Best Printing Techniques for Pre-Roll Packaging Boxes

- Best Printing Techniques for Pre-Roll Packaging Boxes

- Why Printing Technique Matters for Your Pre Roll Packaging Box

- Digital Printing: Fast, Flexible, Ideal for Short Runs

- Offset (Lithography): Consistent Color for Mid-to-High Runs

- Flexography: Efficient for Corrugated or Film-Based Boxes

- Gravure (Rotogravure): Highest Quality for Very High Volumes

- Screen Printing: Specialty Effects and Textures

- UV & LED-UV Printing: Faster Curing and Durable Prints

- Hot Foil Stamping & Cold Foil: High Quality Metallic Effects

- Embossing & Debossing: Tactile Brand Differentiation

- Varnishes, Coatings & Laminates: Protection and Finish

- Security Printing & Holography for Authenticity

- Material and Ink Selection for Cannabis Pre Roll Packaging Boxes

- Regulatory and Child-Resistant Considerations

- Cost, Run-Length, and Sustainability Trade-Offs (Comparison Table)

- Production Workflow & Quality Control

- Cost Optimization and Sustainability Strategies

- Why Choose Best Pack for Your Pre Roll Packaging Box

- Practical Recommendations for Choosing a Technique

- FAQ — Frequently Asked Questions About Printing for Pre-Roll Packaging Boxes

- What is the minimum order quantity (MOQ) for printed pre roll packaging boxes?

- How long does printing and production take?

- Can printing affect child-resistant features?

- Which printing method is best for sustainable packaging?

- How do I ensure color consistency across multiple production runs?

- Can you add security features like holograms or serialized QR codes?

- How should I choose between digital and offset for my pre roll packaging box?

- Contact and Next Steps

Best Printing Techniques for Pre-Roll Packaging Boxes

The right printing technique can transform a simple pre roll packaging box into a powerful brand touchpoint that protects product integrity, ensures regulatory compliance, and improves shelf impact. This guide explains popular printing options, materials, finishes, cost and run-length considerations, and best practices specific to cannabis pre-roll packaging.

Why Printing Technique Matters for Your Pre Roll Packaging Box

Printing choices affect visual quality, color consistency, production cost, lead time, and the ability to meet child-resistant and regulatory requirements. A pre roll packaging box must communicate potency, warnings, and brand identity clearly while meeting state or country rules for cannabis. The right mix of technique, ink, and finish ensures your product stands out while remaining compliant and cost-effective.

Digital Printing: Fast, Flexible, Ideal for Short Runs

Digital printing is excellent for short runs, frequent SKU variants, and fast turnarounds. It supports full-color CMYK (and extended gamut on some presses) and variable data (batch numbers, QR codes). For pre roll packaging box production, digital minimizes plate costs and allows on-demand printing for seasonal or promotional SKUs.

Advantages: minimal setup, no plates, quick proofs, good color for photos and gradients. Typical best use: runs under 5,000 units, prototyping, personalized packaging.

Limitations: per-unit cost higher at scale, slightly less consistent color match vs offset for long runs, limited specialty effects unless combined with post-print finishing.

Offset (Lithography): Consistent Color for Mid-to-High Runs

Offset printing delivers precise color and fine detail at competitive per-unit costs for medium runs. It uses plates for each color, giving excellent reproduction of Pantone spot colors and high-resolution CMYK. Offset is a strong choice for printed outer sleeves, high-resolution artwork, and multi-panel pre roll packaging box designs.

Advantages: stable color across large runs, high print resolution, cost-effective for 1,000–50,000+ units. Typical lead time: 7–14 days depending on finishing. Limitation: setup time and plate costs mean short runs are less economical.

Flexography: Efficient for Corrugated or Film-Based Boxes

Flexographic (flexo) printing is widely used for corrugated, folding cartons, and film substrates. It’s a high-speed option that works well for simple graphics and solid color coverage on kraft or coated boards used in many pre roll packaging box styles.

Advantages: fast press speeds, scalable for long runs (often >10,000 units), suitable for various substrates. Limitation: fine photographic detail and gradients are less precise than offset or high-end digital presses.

Gravure (Rotogravure): Highest Quality for Very High Volumes

Gravure offers consistent, high-quality printing for extremely large volumes and long runs, often used in flexible films and shrink sleeves. For pre roll packaging box markets where millions of units are required, gravure can provide excellent color fidelity and unique effects when paired with coatings or foils.

Advantages: excellent tone and color consistency at scale; ideal for very high-volume production. Limitation: very high setup costs, long lead times—best when amortized over millions of units.

