Design Tips for Eye-Catching Custom Cigarette Packaging

- How perception and function drive cigarette box design

- Understand the buyer journey and shelf behavior

- Balance aesthetics with protection

- Introduce the product: factory-direct solution

- Design elements that boost shelf appeal

- Logo, typography, and hierarchy

- Color, finishes, and sensory cues

- Imagery and iconography

- Structural, material, and production considerations

- Choosing the right board and construction

- Insert and closure options for protection

- Production scale, lead times, and cost trade-offs

- Safety, compliance, and child-resistant packaging

- Regulatory landscape and best practices

- Designing for child resistance without sacrificing brand

- Testing and documentation

- Sustainable choices and lifecycle thinking

- Material recyclability and consumer expectations

- Carbon footprint and packaging optimization

- Communicating sustainability on the pack

- Print and finishing techniques that elevate perceived value

- Foil, embossing, and tactile finishes

- Digital vs. offset printing: matching volume and fidelity

- Variable data and personalized runs

- Practical examples and material comparison

- Implementation checklist before mass production

- Frequently Asked Questions (FAQ)

- Q: What sizes and pack counts are commonly available for custom cigarette boxes?

- Q: Can custom Cigarette Boxes be made child-resistant?

- Q: What is the typical lead time for custom printing and finishing?

- Q: How can I ensure my design remains compliant in different markets?

- Q: Do eco-friendly materials affect print quality or finishing options?

- Next steps — view product or contact us

High-converting cigarette packaging combines visual impact, tactile quality, and regulatory compliance. For brands selling non-tobacco herbal pre-rolls, CBD/THC joints, or traditional cigarettes, well-designed Cigarette Boxes are a primary touchpoint that influence purchase decisions, perception of quality, and on-shelf discoverability. This article provides actionable design tips—grounded in material selection, structural choices, print and finishing techniques, and safety/compliance considerations—to help you create eye-catching custom cigarette boxes that protect your product and reinforce Best Pack.

How perception and function drive cigarette box design

Understand the buyer journey and shelf behavior

Packaging is often the first physical interaction between a consumer and a product. In retail and dispensary contexts, shoppers scan shelves quickly; your Cigarette Boxes should communicate brand promise in a glance. Use high-contrast logo placement, readable typography at typical shelf distances, and an iconic color or shape to create instant recognition. Consider the point-of-sale environment—are boxes displayed horizontally in racks, vertically on slatwalls, or in countertop displays? Design for the most common presentation to maximize visibility.

Balance aesthetics with protection

Attractive design must sit alongside product protection. Thick paperboard cases with proper internal supports prevent crushing and maintain High Quality presentation. For non-tobacco pre-rolls and CBD/THC joints, humidity, aroma retention, and fragile tips matter—choose inner linings, inserts, or trays that protect contents while maintaining a slim, elegant exterior. Your packaging should be as functional as it is beautiful.

