Cost Breakdown: Child-Resistant Pre-Roll Packaging

- Cost Breakdown: Child-Resistant Pre-Roll Packaging - pre roll packaging box

- Why understanding pre roll packaging box costs matters

- Overview of cost drivers for child-resistant pre roll packaging box

- Materials: paper, board, plastic and metal

- Child-resistant mechanisms and their cost impact

- Design, printing and finishing for brand impact

- Tooling, die-cut and setup costs amortized per unit

- Inserts, trays and internal protection

- Assembly, labor and manual operations

- Testing, compliance and certification costs

- Shipping, duties and logistics

- Minimum order quantities (MOQs) and price sensitivity

- Typical per-unit cost ranges by packaging format

- Percent breakdown example: where your dollar goes

- How design choices change costs

- Cost-saving strategies that keep safety and brand value

- Sustainability and recycling considerations

- Lead times and planning to avoid rush costs

- Choosing a supplier: what to evaluate

- Why some brands overpay: common pitfalls

- Case study summary: applying the cost breakdown to pricing

- Best practices checklist before ordering a child-resistant pre roll packaging box

- Best Pack: strengths in custom cannabis and cigarette packaging

- Best Pack product strengths and core offerings

- How Best Pack helps cut costs without sacrificing CR safety or branding

- Practical next steps when engaging a vendor like Best Pack

- Conclusion: balancing cost, compliance and brand

- FAQ: What are common questions about child-resistant pre roll packaging box?

- How much does child-resistant pre roll packaging box cost per unit?

- What lead times should I expect for custom CR packaging?

- Do I need third-party testing for child resistance?

- Can CR packaging be recyclable or sustainable?

- What minimum order quantities are typical?

- How can I reduce packaging cost per unit?

- Who should I contact at Best Pack for a quote?

Cost Breakdown: Child-Resistant Pre-Roll Packaging - pre roll packaging box

Why understanding pre roll packaging box costs matters

For brands selling cannabis pre-rolls, knowing the true cost of a child-resistant pre roll packaging box is essential. Packaging affects price, compliance, shelf appeal, and margins. A clear cost breakdown helps procurement, pricing strategy and product development so brands can balance safety, aesthetics and profitability.

Overview of cost drivers for child-resistant pre roll packaging box

Costs fall into several categories: materials, child-resistant mechanism, printing & finishing, tooling and setup, inserts and internal components, assembly/labor, testing & certification, logistics and overhead. Each element varies by packaging format (paperboard drawer, plastic tube, aluminum tin) and by order size.

Materials: paper, board, plastic and metal

Material choice is one of the largest cost factors. Standard kraft or coated paperboard for a pre roll packaging box is generally lower cost, while rigid board, aluminum and High Quality plastics raise unit cost. Typical material cost ranges: paperboard boxes 0.10-0.60 USD/unit at scale; plastic tubes 0.12-0.80 USD/unit; aluminum tins 0.50-2.50 USD/unit, depending on thickness and finish.

Child-resistant mechanisms and their cost impact

Adding a child-resistant (CR) feature increases complexity and cost. Simple CR slide-locks or push-and-slide drawer locks used in paperboard designs are moderate in cost. Plastic CRC caps or patented push–turn mechanisms are more expensive. Expect an incremental CR cost of ~0.10-1.50 USD/unit depending on mechanism and volume. Costs fall with higher volumes and standardized mechanisms.

Design, printing and finishing for brand impact

Printing and finishing contribute to perceived value. Standard digital or flexo printing is cheaper for short or mid runs; offset is better for high volumes. Add-ons like matte/soft-touch lamination, embossing, foil stamping or full-bleed color increase cost. Typical printing/finishing cost: 0.05-0.70 USD/unit at common volumes; High Quality finishes push that higher.

Tooling, die-cut and setup costs amortized per unit

Custom dies, cutting tools and molds are one-time charges that you amortize over order quantities. Die-cutting tools for paperboard often range 100-600 USD. Injection molds for plastic caps or specialized components can be 1,000-10,000+ USD. For small runs these upfront costs add significantly to per-unit cost; larger runs dilute the tooling expense.

Inserts, trays and internal protection

Internal components ensure product protection and presentation. Simple cardboard inserts are low cost; foam or molded trays cost more. Typical insert costs: 0.03-0.40 USD/unit. Inserts can also provide tamper evidence and help meet regulatory expectations for cannabis packaging.

Assembly, labor and manual operations

Some CR mechanisms and High Quality finishes require hand assembly. Labor costs vary by production location. Automated assembly reduces labor but often requires higher tooling investment. Expect assembly to add 0.02-0.40 USD/unit at scale; hand-finished High Quality boxes will be higher.

