Top Logo Printing Techniques for Cigarette Packaging

- Choosing the Right Printing Technique for Cigarette Boxes

- Understanding the end use and brand goals

- Substrate and coating considerations

- Speed, volume and cost trade-offs

- Top Logo Printing Techniques — Pros, Cons, and Use Cases

- Offset Lithography

- Digital Printing

- Spot UV and Varnishes

- Special Effects: Luxury Finishes That Elevate Best Pack

- Hot foil stamping and cold foil

- Embossing and debossing

- Soft-touch coatings and textured finishes

- Durability, Compliance and Child-Resistant Packaging Considerations

- Regulatory and safety requirements

- How printing choices affect child-resistant designs

- Durability testing and real-world performance

- Practical Comparison: Which Technique Fits Your Needs?

- Workflow Recommendations: From Artwork to Finished Cigarette Boxes

- Preparing artwork for printing

- Prototyping and pre-production checks

- Supply chain and sustainability

- FAQs — Frequently Asked Questions

- Q: Which printing technique is best for small-batch branded cigarette boxes?

- Q: Can I combine techniques (e.g., digital + foil) on the same box?

- Q: How do I ensure my printed boxes remain child-resistant?

- Q: Are metallic finishes recyclable?

- Q: What are common pitfalls that degrade logo quality?

