Top Materials for Child-Resistant Pre-Roll Packaging Boxes

- Introduction: Why Material Choice Matters for a Pre Roll Packaging Box

- Key Requirements for Child-Resistant Pre-Roll Packaging Box

- Primary functional requirements

- Top Materials Overview

- Common materials used today

- Paper-Based Materials: Paperboard, SBS, and Kraft

- Why paper remains popular

- Pros and cons

- Plastic Materials: PET, PETG, PP, and HDPE

- Clear plastics for visibility and strength

- Child-resistance and barrier performance

- Flexible Packaging: Mylar and Foil Pouches

- When flexibility and barrier are priorities

- Limitations

- Metal and Glass Options

- High Quality protection and inertness

- Practical considerations

- Comparative Table: Material Attributes for Pre Roll Packaging Box

- Quick side-by-side comparison

- Child-Resistant Mechanisms Compatible with Each Material

- Common CR solutions

- Balancing Barrier, Child-Resistance and Sustainability

- How to prioritize

- Design and Regulatory Considerations

- Labeling, testing and compliance

- Cost Drivers and Manufacturing Practicalities

- What affects the final unit price

- Best Practices for Choosing the Right Pre Roll Packaging Box Material

- Decision checklist

- Case Examples: Common Approaches

- Popular, market-proven combinations

- Why Choose a Custom Solution from a Specialist

- Advantages of OEM/ODM partnerships

- About Best Pack — Advantages and Core Products

- Best Pack’s strengths for custom cannabis packaging

- Main products and their advantages

- Implementation Steps: From Prototype to Production

- Recommended process

- FAQ

- Q: Which material provides the best child resistance for a pre roll packaging box?

- Q: Can a pre roll packaging box be both child-resistant and eco-friendly?

- Q: Do I need laboratory testing for child-resistant packaging?

- Q: How do barrier needs affect material choice?

- Q: What are typical cost trade-offs?

- Sources and Further Reading

- Recommended industry resources

Introduction: Why Material Choice Matters for a Pre Roll Packaging Box

Choosing the right material for your pre roll packaging box affects safety, compliance, shelf life, brand perception and cost. Child-resistant (CR) performance must be balanced with barrier protection (moisture, odor, oxygen), printability, sustainability, and manufacturing feasibility. This guide explains the leading material options, compares their strengths and trade-offs, and shows how to select the best substrate for both regulatory and commercial success.

Key Requirements for Child-Resistant Pre-Roll Packaging Box

Primary functional requirements

Any pre roll packaging box with child-resistant intent should address: tamper evidence, effective child-resistant mechanisms, sufficient barrier to preserve product quality, clear branding and labeling space, and compatibility with testing and certification protocols.Top Materials Overview

Common materials used today

The most widely used materials for pre-roll packaging boxes are paperboard (coated/uncoated), kraft and SBS paper, rigid paperboard with inserts, plastics such as PET, PP or HDPE, flexible foil/mylar pouches, metal tins (aluminum/tinplate), and glass. Each offers different combinations of barrier, durability, printability and recyclability.Paper-Based Materials: Paperboard, SBS, and Kraft

Why paper remains popular

Paperboard and kraft offer excellent printability, High Quality tactile feel, and cost efficiency. They are ideal when brand presentation and sustainability messaging are priorities. For pre roll packaging box applications, paperboard can be engineered with laminated barriers or integrated child-resistant features (e.g., inner locking sleeves, tuck-and-lock designs with CR closures).Pros and cons

Paper-based advantages: high-quality graphics, recyclable in many markets, compostable (depending on coatings), and relatively low cost to produce. Limitations: by itself paper has weaker moisture and odor barriers than plastics or metal; you often need barrier films, foil laminates, or inner liners to preserve pre-roll freshness.Plastic Materials: PET, PETG, PP, and HDPE

Clear plastics for visibility and strength

Rigid PET and PETG are frequently used for clear clamshell-style pre roll packaging boxes, offering visibility of the product, good impact resistance, and excellent printability (via labels or direct printing). Polypropylene (PP) and high-density polyethylene (HDPE) are used for child-resistant jars and tubs; HDPE is favored where robust CR mechanisms and resealability are needed.Child-resistance and barrier performance

Plastics can integrate engineered child-resistant closures (push-and-turn, squeeze-and-turn, or combination lids). They also accept oxygen and moisture barrier liners and can be co-extruded or laminated to improve performance. Recycling rates vary by polymer and region; PET and HDPE are widely recyclable where facilities exist.Flexible Packaging: Mylar and Foil Pouches

When flexibility and barrier are priorities

Mylar and multi-layer foil pouches deliver excellent barrier properties (moisture, oxygen, light) in a lightweight format. These are used for single pre-rolls or small multi-packs where freshness and discreet presentation are key. Child-resistance in flexible formats is commonly achieved with integrated CR zippers or an inner hard container paired with the pouch.Limitations

