Child-Resistant Closure Types for Pre-Roll Boxes

- Child-Resistant Closure Types for Pre-Roll Boxes

- Why closure choice matters for a pre roll packaging box

- Regulatory context for child-resistant pre roll packaging box

- Key child-resistant closure categories suited to pre-roll packaging box

- Latch-and-slide (sliding drawer) closures

- Push-and-release tuck and tab closures

- Magnetic closures with hidden secondary action

- Dual-action flip or hinged-lid closures

- Blister and peel-seal with two-step access

- Recessed twist or coded closures

- Design trade-offs: safety vs. user experience for pre roll packaging box

- Trade-off: level of child resistance versus adult ease-of-use

- Trade-off: cost and production complexity

- Trade-off: materials, sustainability and recyclability

- Comparing closure types: quick reference for pre roll packaging box decisions

- Testing and certification considerations for pre roll packaging box

- Why testing matters for a pre roll packaging box

- Working with a trusted test lab and supplier

- Practical tips for designing child-resistant pre roll packaging box

- Keep user instructions clear on the packaging

- Balance tactile feedback and durability

- Keep scent and light protection in mind

- Consider branding and on-shelf presence

- Cost and production planning for pre roll packaging box

- Estimate cost drivers for child-resistant closures

- Plan for scalability and inventory management

- Case studies and real-world examples for pre roll packaging box

- Example: sliding drawer for multi-pack pre-rolls

- Example: tuck-tab for large-volume SKUs

- How to choose the right child-resistant closure for your pre roll packaging box

- Step 1: Identify regulatory requirements

- Step 2: Define brand positioning and price point

- Step 3: Prototype and test with adults

- Step 4: Arrange formal child-resistance testing

- Best Pack: strengths and product advantages for pre roll packaging box solutions

- Best Pack's capabilities summarized

- Main product lines and advantages

- Why choose Best Pack for your pre roll packaging box

- Frequently Asked Questions (FAQ)

- Q: What closure type is best for a High Quality pre roll packaging box?

- Q: Can cardboard-only designs be child-resistant for pre roll packaging box?

- Q: Do child-resistant closures affect product freshness?

- Q: Are child-resistant closures required for all cannabis pre-rolls?

- Q: How do I test a child-resistant closure for my pre roll packaging box?

- Q: What are common mistakes when specifying CR closures for pre roll packaging box?

- Sources and further reading

Child-Resistant Closure Types for Pre-Roll Boxes

Why closure choice matters for a pre roll packaging box

Choosing the right child-resistant closure for a pre roll packaging box balances safety, user experience, regulatory compliance, and branding. A well-designed child-resistant closure protects children, reduces liability, meets jurisdictional rules, and can still deliver a High Quality unboxing experience for adult customers without sacrificing brand aesthetics.

Regulatory context for child-resistant pre roll packaging box

In the United States, child-resistant packaging requirements are shaped by federal rules such as the Poison Prevention Packaging Act (PPPA) enforced by the Consumer Product Safety Commission (CPSC), and by state-level cannabis packaging laws that frequently mandate child resistance, resealability, and opacity. Globally, many markets follow similar safety expectations or voluntary testing protocols. This regulatory backdrop makes choosing a proven closure type crucial for any cannabis brand producing pre-rolls.

Key child-resistant closure categories suited to pre-roll packaging box

Latch-and-slide (sliding drawer) closures

Sliding drawer boxes with an internal latch are popular for pre roll packaging box because they combine a High Quality feel with a two-step opening action. The adult must depress or lift a hidden tab while sliding the drawer to open, which provides child resistance while preserving a sleek exterior suitable for branding and labeling.

Push-and-release tuck and tab closures

Tuck-and-tab designs modified for child resistance add an internal locking tab or a squeeze-to-release element. This approach works well for low-cost pre roll packaging box runs and can be engineered so the tab is hidden inside the carton, maintaining a clean visual while delivering a secondary action requirement for opening.