Screen Printing: Specialty Effects and Textures

Screen printing is chosen for tactile or opaque inks, metallics, and heavy coats (e.g., metallic, white ink on dark substrates). It’s useful for custom effects on a pre roll packaging box, such as thick spot varnish or unique tactile finishes.

Advantages: vivid opaque colors on varied substrates, robust tactile textures. Limitation: slower and costlier per color; best for embellishments rather than full-box coverage at scale.

UV & LED-UV Printing: Faster Curing and Durable Prints

UV-curable inks dry instantly under UV light, allowing immediate finishing and reducing smudge risks. LED-UV presses are energy-efficient and suitable for many substrates used in pre roll packaging box production. UV printing can produce vibrant colors and better adhesion on coatings and synthetics.

Advantages: faster turnaround, durable surface, less solvent emission. Limitation: some UV inks require careful substrate selection to prevent cracking on folds.

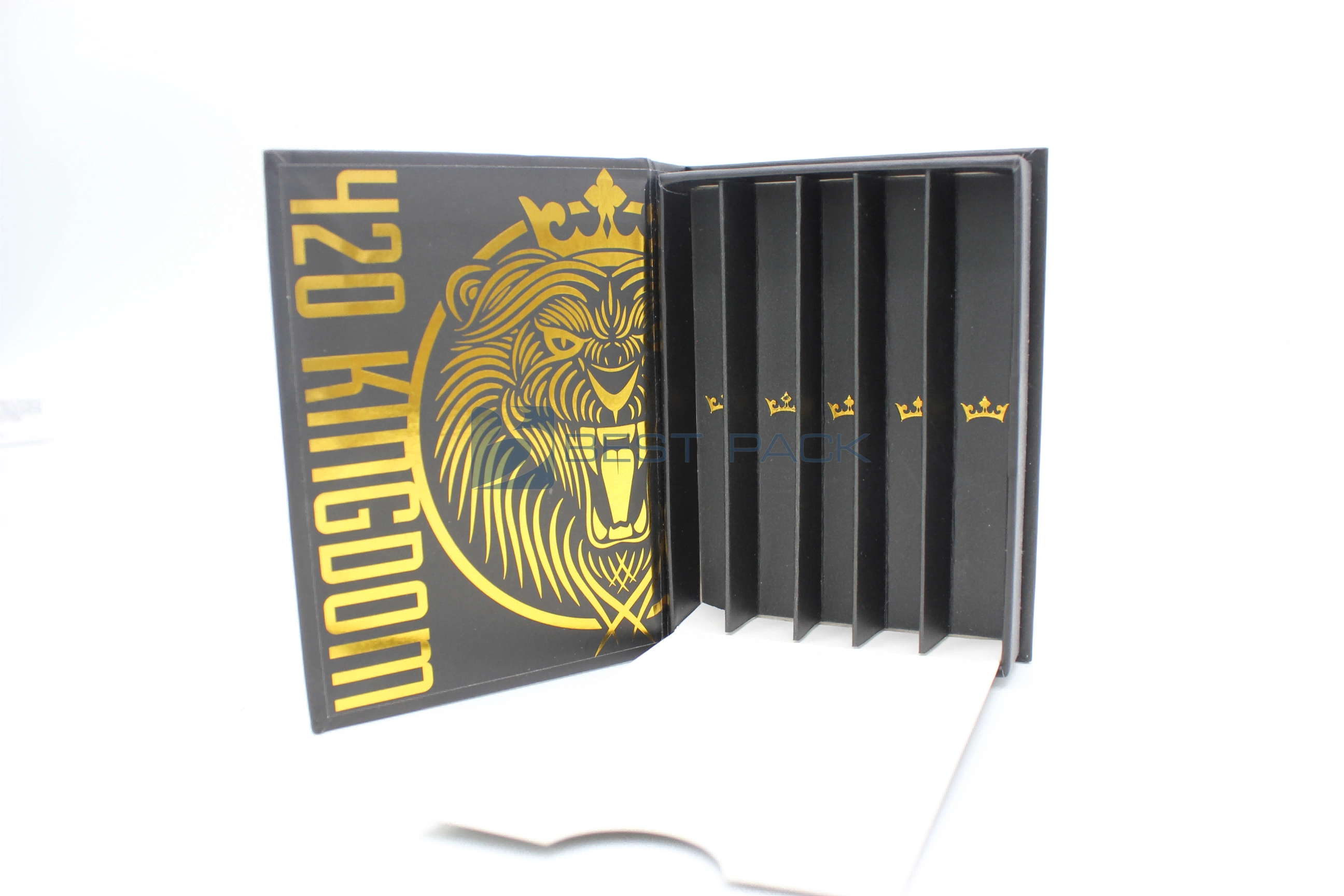

Hot Foil Stamping & Cold Foil: High Quality Metallic Effects

Foiling adds metallic accents and luxury appeal. Hot foil stamping transfers foil through heat and pressure; cold foil (a UV-assisted method) is applied in-line on printing presses. Both are effective on pre roll packaging box panels, logos, and brand marks.