Flexible pouches have limited structural protection and may be perceived as lower-end unless combined with High Quality outer cartons. Recycling for multi-layer films is limited in many regions, although mono-material solutions are emerging to improve recyclability.Metal and Glass Options

High Quality protection and inertness

Aluminum tins and glass tubes provide strong barrier and inertness — they do not interact with cannabinoids and help preserve terpene profiles. Metal tins are durable and well-suited to child-resistant mechanisms (e.g., locking tins). Glass is excellent for High Quality perception and inertness but is heavier and fragile.Practical considerations

Metal and glass are often used as inner containers combined with an outer paperboard pre roll packaging box to achieve both barrier and branding. Recyclability of metal and glass is high where local infrastructure supports it, but shipping costs and breakage risk must be considered.Comparative Table: Material Attributes for Pre Roll Packaging Box

Quick side-by-side comparison

| Material | Barrier (Moisture/Oxygen) | Child-Resistant Compatibility | Printability & Branding | Sustainability / Recyclability | Cost |

|---|---|---|---|---|---|

| Paperboard (SBS, Kraft) | Medium (needs barrier liner) | Medium (engineered CR features available) | High (excellent printing) | High (recyclable/compostable if uncoated) | Low–Medium |

| PET / PETG | Medium–High | High (rigid CR closures feasible) | High (transparent display) | Medium (recyclable where facilities exist) | Medium |

| HDPE / PP | Medium–High | High (widely used for CR jars) | Medium (labels & print possible) | Medium–High (HDPE widely recycled) | Medium |

| Mylar / Foil Pouch | High | Medium (CR zippers or inner containers needed) | Medium (surface for labels) | Low–Medium (multi-layer films limited) | Low–Medium |

| Aluminum / Tinplate | High | High (locking tins feasible) | Medium (can be printed/embossed) | High (recyclable) | Medium–High |

| Glass | Very High | Medium–High (CR caps available) | High (High Quality look) | High (recyclable) | High |

Child-Resistant Mechanisms Compatible with Each Material

Common CR solutions

Different materials support different CR mechanisms. Rigid plastics and metal tins work well with mechanical closures (push-and-turn, squeeze-and-turn, locking sliders). Paperboard solutions typically combine an outer carton with an inner CR container or use engineered locking sleeves, dual closures, or sealed blister sections. Flexible pouches commonly pair with CR resealable zippers or include an inner rigid container for compliance.Balancing Barrier, Child-Resistance and Sustainability

How to prioritize

Brands must prioritize based on product sensitivity and market expectations. For high-terpene pre-rolls where aroma preservation is crucial, choose a material with strong barrier properties (foil-laminated inner, metal tin, or high-barrier PET). For eco-conscious brands, paperboard with a compostable or mono-material barrier can provide an excellent balance of branding and lower environmental impact. For retailers focused on shelf durability and CR compliance, HDPE jars or PET clamshells with tested CR lids are common.Design and Regulatory Considerations

Labeling, testing and compliance

Your pre roll packaging box must meet local regulations for child-resistant packaging. In the U.S., child-resistant packaging is informed by the Poison Prevention Packaging Act and oversight from agencies such as the CPSC; companies typically perform standardized testing with accredited labs. International markets have different regulatory expectations — always verify requirements where you sell. Include clear labeling for contents, potency, and safety instructions while ensuring labels do not interfere with CR closures.Cost Drivers and Manufacturing Practicalities

What affects the final unit price

Material selection, print complexity, die-cutting, additional barrier lamination, CR mechanism complexity, and assembly (hand-crafted inserts, foam or molded trays) all contribute to cost. High-volume runs lower per-unit price. Prototyping and pre-production testing for CR compliance add up-front costs but reduce regulatory risk.Best Practices for Choosing the Right Pre Roll Packaging Box Material

Decision checklist

- Determine required barrier protection for product freshness.- Confirm the child-resistant standard(s) for your market and intended CR mechanism.- Evaluate brand positioning (High Quality vs. value) and desired shelf presence.- Consider sustainability targets and recycling infrastructure of target markets.- Balance cost against long-term benefits (reduced returns, better shelf life, improved brand trust).Case Examples: Common Approaches

Popular, market-proven combinations

- High Quality: Rigid paperboard outer box + inner aluminum tin or glass tube for strong barrier and High Quality unboxing.- Retail-ready: PET clamshell pre roll packaging box with printed sleeve — good for visibility and secure display.- Eco-focused: Kraft paperboard with mono-material coated liner to improve recyclability while preserving brand green credentials.- Value retail: Mylar pouch inside a simple printed boarder or carton for low cost while maintaining freshness.Why Choose a Custom Solution from a Specialist