- Next Steps and How to Order

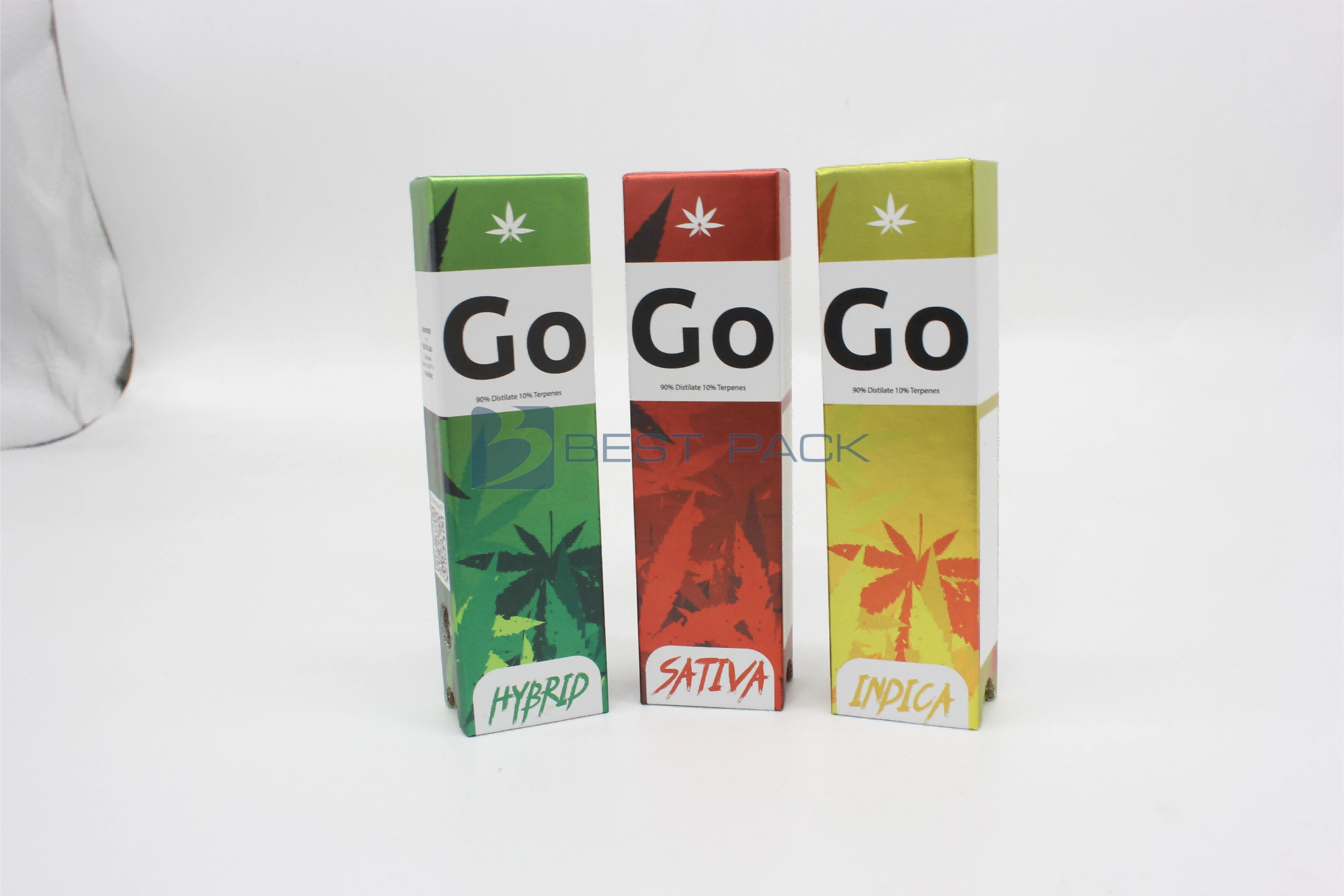

Optimize brand visibility and product protection with proven logo-printing techniques tailored for cigarette packaging and pre-roll boxes. This guide explains how to select the right printing process for your Factory Customized Printing LOGO Pack 10 20 5 Thick Case Pre Roll Non Tobacco Paper Box Cigarette Boxes, balancing print quality, durability, cost, and regulatory / child-resistant considerations to meet market expectations and boost shelf impact.

Product:

Our factory-direct custom pre-roll and cigarette paper boxes are designed for High Quality presentation, protection, and branding. Made with thick, durable paperboard, these boxes are ideal for non-tobacco herbal pre-rolls, cigarettes, or CBD/THC joints. Available in various capacities (5-pack, 10-pack, 20-pack) and fully customizable with your logo and design.

Choosing the Right Printing Technique for Cigarette Boxes

Understanding the end use and brand goals

Before selecting a printing method, clarify how the cigarette boxes will be used: retail shelf display, wholesale packaging, subscription fulfillment, or promotional gift packs. High-resolution photographic artwork and metallic finishes demand different techniques than simple spot-color logos. Your Factory Customized Printing LOGO Pack 10 20 5 Thick Case Pre Roll Non Tobacco Paper Box Cigarette Boxes require a balance of visual impact and tactile quality to stand out while protecting fragile pre-rolls.

Substrate and coating considerations

Thick paperboard used for pre-roll boxes accepts a variety of print processes, but surface coating (matte, gloss, soft-touch) affects final appearance and durability. Uncoated paper gives a natural feel and is easy to write on, while coated boards support high-fidelity color and special effects (foiling, UV). If child-resistant features are required, ensure coatings don't interfere with mechanical closures or tactile grips.

Speed, volume and cost trade-offs

Consider run length: digital printing is best for short runs and variable data (e.g., sequential numbering or batch codes). Offset lithography becomes cost-effective at medium-to-large volumes with consistent artwork. Gravure and flexo suit very large continuous runs. For most customized cigarette boxes (5/10/20 pack), offset or high-end digital printing usually offers the best mix of quality and cost.

Top Logo Printing Techniques — Pros, Cons, and Use Cases

Offset Lithography

Offset lithography provides crisp, consistent color reproduction and is ideal for medium to large runs. It's excellent for full-bleed designs on Cigarette Boxes and allows tight color control (CMYK + spot colors). Offset supports varnishes and coatings to improve scuff resistance.

Digital Printing

Digital printing offers quick turnaround and economical short runs. It supports variable data and quick proofing. For brands testing new artwork on Factory Customized Printing LOGO Pack 10 20 5 Thick Case Pre Roll Non Tobacco Paper Box Cigarette Boxes, digital gives flexibility but may cost more per unit at high volumes.

Spot UV and Varnishes

Spot UV (selective gloss varnish) highlights logo areas for contrast against matte backgrounds. Varnishes add scratch resistance and alter tactile feel. Use spot UV to make logos pop on High Quality cigarette boxes without the cost of metallic foiling.

Special Effects: Luxury Finishes That Elevate Best Pack

Hot foil stamping and cold foil

Foil stamping (hot foil) applies metallic foil using heat and pressure, producing a High Quality metallic logo that works well on dark or matte backgrounds. Cold foil is applied during printing and can be more economical for larger runs. Both techniques are popular on high-end cigarette packaging to convey luxury.

Embossing and debossing

Embossing (raised) or debossing (impressed) adds depth and tactile interest to logos. These techniques pair well with foil stamping or spot varnish to highlight brand elements without increasing visual clutter. On thick paperboard used for pre-roll boxes, embossing adds perceived value and improves shelf presence.

Soft-touch coatings and textured finishes

Soft-touch coatings create a velvety surface and are increasingly used in High Quality Cigarette Boxes to convey quality. Textured finishes can hide fingerprints, increase slip resistance, and improve handling—an advantage for products sold as luxury herbal pre-rolls or CBD/THC joints.