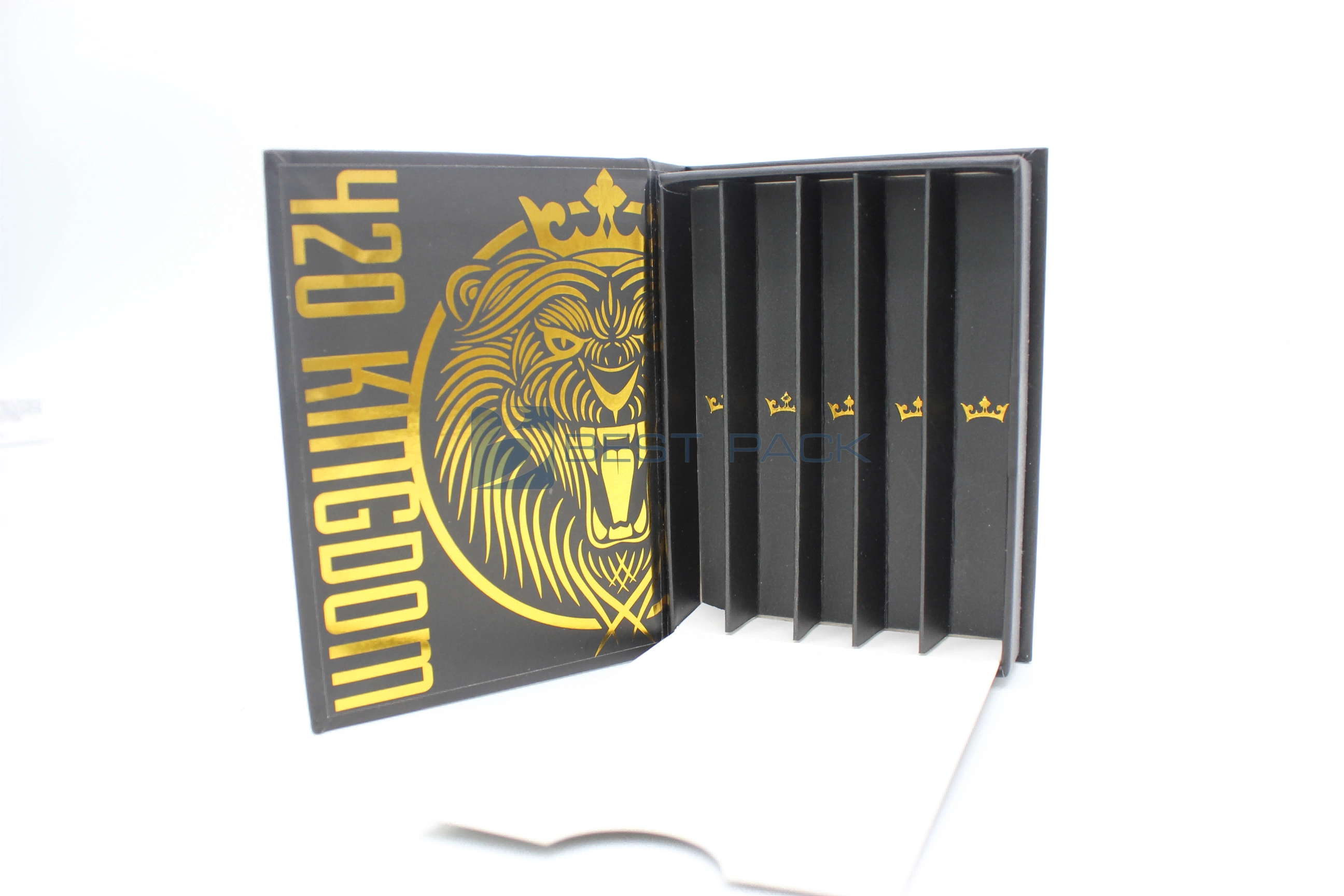

Magnetic closures with hidden secondary action

Magnetic closures are frequently used in High Quality pre roll packaging box lines. By themselves, magnets are not child-resistant, but when combined with a hidden tab or internal latch that must be pressed while opening, they create a two-action requirement that is difficult for children to manage. This solution supports repeat use, resealability, and luxury positioning.

Dual-action flip or hinged-lid closures

Hinged-lid boxes that require pressing an internal latch while flipping the lid perform well as child-resistant pre roll packaging box formats. The tactile interaction can be made intuitive for adults while maintaining complexity for children, and the design supports internal inserts for odor control or rolling paper compartments.

Blister and peel-seal with two-step access

Blister packs or sealed pouches integrated into a pre roll packaging box provide an additional barrier. Examples include an outer carton with an inner peel-and-tear pouch that requires two distinct actions to access the product. This is especially useful for single pre-roll or multi-pack cartridges where an extra tamper-evident and child-resistant layer is preferred.

Recessed twist or coded closures

Some designs use a recessed twist or code-like manipulation where the user must align marks and twist or slide sections simultaneously. These are more complex mechanically but can be effective for High Quality pre roll packaging box lines that want to combine security and distinctive user interaction.

Design trade-offs: safety vs. user experience for pre roll packaging box

Trade-off: level of child resistance versus adult ease-of-use

Higher child resistance typically means more complex opening actions, which can frustrate older adults and frequent customers. The design goal is to meet regulatory requirements and testing while minimizing the cognitive and physical effort required by an adult to open and reseal a pre roll packaging box.

Trade-off: cost and production complexity

Simple CR tuck inserts are cost-effective but can be less High Quality; magnetic + latch systems are more expensive and require tighter production tolerances. Brands should compare expected volumes, price positioning, and supplier capabilities when selecting a closure for a pre roll packaging box.