Testing, compliance and certification costs

Child-resistant packaging must meet local regulations. In the US, many cannabis products must be packaged in child-resistant containers per state rules and the spirit of the federal Poison Prevention Packaging Act (PPPA) enforced by the CPSC. Third-party lab testing of CR performance is commonly required by states; typical testing costs range 500-3,000 USD per test sequence depending on the lab and scope. Per-unit testing amortization depends on how many SKUs or designs you certify.

Shipping, duties and logistics

Freight and duties impact landed cost. Heavy or bulky designs raise shipping costs. Shipping from Asia to the U.S. or EU varies with volume, seasonal freight rates and whether you choose air or sea. For example, sea freight per-unit for a large order can add 0.05-0.40 USD/unit; air freight will be significantly higher. Factor in storage, local transport and returns handling as well.

Minimum order quantities (MOQs) and price sensitivity

MOQs strongly affect unit price. Small orders (1,000 units or less) often carry higher per-unit prices because tooling and setup costs are spread across fewer pieces. At 10,000 units or more, you may see dramatic unit cost reductions. Plan SKUs and inventory to hit favorable price breaks without overstocking.

Typical per-unit cost ranges by packaging format

Below is a practical cost comparison for common child-resistant pre-roll packaging box formats. These ranges reflect typical manufacturing in Asia with FOB pricing and do not include brand margin or retail markup.

| Format | Estimated cost per unit (1,000 units) | Estimated cost per unit (10,000 units) | Notes |

|---|---|---|---|

| Paperboard drawer pre roll packaging box with CR slide | 1.20 - 2.50 USD | 0.50 - 1.10 USD | Good branding surface; lower weight; CR mechanism moderate cost |

| Plastic tube with CRC cap | 0.80 - 1.80 USD | 0.40 - 0.90 USD | Highly protective and portable; easier to automate |

| Aluminum or tin container with CR lid | 1.50 - 3.50 USD | 0.90 - 1.80 USD | High Quality look and feel; heavier and costlier to ship |

Percent breakdown example: where your dollar goes

As a rule of thumb for a mid-range paperboard pre roll packaging box with CR feature at mid-volume, costs might split approximately: materials 30-45%, printing & finishing 10-20%, CR mechanism 10-20%, tooling amortization 5-15%, assembly & labor 5-15%, testing & compliance 2-8%, freight & logistics 5-10%.

How design choices change costs

Simplifying artwork, using standard dielines, selecting common sizes and minimizing heavy finishing reduce costs. Conversely, special shapes, unique window cuts, multi-component constructions and luxury finishes raise both unit cost and tooling needs.

Cost-saving strategies that keep safety and brand value

To control costs while maintaining compliance and branding: standardize sizes, combine functions (e.g., integrated tray), choose volume-friendly CR mechanisms, use efficient printing methods (digital for short runs), consolidate SKUs, and negotiate bundled services with a single supplier for design, printing and assembly.

Sustainability and recycling considerations

Sustainable materials (recycled content, biodegradable inks, mono-material constructions) are increasingly demanded by consumers and retailers. These may increase material costs by a small margin but can improve marketability. Designing for recyclability (avoid mixed materials that are hard to separate) is both greener and can reduce end-of-life friction.

Lead times and planning to avoid rush costs

Typical lead times: 2-6 weeks for standard stock-style items, 4-12+ weeks for custom designs depending on tooling needs and seasonality. Rushed production or urgent air freight can greatly increase costs, so plan production well ahead of launch and promotional cycles.

Choosing a supplier: what to evaluate

Assess suppliers on compliance support, CR testing experience, OEM/ODM capabilities, quality control, transparency on material specs and costs, and the ability to consolidate services (design, prototyping, printing and assembly). Good suppliers provide samples, test reports and clear MOQs and lead times.

Why some brands overpay: common pitfalls

Pitfalls include poor specification management, frequent design changes, choosing bespoke features without volume to amortize cost, not consolidating manufacturing, and ignoring freight optimization. Clear specifications and partnering with an experienced packaging vendor reduce surprises.

Case study summary: applying the cost breakdown to pricing

If a company targets a retail price of 9.99 USD for a pack of pre-rolls, and packaging cost is 0.80 USD/unit, then packaging consumes about 8% of retail price before distribution and tax. Moving packaging to a High Quality tin that costs 1.80 USD raises packaging share to ~18%. Understanding these trade-offs helps position your product and set margins.

Best practices checklist before ordering a child-resistant pre roll packaging box

Before placing an order: confirm regulatory CR requirements for your markets, finalize dielines and artwork, request CR test protocol capability from supplier, get clear MOQ and tooling quotes, order functional prototypes, and plan inventory for promotional peaks.