Durability, Compliance and Child-Resistant Packaging Considerations

Regulatory and safety requirements

Manufacturers should understand relevant regulations that may affect packaging for nicotine, CBD/THC, or herbal products. In the U.S., child-resistant packaging falls under the Poison Prevention Packaging Act (PPPA) and is enforced by the Consumer Product Safety Commission (CPSC). See the CPSC PPPA guidance here: CPSC - PPPA. For international standards on reclosable child-resistant packaging, consult ISO 8317:2015: ISO 8317. For context on industry expectations, the Wikipedia summary of child-resistant packaging provides additional background: Child-resistant packaging - Wikipedia.

How printing choices affect child-resistant designs

Printing and finishing must not interfere with mechanisms intended to be child-resistant. For example, applying thick foils or embossing over hinge areas or push-and-slide mechanisms can impede functionality. Work with suppliers to prototype final assemblies and test operation cycles after printing and finishing to ensure compliance with ISO or local standards.

Durability testing and real-world performance

Print durability matters during transport, retail handling, and consumer use. Perform rub tests, humidity exposure, and drop tests to confirm ink adhesion and finish resilience. Use protective coatings (aqueous or UV) to increase scuff resistance and preserve logo appearance on high-contact surfaces of cigarette boxes.

Practical Comparison: Which Technique Fits Your Needs?

Below is a compact comparison of common printing techniques for logo applications on Cigarette Boxes, focused on typical pre-roll pack sizes (5, 10, 20).

| Technique | Best For | Run Length | Cost per Unit | Notable Benefits |

|---|---|---|---|---|

| Digital Printing | Short runs, variable data | 1 - 5,000 | Medium–High | Fast proofing, customization, low setup |

| Offset Lithography | High-fidelity color, medium/long runs | 5,000+ | Low–Medium | Consistent color, cost-effective at scale |

| Hot Foil + Emboss | Luxury branding, High Quality lines | 2,000+ | High | High perceived value, metallic finish |

| Spot UV / Varnish | Accenting logos on matte boards | Any | Low–Medium | Contrast, scratch resistance |

Workflow Recommendations: From Artwork to Finished Cigarette Boxes

Preparing artwork for printing

Provide vector logos (AI, EPS, or PDF) with Pantone references for spot colors. For photographic art, supply high-resolution images (300 DPI at print size). Include dielines and indicate emboss/foiling areas clearly on separate layers. Label varnish and foil areas as spot elements in the file to avoid production confusion.

Prototyping and pre-production checks

Order a physical prototype or press proof, especially when using embossing, foil, or child-resistant mechanisms. Verify that all finishes behave as intended and that the box opens and closes reliably after finishing. If your Factory Customized Printing LOGO Pack 10 20 5 Thick Case Pre Roll Non Tobacco Paper Box Cigarette Boxes include tuck or slide closures, test functionality after laminating or coating.

Supply chain and sustainability

Request FSC-certified paperboard or recycled-content options to appeal to environmentally conscious consumers. Some finishes, like certain cold foils, offer better recyclability than metallic laminates. Be transparent about materials used on product pages to improve consumer trust and meet international import requirements.

FAQs — Frequently Asked Questions

Q: Which printing technique is best for small-batch branded cigarette boxes?

A: For small batches (under 5,000 units), digital printing is usually the fastest and most flexible choice. It minimizes setup costs and supports variable data like batch codes or limited-edition numbering.

Q: Can I combine techniques (e.g., digital + foil) on the same box?

A: Yes. Hybrid approaches such as digital printing for full-color artwork combined with offline foil stamping or hand-applied embellishments are common for limited editions. Confirm that substrates and coatings are compatible before full production.

Q: How do I ensure my printed boxes remain child-resistant?

A: Work with packaging engineers early to integrate child-resistant mechanisms without compromising print or finish. Follow guidance from regulatory authorities (CPSC PPPA) and test to ISO 8317 where applicable: ISO 8317. Avoid decorative elements that interfere with mechanical parts.

Q: Are metallic finishes recyclable?

A: Traditional metallic laminates can complicate recycling. Cold foil or aqueous-coated papers may be more recycling-friendly. Ask your manufacturer for materials data and recyclability certificates if sustainability is a priority.

Q: What are common pitfalls that degrade logo quality?

A: Low-resolution artwork, incorrect color profiles (use CMYK or specified Pantone), improper trapping for small text, and finishing operations applied before curing inks can all reduce logo clarity. Always request a press proof and follow prepress guidelines from your printer.

