E-commerce Shipping Tips for Pre-Roll Packaging Boxes

- E-commerce Shipping Tips for Pre-Roll Packaging Boxes

- Why shipping matters for your pre roll packaging box business

- Understand buyer intent for pre roll packaging box purchases

- Comply with carrier rules and legal constraints

- Choose the right carrier and service levels

- Account for dimensional weight (DIM) to control shipping costs

- Example DIM calculation and cost impact

- Design pre roll packaging box for shipping efficiency

- Material choices: protection, cost, and sustainability

- Packaging material comparison

- Minimize damage with smart internal protection

- Labeling, tracking, and protective labeling

- Returns policy and reverse logistics

- International shipping and customs considerations

- Sustainability and brand value

- Fulfillment operations and kitting best practices

- Packaging testing and insurance

- Improve conversions with clear shipping messaging

- How Best Pack helps with pre roll packaging box shipping challenges

- Best Pack’s OEM/ODM capabilities and fulfillment-friendly designs

- Practical checklist before you ship

- Case example: reducing costs by optimizing box size

- Customer communication templates for shipping

- Analytics to monitor shipping performance

- Final recommendations and next steps

- FAQ

- Can I ship pre roll packaging box products internationally?

- How does dimensional weight affect my shipping bill?

- What packaging materials best protect pre rolls during transit?

- Are there child-resistant packaging requirements for pre roll packaging box?

- How can I reduce shipping costs without increasing damage?

- How does Best Pack support e-commerce brands?

E-commerce Shipping Tips for Pre-Roll Packaging Boxes

Why shipping matters for your pre roll packaging box business

Shipping is a conversion driver. Customers expect fast, affordable, and secure delivery — especially for delicate products like pre roll packaging box items that must remain sealed, child-resistant, and presentable on arrival. Poor shipping choices increase returns, damage rates, and negative reviews, which directly hurt SEO and sales. Optimizing shipping reduces cart abandonment and strengthens Best Pack’s reputation.

Understand buyer intent for pre roll packaging box purchases

When a shopper searches for a pre roll packaging box, their intent can be transactional (buy now), informational (learn about materials, child-resistant features), or commercial (compare suppliers). Address each intent on product pages and shipping policies: list exact dimensions, shipping options, lead times, and compliance information. Clear shipping information answers questions before checkout and improves conversion rates.

Comply with carrier rules and legal constraints

Shipping anything associated with cannabis requires strict compliance. Carriers often restrict or prohibit shipping controlled substances, so check local laws and each carrier’s policy before offering shipping for pre roll packaging box products that will carry cannabis. For hemp or non-controlled accessories, still confirm regulations across regions and verify packaging labels to avoid seizures or delays.

Choose the right carrier and service levels

Select carriers based on where your customers are, their expected delivery speed, and your product risk profile. Offer tiered services (standard, expedited, tracked) and make trade-offs transparent. Standard may be economical for non-urgent bulk orders of pre roll packaging box inventory, while expedited or white-glove options suit B2B clients or retail launch kits.

Account for dimensional weight (DIM) to control shipping costs

Carriers price many packages by dimensional weight — a cost based on volume rather than just scale. For lightweight but bulky boxes, DIM pricing can dramatically increase shipping costs. Design pre roll packaging box dimensions to be compact for typical quantities shipped, and use nested inserts or mailer-friendly folding options to reduce DIM fees.

Example DIM calculation and cost impact

DIM weight is usually calculated as (Length x Width x Height) / carrier divisor (e.g., 5000 cm³/kg or 139 in³/lb depending on carrier). For example, a 40 x 30 x 10 cm box equals 12,000 cm³; dividing by 5000 gives a DIM weight of 2.4 kg. If the actual weight is 0.8 kg, carriers bill 2.4 kg. Being mindful of volume cuts unexpected charges.

Design pre roll packaging box for shipping efficiency

Right-sizing is the most effective strategy. Use corrugated shippers or ship-in-mailer designs that fit the product snugly. Consider collapsible or fold-flat secondary packaging to reduce volume in transit. Incorporate secure inserts to prevent movement, and use tamper-evident seals to reassure customers about product integrity.

