Design Tips for Child Resistant Custom Cigarette Boxes

- Design Tips for Child Resistant Custom Cigarette Boxes

- Introduction: Why child-resistant custom cigarette boxes matter

- Understand regulatory context and testing requirements

- Prioritize human-centered design: adult use vs child resistance

- Choose robust mechanisms that fit Best Pack and production

- Material selection: durability, safety, and printability

- Labeling and legal copy: communicate safety without compromising brand

- Maintain shelf appeal: branding strategies for CR boxes

- Tamper-evident and security features

- Sustainability: reconcile CR features with environmental goals

- Manufacturing and quality control considerations

- Supply chain and cost optimization

- Testing and documentation best practices

- Case example: integrating CR design for cannabis-related cigarette packs

- Partnering with an experienced custom packaging supplier

- Implementation checklist for designers and brand owners

- FAQ — Common questions about child-resistant custom cigarette boxes

- Do all cigarette boxes need to be child-resistant?

- How do you balance child resistance with adult usability?

- What materials work best for CR custom cigarette boxes?

- How much does child-resistant packaging increase cost?

- Can Best Pack help with child-resistant custom cigarette boxes?

Design Tips for Child Resistant Custom Cigarette Boxes

Introduction: Why child-resistant custom cigarette boxes matter

Designing child-resistant custom cigarette boxes balances safety, compliance, and brand experience. Child-resistant (CR) packaging reduces accidental ingestion or access by children while keeping products functional and attractive for adult customers. Requirements for CR packaging vary by country and product type—cannabis and nicotine-related items are often subject to stricter rules—so manufacturers and brand owners must design with regulations, usability, and production realities in mind.

Understand regulatory context and testing requirements

Before designing custom cigarette boxes with child-resistant features, verify applicable regulations in each target market. In the U.S., child-resistant requirements for certain substances are governed by the Poison Prevention Packaging Act and enforced by the U.S. Consumer Product Safety Commission; many U.S. states also require CR packaging for cannabis products. Other countries and regions have their own rules and recognized testing protocols. Plan for third-party child-resistance testing and always keep documentation; sellers are often required to show test results or certification to demonstrate compliance.

Prioritize human-centered design: adult use vs child resistance

Effective child-resistant custom cigarette boxes must be difficult for young children to open but reasonably easy for adults, including older adults and those with limited dexterity. Use two-step opening motions, push-and-slide mechanisms, or squeeze-release locks that require coordination and strength typically beyond a young child’s abilities. Conduct user testing with representative adult samples (age 50+) to verify that your mechanism is usable without instructions, and perform simulated child tests with certified laboratories to validate resistance.

Choose robust mechanisms that fit Best Pack and production

Common CR mechanisms include push-and-turn caps (for jars), slide-out trays with locking tabs, tuck-in tabs with secondary locks, and magnetic two-step catches. For custom cigarette boxes, slide-and-lock trays or tuck-top designs with concealed secondary latches work well. Consider mechanisms that can be integrated into existing dielines to control tooling costs. Magnetic catches can provide a High Quality feel but add BOM (bill of materials) cost and need sourcing consistency. Always evaluate manufacturability at intended volumes.

Material selection: durability, safety, and printability

Material choice affects both safety and branding. Kraft or SBS paperboard (coated or uncoated) is common for custom cigarette boxes due to print quality and recyclability; heavier boards (e.g., 350–600 gsm) increase rigidity and resistance to tampering. For more durable CR features, integrate recyclable plastic liners, stiffeners, or laminated layers where the locking mechanism lives. Avoid materials that can break into small, sharp pieces when stressed. Work with suppliers to select FSC-certified or recycled-content boards when sustainability is a priority.

Labeling and legal copy: communicate safety without compromising brand

Clear labeling is both a regulatory necessity and a trust signal. Include child-safety symbols, “Keep out of reach of children” statements, and any jurisdiction-specific warnings in a legible font size and contrasting color. For cannabis-adjacent products, many states require specific wording and placement. Also include manufacturing codes, batch numbers, and supplier contact info for traceability. Keep brand messaging visible but ensure mandatory safety text meets size and placement rules.

