Sample Approval Process for Custom Cigarette Box Manufacturers

- Sample Approval Process for Custom Cigarette Box Manufacturers

- Why a formal sample approval process matters for custom cigarette box production

- Initial Inquiry and Specification (custom cigarette box)

- Artwork Review and Prepress Checks (custom cigarette box)

- Product Preview: Factory Customized Printing LOGO Pack 10 20 5 Thick Case Pre Roll Non Tobacco Paper Box Cigarette Boxes

- Sample Types and When to Use Each (custom cigarette box)

- Material Selection and Durability Checks (custom cigarette box)

- Regulatory and Child-Resistant Considerations (custom cigarette box)

- Pre-Production Approval Checklist (custom cigarette box)

- Timelines, Costs, and Risk Management (custom cigarette box)

- Quality Assurance and Incoming Inspection (custom cigarette box)

- Brand Advantages of Choosing Our Factory for Your Custom Cigarette Box

- Practical Tips to Speed Up Sample Approval (custom cigarette box)

- FAQ — Sample Approval for Custom Cigarette Box

- Q: How many sample iterations are typical?

- Q: How long will full sample approval take?

- Q: Can you ensure color matches across different production runs?

- Q: Are child-resistant features available for the Factory Customized Printing LOGO Pack 10 20 5 Thick Case Pre Roll Non Tobacco Paper Box Cigarette Boxes?

- Q: What if the pre-production sample fails inspection?

- Next Steps — Contact and View Product

- References and Authoritative Resources

Sample Approval Process for Custom Cigarette Box Manufacturers

Selecting the right sample approval workflow is critical for any brand ordering a custom cigarette box. Whether you’re launching a line of CBD pre-rolls or branded non-tobacco herbal products, an efficient, documented sample approval process saves time, reduces cost, and ensures compliance. This guide walks you through a professional, step-by-step approval process tailored to custom cigarette box manufacturing and includes practical tips for approving Factory Customized Printing LOGO Pack 10 20 5 Thick Case Pre Roll Non Tobacco Paper Box Cigarette Boxes.

Why a formal sample approval process matters for custom cigarette box production

When ordering a custom cigarette box at scale, skipping or rushing sample approval often leads to costly mistakes: color mismatches, incorrect dielines, structural failures, or packaging that doesn't meet regulatory or child-resistant requirements. A formal sample approval process ensures your final packaging accurately represents Best Pack, protects the product, and meets legal and retail requirements. This is especially true for High Quality paperboard products such as the Factory Customized Printing LOGO Pack 10 20 5 Thick Case Pre Roll Non Tobacco Paper Box Cigarette Boxes, which rely on precise printing, finishing, and structural integrity.

Initial Inquiry and Specification (custom cigarette box)

The sample approval process begins with a detailed inquiry and specification sheet. Provide your manufacturer with as much information as possible: product dimensions, desired capacity (5-pack, 10-pack, 20-pack), material thickness, print finishes (UV, matte, gloss, soft-touch), and any child-resistant features required. Include the following in your initial file:

- Product name and SKU: Factory Customized Printing LOGO Pack 10 20 5 Thick Case Pre Roll Non Tobacco Paper Box Cigarette Boxes

- Target quantity and order cadence

- Exact dimensions, internal trays or inserts if needed

- Artwork files (AI/PSD/PDF) with dielines and fonts outlined

- Required compliance or labeling text (e.g., state cannabis warnings, batch codes)

Clear specifications reduce back-and-forth, shorten lead times, and improve sample accuracy.

Artwork Review and Prepress Checks (custom cigarette box)

Artwork and prepress validation are the most frequent causes of sample rejection. Manufacturers should perform a checklist review covering:

- Color mode and profiles (CMYK for print; spot colors identified)

- Bleed, safe zone, and dieline alignment

- Font embedding or outlining

- Pantone references or color proofs

- Variable data areas for batch codes or serial numbers

Ask for a digital proof (PDF proof or soft proof) first. A high-resolution physical color proof (press proof or giclée) is recommended when exact color matching is critical for brand identity.

