ROI of custom printed pre roll packaging for small brands

- Why small brands should measure the ROI of pre roll packaging

- Product highlight: Factory Customized Printing LOGO Pack 10 20 5 Thick Case Pre Roll Non Tobacco Paper Box Cigarette Boxes

- How pre roll packaging drives measurable business outcomes (and which metrics to track)

- Key cost components for custom pre roll packaging

- Typical ROI levers for pre roll packaging

- Illustrative ROI scenarios (small brand modeling)

- How to choose specs to maximize ROI

- Regulatory & product-protection ROI: why compliance matters economically

- Manufacturing channels: factory-direct vs middlemen and what it means for ROI

- Measuring success: A/B testing packaging and tracking meaningful KPIs

- Brand advantages of choosing Factory Customized Printing product

- Practical checklist before ordering custom pre roll packaging

- FAQ — Common questions about ROI and pre roll packaging

- Q: How quickly can I expect packaging to pay for itself?

- Q: Is custom printing worth it versus generic plain boxes?

- Q: How do child-resistant features affect cost and ROI?

- Q: What order quantity should new brands start with?

- Q: Can you print different SKUs (5/10/20) with different artwork in the same run?

- Final takeaways and next steps

- Contact us / View product

- Sources & further reading

Why small brands should measure the ROI of pre roll packaging

For small cannabis, CBD, or herbal brands, every dollar spent on packaging must prove its value. Pre roll packaging is not just a container — it is a product touchpoint that protects fragile goods, meets regulatory and child-resistant needs, and communicates brand quality. Understanding the return on investment (ROI) for pre roll packaging helps founders prioritize spend, choose the right supplier, and scale sustainably. To maximize ROI from custom printed pre-roll packaging, ensure that you follow an artwork preparation guide for pre-roll logo printing. Proper preparation is crucial to creating professional designs that reproduce well on packaging and enhance your brand's identity.

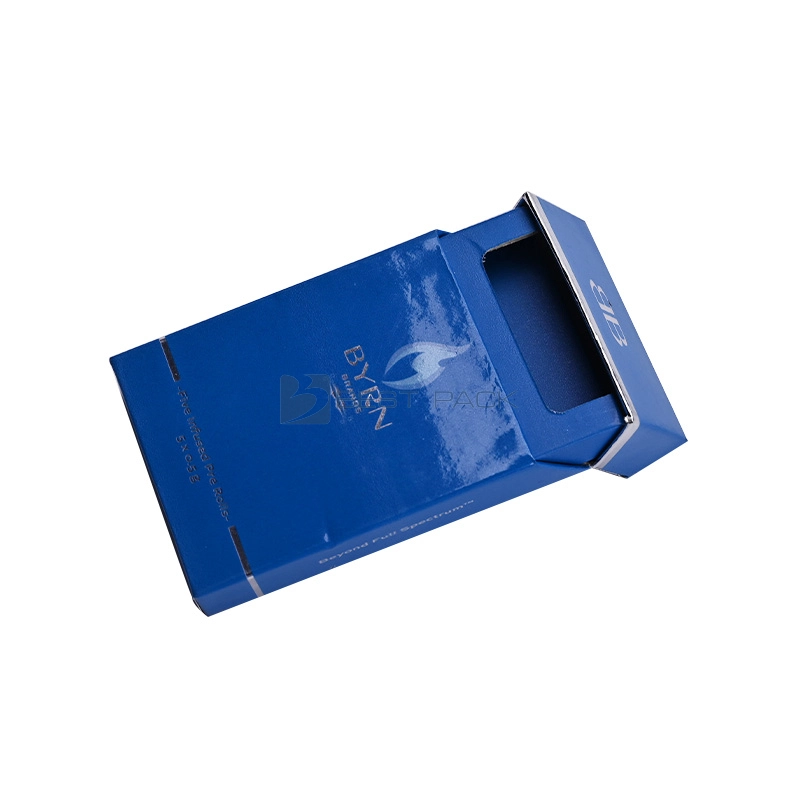

Product highlight: Factory Customized Printing LOGO Pack 10 20 5 Thick Case Pre Roll Non Tobacco Paper Box Cigarette Boxes

Our factory-direct custom pre-roll and cigarette paper boxes are designed for High Quality presentation, protection, and branding. Made with thick, durable paperboard, these boxes are ideal for non-tobacco herbal pre-rolls, cigarettes, or CBD/THC joints. Available in various capacities (5-pack, 10-pack, 20-pack) and fully customizable with your logo and design.

How pre roll packaging drives measurable business outcomes (and which metrics to track)

Packaging affects multiple levers of business performance. When evaluating ROI, track these core metrics:

- Unit cost of packaging (material + printing + assembly + shipping)

- Per-unit gross margin (price minus product cost excluding packaging)

- Lift in price tolerance (ability to charge High Quality based on packaging)

- Sales conversion and repeat purchase rate

- Spoilage, returns, and product loss reduction due to protection

- Compliance costs avoided (fines, unsaleable inventory, rework)

By modeling these items, small brands convert qualitative benefits (brand perception) into quantitative ROI figures.

