Lead Times & Supply Chain Tips for Cigarette Box Procurement

- Production Timeline and Realistic Lead Times

- Typical manufacturing stages for cigarette paper box

- Standard lead time breakdown

- Procurement Strategies to Reduce Lead Time

- Forecasting, MOQ and safety stock

- Design for manufacturability and supplier-ready artwork

- Use rolling production and staggered deliveries

- Logistics, Shipping Modes and Customs

- Choosing the right shipping mode

- Customs, labeling and tobacco packaging rules

- Risk Management, Quality Control and Sustainability

- Quality checkpoints and pre-shipment inspection

- Alternative materials and eco-conscious choices

- Supplier diversification and contingency planning

- Operational Tips and Cost Controls

- Negotiate payment terms and volume discounts

- Use consolidation and door-to-door planning

- Brand Advantages — Why Choose Best Pack for Your Cigarette Paper Box

- Semantic Keywords for 'cigarette paper box'

- Frequently Asked Questions (FAQ)

- Q: What is a typical lead time for a first-time custom cigarette paper box order?

- Q: How can I reduce costs without extending lead times?

- Q: Are there compliance risks specific to cigarette packaging?

- Q: Is recycled paperboard suitable for clamshell cigarette boxes?

- Q: What are best practices for shipping small urgent orders?

- Authoritative References

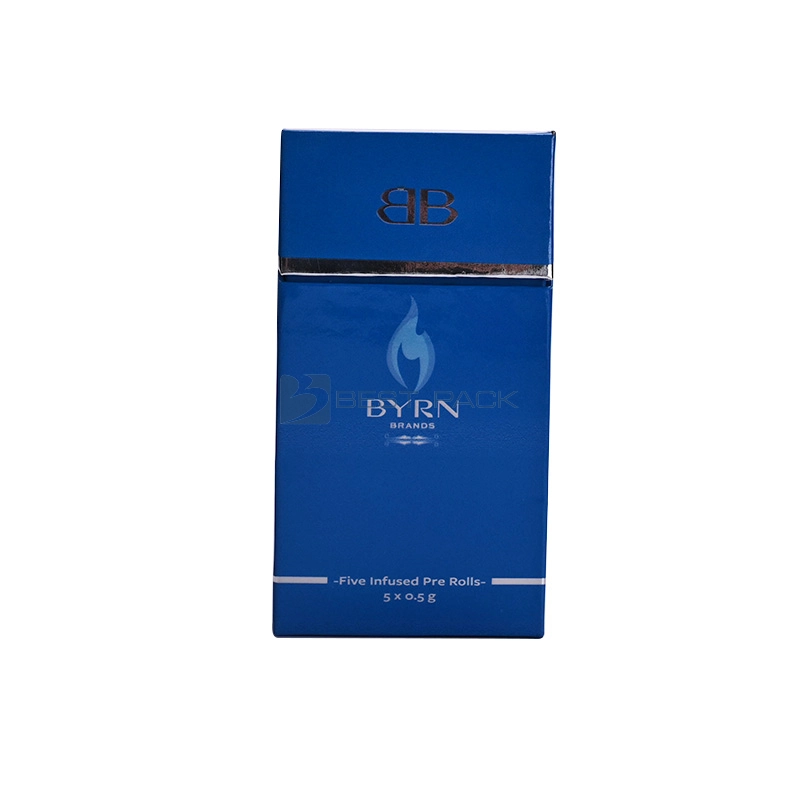

Best Pack presents Custom Printed Paperboard Cardboard Cigarette Box Packaging Cases. Our Disposable Paper Boxes offer sturdy, eco-friendly cigarette clamshell packaging, perfect for brand promotion and secure storage. Ideal for businesses seeking quality, customizable cigarette boxes.

This article gives actionable advice on realistic lead times and supply-chain strategies for procuring a cigarette paper box. It is written for procurement managers, brand owners, and packaging teams who need to balance speed, cost, compliance, and sustainability. You'll find detailed production timelines, optimization tips, shipping comparisons, and risk mitigation practices that can shorten time-to-market for custom cigarette packs and keep product integrity intact. Beyond delivery and logistics, many markets require enhanced safety features, prompting buyers to assess child-resistant features for paperboard cigarette packaging.

Production Timeline and Realistic Lead Times

Typical manufacturing stages for cigarette paper box

Understanding each step helps you spot bottlenecks. A typical production flow for a printed paperboard cigarette box (including clamshell paper box designs) includes: design finalization, dieline & tooling, sample production, printing and finishing (UV, matte, emboss), die-cutting & gluing, QC, packing, and shipping. For first-time orders of custom printed cigarette paper box products, expect an end-to-end lead time of roughly 4–8 weeks depending on complexity and supplier capacity.