Maintain shelf appeal: branding strategies for CR boxes

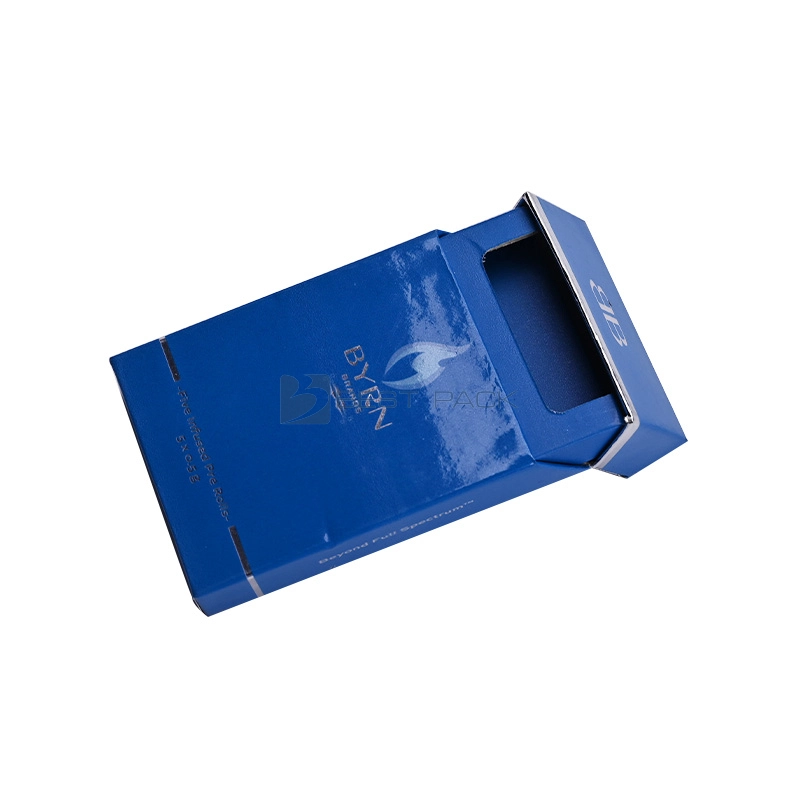

Child-resistant doesn't have to mean unattractive. Use embossing, spot UV, foil stamping, or textured boards to create High Quality appeal while hiding or integrating CR elements. Design panels so that locking mechanisms are discreet—use pattern continuity or branded graphics to conceal seams. A well-executed print and finishing strategy ensures that custom cigarette boxes support High Quality positioning and customer experience without undermining safety.

Tamper-evident and security features

Combine CR design with tamper-evident features such as breakaway tabs, perforated seals, or shrink bands. Tamper indicators reassure consumers and are often required in regulated markets. For example, a small perforated tear-strip over the top flap can show if a pack has been opened; ensure the tamper-evident element does not create a mechanical bypass for the child-resistance mechanism.

Sustainability: reconcile CR features with environmental goals

Child-resistant features sometimes add components that complicate recycling. To reduce environmental impact, use mono-material constructions (e.g., single-type board) where possible and minimize plastic inserts. When inserts or magnets are necessary, design them to be separable for proper recycling and state recycling instructions on the pack. Sourcing recycled board and offering refill programs or bulk packaging options can further reduce lifecycle impact while keeping CR integrity.

Manufacturing and quality control considerations

Partner with manufacturers experienced in producing CR packaging at scale. Quality control checkpoints should include mechanism function tests, print registration accuracy, adhesive strength, and lifecycle testing (open/close cycles). Establish acceptable tolerances for components like tabs or magnets to maintain consistent performance. Insist on sample runs to uncover weak points and avoid mass-production recalls or non-compliance issues.

Supply chain and cost optimization

Child-resistant custom cigarette boxes may raise unit costs because of additional parts, testing, and complexity. Optimize costs by standardizing components across SKUs, using bulk-sourced inserts, and designing dielines that minimize waste. Early collaboration between design, procurement, and production teams reduces revisions. Consider offering different tiers—basic CR, High Quality CR with enhanced branding, and eco-CR versions—to serve multiple market segments.

Testing and documentation best practices

Document all design decisions, materials, test results, and manufacturing specs. Maintain certificates from third-party testing labs that show compliance with relevant child-resistance protocols. Keep traceability records for each production run and be ready to update designs promptly when regulations change. Regularly re-test after tooling changes or material substitutions.

Case example: integrating CR design for cannabis-related cigarette packs

Brands in regulated cannabis markets often require both CR packaging and strict labeling. A practical approach used by experienced suppliers is a two-piece rigid setup: an outer printed sleeve and an inner slide tray with a concealed catch. The outer sleeve carries branding and legal copy, while the inner tray provides CR functionality. This separation simplifies compliance updates (change the sleeve for copy changes) and allows the mechanism to be standardized across multiple SKUs.