Key cost components for custom pre roll packaging

Understanding the cost structure clarifies where savings or investments matter most:

- Materials: paperboard thickness, coatings, tamper/child-resistant inserts.

- Printing & finishing: CMYK, spot colors, embossing, varnish, foil stamping.

- Tooling & setup: die lines, printing plates, minimum order quantities (MOQs).

- Logistics: flat-packed vs assembled, shipping weight and volume.

- Compliance & testing: child-resistant certification or special labeling.

Factory channels (like our Factory Customized Printing product) often reduce per-unit costs by eliminating middlemen and allowing tighter control of specs.

Typical ROI levers for pre roll packaging

Small brands usually realize ROI through four primary pathways:

- Increased sell-through rate and conversion (better shelf/online performance).

- High Quality pricing ability (perceived quality and differentiation).

- Reduced product damage and returns (lower COGS waste).

- Lower per-unit cost at scale (volume discounts and optimized specs).

Combining even modest improvements across these areas compounds ROI — e.g., a 10% conversion lift plus a 5% reduction in returns and a small High Quality creates outsized margin improvement over time.

Illustrative ROI scenarios (small brand modeling)

The table below shows three modeled scenarios to demonstrate how packaging investments pay back. These are illustrative examples using conservative assumptions; use your own numbers for precise planning.

| Metric / Scenario | Low Volume (500 units/mo) | Mid Volume (2,000 units/mo) | Higher Volume (10,000 units/mo) |

|---|---|---|---|

| Packaging unit cost (custom printed) | $0.80 | $0.55 | $0.30 |

| Average retail price per pack | $12.00 | $12.00 | $12.00 |

| Estimated sales uplift after packaging refresh | +6% | +9% | +12% |

| Monthly incremental revenue | $360 | $2,160 | $14,400 |

| Monthly incremental gross (assume 40% gross margin) | $144 | $864 | $5,760 |

| Added packaging cost vs generic box (assume delta $0.30/unit) | $150 | $600 | $3,000 |

| Net monthly benefit (incremental gross - added packaging cost) | -$6 (payback ~ slightly negative at current assumptions) | $264 (payback within months) | $2,760 (clear, rapid payback) |

Notes: the assumptions above are illustrative. Packaging unit costs vary by specifications and MOQs; real uplift depends on category, placement, and marketing synergy. For many small brands, ROI improves significantly as order volume increases and as packaging is combined with point-of-sale or online imagery that reinforces perceived value.

How to choose specs to maximize ROI

Not every High Quality feature contributes equally to ROI. Focus first on features that protect shelf integrity and meaningfully affect perception:

- Sturdy paperboard (prevents crushing and product loss).

- Clear, consistent branding (logo, color, typography) to build recognition.

- Functional formats (5/10/20 pack sizes matched to consumer behavior).

- Child-resistant or tamper-evident options where required — avoids costly compliance failures.

Avoid over-engineering finishes (heavy foiling, embossing) until you validate the price elasticity with customers. Use your initial runs to test High Quality increments and measure lift.

Regulatory & product-protection ROI: why compliance matters economically

In regulated markets, non-compliant packaging can lead to product seizures, fines, and costly rework. Choosing packaging that meets local labeling and child-safety standards is an insurance policy that preserves revenue and brand reputation. Even if the compliance feature increases unit cost slightly, the avoided legal and inventory costs often justify the expense.

Manufacturing channels: factory-direct vs middlemen and what it means for ROI

Factory-direct manufacturing like the Factory Customized Printing LOGO Pack 10 20 5 Thick Case Pre Roll Non Tobacco Paper Box Cigarette Boxes product offers advantages:

- Lower per-unit costs at higher volumes (fewer intermediaries).

- Better control of print color and dieline accuracy (fewer surprises).

- Ability to negotiate tooling and MOQ trade-offs for phased rollouts.

For small brands, a hybrid approach can work: start with a smaller MOQ to validate the design and then scale with factory-direct runs to capture unit cost reductions once demand is proven.

Measuring success: A/B testing packaging and tracking meaningful KPIs

Implement simple tests before committing large budgets:

- A/B test two designs in a single retailer or across two similar digital ads.

- Track conversion rate, average order value, and repeat purchase rate by SKU.

- Monitor spoilage and returns for the SKU with upgraded packaging vs control.

Keeping tests short (4–8 weeks) and focused reduces risk and delivers actionable ROI insights quickly.

Brand advantages of choosing Factory Customized Printing product

When you select the Factory Customized Printing LOGO Pack 10 20 5 Thick Case Pre Roll boxes you gain concrete brand advantages:

- Consistent High Quality appearance: thick paperboard and precise printing lift perceived value and allow High Quality pricing.

- Flexible pack sizes (5/10/20) match consumer preferences and support tiered pricing and promotions.

- Factory-direct production reduces lead time variability and lowers long-term costs.

- Custom printing ensures brand recognition across retail and online channels, supporting faster shelf recall and loyalty.

Those advantages translate to higher conversion, better repeat purchase rates, and lower damage-related costs — the primary drivers of ROI.