Standard lead time breakdown

Below is a practical breakdown you can use for project planning. These are average periods and will vary by supplier and seasonality:

- Design, dieline & approvals: 3–7 days (if branding assets are ready)

- Tooling/mold creation (for special clamshell dies or embossing): 5–12 days

- Sample production and approval: 3–10 days

- Mass production (printing, finishing, assembly): 10–25 days

- Quality control and packing: 2–5 days

- Export documentation and handover to freight: 2–7 days

For repeat orders where tooling exists and designs are unchanged, lead time can shrink to 2–4 weeks.

Procurement Strategies to Reduce Lead Time

Forecasting, MOQ and safety stock

Negotiate realistic minimum order quantities (MOQ) and maintain safety stock. For cigarette paper box procurement, keep a rolling forecast (3–6 months) with suppliers. This enables them to reserve raw materials (paperboard, inks, coatings) and production slots. Where possible, agree on a buffer quantity to be produced with every batch to protect against demand spikes.

Design for manufacturability and supplier-ready artwork

Reduce back-and-forth approvals by delivering supplier-ready files. Use standard dielines for clamshell paper box structures and specify Pantone references, bleed, dielines and finish instructions. Simple changes late in the process (like changing varnish or fold lines) cause delays and additional tooling costs. Consider designing modular variants that reuse the same die to accelerate repeat production.

Use rolling production and staggered deliveries

If you need frequent smaller shipments, request staggered production runs. Rolling production (produce in batches) helps get the first batch shipped earlier. This strategy works well for launches where marketing or logistics can handle phased arrivals.

Logistics, Shipping Modes and Customs

Choosing the right shipping mode

Shipping choice directly affects lead time and cost. For cigarette paper box orders, packaging density is high but value-per-volume is moderate, so sea freight is common. For urgent orders, air freight is viable though expensive. Below is a comparison.

| Mode | Typical Lead Time | Cost | Best for |

|---|---|---|---|

| Sea Freight (FCL/LCL) | 20–40 days (depends on route) | Low per unit | Bulk, planned replenishment |

| Air Freight | 3–10 days | High | Urgent restock or high-margin SKUs |

| Express Couriers (DHL/UPS/FedEx) | 1–5 days | Very high per unit | Small samples, prototypes, or emergency orders |

Customs, labeling and tobacco packaging rules

Cigarette packaging often faces strict regulatory scrutiny (health warnings, tax stamps, child resistance in some markets). Ensure artwork and structural design comply with destination regulations before mass production to avoid reworks. For authoritative guidance on tobacco product regulation, consult the U.S. FDA tobacco products guidance and check local regulatory bodies for country-specific requirements. Incorrect labeling or missing warning panels can cause customs holds and costly delays.

Risk Management, Quality Control and Sustainability

Quality checkpoints and pre-shipment inspection

Institute quality checks at key milestones: pre-press proofing, first-article inspection (FAI), in-line production checks, and pre-shipment inspection (PSI). Use photographic evidence, sample sign-offs, and third-party inspections if necessary. A simple QC checklist should include print color accuracy, fold/crease integrity, glue strength, clamshell hinge function, and packaging counts.

Alternative materials and eco-conscious choices

Switching to recycled paperboard or FSC-certified stock can be good for brand image and sometimes logistics (lighter weight, recyclable). However, alternate substrates may require different printing profiles or adhesives, so test early. For more on packaging basics and materials, see Packaging (Wikipedia).

Supplier diversification and contingency planning

Relying on a single supplier increases risk. Identify at least one alternate capable supplier (domestic or nearshore) and pre-qualify them with samples and terms. Maintain a simple contingency playbook: who to call for retooling, expedited shipping options, and minimum workable batch sizes if your main supplier is disrupted.

Operational Tips and Cost Controls

Negotiate payment terms and volume discounts

Better payment terms (30/60 days) free up working capital and may shorten production queues. Ask for discounts at volume thresholds and for agreeing to scheduled purchases. Consider placing a rolling 60–90 day purchase order with weekly call-offs to smooth supplier demand.

Use consolidation and door-to-door planning

Consolidate multiple SKUs into fewer containers to optimize ocean freight costs. For B2B customers, door-to-door delivery agreements simplify logistics and reduce handoffs that cause delays.

