How to Source Custom Recyclable Child-Resistant Packaging Paper Tubes

- How to Source Custom Recyclable Child-Resistant Packaging Paper Tubes

- Why choose a packaging paper tube for child-resistant needs?

- Know the product: Custom Recyclable Cardboard Childproof Child Resistant Packaging Child Proof Round Paper Tube Box with Lock Button

- Understand regulations and standards for child-resistant packaging

- Material selection: what makes a tube recyclable and childproof?

- Design considerations for Custom Recyclable Cardboard Childproof Child Resistant Packaging Child Proof Round Paper Tube Box with Lock Button

- How to evaluate manufacturers and suppliers of packaging paper tube

- Prototyping and testing: child-resistance testing and recyclability verification

- Sustainability and end-of-life: ensuring your paper tube is truly recyclable

- Costing and order planning for packaging paper tube

- Comparison: paper tube vs plastic vs glass for child-resistant recyclable packaging

- How to order: a practical supplier specification checklist

- Brand advantages: why choose Best Pack’s solution

- FAQ — Frequently Asked Questions

- Is a paper tube with a lock-button truly child-resistant?

- Are paper tubes recyclable with a lock-button or insert?

- What tests should I require from suppliers?

- How many samples should I prototype before mass production?

- What is the typical lead time for custom paper tubes?

- Contact / View Product

- References and authoritative sources

How to Source Custom Recyclable Child-Resistant Packaging Paper Tubes

Why choose a packaging paper tube for child-resistant needs?

Packaging paper tube solutions combine structural strength, shelf appeal, and recyclability in one format. For products that require controlled access (pharmaceuticals, nutraceuticals, certain over-the-counter products, and adult-use goods), a well-designed packaging paper tube can be fitted with a secure childproof mechanism while remaining fully recyclable. Choosing a paper tube allows brands to communicate sustainability without sacrificing safety or user experience.