Material choices: protection, cost, and sustainability

Material selection balances protection with sustainability and cost. Options range from single-wall corrugated to rigid boxes, kraft mailers, and recyclable foam or molded pulp inserts. Evaluate puncture resistance, moisture resistance, and recyclability to match customer values and reduce damage claims.

Packaging material comparison

Below is a practical comparison to help choose materials for your pre roll packaging box shipments:

| Material | Protection | Cost | Sustainability | Best for |

|---|---|---|---|---|

| Single-wall corrugated | Moderate | Low | High (recyclable) | Most single pre-roll packs, low-cost bulk orders |

| Double-wall corrugated | High | Medium | Medium-High | Multiple units, fragile inserts, international shipments |

| Rigid boxes (paperboard) | High (High Quality look) | High | Varies | Retail display packaging, High Quality pre roll packaging box products |

| Molded pulp inserts | Good (shock absorption) | Medium | High (recyclable/compostable) | Environmentally focused brands |

| Plastic foam / PE inserts | Very High | Medium | Low (less recyclable) | High-value or fragile items requiring precise fit |

Minimize damage with smart internal protection

For pre roll packaging box shipments, internal protection like molded inserts or dividers prevents abrasion and crushing. Choose designs that stabilize each roll without compressing or deforming the product. Testing packaging with drop and compression tests reduces returns and supports insurance claims if transit damage occurs.

Labeling, tracking, and protective labeling

Clear labels reduce transit errors. Use strong barcode labels, include packing lists inside the package, and print handling instructions such as “Fragile” or “Keep Upright” when appropriate. Provide tracking numbers immediately upon shipment. Proactive communication lowers customer anxiety and support tickets.

Returns policy and reverse logistics

A clear returns policy is part of the shipping UX. Offer pre-paid return labels where possible, or require customers to contact support to reduce frivolous returns. Streamlined returns help recover resaleable packaging and maintain inventory accuracy for your pre roll packaging box products.

International shipping and customs considerations

Cross-border shipping adds complexity: customs declarations, harmonized codes (HS), duties, and restricted items lists. Many countries restrict cannabis-adjacent items. Always declare contents accurately and include commercial invoices. When in doubt, consult customs brokers or avoid shipping regulated items internationally.

Sustainability and brand value

Consumers increasingly expect eco-friendly packaging. Recyclable or compostable materials for pre roll packaging box shipments can boost brand perception and reduce landfill waste. Communicate sustainability on product pages and packing slips — customers appreciate transparency and may choose brands that align with their values.

Fulfillment operations and kitting best practices

Efficient fulfillment reduces shipping time and errors. Use batch picking for high-volume SKUs, implement simple packing checklists, and consider automation for labeling and weighing. Kitting pre roll packaging box assortments in advance for subscription or bundle orders saves labor during peak periods.

Packaging testing and insurance

Perform standardized tests: drop, vibration, and compression, in addition to environmental exposure if shipping long distances. Insure high-value shipments and set claims processes internally for faster resolution. Data from claims helps refine packaging choices and justify investments in better materials.

Improve conversions with clear shipping messaging

Display shipping costs and timelines early in the shopping process. Offer shipping estimates by postal code and highlight free or discounted shipping thresholds. According to the Baymard Institute, cart abandonment averages near 70% (Baymard Institute, 2023); unclear or expensive shipping is a major driver. Transparency reduces abandonment and builds trust for pre roll packaging box customers.

How Best Pack helps with pre roll packaging box shipping challenges

Best Pack is a custom cannabis cigarette packaging company that provides one-stop services from design and printing to handicraft processing. We constantly insist on offering products of the best quality, excellent services and competitive prices to our customers. At the same time, the company persists in its team-working spirit and develops innovation continually to meet the chance and challenge brought by the Information Technology Age.

