Sustainable Child-Resistant Pre-Roll Packaging Options

- Sustainable Child-Resistant Pre-Roll Packaging Options

- Why sustainable pre roll packaging box matters

- Materials to consider for a sustainable pre roll packaging box

- Child-resistant mechanisms that work with sustainable packaging

- Design strategies: balancing safety, sustainability, and user experience

- Supply chain and manufacturing considerations for eco-friendly pre roll packaging box

- How Best Pack supports sustainable, child-resistant pre roll packaging box solutions

- Certifications and verification to look for

- Cost considerations and ROI for switching to sustainable packaging

- Real-world examples and practical formats

- FAQ

- Is a pre roll packaging box required to be child-resistant?

- Can child-resistant mechanisms be recyclable or compostable?

- What certifications should I ask my supplier for?

- Does sustainable packaging cost more?

- How can Best Pack help my brand transition to sustainable pre roll packaging box solutions?

- How should I label sustainable and CR features on-pack?

Sustainable Child-Resistant Pre-Roll Packaging Options

Why sustainable pre roll packaging box matters

Consumers and regulators increasingly expect cannabis brands to minimize environmental impact while keeping products safe for children. A sustainable pre roll packaging box reduces waste, improves brand perception, and can help meet state-level child-resistant requirements for cannabis products. Choosing the right materials and closures allows brands to balance compliance, shelf appeal, and environmental responsibility.

Materials to consider for a sustainable pre roll packaging box

Selecting materials is the first step toward sustainability. Below is a comparison of common material choices for pre-roll packaging and how they perform on recyclability, compostability, cost, and compatibility with child-resistant (CR) mechanisms.

| Material | Recyclability | Compostability | Typical Cost | Child-Resistant Compatibility |

|---|---|---|---|---|

| Recycled Paperboard / Kraft | Widely recyclable in paper stream | Not industrially compostable if laminated; uncoated kraft can biodegrade | Low–Medium | Compatible with CR inserts, sliding tuck, or multi-layer construction |

| FSC-Certified Paperboard | Widely recyclable; verifies responsible sourcing | Similar to paperboard; depends on coatings | Medium | Compatible with many mechanical CR designs |

| PCR Plastics (HDPE/PET) | Recyclable where local streams accept PCR | Not compostable | Medium | Good for screw caps and snap-fit CR lids |

| Compostable Bioplastics (e.g., PLA) | Limited recycling; industrial composting recommended | Compostable in industrial facilities (ASTM D6400 / EN 13432) | Medium–High | Possible but needs specially designed CR closures |

| Aluminum / Metal Tubes | Recyclable widely | Not compostable | High | Compatible with CR caps and child-resistant inserts |

| Glass Tubes | Recyclable; heavier carbon footprint | Not compostable | High | Can pair with CR caps or secondary locking sleeves |

Child-resistant mechanisms that work with sustainable packaging

Child-resistant design is about behavior, not just material. Effective CR mechanisms that can be used with sustainable pre roll packaging box formats include:

- Push-and-turn or squeeze-and-turn caps on tubes and jars (works with PCR-plastic or metal caps)

- Sliding inner-liner inserts in paperboard tubes or boxes that require two-step actions

- Pop-top lids with secondary latches for tins

- Tamper-evident tear strips combined with CR tuck designs for folding cartons

Brands must design CR systems that are reliable over the product’s life, compatible with recycling streams, and able to pass state-required testing for cannabis packaging.

Design strategies: balancing safety, sustainability, and user experience

Good design minimizes material complexity while ensuring CR performance and a High Quality customer experience. Practical strategies include:

- Mono-material design: use the same material for most components so recycling is simpler.

- Minimal coatings: prefer water-based or aqueous coatings over plastic laminates to keep paperboard recyclable.

- Limited ink coverage and soy- or vegetable-based inks to reduce contamination of recycling streams.

- Small, reusable formats (e.g., durable tubes or tins) that encourage reuse instead of single-use disposal.

- Clear on-pack labeling for recycling instructions and CR warnings to help consumers dispose correctly.

Supply chain and manufacturing considerations for eco-friendly pre roll packaging box

Making sustainable choices requires coordination across suppliers. When selecting a packaging partner, look for capabilities such as sourcing recycled or FSC-certified papers, using water-based inks, and offering CR engineering support. Manufacturing processes that reduce waste (die-cut optimization, offcut recycling) also improve environmental performance and can lower costs.