Trade-off: materials, sustainability and recyclability

Some child-resistant mechanisms incorporate plastic, metal, or mixed materials that complicate recycling. Cardboard-based CR inserts and cleverly engineered paper latches can provide responsible choices for brands prioritizing sustainability for their pre roll packaging box while maintaining regulatory compliance.

Comparing closure types: quick reference for pre roll packaging box decisions

| Closure Type | Child Resistance | Adult Ease-of-Use | Cost | Best Use Case for Pre Roll Packaging Box |

|---|---|---|---|---|

| Latch-and-slide | High | Good (after learning) | Medium | Multi-unit pre-roll packs, High Quality brands |

| Tuck-and-tab (CR insert) | Medium | Good | Low | Large runs, cost-sensitive brands |

| Magnetic + hidden latch | High | Very good | High | Luxury pre roll packaging box, flagship SKUs |

| Hinged-lid + internal latch | High | Good | Medium | Resealable multi-unit boxes |

| Blister + peel-seal | High | Fair | Medium | Single pre-roll, high security + tamper evidence |

| Recessed twist/code | Very High | Fair to Poor | High | Specialty/novelty High Quality pre roll packaging box |

Testing and certification considerations for pre roll packaging box

Why testing matters for a pre roll packaging box

Child-resistance claims should be backed by testing. Suppliers and brands usually subject closures to recognized test protocols to demonstrate that young children cannot access contents while the majority of adults can. Testing reduces liability and helps meet regulatory or state requirements for a pre roll packaging box.

Working with a trusted test lab and supplier

Work with labs experienced in child-resistance testing for consumer products and vendors familiar with cannabis packaging regulations. Include prototypes early in the design cycle to iterate on latch forces, required dexterity, and reseal behavior for your pre roll packaging box.

Practical tips for designing child-resistant pre roll packaging box

Keep user instructions clear on the packaging

Clear pictorial cues and short text on how to open and reclose a child-resistant pre roll packaging box reduce consumer confusion. Indicate two-step actions using icons and brief instructions so adult users can quickly learn the method.

Balance tactile feedback and durability

Adults rely on tactile feedback to open closures confidently. Ensure latches provide clear clicks or resistance without excessive force and design for durability through repeated openings and reseal cycles expected in a pre roll packaging box.

Keep scent and light protection in mind

Many cannabis users value discrete, odor-controlling packaging. Consider integrating inner liners, foil barriers, or odor-absorbing components into your child-resistant pre roll packaging box to meet customer expectations while staying compliant.

Consider branding and on-shelf presence

Child-resistant mechanisms should not undermine Best Pack. Use finishing techniques (embossing, soft-touch coating, spot UV) around the closure so the pre roll packaging box looks High Quality while retaining a functional, compliant design.

Cost and production planning for pre roll packaging box

Estimate cost drivers for child-resistant closures

Major cost drivers include tooling for custom inserts, additional assembly steps, mixed-material components, and lower run-length economies. Early supplier quotes help decide whether to standardize on a low-cost CR insert or invest in a proprietary magnetic-latch pre roll packaging box design.

Plan for scalability and inventory management

Complex closures may increase lead times and require separate inventory for inserts or magnets. Forecast demand and build buffer stock to avoid packaging shortages that can stall product launches for your pre roll packaging box.

Case studies and real-world examples for pre roll packaging box

Example: sliding drawer for multi-pack pre-rolls

A regional cannabis brand switched to a sliding drawer pre roll packaging box with an internal push-tab and saw improved perceived value and reduced customer complaints about product damage. The drawer maintained resealability and provided space for multiple pre-rolls plus terpene/strain labeling.

Example: tuck-tab for large-volume SKUs

Another brand used a cardboard CR tuck insert for high-volume single-unit pre roll packaging box SKUs. The low-cost solution remained compliant with local rules and allowed the brand to compete on price while retaining a consistent shelf presence.

How to choose the right child-resistant closure for your pre roll packaging box

Step 1: Identify regulatory requirements

Confirm federal, state, and local rules that apply to your market for child resistance, opacity, resealability, and labeling. Requirements vary by jurisdiction, so align your pre roll packaging box design early to avoid costly redesigns.

Step 2: Define brand positioning and price point

If you position as High Quality, consider magnetic + hidden latch or sliding drawer solutions. If you need cost-efficiency for mass distribution, CR tuck inserts are a sensible choice for a pre roll packaging box.

Step 3: Prototype and test with adults

Iterative user testing with representative adult users helps refine force thresholds and actions so your pre roll packaging box is usable and reduces return rates or customer frustration.

Step 4: Arrange formal child-resistance testing

Before market launch, commission recognized child-resistance testing to document compliance and support claims about your pre roll packaging box. Maintain records for regulatory inspections and retailer requirements.