Next Steps and How to Order

If you’re ready to produce High Quality branded cigarette packaging, our factory can help with design-for-manufacture, proofs, and production runs for the Factory Customized Printing LOGO Pack 10 20 5 Thick Case Pre Roll Non Tobacco Paper Box Cigarette Boxes. We can recommend the optimal combination of printing technique and finish based on run size, budget, and compliance needs.

Contact our sales team to request a quote, upload artwork, or order a prototype sample.

Customer support: Contact Us — or view full product details and order samples on our product page.

What are the application scenarios of vintage cigarette box?

Role of typography and graphics on custom cigarette boxes

Quality control checklist for factory-customized pre rolls

Tips for Artwork and Logo Placement on Cigar Boxes

FAQs

What services do you provide?

We offer one-stop packaging solutions, including design, printing, and handicraft processing for electronic boxes, plastic boxes, paper boxes, paper bags, and book printing.

What types of packaging do you specialize in?

We specialize in electronic packaging, plastic boxes (PVC/PET/PP), paper boxes, paper bags, and custom book printing.

About us

Leading time for samples production?

Normally we need 3-7 days for samples making, 10-12 days to complete your orders,but the delivery time more depends on the order QTY.

Are you able to do design for my products?

Yes, just send us your logo artwork in Vector file, such as AI or PDF format,and text information you want to print ,we can put it on box to make the design to let you check. Once you say ok, then we go on to make samples or production.

The process of your packaging box production?