Advantages: High Quality metallic finishes, strong shelf presence. Limitation: cost increases—best used strategically on focal elements rather than entire boxes.

Embossing & Debossing: Tactile Brand Differentiation

Embossing (raised) and debossing (indented) create physical texture on a pre roll packaging box. When paired with foiling or spot UV, these techniques deliver a high-end sensory experience that can justify a price High Quality.

Advantages: tactile differentiation, perceived value increase. Limitation: additional tooling and setup costs; deep embossing may affect stacking and shipping if not planned correctly.

Varnishes, Coatings & Laminates: Protection and Finish

Finishes such as aqueous coatings, UV varnish, soft-touch lamination, and matte/gloss options influence durability, odor control, and tactile feel. A soft-touch laminate can convey luxury, while a gloss or spot UV can highlight specific artwork on a pre roll packaging box.

Advantages: protects print, enhances tactile and visual appeal, can provide moisture resistance. Limitation: each finish adds cost and can affect recyclability—choose based on priority (durability vs sustainability).

Security Printing & Holography for Authenticity

Security features—holographic foils, microtext, tamper-evident seals, serialized QR codes—help prevent counterfeiting and build consumer trust. For cannabis products where authenticity and regulation are important, combining printed security cues with unique packaging is effective.

Material and Ink Selection for Cannabis Pre Roll Packaging Boxes

Substrate choices impact printing performance and regulatory compliance. Common substrates: SBS (coated folding carton), kraft (natural look), coated paperboard, and specialized barrier boards for odor control. Use inks compatible with food-contact or skin-contact regulations when applicable; water-based or soy-based inks are common sustainable choices. For strong color matching, Pantone spot colors are frequently used alongside CMYK process printing.

Regulatory and Child-Resistant Considerations

Cannabis packaging must meet varying state and national regulations—labeling requirements, child-resistant mechanisms, and sometimes opaque packaging rules. The printing process must permit clear, permanent printing of required warnings, amounts, and batch information. For child-resistant packaging, ensure printing and finishing do not compromise mechanical features (e.g., locking tabs). Always verify local regulatory requirements during design and before mass production.

Cost, Run-Length, and Sustainability Trade-Offs (Comparison Table)

| Printing Method | Color Quality | Ideal Run Length | Cost Level | Best For |

|---|---|---|---|---|

| Digital | High for photos; good CMYK | Short (up to ~5,000 units) | Low setup, higher per-unit at scale | Short runs, personalization, prototypes |

| Offset | Very high, excellent color matching | Medium (1,000–50,000+) | Medium per-unit | Detailed artwork, consistent large runs |

| Flexography | Good for solids, limited detail | High (>10,000) | Low per-unit at scale | Corrugated/film boxes, high-speed jobs |

| Gravure | Excellent continuous tone | Very high (hundreds of thousands to millions) | High setup, low per-unit at scale | Huge volumes, High Quality flexible packaging |

| Screen | High for specialty inks | Small to medium | Medium to high | Tactile effects, metallic/opaque inks |

Production Workflow & Quality Control

To minimize revisions and waste, follow a disciplined prepress workflow: provide print-ready dielines, convert to CMYK or provide Pantone specs, supply high-res artwork (300 DPI), request digital or physical proofs, and conduct press checks when possible. Check adhesion, fold cracking, and child-resistant mechanism integrity before full production. For serialized or regulatory printing, confirm barcode and QR readability post-print.

Cost Optimization and Sustainability Strategies

To optimize cost and sustainability: consolidate SKUs where possible, use digital for short runs, use spot treatments rather than full-surface foiling, and choose recyclable or FSC-certified substrates. Reduce material thickness where allowed to lower shipping costs. Many brands now prefer soy-based inks and water-based varnishes to improve recyclability and reduce environmental impact.

Why Choose Best Pack for Your Pre Roll Packaging Box

Best Pack is a custom cannabis cigarette packaging company offering one-stop services—from design and printing to handicraft processing. We emphasize quality, competitive pricing, and continuous innovation. Our OEM/ODM experience spans cannabis protective packaging, cartridge box packaging, and custom pre roll packaging box solutions. We provide sample runs, full regulatory labeling support, and finishing options like foiling, embossing, soft-touch lamination, and child-resistant mechanisms. Visit https://www.gzbestpack.com/ to see real customer cases demonstrating our attention to detail and manufacturing capability.

