Retail-ready pre roll packaging that drives purchases

- Retail-ready pre roll packaging that drives purchases

- Why retail-ready pre roll packaging matters for purchase decisions

- Product spotlight: Factory Customized Printing LOGO Pack 10 20 5 Thick Case Pre Roll Non Tobacco Paper Box Cigarette Boxes

- Design elements that increase on-shelf conversion for pre roll packaging

- Functional features: protection, freshness, and compliance

- Retail-ready formats and merchandising strategies for pre roll packaging

- Sustainability: materials that meet consumer expectations and recycling systems

- Production and customization: what to ask your packaging factory

- Cost vs ROI: how High Quality pre roll packaging drives purchases

- Box configuration comparison: pick the right pack size

- Child-resistant options and regulatory compliance

- Brand advantage: why Factory Customized Printing LOGO Pack stands out

- FAQs

- Q: Can these pre roll boxes be made child-resistant?

- Q: What are typical lead times for custom printed runs?

- Q: Can I get a sample before placing a full order?

- Q: Are these boxes recyclable?

- Q: What file specifications should I provide for custom printing?

- Contact & View Product

- Sources

Retail-ready pre roll packaging that drives purchases

Why retail-ready pre roll packaging matters for purchase decisions

In retail environments shoppers often decide to buy in seconds. Pre roll packaging is more than a container — it's the first tactile touchpoint between the consumer and your product. Smart pre roll packaging communicates quality, brand promise, and regulatory compliance while protecting the product. When designed to be retail-ready, packaging reduces friction at shelf and at checkout, increases perceived value, and improves impulse and planned purchase rates. In short: converting browsers into buyers starts with packaging that performs both visually and functionally.

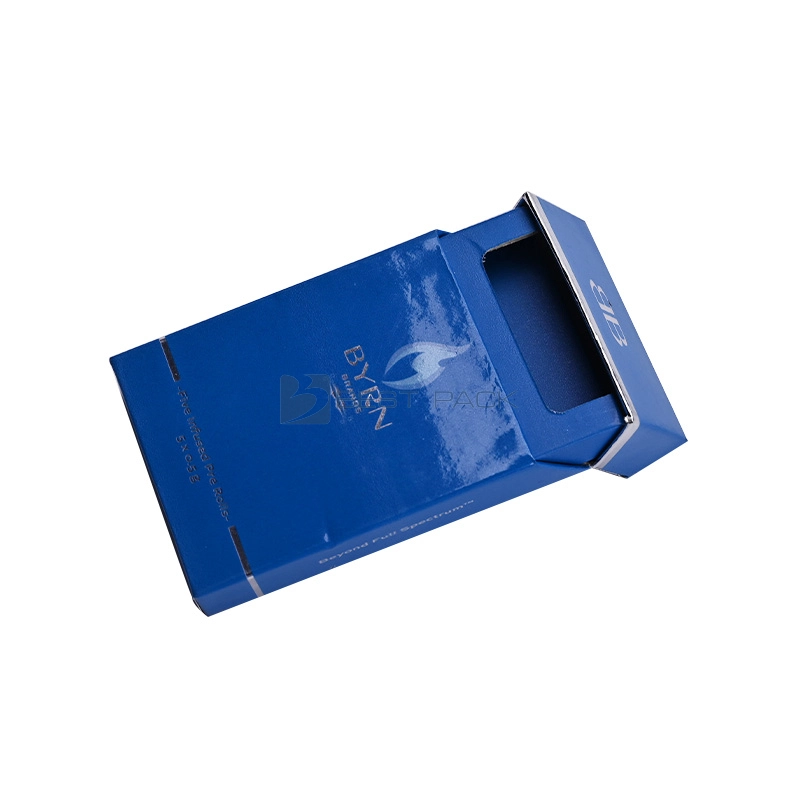

Product spotlight: Factory Customized Printing LOGO Pack 10 20 5 Thick Case Pre Roll Non Tobacco Paper Box Cigarette Boxes

Our factory-direct custom pre-roll and cigarette paper boxes are designed for High Quality presentation, protection, and branding. Made with thick, durable paperboard, these boxes are ideal for non-tobacco herbal pre-rolls, cigarettes, or CBD/THC joints. Available in various capacities (5-pack, 10-pack, 20-pack) and fully customizable with your logo and design.

