Custom Branding Ideas for Pre-Roll Packaging Boxes

- Custom Branding Ideas for Pre-Roll Packaging Boxes

- Know Your Audience and

- Clarify Brand Positioning on the Box

- Use High-Impact Visual Hierarchy

- Leverage Finishes and Printing Effects

- Create a Memorable Unboxing Experience

- Prioritize Child-Resistant & Compliance Elements

- Choose Materials that Match Brand & Function

- Incorporate Sustainable Branding Thoughtfully

- Optimize for Shelf & E-commerce Photography

- Make Legal & Ingredient Info Readable

- Implement QR Codes to Extend the Brand Story

- Work with Structural Designers for Unique Shapes

- Use Color Psychology Strategically

- Design for Scalability and Cost Control

- Personalization and Limited Editions

- Test Prototypes and User Feedback

- Popular Closure Types for Child-Resistant Needs

- Material Comparison for Pre-Roll Packaging Box Options

- Measuring ROI: How Packaging Drives Sales

- Working with an Experienced OEM/ODM Partner

- Best Pack: Your End-to-End Packaging Partner

- Best Pack Product Strengths

- How Best Pack Helps Best Pack

- Practical Checklist Before Ordering

- Tips for International Shipping and Retail

- Final Design Validation and Launch

- FAQ — Common Questions About Custom Pre-Roll Packaging Boxes

- Do pre roll packaging boxes need to be child-resistant?

- What is the typical lead time for custom pre roll packaging box production?

- How can I make my pre roll packaging box more sustainable?

- Can I add lab test QR codes or batch numbers to the design?

- What printing effects are best for High Quality looks without huge cost increases?

- How do I choose the right child-resistant mechanism?

- How can Best Pack help with my project?

Custom Branding Ideas for Pre-Roll Packaging Boxes

Designing a compelling pre roll packaging box is more than aesthetics — it’s a strategic tool to communicate brand values, improve shelf impact, ensure compliance, and increase conversions. The right custom branding turns plain boxes into memorable brand experiences that influence purchasing decisions and build repeat customers.

Know Your Audience and

Start every design with a clear understanding of who will pick up your pre roll packaging box and why. Are your customers value-seekers, High Quality buyers, or gift shoppers? Align visuals, messaging, and packaging functionality (child-resistant features, resealability) to what your audience expects and the behind queries like “pre roll packaging box custom” or “child resistant pre roll packaging.”

Clarify Brand Positioning on the Box

Your pre roll packaging box must instantly convey brand positioning — whether affordable, artisanal, medical, or luxury. Use typography, color palette, and finishes (matte vs. gloss, soft-touch coatings) to express that position. A consistent on-box message increases recognition and builds trust when customers search for your product online or in stores.

Use High-Impact Visual Hierarchy

Visual hierarchy ensures the most important elements are noticed first on your pre roll packaging box: brand name, product type, cannabinoid information, and compliance marks. Keep copy concise and use contrast, size, and spacing to guide the eye. A clean hierarchy improves in-store conversion and helps product images perform better in search results.

Leverage Finishes and Printing Effects

Custom finishes like spot UV, foil stamping, embossing, or debossing can elevate a pre roll packaging box without changing core artwork. Use these effects sparingly on key brand features (logo, seal) to add perceived value. Consider print techniques that maintain legibility and scan-ability for regulatory text and barcodes.