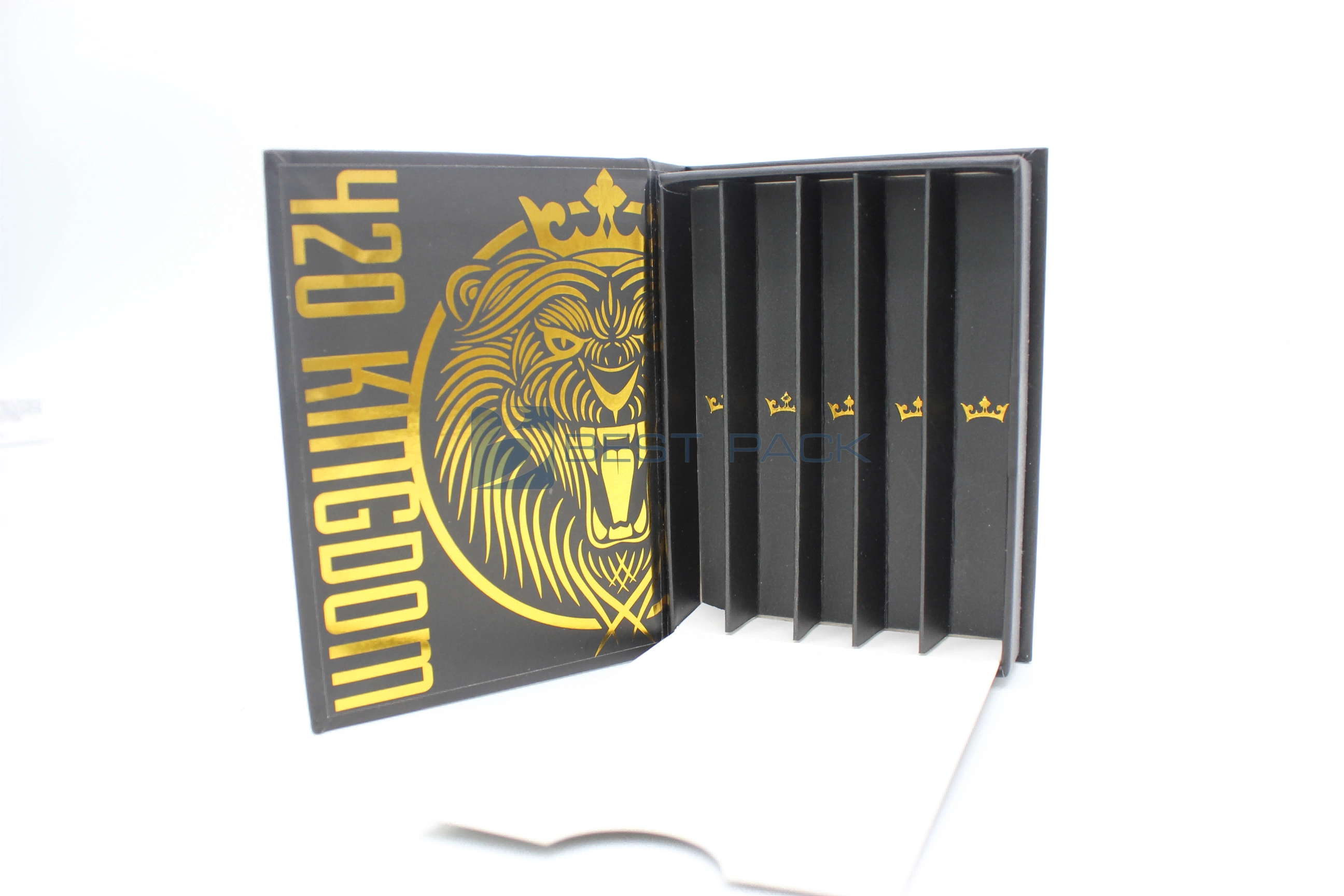

Best Pack: strengths in custom cannabis and cigarette packaging

Best Pack is a custom cannabis cigarette packaging company offering one-stop services from design and printing to handicraft processing. They emphasize high quality, competitive prices and ongoing innovation. Their OEM/ODM experience across cannabis protective packaging, cartridge box packaging and cigarette packaging box gives them practical expertise in CR solutions and presentation. Real customer cases show attention to detail, strong quality control and the ability to deliver tailored, brand-enhancing packaging that drives purchasing decisions.