This product is optimized for brands that need rapid customization, tight quality control, and consistent on-shelf presence. Because it's factory-direct, you benefit from lower unit costs, faster iteration on artwork proofs, and the ability to specify structural and finishing options tailored to your retail channels.

Design elements that increase on-shelf conversion for pre roll packaging

Design is the strongest immediate signal of product quality. For pre roll packaging, focus on clarity, hierarchy, and sensory cues that make shoppers stop and inspect. Key design elements include:

- Readable typography: clear product name, strain or SKU, and potency info that’s visible from 1–2 meters.

- Strong brand mark: consistent logo placement that builds recognition across displays and POS.

- Distinctive colorways: use color intentionally to signal product family (e.g., indica/sativa/hybrid or CBD vs THC).

- Finish and tactile cues: soft-touch or spot UV for High Quality feel; embossing or debossing for tactile differentiation.

- Functional windows or die-cuts: small transparent windows or cutouts that let consumers inspect product color/consistency without compromising integrity.

- Clear regulatory panel: required warnings, batch numbers, and scannable QR codes should be present but visually secondary.

When deploying the Factory Customized Printing LOGO Pack product, leverage high-resolution artwork and request print proofs (digital and physical) to ensure color fidelity and legibility under retail lighting.

Functional features: protection, freshness, and compliance

Apart from aesthetics, packaging must protect and preserve product quality. Pre-rolls are sensitive to crushing, moisture, and contamination. Effective retail-ready pre roll packaging addresses these issues:

- Robust paperboard construction: thick case paperboard reduces crushing in transit and on shelf.

- Inner lining or barrier options: foil or moisture-barrier liners help maintain dryness for longer shelf life.

- Tamper-evident seals: tamper bands or perforated seals reassure customers that the product is intact.

- Batch coding and traceability: printed lot codes and QR codes enable traceability for recalls and provenance checks.

Factory Customized Printing LOGO Pack supports these features during production so your packaging is ready for retail handling and regulatory inspections.

Retail-ready formats and merchandising strategies for pre roll packaging

Retail-ready packaging considers shelf, display, and checkout placement. Common strategies that increase purchases include:

- Multipack configurations: 5-pack, 10-pack, and 20-pack options let you target price-conscious and High Quality buyers within the same SKU family.

- Shelf-ready master cartons: outer cartons that convert to display trays reduce labor and improve presentation at POS.

- Counter displays: compact, branded countertop trays encourage impulse buys at checkout.

- Hanging fixtures and back-bar modules: compatible hang-tabs and standardized dimensions make it easy for retailers to slot product into existing fixtures.

An example merchandising approach: use a 5-pack for single-use trial offers and a High Quality 20-pack with tactile finishes for loyal customers. The Factory Customized Printing PACK can be supplied in retail-ready master cases sized to convert easily to counter displays.

Sustainability: materials that meet consumer expectations and recycling systems

Consumers increasingly expect eco-conscious packaging. Paperboard supports recyclability and has high consumer acceptance compared with mixed-material or plastic packs. When specifying materials, consider:

- Recyclable SBS or FBB paperboard: widely accepted in municipal recycling programs.

- Mono-material window films: if using a window, choose recyclable cellulose or mono-PET solutions to simplify sorting.

- Vegetable-based inks and aqueous coatings: lower the environmental impact and aid recyclability.

According to the U.S. EPA, paper and paperboard remain among the most-recycled packaging materials in municipal waste streams, making paperboard a responsible choice for brands balancing presentation and sustainability.

Production and customization: what to ask your packaging factory

Working directly with a factory gives you control — but only if you ask the right questions. Before signing an order, confirm:

- Minimum order quantities (MOQs): are small runs available for market testing?

- Lead times: from artwork approval to shipped goods, especially for seasonal launches.

- Print capabilities: CMYK + spot colors, Pantone matching, and handling of metallic or specialty inks.