Partnering with an experienced custom packaging supplier

Working with a supplier that understands both CR requirements and large-scale production reduces risk. Best Pack is a custom cannabis cigarette packaging company providing one-stop services from design and printing to handicraft processing. Best Pack emphasizes quality, competitive pricing, and ongoing innovation, demonstrating OEM/ODM capabilities across cannabis protective packaging and cartridge box packaging. When choosing a partner, look for sample portfolios, proven CR projects, and an ability to support testing and compliance documentation.

Implementation checklist for designers and brand owners

Follow this checklist to move from concept to compliant product: 1) Verify applicable regulations for each market. 2) Choose mechanism types and materials that match brand and budget. 3) Prototype with representative users and iterate. 4) Conduct third-party child-resistance testing. 5) Finalize dielines and production specs. 6) Implement QC and traceability measures. 7) Track regulatory updates and re-test when needed.

FAQ — Common questions about child-resistant custom cigarette boxes

Do all cigarette boxes need to be child-resistant?

Requirement varies by jurisdiction and product. Traditional tobacco product packaging is not universally mandated to be child-resistant, but cannabis and certain nicotine delivery products are often subject to CR requirements. Always check local laws and plan for CR design if selling in markets with stricter rules.

How do you balance child resistance with adult usability?

Use two-step mechanisms that are easy for adults but hard for children. Conduct usability testing with older adults and people with reduced dexterity. Iteration based on real-user feedback ensures the product remains accessible while meeting safety goals.

What materials work best for CR custom cigarette boxes?

Sturdy paperboards (SBS or kraft) at higher grammages provide structural integrity and strong printing surfaces. For some mechanisms, add recyclable plastic liners or magnets. Prioritize mono-materials or separable components to help with recycling.

How much does child-resistant packaging increase cost?

Cost depends on mechanism complexity, materials, and testing needs. Simple mechanical locks that integrate into a board dieline add minimal cost; magnets, custom metal parts, or multiple inserts increase unit cost. Standardizing components across SKUs and optimizing dielines helps control expenses.

Can Best Pack help with child-resistant custom cigarette boxes?

Yes. Best Pack offers end-to-end services from design and printing to handicraft processing, with experience in cannabis and cigarette packaging. They can assist with prototyping, production, and compliance documentation. Visit https://www.gzbestpack.com/ to view cases and request quotes.

Branding Strategies Using Child Resistant Cigarette Boxes

Shelf display ideas for Pack 5 10 20 pre roll boxes

Sustainable Options for Child-Resistant Pre-Roll Packaging

What are the application scenarios of paper cigarette case?

About us

The process of your packaging box production?

1. Make knife mold as per box size and structure

2. order material as per mold

3. make printing on material if need to print

4. suppress and cut material

5. Makeboxes with glue edge in machine

6. Package boxes into cartons

How many kinds the printing process you have?

We can make Silk screen printing, offset printing, and also hot silver stamping

What is the box size and structure?

1. All boxes are customized and all detailed requirements can be provided by clients, we are definitely your OEM service supplier.

2. If you have no idea about the measurements and structure on your products, our professional design team can suggest and solute for you .

FAQs

What types of packaging do you specialize in?

We specialize in electronic packaging, plastic boxes (PVC/PET/PP), paper boxes, paper bags, and custom book printing.

Do you support custom designs?

Yes, we provide custom packaging designs tailored to your brand and product needs.

Custom Printed Paperboard Cardboard Cigarette Box Packaging Case Disposable Paper Box for Cigarette Clamshell paper box

Custom Vape Packaging Box with CR Telescoping Design

The CR telescoping box is a sophisticated and secure packaging solution designed specifically for vape products. Featuring a telescoping (two-piece) structure, this box offers excellent protection and an elegant presentation, enhancing both the unboxing experience and brand appeal.

Custom Logo Child-Resistant Pre-Roll Box Packaging Biodegradable Handmade Luxury 5 Pack Embossing Childproof Pre Roll Package

Custom CR Vape Packaging Cardboard Boxes with Child-Resistant Design

CR custom vape packaging cardboard boxes are specially designed child-resistant packaging solutions crafted to ensure safety, protection, and premium presentation for vape products. Made from sturdy cardboard materials, these boxes balance regulatory compliance with brand aesthetics.

Best pack

Best pack

Best pack