Best Pack: strengths and product advantages for pre roll packaging box solutions

Best Pack's capabilities summarized

Best Pack is a custom cannabis cigarette packaging company offering one-stop services from design and printing to craft processing. The company emphasizes high quality, competitive pricing, strong service, and continuous innovation driven by team collaboration and digital tools. Best Pack showcases OEM/ODM capabilities through real customer cases that highlight attention to detail and consistent quality for pre roll packaging box projects.

Main product lines and advantages

Best Pack's core offerings include Child Resistant Packaging Box, cannabis protective packaging, vape packaging, cigarette packaging box, custom vape cartridge boxes, cannabis packaging boxes, custom cannabis packaging, and custom cigarette packaging. Advantages include customizable child-resistant mechanisms, integrated design and printing services, experience with regulatory considerations, and the capacity to produce both economical and High Quality pre roll packaging box solutions to match brand needs. Their full-service model reduces vendor management, shortens development cycles, and helps brands translate packaging ideas into compliant, shelf-ready products.

Why choose Best Pack for your pre roll packaging box

Brands that partner with Best Pack gain access to tailored CR closure engineering, multiple material and finish options, and proven production workflows. Whether you need a recyclable CR tuck-and-tab for high-volume SKUs or a luxury magnetic + latch pre roll packaging box, Best Pack combines design, manufacturing, and quality control to deliver consistent, compliant packaging at competitive pricing. Website: https://www.gzbestpack.com/.

Frequently Asked Questions (FAQ)

Q: What closure type is best for a High Quality pre roll packaging box?

A: Magnetic closures combined with a hidden latch or sliding drawer systems tend to deliver the best High Quality experience while providing strong child resistance and resealability.

Q: Can cardboard-only designs be child-resistant for pre roll packaging box?

A: Yes. Cardboard-based child-resistant inserts and cleverly engineered tuck mechanisms can meet child-resistance goals when properly designed and validated, and they offer better recyclability than mixed-material systems.

Q: Do child-resistant closures affect product freshness?

A: Properly designed CR closures should preserve freshness; many brands add inner liners, foil pouches, or odor-control inserts within the pre roll packaging box to ensure product protection and reseal function.

Q: Are child-resistant closures required for all cannabis pre-rolls?

A: Requirements vary by jurisdiction. Many U.S. states and international markets mandate child-resistant packaging for cannabis products; verify local regulations before finalizing a pre roll packaging box design.

Q: How do I test a child-resistant closure for my pre roll packaging box?

A: Work with a recognized lab experienced in child-resistance protocols. Start with prototypes and informal adult usability tests, then proceed to formal child-resistance testing to document compliance for your pre roll packaging box.

Q: What are common mistakes when specifying CR closures for pre roll packaging box?

A: Common errors include underestimating assembly complexity, neglecting adult usability testing, choosing mixed materials that hinder recycling, and failing to align with specific state or local regulatory details.

Sources and further reading

Consumer Product Safety Commission (CPSC) and Poison Prevention Packaging Act summaries; state-level cannabis packaging regulations; industry design guides and supplier technical datasheets. Consult experienced packaging suppliers and independent test labs for the most current regulatory and testing information.

Sustainability Metrics for Recyclable Child-Resistant Packaging

Top 10 cannabis protective packaging Manufacturers and Supplier Brands

Compliance Checklist for Child-Resistant Packaging Paper Tubes

Cigarette Box Child-Resistant Standards in 2026

About us

When can I get the quotation?

1. The quotation will be offered within 24 hours after getting your detailed request.

2. If you get the urgent inquiry, please call us or mark it via E-mail, then we could make it into priority list.

What is the box size and structure?

1. All boxes are customized and all detailed requirements can be provided by clients, we are definitely your OEM service supplier.

2. If you have no idea about the measurements and structure on your products, our professional design team can suggest and solute for you .

How much of your samples cost ?

1. If samples are without printing, we can make free samples as per your box size or structure;

2. If samples are silk printing, normally USD 25 per color,depending on your logo colors;

3. If samples are offset printing, need USD 180 as offset printing mold cost is high.

FAQs

What types of packaging do you specialize in?

We specialize in electronic packaging, plastic boxes (PVC/PET/PP), paper boxes, paper bags, and custom book printing.

How do you ensure product quality?

We maintain strict quality control at every stage, from material selection to final production, ensuring high-quality standards.

Custom Pre Cone 5 Pack Magnetic Paper Cigarettes Box Pre Roll Packaging Box

Custom Printed Paperboard Cardboard Cigarette Box Packaging Case Disposable Paper Box for Cigarette Clamshell paper box

Custom Vape Packaging Box with CR Telescoping Design

The CR telescoping box is a sophisticated and secure packaging solution designed specifically for vape products. Featuring a telescoping (two-piece) structure, this box offers excellent protection and an elegant presentation, enhancing both the unboxing experience and brand appeal.

Best pack

Best pack

Best pack