Heat-seal vs adhesive: sealing methods for pre rolls

- Heat-seal vs Adhesive: Choosing the Right Sealing Method for Pre Roll Packaging

- Why sealing method matters for pre roll packaging

- Overview of heat-seal technology for pre roll packaging (pre roll packaging)

- Overview of adhesive sealing for pre roll packaging (pre roll packaging)

- Direct product fit: Factory Customized Printing LOGO Pack 10 20 5 Thick Case Pre Roll Non Tobacco Paper Box Cigarette Boxes

- Performance comparison: heat-seal vs adhesive (pre roll packaging)

- Regulatory and child-resistance considerations for pre roll packaging

- Sustainability and recyclability: what to expect

- Branding, print quality, and unboxing experience (pre roll packaging)

- Cost analysis and production scale guidance

- Practical recommendations: selecting the right seal for your product

- Case study snapshot: applying choices to the Factory Customized Printing LOGO Pack 10 20 5 Thick Case Pre Roll Non Tobacco Paper Box Cigarette Boxes

- Installation and supplier checklist before ordering pre roll packaging

- Brand advantages: Why choose our Factory Customized Printing LOGO Pack 10 20 5 Thick Case Pre Roll Non Tobacco Paper Box Cigarette Boxes

- FAQ — Frequently Asked Questions (related to pre roll packaging and sealing)

- Q1: Which sealing method preserves terpenes better — heat-seal or adhesive?

- Q2: Can heat-seal coatings make my box non-recyclable?

- Q3: Are adhesive-sealed boxes compatible with child-resistant packaging?

- Q4: What is the minimum order quantity for customization of the Factory Customized Printing LOGO Pack 10 20 5 Thick Case Pre Roll Non Tobacco Paper Box Cigarette Boxes?

- Q5: How do I test which sealing method suits my production line?

- Contact us / See product — call to action

- References and sources

Heat-seal vs Adhesive: Choosing the Right Sealing Method for Pre Roll Packaging

Why sealing method matters for pre roll packaging

Sealing is more than a finishing step — it protects product freshness, preserves terpene profiles for herbal pre-rolls, ensures tamper evidence, and supports Best Pack presentation. For businesses selling pre roll products, packaging choices directly impact shelf life, regulatory compliance, and customer experience. Among common sealing methods, heat-seal and adhesive-based seals are widely used. Understanding their strengths and trade-offs helps you choose the optimal pre roll packaging solution, such as the Factory Customized Printing LOGO Pack 10 20 5 Thick Case Pre Roll Non Tobacco Paper Box Cigarette Boxes.

Overview of heat-seal technology for pre roll packaging (pre roll packaging)

Heat-seal uses heat and pressure to activate a thermoplastic coating (often on film or coated paperboard) that bonds when cooled. For pre roll packaging, manufacturers can apply a heat-seal coating to the box interior or use a heat-sealable closure flap. Typical attributes of heat-seal closures:

- Provides strong, uniform seals with good moisture and aroma barrier when paired with appropriate substrates.

- Produces a tamper-evident bond when designed as a single-use seal (common for freshness assurance).

- Compatible with automated high-speed equipment for scalable packing lines.

- Works well with coated paperboard used in High Quality boxes like those used in custom pre-roll packs.

Overview of adhesive sealing for pre roll packaging (pre roll packaging)

Adhesive sealing relies on glues — hot-melt, pressure-sensitive, or water-based — to bond flaps or tabs. Adhesive seals are versatile and common in many retail-ready packaging formats. Their characteristics include:

- Flexible application across a wide range of substrates including thick paperboard used in High Quality cigarette-style boxes.

- Options for resealable adhesives (reclosable flaps) or permanent adhesives for tamper evidence.

- Lower upfront tooling costs compared to some heat-seal setups; simple to implement for short runs and custom print jobs.

- Potential sensitivity to contamination or low surface energy substrates requiring primer/coating for reliable adhesion.

