Everything You Need to Know About cigarette box packaging company

- Everything You Need to Know About cigarette box packaging company

- Introduction: Why selecting the right cigarette box packaging company matters

- Market context and regulatory landscape for cigarette and cannabis packaging

- Child-resistant packaging: safety, compliance, and consumer trust

- Materials and sustainability options from a cigarette box packaging company

- Printing, finishing and branding capabilities that sell

- Custom solutions, OEM/ODM services and real-world case examples

- Quality control, testing and certifications to expect

- Costs, lead time and minimum order quantities (MOQ)

- How to evaluate and choose a cigarette box packaging company

- Design tips to optimize packaging for sales and compliance

- Supply chain, logistics and scalability considerations

- Case for partnering with specialists like Best Pack

- Conclusion: How the right cigarette box packaging company adds value

Everything You Need to Know About cigarette box packaging company

Introduction: Why selecting the right cigarette box packaging company matters

Choosing the right cigarette box packaging company affects product safety, legal compliance, shelf impact and cost. For cannabis and tobacco-related products, packaging is not just a container — it’s a compliance tool, a brand stage and a sales driver. A specialist packaging partner helps you meet strict regulations, create child-resistant solutions and deliver packaging that elevates perceived value and conversion rates.

Market context and regulatory landscape for cigarette and cannabis packaging

Regulations for cigarette and cannabis packaging have tightened globally. In the U.S., child-resistant packaging requirements stem from the Poison Prevention Packaging Act and state-level cannabis laws demand secure packaging. Many countries and regions require clear labeling, tamper-evidence, and restrictions on marketing appeals for nicotine and cannabis products. Working with a cigarette box packaging company that understands these evolving rules reduces legal risk and avoids costly redesigns.

Child-resistant packaging: safety, compliance, and consumer trust

Child-resistant (CR) packaging is essential for cigarettes and cannabis products. CR features — such as push-and-slide closures, lock-inserts, or specialized blister designs — reduce accidental ingestion and demonstrate social responsibility. For cannabis brands especially, state regulators often require tested CR solutions. Selecting a packaging partner experienced in CR design and lab testing ensures compliance and builds consumer trust.

Materials and sustainability options from a cigarette box packaging company

Materials influence cost, appearance and environmental impact. Common options include paperboard, rigid boxes, corrugated cartons, metal tins and plastic or bioplastic inserts. Sustainable choices — recycled paperboard, FSC-certified paper, soy-based inks, and compostable films — are increasingly available and expected by retailers and consumers. A reputable cigarette box packaging company will offer material certificates and advise on circular solutions that balance sustainability with product protection.

Printing, finishing and branding capabilities that sell

High-impact printing and finishing transform a box into a brand asset. Typical capabilities include digital and offset printing, embossing, debossing, foil stamping, spot UV, soft-touch or gloss lamination, and specialized coatings for durability. For limited runs or fast changes, digital printing lowers setup time; for high-volume runs, offset may reduce unit cost. A packaging partner with full-service printing and finishing capabilities helps maintain consistent brand presentation across SKUs.