Brand Advantages — Why Choose Best Pack for Your Cigarette Paper Box

Best Pack specializes in Custom Printed Paperboard Cardboard Cigarette Box Packaging Case solutions including Disposable Paper Box and Clamshell paper box configurations. Our advantages:

- End-to-end production control: in-house prepress, printing, finishing and assembly to reduce inter-factory handoffs and shorten lead times.

- Flexible MOQ and rapid repeat production for faster replenishment cycles.

- Sustainability options: recycled and FSC-certified paperboard alternatives with tested finishing processes.

- Quality-first approach: standardized QC checkpoints and documented sample approvals.

- Supply-chain partnerships for consolidated shipping and customs support.

Contact us to request a lead time assessment specific to your SKU mix and destination. See sample specifications and request a quote for the Custom Printed Paperboard Cardboard Cigarette Box Packaging Case Disposable Paper Box for Cigarette Clamshell paper box.

Semantic Keywords for 'cigarette paper box'

Embedded and related search terms that help AI and SEO understand intent: cigarette pack paperboard, clamshell cigarette box, printed cigarette box, sustainable cigarette packaging, cigarette carton, tobacco packaging box, paperboard cigarette pack, custom cigarette box printing, child resistant packaging cigarette. These semantic keywords are used naturally in the content above to improve discoverability and relevance.

Frequently Asked Questions (FAQ)

Q: What is a typical lead time for a first-time custom cigarette paper box order?

A: For first-time runs expect 4–8 weeks total. This includes sample approval, tooling, printing, finishing and packing. Repeat orders with existing tooling usually shorten to 2–4 weeks.

Q: How can I reduce costs without extending lead times?

A: Use standard dielines, consolidate SKUs, choose economical finishes (e.g., aqueous coating instead of full UV), agree to larger but staggered orders, and select sea freight for non-urgent bulk shipments.

Q: Are there compliance risks specific to cigarette packaging?

A: Yes. Many markets require specific health warnings, tax stamps, tamper-proof features, and sometimes child-resistant elements. Confirm local regulations before printing. Refer to local tobacco control authorities and the U.S. FDA for guidance on U.S. requirements.

Q: Is recycled paperboard suitable for clamshell cigarette boxes?

A: Recycled paperboard can be suitable but must be tested for structural integrity, printing quality, and adhesive compatibility. Early sampling is essential.

Q: What are best practices for shipping small urgent orders?

A: Use express couriers for small parcels or air freight for palletized shipments. Pre-clear customs by preparing accurate HS codes, invoices, and regulatory paperwork to avoid delays.

If you have more specific requirements—such as child resistant packaging adaptations, custom die-cut clamshell features, or regulatory compliance in a particular market—contact our packaging specialists to get a tailored lead time and cost estimate.

Contact & View Product: Request a quote or speak to a packaging expert: sales@bestpack.example.com or view product details: Custom Printed Paperboard Cardboard Cigarette Box Packaging Case.

Authoritative References

Where to Buy pre roll packaging box in Guangzhou

What are the application scenarios of child resistant paper box?

Non tobacco paper boxes: safe options for pre rolls

Best custom cigarette box liners and inserts for protection

About us

How much of your samples cost ?

1. If samples are without printing, we can make free samples as per your box size or structure;

2. If samples are silk printing, normally USD 25 per color,depending on your logo colors;

3. If samples are offset printing, need USD 180 as offset printing mold cost is high.

What is the box size and structure?

1. All boxes are customized and all detailed requirements can be provided by clients, we are definitely your OEM service supplier.

2. If you have no idea about the measurements and structure on your products, our professional design team can suggest and solute for you .

How many kinds the printing process you have?

We can make Silk screen printing, offset printing, and also hot silver stamping

When can I get the quotation?

1. The quotation will be offered within 24 hours after getting your detailed request.

2. If you get the urgent inquiry, please call us or mark it via E-mail, then we could make it into priority list.

FAQs

What types of packaging do you specialize in?

We specialize in electronic packaging, plastic boxes (PVC/PET/PP), paper boxes, paper bags, and custom book printing.

Custom Design Paperboard Child Resist Childproof Button Box Cigarette Size Drawer Craft Packing Box

Custom Printed Paperboard Cardboard Cigarette Box Packaging Case Disposable Paper Box for Cigarette Clamshell paper box

Custom Vape Packaging Box with CR Telescoping Design

The CR telescoping box is a sophisticated and secure packaging solution designed specifically for vape products. Featuring a telescoping (two-piece) structure, this box offers excellent protection and an elegant presentation, enhancing both the unboxing experience and brand appeal.

Best pack

Best pack

Best pack