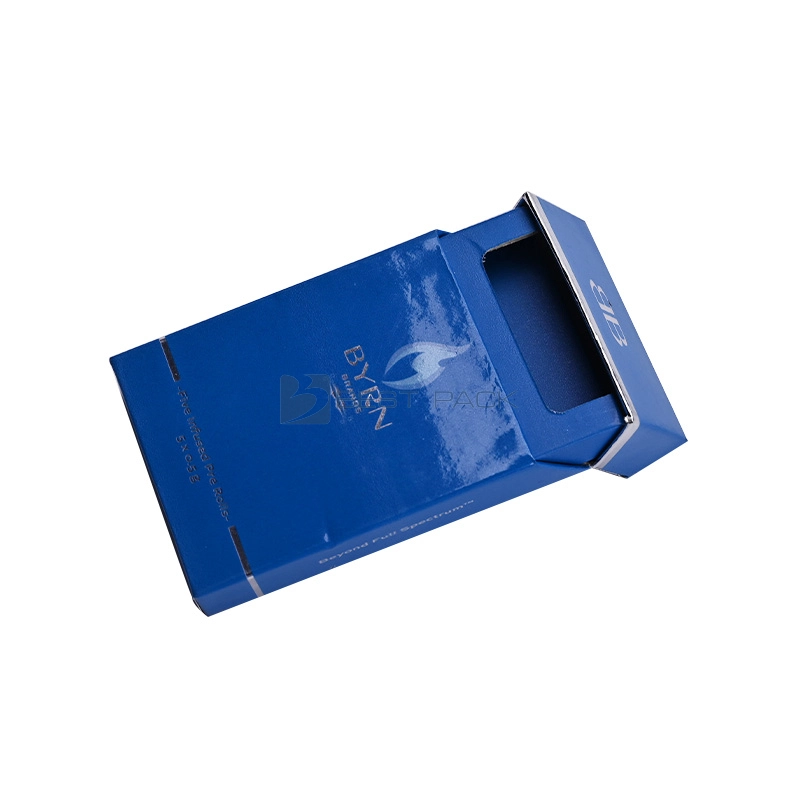

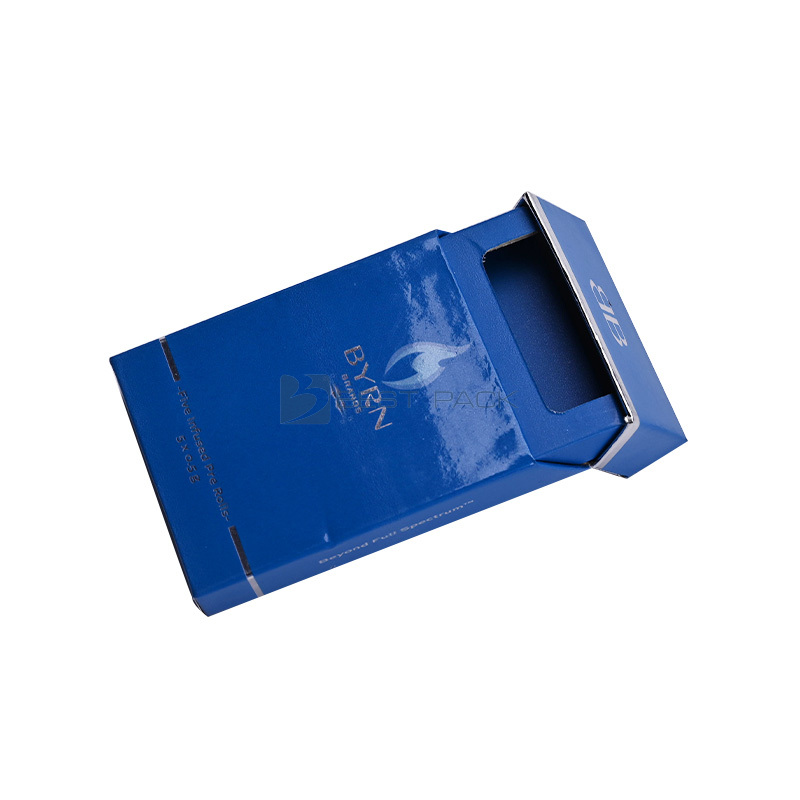

Direct product fit: Factory Customized Printing LOGO Pack 10 20 5 Thick Case Pre Roll Non Tobacco Paper Box Cigarette Boxes