Custom solutions, OEM/ODM services and real-world case examples

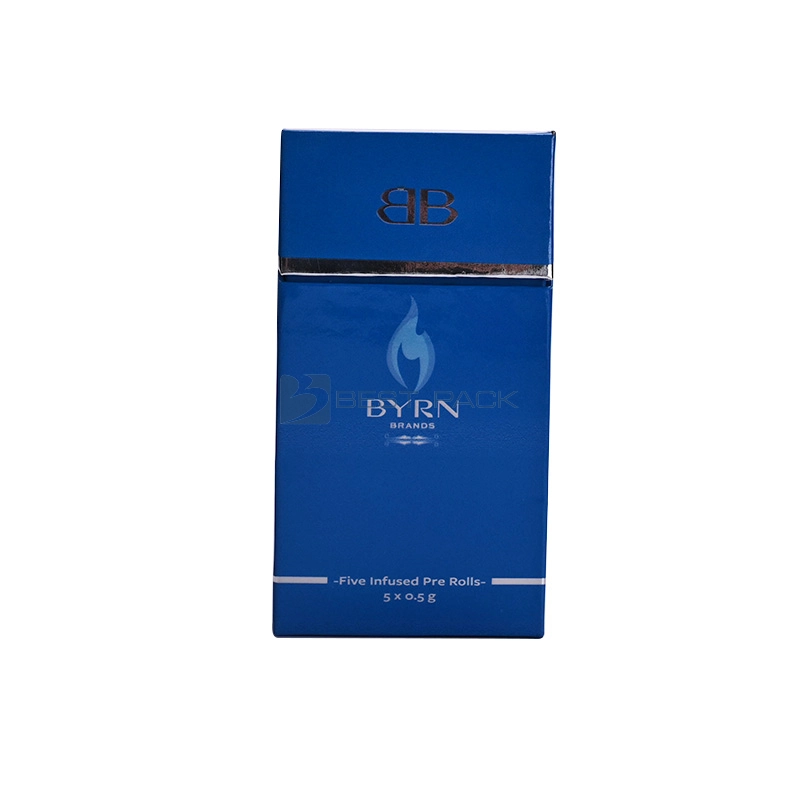

Brands often need unique solutions: custom-fit trays, child-resistant mechanisms, discreet transport packaging or integrated promotional inserts. A full-service cigarette box packaging company offers OEM/ODM services — from concept sketches to prototyping and mass production. Best Pack, for example, is a custom cannabis cigarette packaging company providing one-stop services from design and printing to handicraft processing. Their portfolio ranges from cannabis protective packaging to cartridge box packaging, demonstrating OEM/ODM flexibility and attention to detail.

Quality control, testing and certifications to expect

Quality control is non-negotiable for regulated products. Look for partners with documented QC processes, in-house inspection, and third-party testing for CR performance, material safety and chemical migration if relevant. Useful certifications include ISO 9001 for quality management and FSC chain-of-custody for responsibly sourced paper. A cigarette box packaging company should provide test reports and supply-chain traceability upon request.

Costs, lead time and minimum order quantities (MOQ)

Understanding pricing drivers helps you plan. Costs depend on material, printing complexity, finishing, CR mechanisms, tooling and order quantity. Tooling and die-cut setups add upfront cost but reduce per-unit price for larger runs. MOQs vary widely — some suppliers accept small digital-print batches, while traditional offset runs expect higher MOQs. Typical lead times range from 2–8 weeks: prototyping and approvals add time, while established OEM/ODM partners can streamline schedules through experience and inventory planning.

How to evaluate and choose a cigarette box packaging company

When selecting a packaging partner, evaluate these criteria: 1) Regulatory expertise in tobacco and cannabis packaging; 2) Proof of CR design and testing; 3) Range of materials and sustainable options; 4) In-house design, prototyping and finishing; 5) OEM/ODM case studies and client references; 6) Certifications and QC systems; 7) Transparent pricing and lead times. Request samples, a capability deck and a compliance checklist to compare suppliers objectively.

Design tips to optimize packaging for sales and compliance

Design should balance compliance, protection and brand appeal. Keep required text and warnings legible and positioned per local rules. Use smart dielines to ensure structural integrity and tamper evidence. Integrate features that enhance unboxing — such as slide boxes or magnetic closures — while keeping CR functions effective. Work with packaging designers who understand print separations, color matching (Pantone) and how finishing options affect tactile perception and shelf presence.

Supply chain, logistics and scalability considerations

Reliable supply chain management matters. A cigarette box packaging company should offer flexible inventory options: just-in-time shipments, bulk warehousing or staggered deliveries. Evaluate their supplier network for raw materials, contingency plans for disruptions and export experience if you sell internationally. Scalability means the partner can grow with you, handling seasonal spikes, new SKUs and global rollouts without quality loss.

Case for partnering with specialists like Best Pack

Specialist suppliers bring industry-specific knowledge that general packaging firms may lack. Best Pack positions itself as a custom cannabis cigarette packaging company providing end-to-end services — design, printing, handicraft processing, OEM/ODM execution and examples across cannabis protective packaging and cartridge box packaging. Their emphasis on quality, competitive pricing and continuous innovation matches what many brands need: a partner that understands both market trends and technical compliance challenges.

