 5 Pack Embossing Childproof Pre Roll Package

Custom CR Vape Packaging Cardboard Boxes with Child-Resistant Design

CR custom vape packaging cardboard boxes are specially designed child-resistant packaging solutions crafted to ensure safety, protection, and premium presentation for vape products. Made from sturdy cardboard materials, these boxes balance regulatory compliance with brand aesthetics.

Best pack

Best pack

Best pack