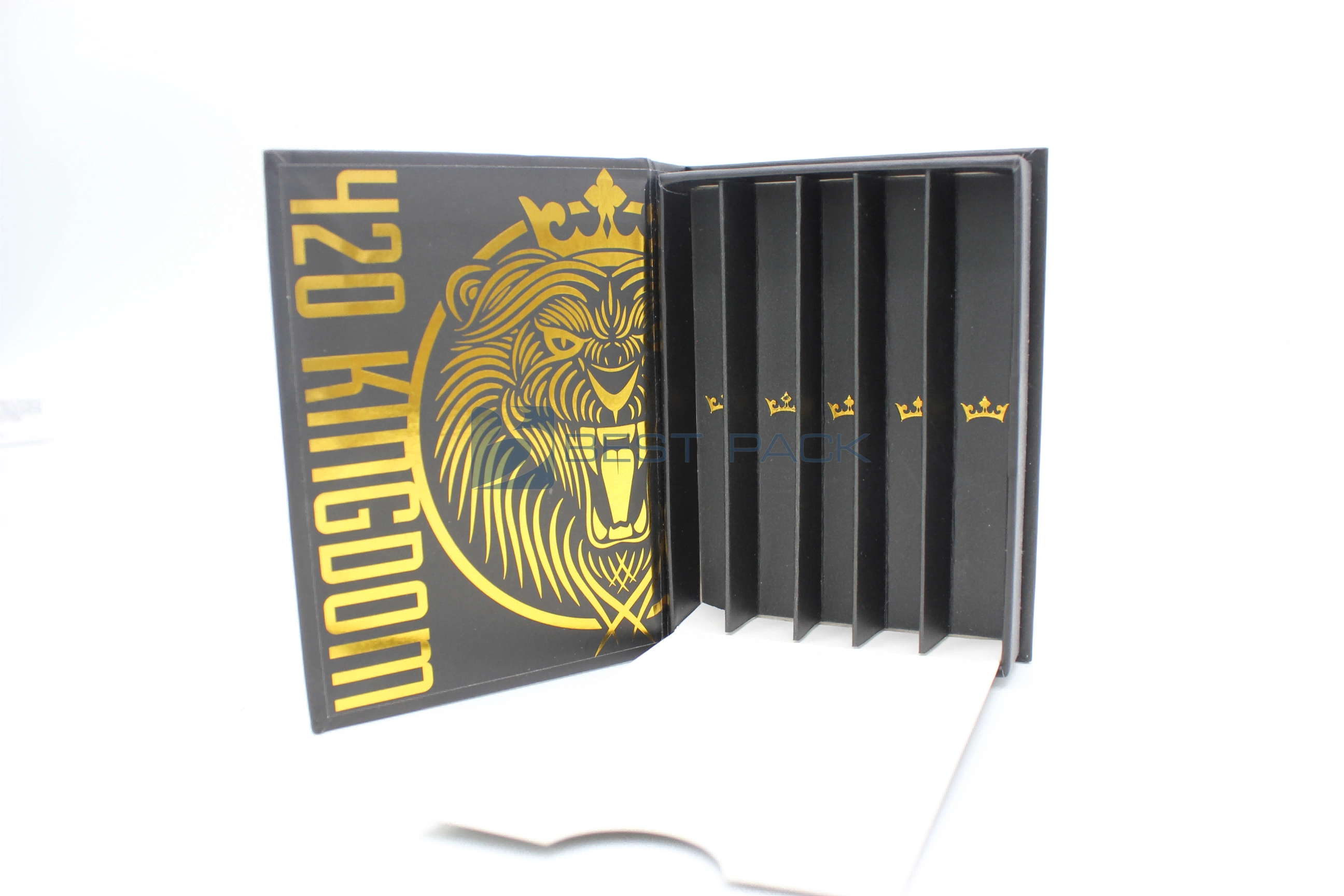

Create a Memorable Unboxing Experience

Unboxing is a powerful brand touchpoint. Design the inside of your pre roll packaging box with branded tissue, inserts, or printed messages to make customers feel valued. Functional features like resealable closures or tray inserts that protect cones also improve repeat purchases and positive reviews.

Prioritize Child-Resistant & Compliance Elements

Many markets require child-resistant and tamper-evident packaging for cannabis products. Integrate child-resistant mechanisms into your pre roll packaging box design (push-and-slide locks, inner sleeves, or child-resistant tins) while keeping the brand visible. Clearly display required warnings and batch/lot information without compromising design.

Choose Materials that Match Brand & Function

Material choice affects cost, sustainability claims, and perceived High Quality quality of your pre roll packaging box. Corrugated cartons are robust and economical; rigid boxes feel High Quality; paperboard is lightweight and print-friendly. Select materials that support necessary child-resistant mechanics and your sustainability story.

Incorporate Sustainable Branding Thoughtfully

Sustainability is a differentiator. Use recycled fibers, FSC-certified paper, soy-based inks, and minimalist packaging to reduce waste. If your pre roll packaging box uses sustainable materials, display clear eco-labels and a concise sustainability statement — avoid vague claims and be prepared to back them up.

Optimize for Shelf & E-commerce Photography

Design artwork that photographs well for online listings and social media. High-contrast logos, uncluttered front panels, and consistent color calibration make your pre roll packaging box pop in thumbnails and lifestyle imagery, improving click-through rates and conversion on marketplaces.