Introduce the product: factory-direct solution

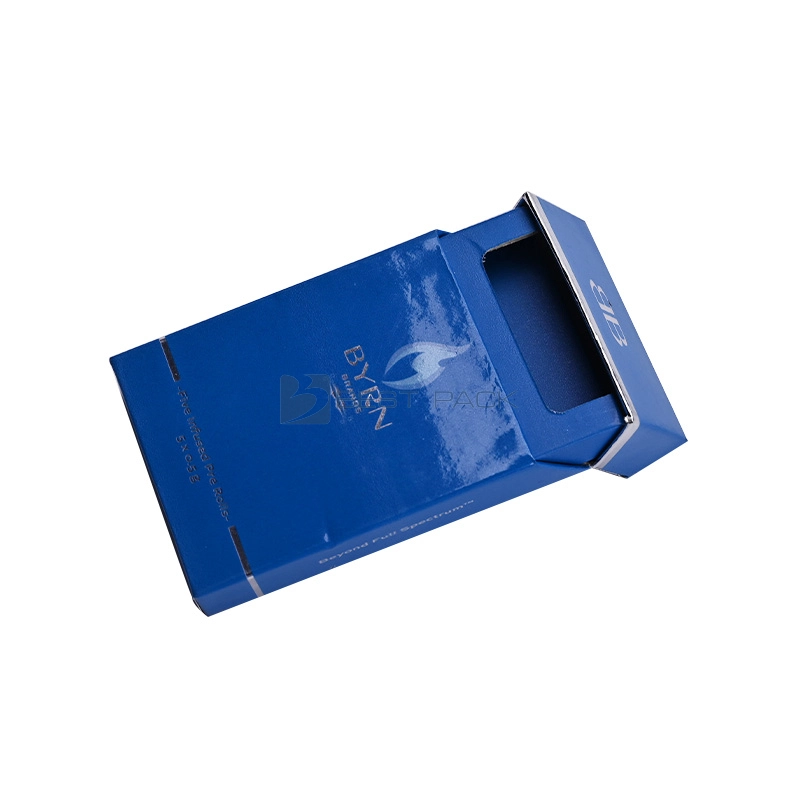

Factory Customized Printing LOGO Pack 10 20 5 Thick Case Pre Roll Non Tobacco Paper Box Cigarette Boxes

Our factory-direct custom pre-roll and cigarette paper boxes are designed for High Quality presentation, protection, and branding. Made with thick, durable paperboard, these boxes are ideal for non-tobacco herbal pre-rolls, cigarettes, or CBD/THC joints. Available in various capacities (5-pack, 10-pack, 20-pack) and fully customizable with your logo and design.