Product highlight:

Our factory-direct custom pre-roll and cigarette paper boxes are designed for High Quality presentation, protection, and branding. Made with thick, durable paperboard, these boxes are ideal for non-tobacco herbal pre-rolls, cigarettes, or CBD/THC joints. Available in various capacities (5-pack, 10-pack, 20-pack) and fully customizable with your logo and design.

These thick case-style boxes are optimized for printing and can be supplied with either adhesive or heat-seal-compatible coatings depending on required barrier properties, tamper evidence, and production workflow.

Performance comparison: heat-seal vs adhesive (pre roll packaging)

Below is a practical comparison to help you match sealing technique to priorities such as freshness, speed, cost, and branding.

| Criteria | Heat-seal | Adhesive |

|---|---|---|

| Freshness & aroma retention | Excellent with proper coating; creates continuous barrier when sealed | Good when seals fully contact; may allow slow permeation if adhesive or substrate not optimized |

| Tamper evidence | High — single-use heat seals are clear tamper indicators | Variable — permanent adhesives provide tamper evidence; resealable adhesives do not |

| Production speed & automation | Very high on automated lines; requires heat-seal equipment | High and flexible; adhesives work with many packing setups |

| Cost | Higher initial equipment/coating costs; lower per-unit for large volumes | Lower setup cost; per-unit adhesive cost varies |

| Compatibility with thick paperboard boxes | Requires compatible heat-activated coating; can be applied to thick boards | Highly compatible; adhesives bond well to uncoated or coated boards with right glue |

| Sustainability / recyclability | Depends on coating polymer; some coatings complicate paper recycling | Water-based adhesives can be more easily deinked and compatible with recycling |

Sources: industry packaging surveys and technical notes from packaging associations (see citations below).

Regulatory and child-resistance considerations for pre roll packaging

Many regions require child-resistant packaging for cannabis-derived products or certain nicotine products. Whether you choose heat-seal or adhesive, the sealing method must integrate with child-resistant closure systems and meet local standards for testing and certification. Key considerations:

- Child-resistant compliance is about overall closure design, not just seal type — ensure the chosen method is compatible with certified child-resistant hinges, push-and-turn mechanisms, or locking slides.

- Tamper-evident heat seals are complementary to child-resistant designs but do not themselves guarantee child resistance.

- Work with packaging manufacturers experienced in CR testing and documentation for your market (e.g., ASTM or local equivalents).

Sustainability and recyclability: what to expect

Brand owners increasingly demand recyclable or compostable pre roll packaging. The sealing method affects end-of-life processing:

- Heat-seal coatings often use polyolefin or PVdC layers which can hinder paper recycling unless specially formulated; some water-based, heat-activated coatings are more recycling-friendly.

- Water-based adhesives with low solids and easy de-inking tend to be more compatible with existing paper recycling streams.

- Work with suppliers to obtain material declarations (e.g., recyclability certifications) and perform local recycling trials where possible.

Branding, print quality, and unboxing experience (pre roll packaging)

For High Quality products, the tactile and visual quality of packaging matters as much as functional sealing. Thick paperboard boxes like Factory Customized Printing LOGO Pack 10 20 5 Thick Case Pre Roll Non Tobacco Paper Box Cigarette Boxes allow high-fidelity printing, embossing, and foil stamping. Consider:

- Heat-seal coatings can dull or alter surface gloss — specify the finish to retain your intended look.

- Adhesive flaps allow complex structural designs (drawer boxes, tuck-flaps) enhancing unboxing.

- Include clear labeling of product type, potency (if applicable), and tamper/child-resistance information where legally required.