How Best Pack supports sustainable, child-resistant pre roll packaging box solutions

Best Pack is a custom cannabis cigarette packaging company offering one-stop services from design and printing to handicraft processing. We work with clients to specify recycled and FSC-certified paperboard, PCR plastics, and low-impact coatings where available. Our OEM/ODM capabilities include developing CR closures, inner- liner solutions, and folding cartons engineered for recycling. Best Pack’s experience with cannabis protective packaging and cartridge box packaging allows us to tailor sustainable, compliant pre roll packaging box solutions that align with brand goals and regulatory requirements.

Certifications and verification to look for

When evaluating sustainable pre roll packaging box options, check for credible certifications and marks, such as:

- FSC or PEFC chain-of-custody for responsible paper sourcing

- Recycled content claims verified by third parties

- Industrial compostability certifications (e.g., TÜV OK Compost INDUSTRIAL, ASTM D6400 / EN 13432) for compostable plastics

- ISO 14001 or equivalent environmental management certification for manufacturers

- Third-party child-resistance testing and certification per applicable state regulations

Always request documentation and test reports from manufacturers or suppliers before finalizing a design.

Cost considerations and ROI for switching to sustainable packaging

Upfront costs for sustainable materials and CR engineering can be higher than conventional alternatives, particularly for metal, glass, or certified papers. However, benefits include stronger brand differentiation, improved shelf appeal, potential price High Qualitys, and reduced regulatory risk. Efficient design (mono-materials, reduced ink coverage, optimized dielines) can lower production costs and improve recyclability without sacrificing child-resistant performance.

Real-world examples and practical formats

Examples of practical, sustainable pre roll packaging box formats include:

- Recycled paperboard folding carton with an inner sliding CR liner — easy to print, low cost, recyclable where materials are mono-fiber.

- Aluminum tube with recyclable metal cap and CR insert — durable and recyclable, good for High Quality positioning.

- Kraft tuck box with tamper-evident strip and a child-resistant flap mechanism — cost-effective and visually aligned with eco brands.

FAQ

Is a pre roll packaging box required to be child-resistant?

Most U.S. states require child-resistant packaging for cannabis products; requirements are state-specific. Always consult local regulations and third-party testers to ensure compliance.

Can child-resistant mechanisms be recyclable or compostable?

Yes — but design matters. Mono-material solutions (paperboard with paper inserts) are easier to recycle; some compostable plastics can work with CR mechanisms but require industrial composting to fully break down. Avoid mixing incompatible materials that prevent recycling.

What certifications should I ask my supplier for?

Ask for FSC/PEFC for paper, third-party verification of recycled content, industrial compostability certificates (e.g., TÜV OK Compost, ASTM D6400), and ISO 14001 for manufacturers. Also request child-resistance test reports relevant to your market.

Does sustainable packaging cost more?

Material costs can be higher, especially for certified or specialty materials. Smart design and supply chain choices, however, can limit cost increases and often deliver marketing and compliance value that offsets price differentials.

How can Best Pack help my brand transition to sustainable pre roll packaging box solutions?

Best Pack offers end-to-end services — design, material sourcing, printing, and CR engineering. We collaborate with brands to specify recycled or certified materials, optimize designs for recycling, and prototype child-resistant mechanisms that meet local regulatory requirements.

How should I label sustainable and CR features on-pack?

Be clear and honest: provide disposal instructions (e.g., Recycle paperboard), list relevant certifications, and include child-resistant warnings and usage instructions. Clear labeling helps consumers recycle correctly and use CR features safely.

If you’d like a sample, technical drawing, or cost estimate for a sustainable child-resistant pre roll packaging box, Best Pack can provide design options and compliance support tailored to your market.

Top cigarette paper case Manufacturers and Suppliers in China

Child-Resistant Closure Types for Pre-Roll Boxes

Cost-Saving Strategies for Buying Cardboard Childproof Paper Tubes

Where to Buy child safe pre roll packaging box in Guangzhou

FAQs

How do you ensure product quality?

We maintain strict quality control at every stage, from material selection to final production, ensuring high-quality standards.

What services do you provide?

We offer one-stop packaging solutions, including design, printing, and handicraft processing for electronic boxes, plastic boxes, paper boxes, paper bags, and book printing.

What types of packaging do you specialize in?

We specialize in electronic packaging, plastic boxes (PVC/PET/PP), paper boxes, paper bags, and custom book printing.

About us

What is the box size and structure?

1. All boxes are customized and all detailed requirements can be provided by clients, we are definitely your OEM service supplier.

2. If you have no idea about the measurements and structure on your products, our professional design team can suggest and solute for you .

When can I get the quotation?