Design elements that boost shelf appeal

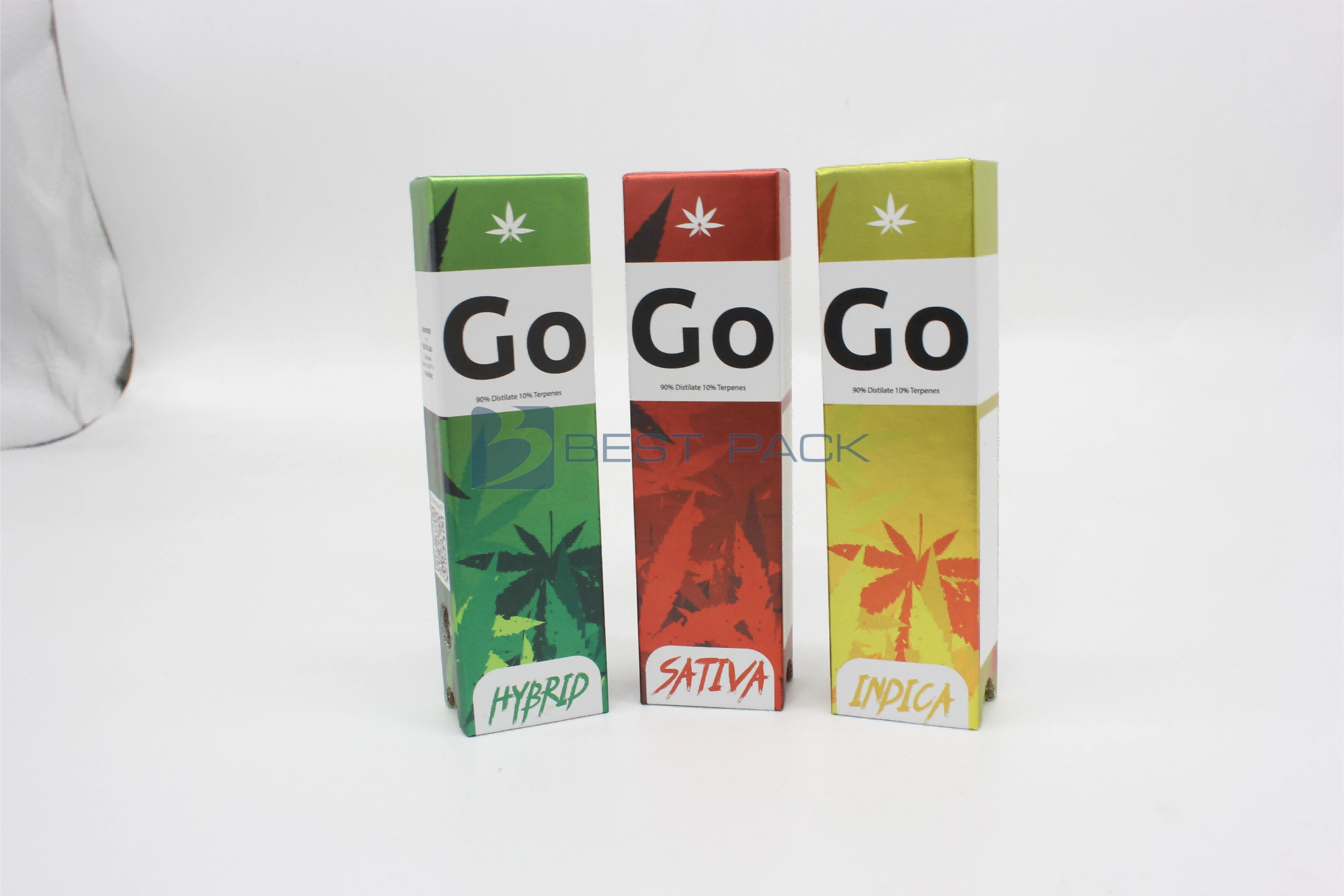

Logo, typography, and hierarchy

Your logo should be instantly legible at small sizes. Create a typographic hierarchy: brand name, product type (e.g., Herbal Pre-Roll), quantity (5/10/20), and key attributes (organic, terpene-rich, indica/sativa). Limit fonts to two complementary families and ensure contrast between text and background for legibility under varied lighting.

Color, finishes, and sensory cues

Color conveys flavor and potency quickly—greens for herbal/CBD, warm ambers for tobacco-like notes, or bold blacks/golds for High Quality lines. Finish choices (matte, gloss, soft-touch, spot UV) amplify tactile perception: a soft-touch matte beckons to touch and signals High Quality, while spot gloss over a logo can create a high-impact focal point without overwhelming the design.

Imagery and iconography

Iconography (flavor symbols, terpene icons, or strength meters) helps communicate key product details at a glance. Avoid overly detailed imagery that clutters small surfaces. Simple line icons and pattern treatments can create a signature look without distracting from regulatory information or warning labels.

Structural, material, and production considerations

Choosing the right board and construction

Thicker paperboard improves rigidity and perceived value. Typical retail cigarette boxes use folding carton stock in the 14-24 pt (300-600 gsm) equivalent range for High Quality products—select weight and caliper based on capacity (5 vs. 20 packs) and protection needs. Consider reinforced edges or tuck-flap designs to reduce deformation during shipping.

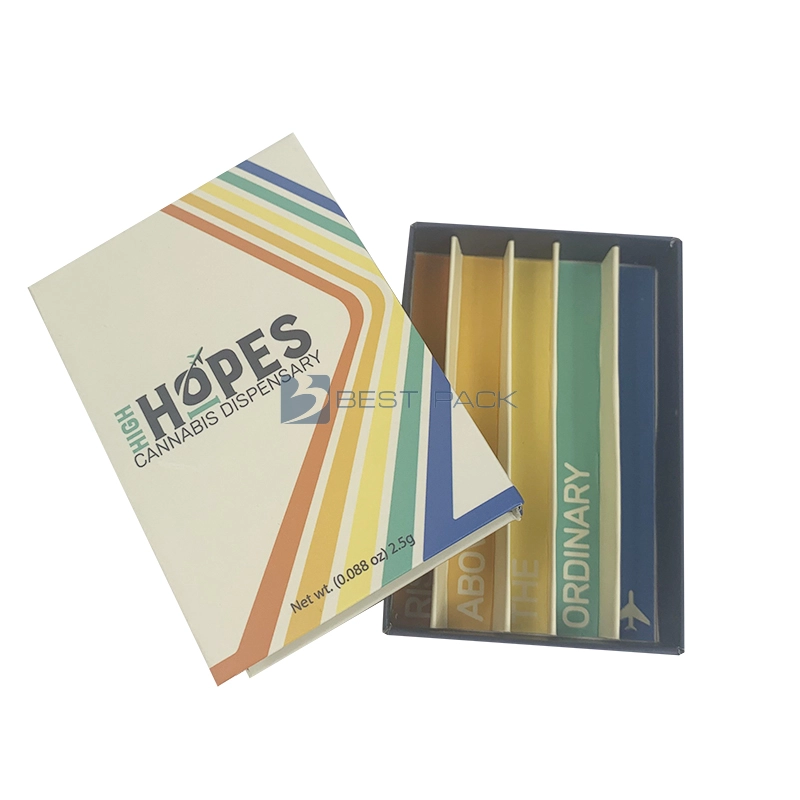

Insert and closure options for protection

Internal trays, molded pulp inserts, or foam-lined channels secure pre-rolls and prevent tip damage. Magnetic closures, tuck ends, or slider mechanisms can enhance user experience—choose based on production complexity and per-unit cost. For child-resistant requirements, specific closure mechanisms and testable features may be necessary (see compliance section).