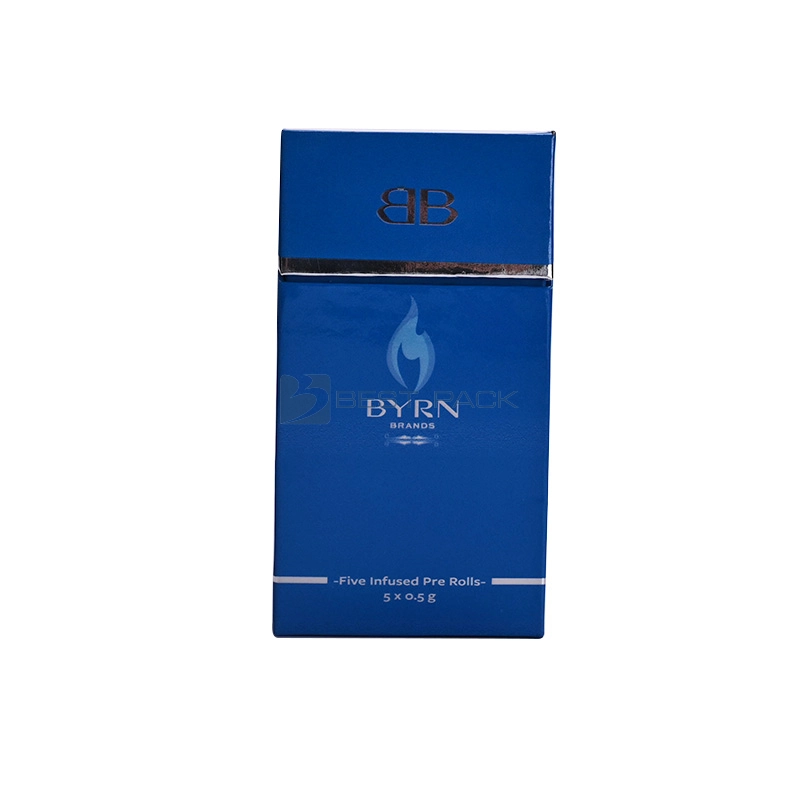

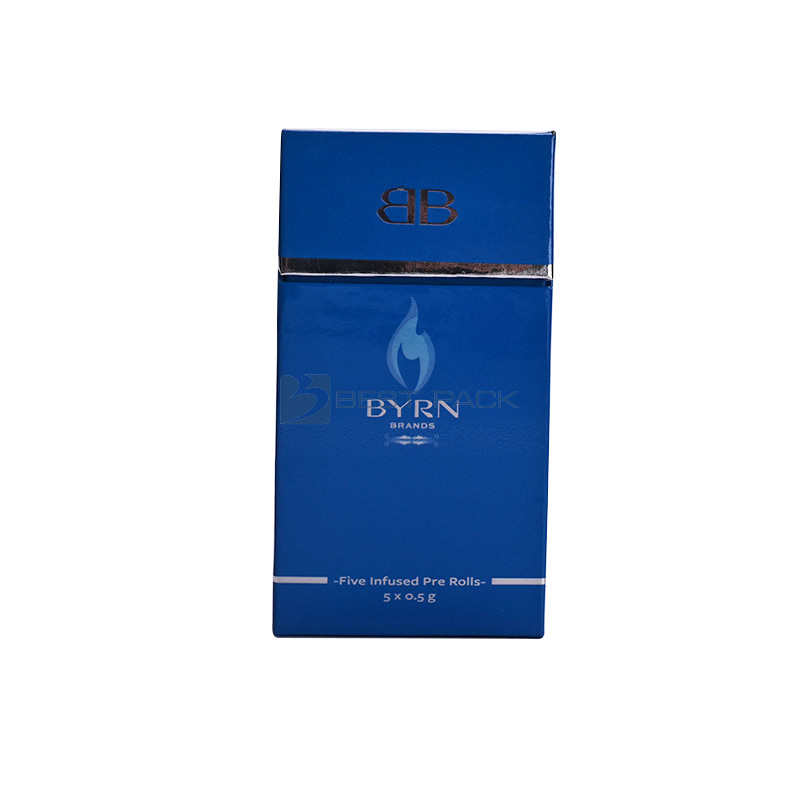

Product Preview: Factory Customized Printing LOGO Pack 10 20 5 Thick Case Pre Roll Non Tobacco Paper Box Cigarette Boxes

Our factory-direct custom pre-roll and cigarette paper boxes are designed for High Quality presentation, protection, and branding. Made with thick, durable paperboard, these boxes are ideal for non-tobacco herbal pre-rolls, cigarettes, or CBD/THC joints. Available in various capacities (5-pack, 10-pack, 20-pack) and fully customizable with your logo and design.