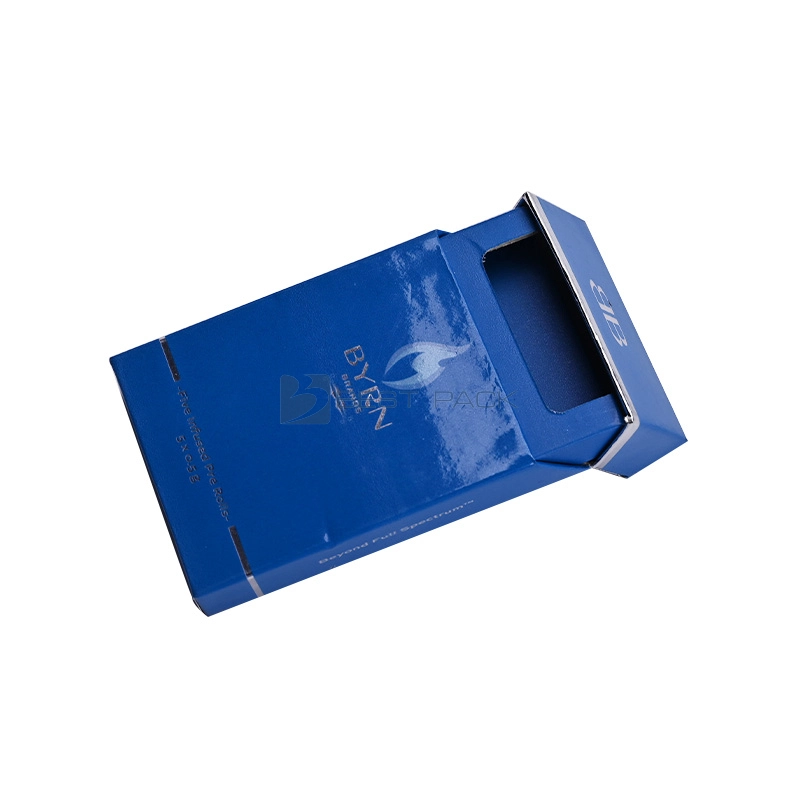

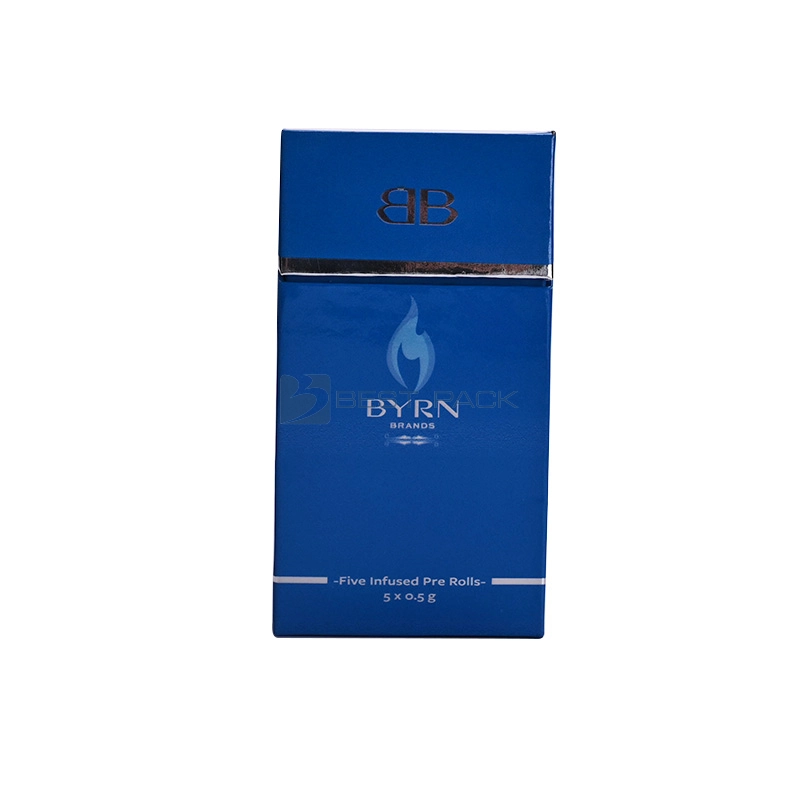

Know the product: Custom Recyclable Cardboard Childproof Child Resistant Packaging Child Proof Round Paper Tube Box with Lock Button

Best Pack’s Custom Recyclable Cardboard Childproof Packaging Box offers secure, eco-friendly storage with a child-resistant lock button. Designed as a round paper tube box, it ensures safety and sustainability, ideal for protecting products while supporting green packaging solutions.

Understand regulations and standards for child-resistant packaging

Before sourcing, become familiar with the regulatory landscape affecting child-resistant packaging in your target markets. Regulations and voluntary standards set performance requirements for packaging intended to be difficult for children to open while still accessible to adults.

- U.S. Consumer Product Safety Commission (CPSC) – Poison Prevention Packaging Act (PPPA) outlines child-resistant packaging requirements for certain household substances.

- ASTM and ISO standards provide test methods for evaluating child-resistance and effectiveness.

- Local and regional recycling rules (municipal Material Recovery Facilities, MRFs) determine whether a paper tube with certain coatings or inserts is recyclable in practice.

Work with legal and compliance teams or third-party testing labs to verify that your chosen paper tube design meets the relevant requirements in each market you serve.

Material selection: what makes a tube recyclable and childproof?

Material choice determines both recyclability and the mechanical performance needed for child-resistance:

- Paperboard grade: High-strength virgin or recycled kraft paperboard gives the tube rigidity. A thicker GSM (grams per square meter) increases crush resistance.

- Inner liners and inserts: Use paper-based inserts or corrugated rings instead of plastic foam where possible. Paperboard inserts can be engineered to add friction that supports childproof closures.

- Coatings and barriers: Avoid polyethylene (PE) or metalized coatings when recyclability is a priority. Water-based, water-soluble, or PLA coatings may be acceptable but check local recycling acceptance.

- Adhesives and inks: Choose water-based adhesives and soy or water-based inks to reduce contamination during pulping.

Balancing these choices will ensure the packaging paper tube is both child-resistant and recyclable in most municipal systems.

Design considerations for Custom Recyclable Cardboard Childproof Child Resistant Packaging Child Proof Round Paper Tube Box with Lock Button

When specifying design features for a round paper tube with a lock button, include the following:

- Lock-button mechanism: The lock should require a two-step adult action (e.g., press-and-twist or press-and-slide). Ensure the mechanism can be manufactured from paperboard components or minimal, recoverable plastic parts.

- Child-resistance vs adult usability: Test with adult panels to verify that intended users can open and reclose the product easily while children under specified ages cannot.