Best Pack’s OEM/ODM capabilities and fulfillment-friendly designs

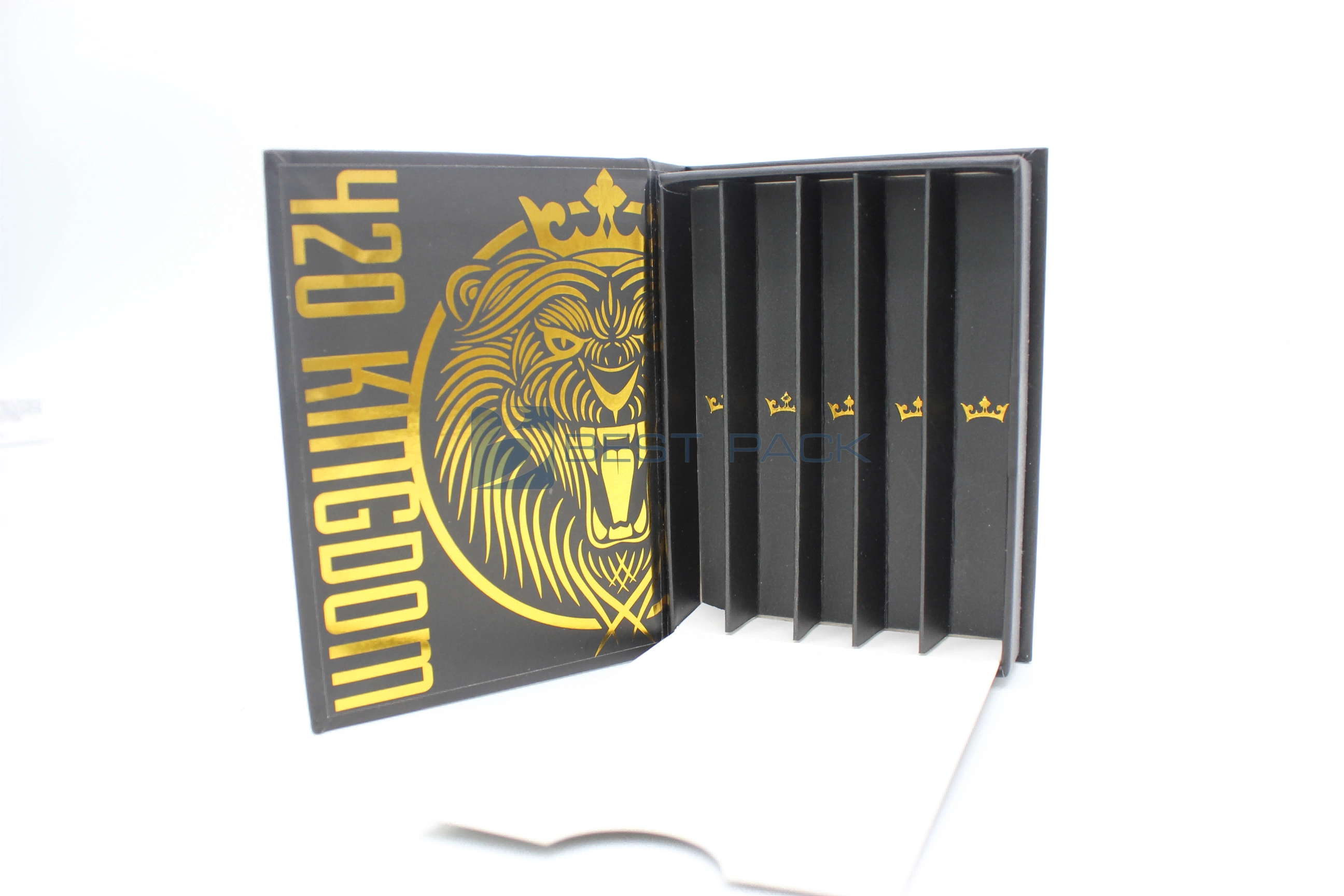

From cannabis protective packaging to cartridge box packaging, our real customer cases showcase our OEM/ODM capabilities, attention to detail, and commitment to quality. We design pre roll packaging boxes that reduce DIM weight, incorporate protective inserts, and meet child-resistant requirements where applicable. Our custom packaging not only enhances Best Pack image but also provides high-quality, tailor-made packaging solutions that elevate brand value, driving more purchasing decisions through promotions and customer feedback.

Practical checklist before you ship

Use this checklist for every SKU of pre roll packaging box: confirm carrier acceptance, measure DIM and actual weight, choose protective inserts, print clear labels, include packing slip, insure high-value shipments, and upload tracking info. Test packaging under real-world conditions twice a year or after any design change.