- Structural dielines and samples: do you provide digital dielines and physical prototypes prior to full run?

- Finishing options: varnish, soft-touch, embossing, foil stamping, and die-cut windows.

- Compliance testing: can the factory produce child-resistant features and provide test documentation on request?

Factory Customized Printing LOGO Pack is positioned as a factory-direct offering, which means close collaboration on dielines, finishes, and pre-production samples is part of the value proposition.

Cost vs ROI: how High Quality pre roll packaging drives purchases

Upfront package cost must be evaluated against the revenue uplift High Quality packaging can generate. High Quality finishes and clear branding increase perceived value and can support higher price points or better shelf placement. A simple way to think about ROI is to measure conversion lift after a packaging refresh in a controlled retail set. Even a single-digit increase in conversion or a modest lift in average order value can justify higher unit packaging costs for many brands.

Box configuration comparison: pick the right pack size

Below is a concise comparison of the 5-pack, 10-pack, and 20-pack configurations available with the Factory Customized Printing LOGO Pack. These are standard structural and positioning recommendations; dimensions and thickness can be customized.

| Pack Size | Typical Use | Suggested Internal Divider | Recommended Board Thickness |

|---|---|---|---|

| 5-pack | Trials, sample packs, promotions | Foam or molded paper divider to prevent rolling | 18–20 pt (solid feel, low cost) |

| 10-pack | Everyday purchase, subscription SKUs | Paperboard dividers or tuck fixtures | 20–24 pt (balanced protection and aesthetics) |

| 20-pack | Value or High Quality multi-packs; retail displays | Reinforced compartments or corrugated inserts | 24–32 pt (high protection; High Quality feel) |

Note: board thickness ranges are recommendations based on product fragility and retail handling. Factory Customized Printing can produce custom dielines and recommend the ideal caliper for your SKU.

Child-resistant options and regulatory compliance

Many jurisdictions require child-resistant (CR) packaging for cannabis and related products. Even when not legally required for herbal pre-rolls, offering CR closures increases retailer confidence and can reduce liability. Key points:

- Understand local regulations: U.S. federal rules for cannabis are still evolving, but many states require CR closures for cannabis products. For general consumer products, the Poison Prevention Packaging Act (PPPA) and CPSC guidance (16 CFR 1700) remain relevant for child-safety design considerations.

- CR mechanism types: push-and-turn lids, slide locks, and combination locks can be integrated into outer boxes or inner tubes.

- Testing and documentation: CR packaging should be tested to recognized protocols to document performance during procurement.

- Balancing usability and safety: ensure CR features don't render packaging inaccessible to older adults or those with dexterity challenges; consider dual-layer systems where the outer box is easy to open but an inner child-resistant sleeve secures contents.

Factory Customized Printing can incorporate CR design elements or provide guidance on pairing your printed paperboard box with an inner CR insert or tube solution.

Brand advantage: why Factory Customized Printing LOGO Pack stands out

When selecting pre roll packaging that drives purchases, consider three core advantages of the Factory Customized Printing LOGO Pack 10 20 5 Thick Case Pre Roll Non Tobacco Paper Box Cigarette Boxes:

- Factory-direct pricing and control: direct access to production reduces intermediaries, lowers unit costs, and speeds iteration for seasonal or regional launches.

- High Quality structural quality: thick, durable paperboard designed to meet retail handling and display needs while protecting delicate pre-rolls.

- Full customization: printed logos, spot varnish, embossing, and dieline variations allow you to deliver a cohesive brand experience from shelf to hand.

Together, these advantages translate into packaging that increases perceived value, supports a cohesive merchandising plan, and reduces supply chain complexity.

FAQs

Q: Can these pre roll boxes be made child-resistant?

A: Yes. While the base offering is a High Quality printed paperboard box, we can integrate child-resistant solutions by pairing the box with CR inner tubes, adopting CR-enabled closures, or coordinating with certified CR insert manufacturers. We recommend confirming local regulatory requirements so the packaging meets mandated test standards.

Q: What are typical lead times for custom printed runs?