- Tamper evidence: Add a single-use seal or perforation that indicates prior opening. Choose paper seals or recyclable tamper-tabs.

- Dimensional tolerances: Provide precise inner and outer diameter specifications, wall thickness, and allowable variation for consistent locking action across batches.

- Branding and print: Use direct printing or labels optimized for recyclability. Avoid heavy metallic finishes if recyclability is required.

Document these details clearly in your technical specification for supplier quotes.

How to evaluate manufacturers and suppliers of packaging paper tube

Choosing the right supplier is critical. Use this evaluation checklist when sourcing:

- Certifications: Verify FSC/PEFC for responsible sourcing, ISO 9001 for quality management, and ISO 14001 for environmental management where applicable.

- Child-resistant experience: Prefer suppliers with demonstrated experience producing childproof closures and that can show testing evidence.

- Prototyping and tooling capabilities: Ensure they can produce rapid prototypes and invest in custom tooling for lock buttons and inserts.

- Quality control: Request inspection reports, sample test results, and details about incoming material checks.

- Supply chain transparency: Confirm pulp source, recycled content claims, and traceability.

- Lead times and MOQ: Confirm production capacity, minimum order quantities, and typical lead times for repeat orders.

Prototyping and testing: child-resistance testing and recyclability verification

Prototyping mitigates risk and avoids costly redesigns:

- Create multiple prototype iterations to validate fit, locking force, and user ergonomics.

- Arrange third-party child-resistance testing per applicable standards (e.g., CPSC test protocols or ASTM methods). Testing should include groups of children and adult-use panels.

- Test recyclability with representative samples by consulting local MRFs or using standardized pulping assessments. Some coatings that are theoretically recyclable are rejected by MRFs in practice — verify ahead of volume production.

Sustainability and end-of-life: ensuring your paper tube is truly recyclable

To maximize real-world recyclability:

- Use mono-material construction where possible (paperboard body, paper liners).

- Avoid mixed-material lamination (paper + PE + foil). If barrier properties are essential, prioritize recyclable fiber-based barriers or single-material bio-based barriers accepted by local recyclers.

- Label the package with clear recycling instructions and certifications (FSC, How2Recycle label) to guide consumers.

Costing and order planning for packaging paper tube

Pricing depends on many variables. Understand these cost drivers:

- Material grade and recycled content

- Complexity of lock-button tooling and inserts

- Print and finishing (special finishes increase cost)

- Order quantity and economies of scale (unit cost drops as volume increases)

- Shipping and import duties

Ask suppliers for a detailed BOM-based quote and run total landed cost analysis (including returns due to failed testing) before committing.

Comparison: paper tube vs plastic vs glass for child-resistant recyclable packaging

| Material | Child-Resistance Potential | Recyclability (Practical) | Brand Perception |

|---|---|---|---|

| Paperboard tube | High (with proper lock mechanism) | High (if mono-material, water-based inks/coatings) | High Quality, eco-friendly |

| Plastic container | Very high (robust mechanisms) | Variable (dependent on resin and local recycling programs) | Durable, but less eco-friendly |

| Glass jar | Moderate (childproof caps easy to implement) | High (widely recyclable) | High Quality, fragile |

How to order: a practical supplier specification checklist

Provide suppliers with a concise specification file to accelerate quoting and production:

- Product name and SKU: Custom Recyclable Cardboard Childproof Child Resistant Packaging Child Proof Round Paper Tube Box with Lock Button

- Dimensions: outer diameter, inner diameter, height, wall thickness

- Material: paperboard grade, recycled content %

- Lock mechanism description: type, required opening force, two-step action

- Finish & printing: number of colors, ink type (water-based), varnish or coatings

- Inserts and liners: material, tolerances

- Testing: child-resistance test protocol required, recyclability verification

- Quantity, lead time, packaging for shipment

- Certifications required: FSC, ISO, CPSC testing evidence

Brand advantages: why choose Best Pack’s solution

Best Pack’s Custom Recyclable Cardboard Childproof Child Resistant Packaging Child Proof Round Paper Tube Box with Lock Button brings together safety, sustainability, and scalable manufacturing:

- Proven child-resistant lock-button concept tailored for paperboard construction.

- Design optimized for recyclability—mono-fiber construction and water-based finishes.

- Available for custom dimensions and graphics to support brand differentiation.

- Support for prototyping and third-party testing to shorten time-to-market.