Cost analysis and production scale guidance

Choosing between heat-seal and adhesive often comes down to volume and unit economics:

- Low-to-moderate runs (custom branding, variable SKUs): adhesive solutions frequently reduce setup fees and minimum order quantities.

- High-volume production: heat-seal can lower per-unit costs and deliver faster line speeds, offsetting higher initial tooling/coating expenses.

- Factory-direct packaging like the Factory Customized Printing LOGO Pack 10 20 5 Thick Case Pre Roll Non Tobacco Paper Box Cigarette Boxes can often negotiate better per-unit pricing for larger runs and provide options for both sealing methods.

Practical recommendations: selecting the right seal for your product

Decision flow to choose sealing method:

- Define priorities: freshness/tamper evidence, child resistance, sustainability, or cost.

- Assess expected volumes and SKU variability.

- Evaluate substrate: thick paperboard for High Quality boxes vs thin cartons for economy packs.

- Request material datasheets and recycling statements from your supplier.

- Pilot test: run sealing trials with actual product to verify aroma retention, child resistance integration, and production throughput.

Example recommendation: For a High Quality, branded 10-pack pre roll box that prioritizes freshness and a tamper-evident presentation, a heat-seal coated interior combined with a precision tuck or tab gives the best user experience. For artisan or low-volume brands offering multiple custom designs, an adhesive flap with a secure permanent glue provides flexibility and lower upfront costs.

Case study snapshot: applying choices to the Factory Customized Printing LOGO Pack 10 20 5 Thick Case Pre Roll Non Tobacco Paper Box Cigarette Boxes

Scenario: a CBD brand launching a 5-pack and 20-pack SKU. Goals: High Quality look, terpene preservation, and reliable tamper evidence.

Recommended approach:

- Use thick paperboard with an interior heat-sealable coating for improved aroma retention.

- Design the closure to incorporate a one-time heat-seal strip for tamper evidence and a perforated pull tab to open.

- Apply exterior varnish and spot UV for aesthetics; confirm finish compatibility with the heat-seal process.

- For a secondary economy line, use adhesive sealing with a permanent glue to reduce costs while retaining adequate protection.

Installation and supplier checklist before ordering pre roll packaging

Before placing an order, verify these items with your packaging supplier:

- Sample boxes with the intended sealing method applied (real product inside).

- Material Safety Data Sheets and recyclability statements for coatings and adhesives.

- Child-resistant testing and certification options if required in your market.

- Lead times, minimum order quantities, and per-unit pricing for different sealing options.

- Quality control and print-proof approvals integrated into production workflow.

Brand advantages: Why choose our Factory Customized Printing LOGO Pack 10 20 5 Thick Case Pre Roll Non Tobacco Paper Box Cigarette Boxes

Our factory-direct solution brings these advantages to brands focused on pre roll packaging:

- Customization: full-color printing, logo options, and structural customization for 5/10/20 pack configurations.

- Material expertise: thick durable paperboard optimized for either heat-seal coatings or adhesive-compatible finishes.

- Cost efficiency: factory-direct pricing and scalable production runs to match startup or enterprise needs.

- Compliance support: assistance with child-resistant integration, tamper-evident finishes, and labeling guidance.

- Sustainability consulting: options for more recyclable adhesives and coatings to support circular packaging goals.

FAQ — Frequently Asked Questions (related to pre roll packaging and sealing)

Q1: Which sealing method preserves terpenes better — heat-seal or adhesive?

A1: Heat-seal typically offers a more continuous barrier when applied correctly and therefore better short-term aroma and terpene preservation. Adhesive seals can be effective but depend on full contact and substrate compatibility.

Q2: Can heat-seal coatings make my box non-recyclable?

A2: Some traditional heat-seal polymers complicate paper recycling. However, suppliers now offer recyclable-compatible coatings. Request material declarations and conduct local recycling trials.

Q3: Are adhesive-sealed boxes compatible with child-resistant packaging?