Conclusion: How the right cigarette box packaging company adds value

A qualified cigarette box packaging company does more than manufacture boxes: it reduces compliance risk, improves product safety with child-resistant options, elevates brand perception through design and finishing, and optimizes cost and logistics. For cannabis and tobacco brands, partnering with a vendor experienced in industry-specific regulations and OEM/ODM workflows — such as Best Pack — accelerates time to market and protects brand reputation. Prioritize companies with proven CR experience, sustainability credentials and transparent quality systems when making your selection.

Frequently Asked Questions

Q: What is child-resistant packaging and why is it important for cigarette and cannabis products?A: Child-resistant packaging uses mechanisms that are difficult for young children to open while remaining accessible for adults. It reduces accidental ingestion risks and is commonly required by regulators for nicotine and cannabis products.

Q: How long does it take to produce custom cigarette boxes?A: Typical lead times vary from 2 to 8 weeks depending on design complexity, prototyping needs, printing method and order size. Working with an experienced OEM/ODM partner can shorten approval cycles.

Q: Can I get sustainable cigarette box packaging without high costs?A: Yes. Using recycled paperboard, FSC-certified materials, water-based inks, and simplified finishing can reduce environmental impact with reasonable cost. Suppliers can recommend the best balance between sustainability and budget.

Q: What is OEM vs ODM in packaging services?A: OEM (Original Equipment Manufacturer) means the supplier manufactures per your design. ODM (Original Design Manufacturer) means the supplier offers design and development alongside manufacturing. Many companies provide both services for turnkey solutions.

Q: Do cigarette box packaging companies handle compliance testing?A: Reputable companies coordinate or provide compliance testing, especially for child-resistant features and material safety. Always request test reports and third-party verification when compliance is critical.

Q: How can Best Pack help my brand?A: Best Pack is a custom cannabis cigarette packaging company offering one-stop services from design and printing to handicraft processing. They provide OEM/ODM solutions, showcase case studies in cannabis protective packaging and cartridge box packaging, and emphasize quality, competitive pricing and innovation. Visit https://www.gzbestpack.com/ for details.

Packaging Regulations Every Brand Should Know About Child-Proof Paper Boxes

Design Tips for Child Resistant Custom Cigarette Boxes

Anti-counterfeit features for premium pre roll boxes

Choosing Suppliers: Key Questions for Custom Packaging Orders

About us

Leading time for samples production?

Normally we need 3-7 days for samples making, 10-12 days to complete your orders,but the delivery time more depends on the order QTY.

How many kinds the printing process you have?

We can make Silk screen printing, offset printing, and also hot silver stamping

The process of your packaging box production?

1. Make knife mold as per box size and structure

2. order material as per mold

3. make printing on material if need to print

4. suppress and cut material

5. Makeboxes with glue edge in machine

6. Package boxes into cartons

When can I get the quotation?

1. The quotation will be offered within 24 hours after getting your detailed request.

2. If you get the urgent inquiry, please call us or mark it via E-mail, then we could make it into priority list.

FAQs

Do you support custom designs?

Yes, we provide custom packaging designs tailored to your brand and product needs.

Custom Printed Paperboard Cardboard Cigarette Box Packaging Case Disposable Paper Box for Cigarette Clamshell paper box

Custom Vape Packaging Box with CR Telescoping Design

The CR telescoping box is a sophisticated and secure packaging solution designed specifically for vape products. Featuring a telescoping (two-piece) structure, this box offers excellent protection and an elegant presentation, enhancing both the unboxing experience and brand appeal.

Custom Logo Child-Resistant Pre-Roll Box Packaging Biodegradable Handmade Luxury 5 Pack Embossing Childproof Pre Roll Package

Custom CR Vape Packaging Cardboard Boxes with Child-Resistant Design

CR custom vape packaging cardboard boxes are specially designed child-resistant packaging solutions crafted to ensure safety, protection, and premium presentation for vape products. Made from sturdy cardboard materials, these boxes balance regulatory compliance with brand aesthetics.

Best pack

Best pack

Best pack