Production scale, lead times, and cost trade-offs

Factory-direct printing reduces per-unit cost at higher volumes. Expect lead times of 3–6 weeks for custom tooling and printing; faster options are available with digital short runs but at higher unit costs. Work with your manufacturer to balance minimum order quantities (MOQs), die-cutting, and finishing steps (foil stamping, embossing) for the best ROI.

Safety, compliance, and child-resistant packaging

Regulatory landscape and best practices

Even for non-tobacco products like CBD or herbal pre-rolls, many markets require specific labeling and use restrictions. For regulated tobacco products, authorities such as the U.S. Food and Drug Administration (FDA) set packaging and warning requirements; details are available on the FDA website (FDA - Tobacco Products). For child-resistant closures and testing, industry standards such as ISO 8317 provide testing and performance criteria (ISO 8317). The U.S. Consumer Product Safety Commission (CPSC) also publishes guidance and safety data relevant to child safety (CPSC). Incorporate these references early in your design phase to avoid costly redesigns.

Designing for child resistance without sacrificing brand

Child-resistant packaging requires mechanisms tested for effectiveness—typically two-step operations that are easy for adults but difficult for children. Examples include push-and-turn, squeeze-and-slide, or hidden-release closures. Visually, maintain brand cues on the external surface while integrating discreet instructional icons for adult users. For complex closures, work with certified manufacturers who can supply test reports and documentation.

Testing and documentation

Document all materials, closure mechanisms, and test results. Maintain records demonstrating compliance with local laws and standards. If your market requires it, have third-party testing done and keep certificates on file to present to retailers or regulators.

Sustainable choices and lifecycle thinking

Material recyclability and consumer expectations

Consumers increasingly expect eco-friendly packaging. Paperboard is widely recyclable and communicates sustainability when paired with clear labeling. Avoid mixed-material laminates that complicate recycling; choose water-based inks and minimally coated finishes to improve end-of-life handling. Use clear recycling icons and explain materials on the box to reduce disposal friction.

Carbon footprint and packaging optimization

Optimizing pack size reduces shipping volume and carbon intensity. For example, selecting a 20-pack configuration that nests efficiently in master cartons reduces per-unit transportation emissions. Consider bulk shipping options and right-sizing boxes to minimize void fill while keeping product safe.

Communicating sustainability on the pack

Be transparent: include short statements like Made from 90% recycled paperboard or Plastic-free laminate where accurate. Substantiate claims with supplier documentation and use recognized labels or certifications when possible to maintain trust.

Print and finishing techniques that elevate perceived value

Foil, embossing, and tactile finishes

Foil stamping and embossing can create focal points—brand marks or product names that feel High Quality. Spot UV on a matte background draws attention without increasing ink coverage. Soft-touch coatings are pleasant to hold and signal quality that High Quality consumers expect.

Digital vs. offset printing: matching volume and fidelity

Digital printing supports shorter runs and rapid iteration with fewer setup costs, ideal for limited drops or multiple SKU testing. Offset is more cost-effective for large volumes and has consistent color fidelity for PMS spot colors. Choose based on your product demand forecast and color requirements.

Variable data and personalized runs

Use variable printing (batch numbers, limited edition artwork, or customer personalization) to create scarcity and engagement. Digital print enables personalization without tooling changes—perfect for seasonal collections or localized designs.

Practical examples and material comparison

Below is a quick comparison of common material/finish choices for Cigarette Boxes to help select the best option for your product:

| Material / Finish | Benefits | Best for |

|---|---|---|

| Thick Paperboard (350–600 gsm) | Sturdy, High Quality feel, recyclable | 5/10/20-pack High Quality pre-rolls |

| Soft-Touch Coating | Velvety feel, signals luxury | High-end CBD/THC products |

| Spot UV + Matte | Visual contrast, focal shine | Brand logo highlights |

| Foil Stamping + Emboss | Distinctive, tactile High Quality cue | Limited editions, flagship SKUs |

| Recycled Paperboard | Eco-friendly, marketable claim | Sustainable brand lines |

Implementation checklist before mass production

- Confirm final dieline and ensure bleeds and safety zones are correct.

- Approve material and thickness samples with real product fit-testing.

- Validate color proofs (digital or press proofs) and spot colors/PMS.

- Test closure mechanism for durability and, if required, child resistance under local standards (e.g., ISO 8317).

- Collect compliance documentation for labeling/warnings and store for audits.

- Plan inventory and replenishment lead times with your factory to avoid stockouts.