1. The quotation will be offered within 24 hours after getting your detailed request.

2. If you get the urgent inquiry, please call us or mark it via E-mail, then we could make it into priority list.

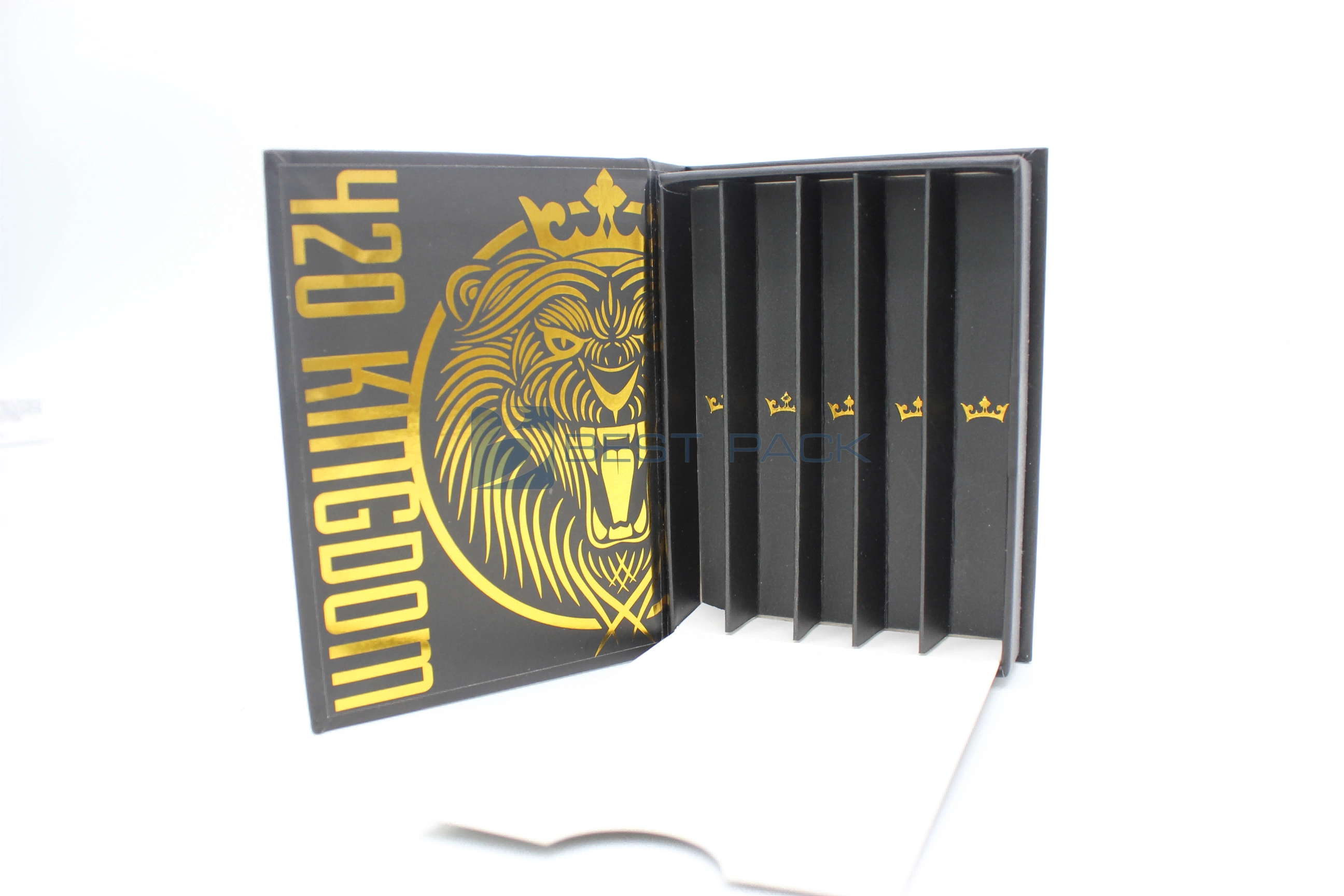

Custom Pre Cone 5 Pack Magnetic Paper Cigarettes Box Pre Roll Packaging Box

Custom Printed Paperboard Cardboard Cigarette Box Packaging Case Disposable Paper Box for Cigarette Clamshell paper box

Custom Vape Packaging Box with CR Telescoping Design

The CR telescoping box is a sophisticated and secure packaging solution designed specifically for vape products. Featuring a telescoping (two-piece) structure, this box offers excellent protection and an elegant presentation, enhancing both the unboxing experience and brand appeal.

Best pack

Best pack

Best pack