Practical Recommendations for Choosing a Technique

- For product launches, limited editions, or numerous SKUs: use digital printing to test market response quickly. - For consistent brand color across large runs: select offset printing with Pantone matching. - For corrugated or film-based pre roll packaging box lines at scale: consider flexo for lower per-unit cost. - For luxurious, shelf-differentiated SKUs: combine offset with hot foil, soft-touch lamination, or embossing. - Always prototype to ensure child-resistant features and printed information remain intact after folding and finishing.

FAQ — Frequently Asked Questions About Printing for Pre-Roll Packaging Boxes

What is the minimum order quantity (MOQ) for printed pre roll packaging boxes?

MOQs depend on printing method. Digital printing often allows MOQs as low as a few dozen to a few hundred units. Offset and flexo require higher minimums (commonly 1,000–5,000 units). Gravure typically requires very large runs due to setup costs. Talk to your supplier about staggered production or inventory strategies to manage MOQ impact.

How long does printing and production take?

Typical lead times: digital printing and finishing can be 3–7 business days; offset may take 7–14 days; flexo and gravure may require longer due to plate-making and press scheduling. Special finishes (foiling, embossing) can add extra days. Always plan for regulatory approvals and sample checks.

Can printing affect child-resistant features?

Yes. The printing and finishing process must not interfere with mechanical child-resistant elements. For example, heavy coatings near tabs can change friction or adhesion. Validate the complete assembled pre roll packaging box to ensure child-resistant mechanisms function as required.

Which printing method is best for sustainable packaging?

Sustainability is more about substrate and ink choice than the printing method. Use recycled or FSC-certified paperboard, water- or soy-based inks, and avoid non-recyclable laminates. Digital and offset both support eco-friendly inks and recyclable substrates; minimize full-surface laminations to improve recyclability.

How do I ensure color consistency across multiple production runs?

Use Pantone spot colors where exact matching is critical, maintain print specs and color profiles with your supplier, request color proofs, and keep a master proof for reference. For long-term consistency, standardize on a particular press/facility for repeat runs.

Can you add security features like holograms or serialized QR codes?

Yes. Holographic foils, tamper-evident seals, and variable-data printing (serialized QR codes or batch numbers) are widely used for cannabis packaging to ensure traceability and consumer trust. Discuss integration with your packaging supplier early in the design phase.

How should I choose between digital and offset for my pre roll packaging box?

Choose digital for small, variable, or fast-turn runs; choose offset for predictable mid-to-large runs where color fidelity and lower per-unit costs matter. If unsure, request a cost and lead-time comparison from your packaging partner for a sample run and projected scaled pricing.

Contact and Next Steps

If you need sample boxes, help selecting a printing technique for your pre roll packaging box, or a full OEM/ODM solution, Best Pack can assist from design through finishing. Visit our site at https://www.gzbestpack.com/ or contact our sales team to discuss technical specs, compliance needs, and samples.

Design Tips for Creating Functional and Attractive Child-Safe Paper Boxes

How to Choose the child resistant vape packaging manufacturer and supplier ?

Design Tips for Custom Pre Roll Cone Packaging

Buyer’s Guide: Custom Printing Options for Cigarette Boxes

About us

What is the box size and structure?

1. All boxes are customized and all detailed requirements can be provided by clients, we are definitely your OEM service supplier.

2. If you have no idea about the measurements and structure on your products, our professional design team can suggest and solute for you .

When can I get the quotation?

1. The quotation will be offered within 24 hours after getting your detailed request.

2. If you get the urgent inquiry, please call us or mark it via E-mail, then we could make it into priority list.

How much of your samples cost ?

1. If samples are without printing, we can make free samples as per your box size or structure;

2. If samples are silk printing, normally USD 25 per color,depending on your logo colors;

3. If samples are offset printing, need USD 180 as offset printing mold cost is high.

FAQs

What services do you provide?

We offer one-stop packaging solutions, including design, printing, and handicraft processing for electronic boxes, plastic boxes, paper boxes, paper bags, and book printing.

What types of packaging do you specialize in?

We specialize in electronic packaging, plastic boxes (PVC/PET/PP), paper boxes, paper bags, and custom book printing.

Custom Pre Cone 5 Pack Magnetic Paper Cigarettes Box Pre Roll Packaging Box

Custom Printed Paperboard Cardboard Cigarette Box Packaging Case Disposable Paper Box for Cigarette Clamshell paper box

Custom Vape Packaging Box with CR Telescoping Design

The CR telescoping box is a sophisticated and secure packaging solution designed specifically for vape products. Featuring a telescoping (two-piece) structure, this box offers excellent protection and an elegant presentation, enhancing both the unboxing experience and brand appeal.

Best pack

Best pack

Best pack