Practical checklist before ordering custom pre roll packaging

Use this checklist to reduce surprises and protect ROI:

- Confirm MOQs and get per-unit quotes at multiple volume points.

- Order a pre-production sample or a short pilot run.

- Validate dielines with actual tubes/joints to ensure perfect fit.

- Specify necessary regulatory labeling and child-safety features.

- Plan photography and digital assets to match new packaging for e-commerce.

FAQ — Common questions about ROI and pre roll packaging

Q: How quickly can I expect packaging to pay for itself?

A: Payback depends on volume and uplift. In many small-brand cases, mid-volume runs (≈2,000 units/month) with measurable conversion lifts can show payback in a few months. High-volume runs show faster ROI due to lower per-unit costs.

Q: Is custom printing worth it versus generic plain boxes?

A: Yes when: (1) you’re trying to differentiate on-shelf or online; (2) you can charge a High Quality or increase sell-through; (3) you plan to scale. If you’re still validating product-market fit, a low-cost printed sleeve or label can be an interim step.

Q: How do child-resistant features affect cost and ROI?

A: Child-resistant inserts or designs increase unit cost but reduce legal and compliance risk. In regulated jurisdictions, their inclusion is often mandatory — the avoided fines and unsaleable inventory usually justify the expense.

Q: What order quantity should new brands start with?

A: Start with the smallest MOQ that allows you to produce a representative sample batch (often a few hundred to a few thousand units). Use that run to test market response, then scale to larger factory-direct orders for lower unit costs.

Q: Can you print different SKUs (5/10/20) with different artwork in the same run?

A: Yes, many factories support multiple SKUs within a single production schedule, but mixing SKUs can increase setup complexity and cost. Discuss SKU splits with your supplier to optimize tooling and run efficiency.

Final takeaways and next steps

Custom printed pre roll packaging is a strategic lever for small brands. When specified intelligently — focusing on protection, fit, and brand clarity — it can increase conversion, justify High Quality pricing, reduce spoilage, and scale profitably as volumes grow. Factory-direct products like the Factory Customized Printing LOGO Pack 10 20 5 Thick Case Pre Roll Non Tobacco Paper Box Cigarette Boxes give small brands a path to high-quality presentation at competitive cost, making packaging an investment rather than an expense.

Contact us / View product

Ready to evaluate custom pre-roll packaging or request samples? Contact our sales team to get a tailored quote, MOQ options, and pre-production sample timelines. View product specs and request a sample: Factory Customized Printing LOGO Pack 10 20 5 Thick Case Pre Roll Non Tobacco Paper Box Cigarette Boxes.

Sources & further reading

- Grand View Research — Cannabis Packaging Market Analysis (industry growth drivers and market trends).

- Statista — Consumer research on packaging influence in CPG purchases.

- Packaging World / Packaging Strategies — articles on cost drivers for custom printed boxes and printing/finishing impacts.

- Industry case studies on packaging A/B testing and conversion uplift (various packaging industry reports and manufacturer whitepapers).

Packaging Innovations: Smart Cigarette Box Tech in 2026

Heat-seal vs adhesive: sealing methods for pre rolls

Reducing Costs with Efficient Custom Cigarette Box Sourcing

How to create child-resistant prototypes for cigarette boxes

About us

When can I get the quotation?

1. The quotation will be offered within 24 hours after getting your detailed request.

2. If you get the urgent inquiry, please call us or mark it via E-mail, then we could make it into priority list.

What is the box size and structure?

1. All boxes are customized and all detailed requirements can be provided by clients, we are definitely your OEM service supplier.

2. If you have no idea about the measurements and structure on your products, our professional design team can suggest and solute for you .

Leading time for samples production?

Normally we need 3-7 days for samples making, 10-12 days to complete your orders,but the delivery time more depends on the order QTY.

The process of your packaging box production?

1. Make knife mold as per box size and structure

2. order material as per mold

3. make printing on material if need to print

4. suppress and cut material

5. Makeboxes with glue edge in machine

6. Package boxes into cartons

FAQs

What services do you provide?

We offer one-stop packaging solutions, including design, printing, and handicraft processing for electronic boxes, plastic boxes, paper boxes, paper bags, and book printing.

Custom CR Vape Packaging Cardboard Boxes with Child-Resistant Design

CR custom vape packaging cardboard boxes are specially designed child-resistant packaging solutions crafted to ensure safety, protection, and premium presentation for vape products. Made from sturdy cardboard materials, these boxes balance regulatory compliance with brand aesthetics.

Custom Luxury Pre Roll Packaging Boxes with Child-Resistant Paper Tray

Our luxury pre-roll packaging boxes are designed to combine elegant presentation with top-tier safety features. Featuring a child-resistant mechanism and a custom paper tray insert, these boxes ensure secure storage while delivering a premium unboxing experience for pre-roll products.

Custom Child-Lock Pre-Roll 5-Pack Packaging Boxes

Our custom child-lock packaging for pre-roll 5-packs is purposefully engineered to combine premium design with certified safety. This packaging solution ensures that five pre-rolls are securely housed in a compact, stylish, and child-resistant format—ideal for compliant cannabis brands that value both form and function.

Best pack

Best pack

Best pack