1. Make knife mold as per box size and structure

2. order material as per mold

3. make printing on material if need to print

4. suppress and cut material

5. Makeboxes with glue edge in machine

6. Package boxes into cartons

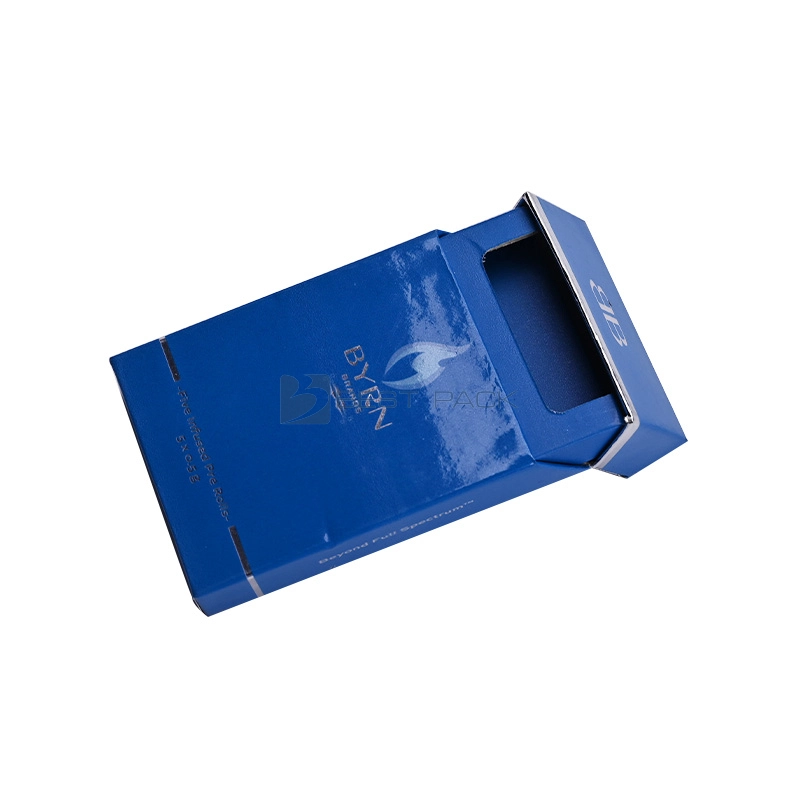

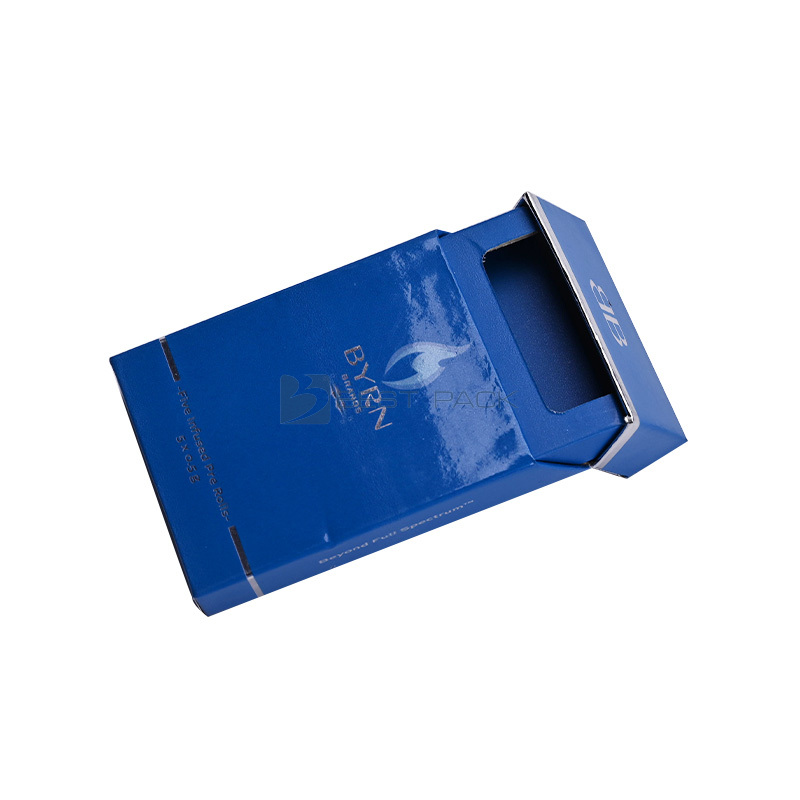

Manufacture Personalized Blank Cigarette Boxes Custom Pre Roll Box Child Resistant Drawer Cardboard Childproof Box

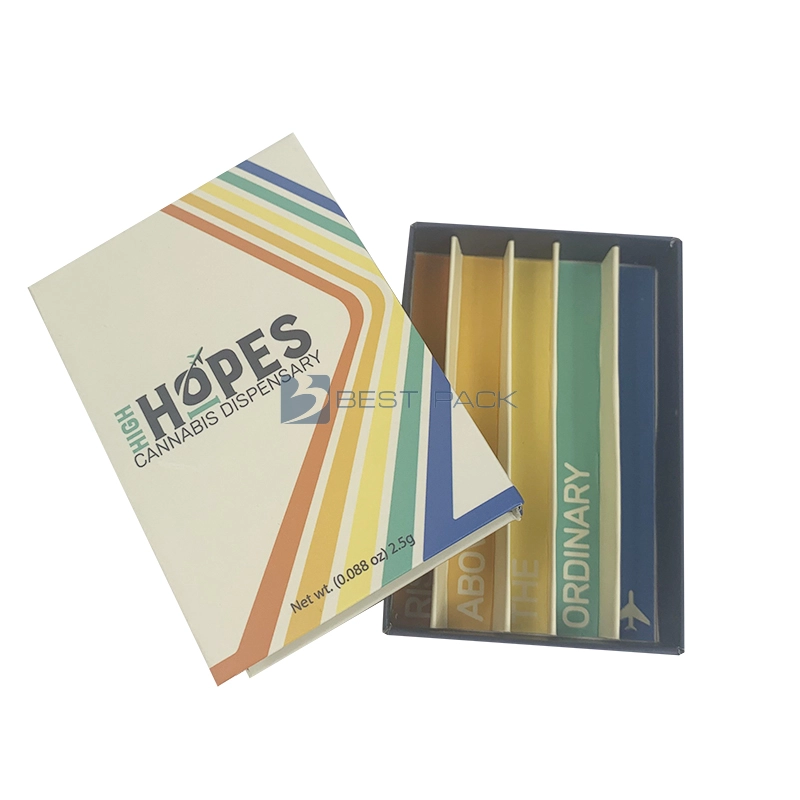

Various Style Design Drawer-Style Packaging Paper Cigarette Boxes Flip Top Closure Pre Rolled Cones Box With Dividers With Child Resistant.

Factory Paperboard Child Resist Childproof Button Box Drawer Craft Packing Box Cigarette Box for Cigarettes

Discover Best Pack’s Factory Paperboard Child-Resistant Childproof Button Box—an ideal cigarette packing box featuring a secure drawer craft packing design. Engineered for safety and style, this childproof button box ensures reliable child resistance while enhancing your cigarette storage experience.

Custom CR Vape Packaging Cardboard Boxes with Child-Resistant Design

CR custom vape packaging cardboard boxes are specially designed child-resistant packaging solutions crafted to ensure safety, protection, and premium presentation for vape products. Made from sturdy cardboard materials, these boxes balance regulatory compliance with brand aesthetics.

Best pack

Best pack

Best pack