Advantages of OEM/ODM partnerships

Custom packaging suppliers can engineer a pre roll packaging box that balances CR compliance, barrier performance and brand aesthetics. Suppliers experienced in cannabis packaging will help avoid common pitfalls — inadequate barrier, incompatible closures, or noncompliant labeling. They also streamline prototyping, testing and production runs.About Best Pack — Advantages and Core Products

Best Pack’s strengths for custom cannabis packaging

Best Pack is a one-stop custom cannabis cigarette packaging company offering design, printing and handicraft processing. The company emphasizes high quality, excellent service, competitive pricing and continuous innovation with a strong team-working spirit. Best Pack’s OEM/ODM capabilities are showcased in real customer cases across cannabis protective packaging and cartridge box packaging. Their focus on attention to detail and quality control helps brands enhance image and drive purchasing decisions through promotions and customer feedback. Their vision is to become the world’s leading cannabis and cigarette packaging box manufacturer. Website: https://www.gzbestpack.com/.Main products and their advantages

- Child Resistant Packaging Box: Expertly engineered CR cartons and boxes that integrate tested CR mechanisms, tamper evidence and compliance support.- Cannabis Protective Packaging: High-barrier and odor-control solutions to preserve terpene and cannabinoid profiles, using laminated liners, tins or hybrid systems.- Vape Packaging: Designed to protect cartridges and batteries with foam inserts, child-resistant closures, and clear branding options.- Cigarette Packaging Box: Custom cigarette boxes with High Quality printing, embossing and secure closures for retail presentation.- Custom Vape Cartridge Boxes & Custom Cannabis Packaging: Tailor-made designs for differentiation, including OEM/ODM support from concept to finished product.- Custom Cigarette Packaging: Integrated solutions for brand protection and market compliance.Each product line benefits from Best Pack’s full-service workflow: concept and structural design, high-quality printing, precision finishing and rigorous quality control, enabling brands to get compliant, attractive and functional pre roll packaging box solutions at competitive prices.Implementation Steps: From Prototype to Production

Recommended process

1) Define product requirements (barrier, CR level, units per pack, shelf life). 2) Select candidate materials and CR mechanisms with your packaging partner. 3) Build prototypes and perform fitment and user testing for closure performance. 4) Conduct regulatory compliance and child-resistance testing with accredited labs. 5) Finalize artwork and order a pilot run before full-scale production.FAQ

Q: Which material provides the best child resistance for a pre roll packaging box?

A: Rigid plastics (HDPE, PET) and metal tins typically provide the most reliable platforms for mechanical child-resistant closures. Paperboard can be compliant when paired with an inner CR container or engineered locking sleeve.Q: Can a pre roll packaging box be both child-resistant and eco-friendly?

A: Yes. Use mono-material paperboard with compostable or recyclable liners, or choose recyclable HDPE containers paired with minimal outer board. Work with suppliers to design mono-material or easily separable components to improve recyclability.Q: Do I need laboratory testing for child-resistant packaging?

A: Yes. To verify compliance you should complete standardized child-resistance testing via accredited labs and follow applicable local regulations or guidelines. Proof of testing is often required by retailers and regulators.Q: How do barrier needs affect material choice?

A: If maintaining terpene and moisture levels is critical, prioritize high-barrier materials (foil laminates, metal tins, or high-barrier plastics) and consider inner liners even if the outer packaging is paperboard for branding.Q: What are typical cost trade-offs?

A: High Quality materials (glass, metal, multi-layer laminates) and complex CR mechanisms raise unit costs. Paperboard and simple plastics are more budget-friendly. Factor in lifecycle costs — better barrier can reduce product loss and returns.Sources and Further Reading

Recommended industry resources

Packaging industry standards and regulatory guidance (such as regional consumer safety agency guidance), manufacturer technical datasheets, and market reports on sustainable packaging are useful when specifying materials. For company-specific capabilities and examples, visit Best Pack’s site at https://www.gzbestpack.com/.

Protecting Cigarettes: Benefits of Paper Drawer Packaging Boxes

Where to Buy custom cigar box

Child-Resistant Features for Paperboard Cigarette Packaging

How Custom Cigarette Packaging Boosts Retail Shelf Appeal

FAQs

How do you ensure product quality?

We maintain strict quality control at every stage, from material selection to final production, ensuring high-quality standards.

What services do you provide?

We offer one-stop packaging solutions, including design, printing, and handicraft processing for electronic boxes, plastic boxes, paper boxes, paper bags, and book printing.

Do you support custom designs?

Yes, we provide custom packaging designs tailored to your brand and product needs.

Can you ship internationally?