Best Pack product strengths and core offerings

Best Pack delivers a range of products suitable for cannabis and tobacco brands: Child Resistant Packaging Box, cannabis protective packaging, vape packaging, cigarette packaging box, custom vape cartridge boxes, cannabis packaging boxes, custom cannabis packaging, and custom cigarette packaging. Strengths include flexible customization, quality printing and finishing, compliance-awareness for CR needs, competitive pricing for volume production, and consolidated services that lower lead time and administrative overhead.

How Best Pack helps cut costs without sacrificing CR safety or branding

By combining design, prototyping, printing and assembly, Best Pack can optimize dielines, recommend cost-effective CR mechanisms, and propose material choices that hit price targets while meeting safety standards. Their experience in OEM/ODM workflows helps reduce tooling waste and iterate prototypes faster.

Practical next steps when engaging a vendor like Best Pack

Share your SKU requirements, anticipated volumes and regulatory markets. Ask for sample CR test reports, request a costed options list (materials, finishes, CR types) and a clear breakdown of tooling and per-unit pricing at multiple volumes. Request lead times and shipping options so you can model landed costs accurately.

Conclusion: balancing cost, compliance and brand

Invest time in understanding each cost driver for a child-resistant pre roll packaging box. With the right supplier and design choices you can achieve safe, compliant packaging that supports brand positioning at a predictable cost. Use MOQs, tooling amortization and smart material choices to manage per-unit cost while maintaining quality.

FAQ: What are common questions about child-resistant pre roll packaging box?

How much does child-resistant pre roll packaging box cost per unit?

Costs vary by format and volume. Typical ranges: paperboard CRC drawer box 0.50-2.50 USD/unit, plastic tube with CRC cap 0.40-1.80 USD/unit, aluminum tins 0.90-3.50 USD/unit. Small runs are more expensive per unit due to tooling and setup.

What lead times should I expect for custom CR packaging?

Expect 4-12 weeks for custom designs. Simple stock items can ship faster; prototypes and molds add time. Seasonal peaks in shipping can increase lead times.

Do I need third-party testing for child resistance?

Many states and retailers require proof of child-resistant performance. Third-party testing is common and recommended. Testing costs vary; factor lab fees of several hundred to a few thousand USD into initial project costs.

Can CR packaging be recyclable or sustainable?

Yes. Using mono-material paperboard, recyclable tubes and recyclable inks helps. Avoid mixed-material laminates that hinder recycling. Sustainable options may add modest cost but improve brand appeal.

What minimum order quantities are typical?

MOQs vary by supplier and product. For custom printed paperboard pre roll packaging box MOQs commonly start at 1,000-3,000 units. Specialized plastic components or molded parts may require higher MOQs due to tooling costs.

How can I reduce packaging cost per unit?

Strategies include increasing order volumes, standardizing sizes and artwork, simplifying finishes, choosing cost-effective CR mechanisms, consolidating SKUs and negotiating bundled services with one supplier.

Who should I contact at Best Pack for a quote?

Visit https://www.gzbestpack.com/ to review product lines and contact their sales team. Provide your specifications, target volumes and markets for a tailored quote and prototype plan.

What Is Child Resistant Box Packaging and Why Your Brand Needs It

Tips for Artwork and Logo Placement on Cigar Boxes

Ensuring Child-Resistant Compliance in Custom Cigarette Boxes

Custom Branding on Vintage Cigar Boxes for Retail Buyers

FAQs

Can you ship internationally?

Yes, we export worldwide and work with reliable logistics partners for timely delivery.

What services do you provide?

We offer one-stop packaging solutions, including design, printing, and handicraft processing for electronic boxes, plastic boxes, paper boxes, paper bags, and book printing.

How do you ensure product quality?

We maintain strict quality control at every stage, from material selection to final production, ensuring high-quality standards.

About us

What is the box size and structure?

1. All boxes are customized and all detailed requirements can be provided by clients, we are definitely your OEM service supplier.

2. If you have no idea about the measurements and structure on your products, our professional design team can suggest and solute for you .

When can I get the quotation?

1. The quotation will be offered within 24 hours after getting your detailed request.

2. If you get the urgent inquiry, please call us or mark it via E-mail, then we could make it into priority list.

Custom Pre Cone 5 Pack Magnetic Paper Cigarettes Box Pre Roll Packaging Box

Custom Printed Paperboard Cardboard Cigarette Box Packaging Case Disposable Paper Box for Cigarette Clamshell paper box

Custom Vape Packaging Box with CR Telescoping Design

The CR telescoping box is a sophisticated and secure packaging solution designed specifically for vape products. Featuring a telescoping (two-piece) structure, this box offers excellent protection and an elegant presentation, enhancing both the unboxing experience and brand appeal.

Best pack

Best pack

Best pack