Case example: reducing costs by optimizing box size

A typical seller reduced average shipping costs by 18% after switching from a 3-unit rigid shipper to a fold-flat mailer with molded pulp inserts. The redesign reduced DIM volume by 30% and lowered damage claims by 12% due to better internal stabilization. Small changes in box geometry often yield outsized savings.

Customer communication templates for shipping

Automate these key messages: order confirmation (with expected ship date), shipping confirmation (carrier, service, tracking), delayed shipment notice (new ETA), and delivery confirmation (request feedback). Include packing and recycling instructions for your pre roll packaging box to reduce post-delivery support questions.

Analytics to monitor shipping performance

Track key metrics: on-time delivery rate, damage rate, claim frequency, shipping cost per order, and cart abandonment linked to shipping cost. Regularly review carrier performance and renegotiate rates or switch services if metrics deteriorate.

Final recommendations and next steps

Prioritize right-sizing, protective inserts, compliance checks, and transparent shipping info on product pages. Test packaging designs, monitor claims data, and iterate. If you need a partner that understands both branding and logistical constraints, consider working with Best Pack to design pre roll packaging box solutions optimized for e-commerce shipping.

FAQ

Can I ship pre roll packaging box products internationally?

Yes, but international shipping requires careful compliance. Many jurisdictions restrict cannabis-related products. Confirm local laws, carrier policies, and customs requirements before shipping internationally. Use HS codes accurately and consider customs brokers for complex routes.

How does dimensional weight affect my shipping bill?

Carriers bill by actual weight or DIM weight, whichever is greater. DIM weight is based on package volume; bulky but light packages may be billed at a higher DIM weight. To reduce charges, decrease empty space and select compact packaging designs for your pre roll packaging box shipments.

What packaging materials best protect pre rolls during transit?

Molded pulp or foam inserts, combined with single- or double-wall corrugated outer boxes, typically provide good protection. Choose materials based on product fragility, desired sustainability, and shipping distance.

Are there child-resistant packaging requirements for pre roll packaging box?

Child-resistant requirements depend on local regulations and whether the packaging will contain regulated substances. Design with child-resistant closures if required by law, and clearly document compliance for carriers and customers.

How can I reduce shipping costs without increasing damage?

Right-size packaging to reduce DIM weight, use efficient inserts, negotiate carrier rates for volume, and consolidate orders where possible. Test packaging to ensure damage rates remain low after any changes.

How does Best Pack support e-commerce brands?

Best Pack offers end-to-end custom design, printing, and handicraft processing, with OEM/ODM capabilities. We optimize packaging for protection, branding, and shipping efficiency while offering competitive pricing and quality control. Visit https://www.gzbestpack.com/ to explore solutions.

How to Choose the cannabis child resistant packaging manufacturer and supplier ?

Packaging Innovations: Smart Cigarette Box Tech in 2026

Choosing paper types for non tobacco pre roll boxes

Ensuring Child-Resistant Compliance in Custom Cigarette Boxes

FAQs

How do you ensure product quality?

We maintain strict quality control at every stage, from material selection to final production, ensuring high-quality standards.

Do you support custom designs?

Yes, we provide custom packaging designs tailored to your brand and product needs.

What services do you provide?

We offer one-stop packaging solutions, including design, printing, and handicraft processing for electronic boxes, plastic boxes, paper boxes, paper bags, and book printing.

About us

What is the box size and structure?

1. All boxes are customized and all detailed requirements can be provided by clients, we are definitely your OEM service supplier.

2. If you have no idea about the measurements and structure on your products, our professional design team can suggest and solute for you .

The process of your packaging box production?

1. Make knife mold as per box size and structure

2. order material as per mold

3. make printing on material if need to print

4. suppress and cut material

5. Makeboxes with glue edge in machine

6. Package boxes into cartons

Custom Pre Cone 5 Pack Magnetic Paper Cigarettes Box Pre Roll Packaging Box

Custom Printed Paperboard Cardboard Cigarette Box Packaging Case Disposable Paper Box for Cigarette Clamshell paper box

Custom Vape Packaging Box with CR Telescoping Design

The CR telescoping box is a sophisticated and secure packaging solution designed specifically for vape products. Featuring a telescoping (two-piece) structure, this box offers excellent protection and an elegant presentation, enhancing both the unboxing experience and brand appeal.

Best pack

Best pack

Best pack