Yes, we export worldwide and work with reliable logistics partners for timely delivery.

About us

The process of your packaging box production?

1. Make knife mold as per box size and structure

2. order material as per mold

3. make printing on material if need to print

4. suppress and cut material

5. Makeboxes with glue edge in machine

6. Package boxes into cartons

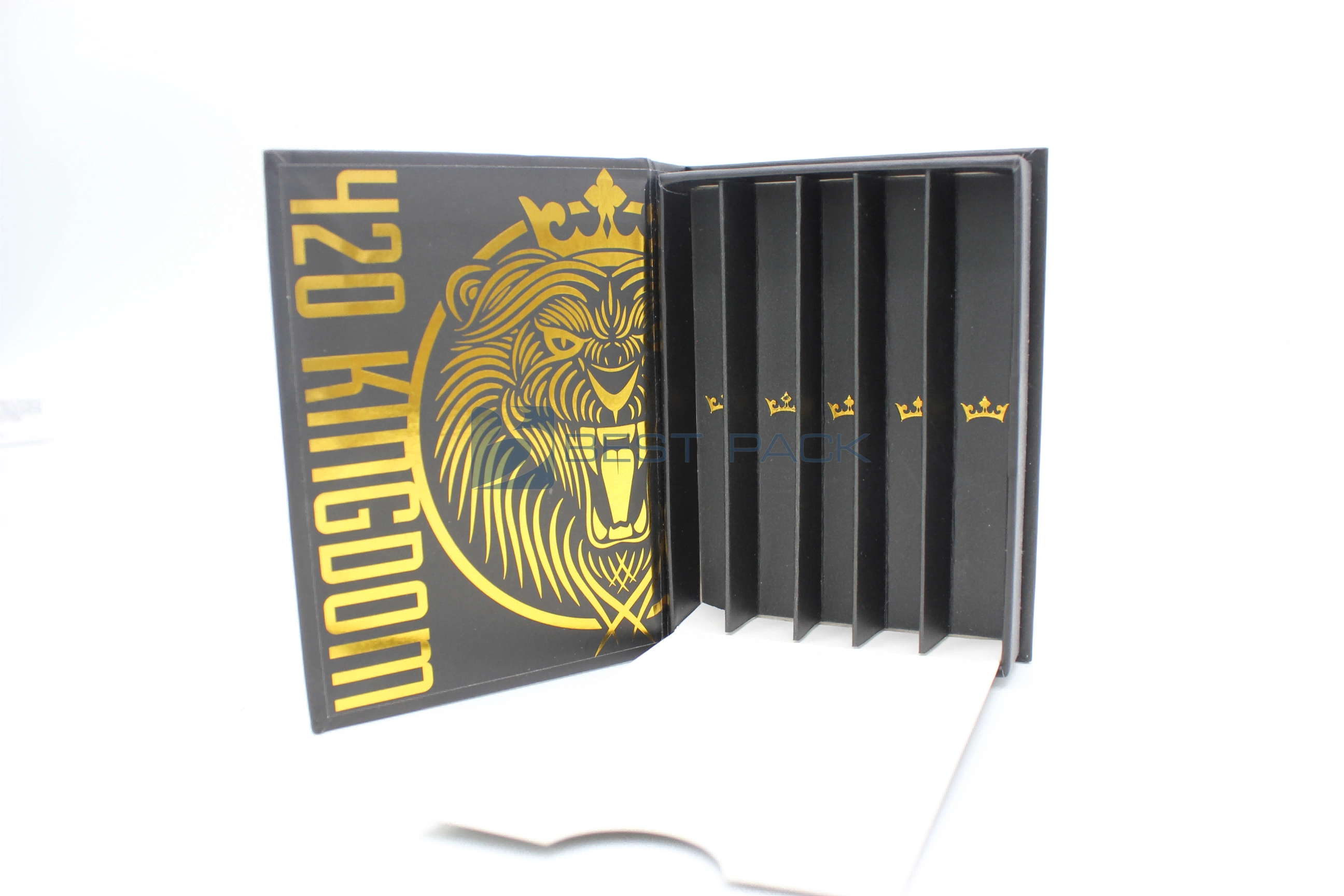

Custom Pre Cone 5 Pack Magnetic Paper Cigarettes Box Pre Roll Packaging Box

Custom Printed Paperboard Cardboard Cigarette Box Packaging Case Disposable Paper Box for Cigarette Clamshell paper box

Custom Vape Packaging Box with CR Telescoping Design

The CR telescoping box is a sophisticated and secure packaging solution designed specifically for vape products. Featuring a telescoping (two-piece) structure, this box offers excellent protection and an elegant presentation, enhancing both the unboxing experience and brand appeal.

Best pack

Best pack

Best pack