Frequently Asked Questions (FAQ)

Q: What sizes and pack counts are commonly available for custom cigarette boxes?

A: Typical configurations include 5-pack, 10-pack, and 20-pack formats. Factory Customized Printing LOGO Pack 10 20 5 Thick Case Pre Roll Non Tobacco Paper Box Cigarette Boxes supports these capacities and can be tailored for custom counts and dimensions based on your product length and diameter.

Q: Can custom Cigarette Boxes be made child-resistant?

A: Yes. Child-resistant designs can be integrated—common solutions involve two-step closures or tamper-evident features. Compliance often requires third-party testing (e.g., according to ISO 8317) and proper documentation. Work with specialized manufacturers to ensure testable and certifiable solutions.

Q: What is the typical lead time for custom printing and finishing?

A: Lead times vary with order size and complexity. For new tooling (dies, emboss plates) and offset printing, expect 3–6 weeks. Digital short runs can be delivered faster (1–2 weeks) but at higher per-unit cost. Plan for extra time for child-resistant testing and compliance documentation where relevant.

Q: How can I ensure my design remains compliant in different markets?

A: Early research is crucial. Check local regulations for labeling, health warnings, and packaging restrictions. Reference agencies such as the FDA for U.S. regulations (FDA), or international standards like ISO for child-resistant testing (ISO 8317). When in doubt, consult legal counsel or compliance specialists before print approval.

Q: Do eco-friendly materials affect print quality or finishing options?

A: Recycled and uncoated stocks can accept most print processes, though certain high-gloss finishes and deep spot colors may need adjustments. Discuss ink compatibility, finish adhesion, and expected color shifts with your printer. Choosing water-based coatings and recyclable laminates improves sustainability while maintaining good printability.

Next steps — view product or contact us

If you’re ready to elevate Best Pack with High Quality, factory-direct Cigarette Boxes, view the Factory Customized Printing LOGO Pack 10 20 5 Thick Case Pre Roll Non Tobacco Paper Box Cigarette Boxes product page for specifications and ordering. For custom quotes, packaging samples, or child-resistant options, contact our sales team at sales@yourcompany.com or visit the product page: View Product.

References: general packaging and safety context at Wikipedia - Packaging, ISO child-resistant standard ISO 8317, U.S. FDA tobacco product guidance FDA - Tobacco Products, and U.S. Consumer Product Safety Commission resources CPSC.

Compliance Checklist for Pre-Roll Non-Tobacco Paper Packaging

How to Choose Factory Custom Cigarette Boxes with Logo

Evaluating Lock Button Mechanisms in Childproof Paper Tube Boxes

Choosing Suppliers: Key Questions for Custom Packaging Orders

About us

What is the box size and structure?

1. All boxes are customized and all detailed requirements can be provided by clients, we are definitely your OEM service supplier.

2. If you have no idea about the measurements and structure on your products, our professional design team can suggest and solute for you .

How many kinds the printing process you have?

We can make Silk screen printing, offset printing, and also hot silver stamping

FAQs

How do you ensure product quality?

We maintain strict quality control at every stage, from material selection to final production, ensuring high-quality standards.

Can you ship internationally?

Yes, we export worldwide and work with reliable logistics partners for timely delivery.

What types of packaging do you specialize in?

We specialize in electronic packaging, plastic boxes (PVC/PET/PP), paper boxes, paper bags, and custom book printing.

Manufacture Personalized Blank Cigarette Boxes Custom Pre Roll Box Child Resistant Drawer Cardboard Childproof Box

Various Style Design Drawer-Style Packaging Paper Cigarette Boxes Flip Top Closure Pre Rolled Cones Box With Dividers With Child Resistant.

Factory Paperboard Child Resist Childproof Button Box Drawer Craft Packing Box Cigarette Box for Cigarettes

Discover Best Pack’s Factory Paperboard Child-Resistant Childproof Button Box—an ideal cigarette packing box featuring a secure drawer craft packing design. Engineered for safety and style, this childproof button box ensures reliable child resistance while enhancing your cigarette storage experience.

Custom CR Vape Packaging Cardboard Boxes with Child-Resistant Design

CR custom vape packaging cardboard boxes are specially designed child-resistant packaging solutions crafted to ensure safety, protection, and premium presentation for vape products. Made from sturdy cardboard materials, these boxes balance regulatory compliance with brand aesthetics.

Best pack

Best pack

Best pack