A: Typical lead times vary by quantity and finishing complexity. For small runs and digital printing, lead times can be 2–4 weeks. For larger offset runs with specialty finishes, expect 4–8 weeks from final artwork approval to delivery. Factory-directed production often shortens these timelines compared with third-party resellers.

Q: Can I get a sample before placing a full order?

A: Yes. We provide digital mockups and physical prototypes (for a fee) so you can verify artwork, dieline fit, and finishes before full production.

Q: Are these boxes recyclable?

A: The base paperboard boxes are recyclable in most municipal paper streams when printed with water-based inks and without mixed-material windows. If you require a window, specify mono-material films or cellulose windows to maintain recyclability.

Q: What file specifications should I provide for custom printing?

A: Provide vector-based logos (AI, EPS) and high-resolution images (300 dpi). Include Pantone references for spot colors when exact matches are required. We will supply dielines and bleed specifications on request.

Contact & View Product

To enhance retail-ready pre-roll packaging, consider shelf display ideas for Pack 5, 10, 20 pre-roll boxes. Thoughtful shelf placement and packaging design will catch the eye of potential buyers and encourage impulse purchases.Ready to convert more shoppers with retail-ready pre roll packaging? Contact our sales team to request samples, pricing, or a custom dieline. View the Factory Customized Printing LOGO Pack 10 20 5 Thick Case Pre Roll Non Tobacco Paper Box Cigarette Boxes and request a quote today — factory-direct quality, full customization.

Sources

- U.S. Consumer Product Safety Commission (CPSC) — Poison Prevention Packaging Act (PPPA) information and regulatory guidance: https://www.cpsc.gov/Regulations-Laws--Standards/Statutes/Poison-Prevention-Packaging-Act

- U.S. Environmental Protection Agency (EPA) — Facts and Figures about Materials, Waste and Recycling: https://www.epa.gov/facts-and-figures-about-materials-waste-and-recycling

- Grand View Research — Cannabis Packaging Market Overview (industry trends and demand for retail-ready packaging): https://www.grandviewresearch.com/industry-analysis/cannabis-packaging-market

Everything You Need to Know About cigar box manufacturer

The latest trends for cardboard cigar box wholesale

How to create child-resistant prototypes for cigarette boxes

Bulk packaging tips for Pack 10 20 5 pre roll orders

FAQs

How do you ensure product quality?

We maintain strict quality control at every stage, from material selection to final production, ensuring high-quality standards.

What services do you provide?

We offer one-stop packaging solutions, including design, printing, and handicraft processing for electronic boxes, plastic boxes, paper boxes, paper bags, and book printing.

About us

Are you able to do design for my products?

Yes, just send us your logo artwork in Vector file, such as AI or PDF format,and text information you want to print ,we can put it on box to make the design to let you check. Once you say ok, then we go on to make samples or production.

The process of your packaging box production?

1. Make knife mold as per box size and structure

2. order material as per mold

3. make printing on material if need to print

4. suppress and cut material

5. Makeboxes with glue edge in machine

6. Package boxes into cartons

Leading time for samples production?

Normally we need 3-7 days for samples making, 10-12 days to complete your orders,but the delivery time more depends on the order QTY.

Custom CR Vape Packaging Cardboard Boxes with Child-Resistant Design

CR custom vape packaging cardboard boxes are specially designed child-resistant packaging solutions crafted to ensure safety, protection, and premium presentation for vape products. Made from sturdy cardboard materials, these boxes balance regulatory compliance with brand aesthetics.

Custom Luxury Pre Roll Packaging Boxes with Child-Resistant Paper Tray

Our luxury pre-roll packaging boxes are designed to combine elegant presentation with top-tier safety features. Featuring a child-resistant mechanism and a custom paper tray insert, these boxes ensure secure storage while delivering a premium unboxing experience for pre-roll products.

Custom Child-Lock Pre-Roll 5-Pack Packaging Boxes

Our custom child-lock packaging for pre-roll 5-packs is purposefully engineered to combine premium design with certified safety. This packaging solution ensures that five pre-rolls are securely housed in a compact, stylish, and child-resistant format—ideal for compliant cannabis brands that value both form and function.

Best pack

Best pack

Best pack