Sample Types and When to Use Each (custom cigarette box)

Manufacturers commonly produce several types of samples. Each has a purpose—understanding the differences will help you decide what to approve before full production.

| Sample Type | Purpose | Typical Turnaround | Cost |

|---|---|---|---|

| Digital Mockup | Visual layout and dieline confirmation | 1–3 days | Low |

| Print Proof (Flat) | Color and finish preview on sheet stock | 3–7 days | Moderate |

| Structural Mockup (Blank Stock) | Check dimensions and fit, no print | 3–7 days | Moderate |

| Physical Pre-Production Sample | Complete printed, finished box—closest to production | 7–14 days | Higher |

| Pilot Run/PP Sample | Small batch from production line for process validation | 2–4 weeks | Higher (but valuable) |

Most brands go through at least a digital mockup, a print proof, and a pre-production sample for packaging that represents the final product—especially for High Quality items like thick paperboard cigarette boxes.

Material Selection and Durability Checks (custom cigarette box)

Material choice affects protection, shelf appeal, and machinability. For the Factory Customized Printing LOGO Pack 10 20 5 Thick Case Pre Roll Non Tobacco Paper Box Cigarette Boxes, common material choices include 300–600 gsm solid bleached board (SBB), kraft board, or recycled rigid paperboard. Important checks:

- Stiffness and board thickness to ensure stacking strength and protection

- Coatings and varnishes tested for rub resistance and scuffing

- Compatibility with adhesives and heat-seal or tuck closures

- Internal inserts or liners for product fit

Request sample panels of the selected board and test them for bending, edge crush, and finish durability. Document test results alongside the sample to assist future audits.

Regulatory and Child-Resistant Considerations (custom cigarette box)

If your product is a non-tobacco pre-roll, CBD, or THC product, local and state regulations may require specific warnings, tamper-evident features, or child-resistant packaging. Even for non-cannabis cigarette boxes, consider consumer safety and retail policies. During sample approval you should:

- Verify required labeling and health warning placements

- Confirm any child-resistant features (if required) function reliably

- Document compliance claims and keep test reports on file

Manufacturers often provide testing options or references for third-party child-resistance testing; include test timelines in your approval schedule if certification is required.

Pre-Production Approval Checklist (custom cigarette box)

Use a standardized checklist to approve pre-production samples. A robust checklist should include:

- Dimensional confirmation (folded and flat)

- Structural integrity (flaps, glue points, interlocks)

- Print quality (registration, color, dot gain)

- Finishing quality (emboss, foil, varnish)

- Functional checks (fit with product: 5/10/20 pack trials)

- Label and legal text verification

- Packing and shipping simulation for transit durability

Only sign off when all critical and major items meet your acceptance criteria. For non-critical issues, document necessary changes and set timelines for corrective action before production.

Timelines, Costs, and Risk Management (custom cigarette box)

Typical timelines depend on sample complexity. Budget factors include tooling (dies, plates), color matching (Pantone/spots), finishing (foil, emboss), and shipping for physical samples. Below is a simple comparison to help plan:

| Stage | Typical Time | Typical Cost Impact |

|---|---|---|

| Digital mockup | 1–3 days | Low |

| Physical print proof | 3–7 days | Moderate |

| Pre-production sample | 7–14 days | Moderate/High |

| Pilot run | 2–4 weeks | High |

Plan for at least one full sample iteration and factor in contingency for additional color or structural revisions—this mitigates the risk of production delays and costly rework.

Quality Assurance and Incoming Inspection (custom cigarette box)

Once samples are approved and production begins, implement an incoming quality inspection (IQC) at the factory before full carton packing. Typical IQC elements:

- Random sample checks for color, registration, and finishing

- Dimensional spot checks against the approved sample

- Functional inspection for child-resistant mechanisms or closures

- Batch labeling and traceability verification

Agree on acceptance criteria and non-conformance procedures with your manufacturer beforehand to avoid disputes and ensure quick corrective action if defects are found.

Brand Advantages of Choosing Our Factory for Your Custom Cigarette Box

When you choose our factory for the Factory Customized Printing LOGO Pack 10 20 5 Thick Case Pre Roll Non Tobacco Paper Box Cigarette Boxes, you get several advantages that streamline sample approval and ensure consistent production quality:

- Factory-direct manufacturing — faster iterations, lower margins, and direct control over sample production

- Experienced prepress team — fewer artwork errors and faster color approvals

- Multiple sample options — digital mockups, press proofs, and production-ready samples tailored to pre-roll and cigarette packaging

- Material testing and documentation — we provide board samples and finish swatches for your records

- Compliance awareness — we support labeling and can guide you on common state-level requirements for non-tobacco products

- Quality control — documented IQC procedures and photographic records for each batch

These advantages shorten your time-to-market, reduce approval cycles, and protect Best Pack reputation.