These strengths help brands meet consumer expectations for safety and environmental responsibility while protecting products effectively.

FAQ — Frequently Asked Questions

Is a paper tube with a lock-button truly child-resistant?

Yes, if the mechanism is designed and tested to relevant standards. Child-resistant performance depends on design details, material tolerances, and user ergonomics. Always validate with child-resistance testing.

Are paper tubes recyclable with a lock-button or insert?

They can be, but it depends on materials used. Use paper-based inserts and avoid mixed plastic liners. Verify with local recycling facilities because practical recyclability varies by region.

What tests should I require from suppliers?

Request third-party child-resistance tests, material certificates (FSC, recycled content), and recyclability verification. Include drop, compression, and lifecycle tests if product safety is critical.

How many samples should I prototype before mass production?

Plan for at least 3–5 functional prototype iterations: initial fit/form, functional lock testing, and finalized print/finish approval. Additional rounds may be needed for user testing.

What is the typical lead time for custom paper tubes?

Lead times vary by complexity and MOQ; generally 4–12 weeks including tooling, prototyping, and pre-production samples. Discuss expedited options with your supplier.

Contact / View Product

Now that you know how to source custom recyclable child-resistant packaging, let’s look at specifying childproof round paper tube boxes for retail buyers. Choosing the right specifications can make all the difference in terms of durability, security, and presentation for your retail packaging needs.If you want a scalable, tested, and recyclable child-resistant solution, contact Best Pack for specifications, samples, and testing support. View the product page or request a quote: https://www.bestpack.com/products/custom-recyclable-childproof-tube

References and authoritative sources

- U.S. Consumer Product Safety Commission (CPSC) — https://www.cpsc.gov/

- EPA — Sustainable Materials Management and Recycling Basics — https://www.epa.gov/recycle

- Forest Stewardship Council (FSC) — https://www.fsc.org/

- How2Recycle (recycling labeling guidance) — https://how2recycle.info/

- Wikipedia — Child-resistant packaging — https://en.wikipedia.org/wiki/Child-resistant_packaging

- ISO — Packaging standards overview — https://www.iso.org/ics/55.140/x/

Using this guide, you can specify, test, and procure an effective Custom Recyclable Cardboard Childproof Child Resistant Packaging Child Proof Round Paper Tube Box with Lock Button that satisfies both safety and sustainability goals. For tailored advice, samples, or compliance testing assistance, contact the Best Pack team through the product page link above.

Compliance Checklist for Pre-Roll Non-Tobacco Paper Packaging

Selecting Suppliers for Cardboard Cigarette Clamshell Packaging

Eco-Friendly Alternatives for Pre Roll Cone Packaging

Sample Approval Process for Custom Cigarette Box Manufacturers

FAQs

What types of packaging do you specialize in?

We specialize in electronic packaging, plastic boxes (PVC/PET/PP), paper boxes, paper bags, and custom book printing.

Can you ship internationally?

Yes, we export worldwide and work with reliable logistics partners for timely delivery.

How do you ensure product quality?

We maintain strict quality control at every stage, from material selection to final production, ensuring high-quality standards.

About us

How many kinds the printing process you have?

We can make Silk screen printing, offset printing, and also hot silver stamping

The process of your packaging box production?

1. Make knife mold as per box size and structure

2. order material as per mold

3. make printing on material if need to print

4. suppress and cut material

5. Makeboxes with glue edge in machine

6. Package boxes into cartons

Custom Printed Paperboard Cardboard Cigarette Box Packaging Case Disposable Paper Box for Cigarette Clamshell paper box

Custom Vape Packaging Box with CR Telescoping Design

The CR telescoping box is a sophisticated and secure packaging solution designed specifically for vape products. Featuring a telescoping (two-piece) structure, this box offers excellent protection and an elegant presentation, enhancing both the unboxing experience and brand appeal.

Custom Logo Child-Resistant Pre-Roll Box Packaging Biodegradable Handmade Luxury 5 Pack Embossing Childproof Pre Roll Package

Custom CR Vape Packaging Cardboard Boxes with Child-Resistant Design

CR custom vape packaging cardboard boxes are specially designed child-resistant packaging solutions crafted to ensure safety, protection, and premium presentation for vape products. Made from sturdy cardboard materials, these boxes balance regulatory compliance with brand aesthetics.

Best pack

Best pack

Best pack