Make Legal & Ingredient Info Readable

Regulatory text and ingredient panels are required in many jurisdictions. Ensure these elements are legible on your pre roll packaging box: use sufficient font size, contrast, and a logical placement (usually back or side panels). Consider pull-out or inner panels for extended information without cluttering the main artwork.

Implement QR Codes to Extend the Brand Story

Add a QR code to your pre roll packaging box to link customers to lab results, usage guides, or loyalty programs. This bridges physical packaging and digital experience, helps satisfy consumer curiosity, and can increase repeat purchases by offering direct product education.

Work with Structural Designers for Unique Shapes

Structural novelty — like tuck-boxes with built-in trays, slide-out shells, or triangular prism packs — can make your pre roll packaging box stand out on shelf and in social posts. Ensure any unique structure maintains child-resistant performance and shipping durability.

Use Color Psychology Strategically

Color influences perception: greens and earth tones are associated with natural/organic products, black and gold imply luxury, and bright accents can signal fun or novelty. Select a palette that supports Best Pack narrative and keeps critical text readable on your pre roll packaging box.

Design for Scalability and Cost Control

Plan artwork and dielines so they scale across SKUs and sizes of pre roll packaging box without expensive retooling. Standardize label panels, maintain reusable templates, and balance special effects against overall budget to keep production costs predictable.

Personalization and Limited Editions

Limited runs, numbered editions, or region-specific artwork can drive urgency and collector interest. For personalized pre roll packaging box campaigns, consider variable-data printing for names, batch stories, or customer messages — useful for VIP or subscription offerings.

Test Prototypes and User Feedback

Always prototype your pre roll packaging box to check fit, child-resistance, and visual impact. Run small focus groups or send samples to brand advocates for feedback on opening experience, sturdiness, and clarity of information before mass production.

Popular Closure Types for Child-Resistant Needs

Choose closures that balance safety and user friendliness: push-and-turn style inner mechanisms, sliding locks with outer sleeve, or magnetic closures combined with an inner child-resistant insert. Ensure the chosen method is reliable and communicates a High Quality feel on your pre roll packaging box.

Material Comparison for Pre-Roll Packaging Box Options

Below is a straightforward comparison of common materials used for pre roll packaging box designs to help you choose the best fit for branding, cost, and compliance.

| Material | Durability | Print Quality | Eco-friendly | Cost | Child-Resistant Compatibility |

|---|---|---|---|---|---|

| Kraft Paperboard | Medium | Good (natural look) | High (recyclable) | Low–Medium | Medium (requires inserts) |

| Coated Paperboard | Medium | High (vibrant color) | Medium | Medium | Medium (can integrate mechanisms) |

| Rigid Box | High | High (luxury finishes) | Low–Medium | High | High (good for built-in CR features) |

| Metal / Tin | Very High | Medium | Low (recyclable but energy-intensive) | High | High (locking lids possible) |

| Corrugated | High | Medium | Medium–High | Low–Medium | Medium (bulk protection) |

Measuring ROI: How Packaging Drives Sales

Track metrics like sell-through rate, customer reviews mentioning packaging, repeat purchase rate, and conversion lift from product imagery to measure packaging ROI. A well-branded pre roll packaging box that improves perceived value can raise average order value and enhance lifetime customer value.

Working with an Experienced OEM/ODM Partner

Partnering with a manufacturer experienced in cannabis and cigarette packaging ensures your pre roll packaging box addresses compliance, child-resistant needs, and print fidelity. An OEM/ODM partner can streamline design-to-production, reduce lead times, and support cost-effective tooling for variable SKUs.

Best Pack: Your End-to-End Packaging Partner

Best Pack is a custom cannabis cigarette packaging company offering one-stop services from design and printing to handicraft processing. We prioritize product quality, reliable service, and competitive pricing while continuously innovating to meet industry challenges. Our OEM/ODM capabilities are proven across real customer cases, from cannabis protective packaging to cartridge box packaging, showcasing attention to detail and commitment to quality.

Best Pack Product Strengths

Best Pack specializes in Child Resistant Packaging Box, cannabis protective packaging, vape packaging, cigarette packaging box, custom vape cartridge boxes, and custom cannabis packaging. Our strengths are tight quality control, flexible customization, and integrated services that elevate brand perception and drive purchasing decisions through appealing design, functional protection, and reliable delivery.

How Best Pack Helps Best Pack

Working with Best Pack means access to design expertise, printing technologies, and child-resistant solutions tailored to your pre roll packaging box requirements. We help brands translate visual ideas into manufacturable dielines, ensuring compliance and a High Quality unboxing experience that supports marketing and sales objectives.