Practical Tips to Speed Up Sample Approval (custom cigarette box)

To make sample approval efficient and predictable, follow these practical tips:

- Provide a single source of truth: one final art file and a written spec sheet

- Approve digital proofs quickly to avoid delays

- Request swatch kits for finishes and board types before full sampling

- Plan for one pilot run to validate packing and logistic handling

- Keep communication in writing and use a version-controlled file naming system

FAQ — Sample Approval for Custom Cigarette Box

Q: How many sample iterations are typical?

A: Most brands do 2–3 iterations: digital mockup, printed proof, and pre-production sample. A pilot run is recommended for new tooling or complex finishes.

Q: How long will full sample approval take?

A: Expect anywhere from 2 to 6 weeks depending on complexity, finishing, and whether pilot runs or compliance testing are required.

Q: Can you ensure color matches across different production runs?

A: Yes—using standardized color profiles, press sheets, and reference swatches we can minimize variance. Request color-locked production dates and archive master proofs for future reorders.

Q: Are child-resistant features available for the Factory Customized Printing LOGO Pack 10 20 5 Thick Case Pre Roll Non Tobacco Paper Box Cigarette Boxes?

A: Depending on design, we can incorporate child-resistant or tamper-evident closures. Child-resistance often requires specific testing and validation—discuss requirements early in the specification phase.

Q: What if the pre-production sample fails inspection?

A: If a pre-production sample fails, document all non-conformances, request corrective actions, and approve a revised sample before authorizing mass production. This reduces the risk of costly recalls or rework.

Next Steps — Contact and View Product

If you’re ready to begin the sample approval process for your custom cigarette box or want a sample of the Factory Customized Printing LOGO Pack 10 20 5 Thick Case Pre Roll Non Tobacco Paper Box Cigarette Boxes, contact our packaging specialists today. We provide detailed spec templates, sample timelines, and a cost estimate tailored to your design and regulatory needs. Request a quote or sample at: (please replace with your company contact link) or visit our product page to view available options.

References and Authoritative Resources

- Child-resistant packaging — Wikipedia: https://en.wikipedia.org/wiki/Child-resistant_packaging

- Poison Prevention Packaging Act — Wikipedia: https://en.wikipedia.org/wiki/Poison_Prevention_Packaging_Act

- U.S. Food and Drug Administration — Tobacco Products: https://www.fda.gov/tobacco-products

- U.S. Consumer Product Safety Commission: https://www.cpsc.gov/

- ASTM International (standards organization): https://www.astm.org/

Note: Regulations for cannabis-derived products (CBD/THC) vary by jurisdiction; consult your legal advisor and local regulatory agencies for state-specific requirements.

Ensuring Child-Resistant Compliance in Custom Cigarette Boxes

What are the application scenarios of personalized cigarette box?

Integrating Security Features into Custom Cigarette Packaging

Cost Breakdown: Child-Resistant Pre-Roll Packaging

About us

How much of your samples cost ?

1. If samples are without printing, we can make free samples as per your box size or structure;

2. If samples are silk printing, normally USD 25 per color,depending on your logo colors;

3. If samples are offset printing, need USD 180 as offset printing mold cost is high.

What is the box size and structure?

1. All boxes are customized and all detailed requirements can be provided by clients, we are definitely your OEM service supplier.

2. If you have no idea about the measurements and structure on your products, our professional design team can suggest and solute for you .

How many kinds the printing process you have?

We can make Silk screen printing, offset printing, and also hot silver stamping

FAQs

Do you support custom designs?

Yes, we provide custom packaging designs tailored to your brand and product needs.

What services do you provide?

We offer one-stop packaging solutions, including design, printing, and handicraft processing for electronic boxes, plastic boxes, paper boxes, paper bags, and book printing.

Custom Printed Paperboard Cardboard Cigarette Box Packaging Case Disposable Paper Box for Cigarette Clamshell paper box

Custom Vape Packaging Box with CR Telescoping Design

The CR telescoping box is a sophisticated and secure packaging solution designed specifically for vape products. Featuring a telescoping (two-piece) structure, this box offers excellent protection and an elegant presentation, enhancing both the unboxing experience and brand appeal.

Custom Logo Child-Resistant Pre-Roll Box Packaging Biodegradable Handmade Luxury 5 Pack Embossing Childproof Pre Roll Package

Custom CR Vape Packaging Cardboard Boxes with Child-Resistant Design

CR custom vape packaging cardboard boxes are specially designed child-resistant packaging solutions crafted to ensure safety, protection, and premium presentation for vape products. Made from sturdy cardboard materials, these boxes balance regulatory compliance with brand aesthetics.

Best pack

Best pack

Best pack