A3: Yes — adhesives can be used in child-resistant designs, but the overall closure mechanism must meet required testing standards. Adhesive alone does not ensure child resistance.

Q4: What is the minimum order quantity for customization of the Factory Customized Printing LOGO Pack 10 20 5 Thick Case Pre Roll Non Tobacco Paper Box Cigarette Boxes?

A4: MOQ varies by finish and sealing options; factory-direct relationships typically offer competitive MOQs. Contact our sales team for specific quotes and lead times.

Q5: How do I test which sealing method suits my production line?

A5: Request sample packs sealed by both methods, run them through your fill and seal process, and perform short-term freshness and tamper tests. Our technical team can support pilot trials.

Contact us / See product — call to action

After deciding on the best sealing methods for pre-rolls, consider the ROI of custom printed pre-roll packaging for small brands. Well-designed packaging not only creates a positive impression but can also lead to significant returns by helping your product stand out in a crowded market.If you need expert guidance or product samples, contact our packaging specialists today to discuss sealing options and order samples of Factory Customized Printing LOGO Pack 10 20 5 Thick Case Pre Roll Non Tobacco Paper Box Cigarette Boxes. We provide mockups, material datasheets, and pilot runs so you can evaluate heat-seal and adhesive performance with your actual product.

Email: sales@example.com | Phone: +1-800-XXX-XXXX | Request a sample: contact form on our product page

References and sources

- Packaging World — technical articles and industry trends on sealing technologies and coatings.

- Smithers — market reports and technical notes on packaging barrier films and seal performance.

- Flexible Packaging Association — guidance on adhesives, coatings, and recyclability considerations.

- Local regulatory bodies and standards organizations for child-resistant packaging and labeling requirements (consult applicable regional authorities for certification requirements).

Note: For precise regulatory standards, testing protocols, and recyclability certification in your target markets, consult local authorities or accredited testing labs.

Sustainable Options for Child-Resistant Pre-Roll Packaging

MOQ and Lead Time Strategies for Custom Cigarette Boxes

Top pre roll cigarette box packaging Manufacturers and Suppliers in China

Quality Checks Before Ordering Factory Custom Boxes

About us

How much of your samples cost ?

1. If samples are without printing, we can make free samples as per your box size or structure;

2. If samples are silk printing, normally USD 25 per color,depending on your logo colors;

3. If samples are offset printing, need USD 180 as offset printing mold cost is high.

When can I get the quotation?

1. The quotation will be offered within 24 hours after getting your detailed request.

2. If you get the urgent inquiry, please call us or mark it via E-mail, then we could make it into priority list.

How many kinds the printing process you have?

We can make Silk screen printing, offset printing, and also hot silver stamping

FAQs

What types of packaging do you specialize in?

We specialize in electronic packaging, plastic boxes (PVC/PET/PP), paper boxes, paper bags, and custom book printing.

What services do you provide?

We offer one-stop packaging solutions, including design, printing, and handicraft processing for electronic boxes, plastic boxes, paper boxes, paper bags, and book printing.

Custom CR Vape Packaging Cardboard Boxes with Child-Resistant Design

CR custom vape packaging cardboard boxes are specially designed child-resistant packaging solutions crafted to ensure safety, protection, and premium presentation for vape products. Made from sturdy cardboard materials, these boxes balance regulatory compliance with brand aesthetics.

Custom Luxury Pre Roll Packaging Boxes with Child-Resistant Paper Tray

Our luxury pre-roll packaging boxes are designed to combine elegant presentation with top-tier safety features. Featuring a child-resistant mechanism and a custom paper tray insert, these boxes ensure secure storage while delivering a premium unboxing experience for pre-roll products.

Custom Child-Lock Pre-Roll 5-Pack Packaging Boxes

Our custom child-lock packaging for pre-roll 5-packs is purposefully engineered to combine premium design with certified safety. This packaging solution ensures that five pre-rolls are securely housed in a compact, stylish, and child-resistant format—ideal for compliant cannabis brands that value both form and function.

Best pack

Best pack

Best pack