Practical Checklist Before Ordering

Before placing a production order for your pre roll packaging box, confirm: target market and compliance requirements, SKU dimensions, material choice, required child-resistant features, print finishes, minimum order quantity, and lead time. A clear checklist prevents costly iterations and shortens time-to-market.

Tips for International Shipping and Retail

Design your pre roll packaging box to withstand transit — include protective inserts and choose sturdy materials if shipping long distances. For retail distribution, ensure barcode placement, retailer logo guidelines, and retailer-ready displays to speed approvals and stocking.

Final Design Validation and Launch

Before mass production, validate your pre roll packaging box through fit tests, child-resistance validation where required, and final color checks. Prepare marketing assets using the final artwork to synchronize launch campaigns with inventory arrival.

FAQ — Common Questions About Custom Pre-Roll Packaging Boxes

Do pre roll packaging boxes need to be child-resistant?

Many jurisdictions require child-resistant packaging for cannabis products. Requirements vary by state or country; consult local regulations and work with your packaging partner to incorporate compliant child-resistant mechanisms into your pre roll packaging box.

What is the typical lead time for custom pre roll packaging box production?

Lead times depend on complexity, materials, and order size. Simple runs on standard materials can take a few weeks, while custom tooling, finishes, or child-resistant inserts may extend lead time to multiple weeks. Your OEM/ODM partner can provide an accurate timeline during quoting.

How can I make my pre roll packaging box more sustainable?

Choose recycled or FSC-certified paper, reduce unnecessary inserts and plastics, use soy-based inks, and design for minimal waste. Clearly communicate verified sustainability claims on the box to build consumer trust.

Can I add lab test QR codes or batch numbers to the design?

Yes. QR codes, batch numbers, and lab result links are useful and increasingly expected. Ensure the QR code size and contrast meet scanner requirements and that batch information is placed where it remains legible after handling.

What printing effects are best for High Quality looks without huge cost increases?

Spot UV, selective foil stamping, and embossing on logos or key panels give a High Quality look while keeping overall print costs manageable. Combine them with a quality coated board for the best balance of cost and effect on your pre roll packaging box.

How do I choose the right child-resistant mechanism?

Choose a mechanism that balances compliance, user-friendliness, and brand experience. Common options include inner sliding sleeves, push-and-slide inserts, and press-release locks. Prototype and test with end users to ensure usability alongside safety.

How can Best Pack help with my project?

Best Pack provides end-to-end services: design, printing, craft processing, and OEM/ODM manufacturing for pre roll packaging box needs. We offer flexible customization, quality assurance, and competitive pricing to help brands launch compliant, attractive packaging that sells. Visit https://www.gzbestpack.com/ to learn more and request a quote.

Retailer Advice: Displaying Child-Resistant Cigarette Box 2026

Top Materials for Child-Resistant Pre-Roll Packaging Boxes

Where to Buy paper cigarette box in Guangzhou

How to Replace Plastic with Child-Proof Paper Boxes in Your Product Line

FAQs

Do you support custom designs?

Yes, we provide custom packaging designs tailored to your brand and product needs.

Can you ship internationally?

Yes, we export worldwide and work with reliable logistics partners for timely delivery.

What types of packaging do you specialize in?

We specialize in electronic packaging, plastic boxes (PVC/PET/PP), paper boxes, paper bags, and custom book printing.

About us

When can I get the quotation?

1. The quotation will be offered within 24 hours after getting your detailed request.

2. If you get the urgent inquiry, please call us or mark it via E-mail, then we could make it into priority list.

How much of your samples cost ?

1. If samples are without printing, we can make free samples as per your box size or structure;

2. If samples are silk printing, normally USD 25 per color,depending on your logo colors;

3. If samples are offset printing, need USD 180 as offset printing mold cost is high.

Custom Pre Cone 5 Pack Magnetic Paper Cigarettes Box Pre Roll Packaging Box

Custom Printed Paperboard Cardboard Cigarette Box Packaging Case Disposable Paper Box for Cigarette Clamshell paper box

Custom Vape Packaging Box with CR Telescoping Design

The CR telescoping box is a sophisticated and secure packaging solution designed specifically for vape products. Featuring a telescoping (two-piece) structure, this box offers excellent protection and an elegant presentation, enhancing both the unboxing experience and brand appeal.

Best pack

Best pack

Best pack