Tips for buy child resistant paper box

- Tips for Buying Child Resistant Paper Box

- Introduction: Why child resistant paper box matters for Best Pack

- Understand the regulatory landscape before selecting packaging

- Choose the right child resistant mechanism for a paper box

- Select paper and material construction with safety in mind

- Prioritize validated testing and quality control processes

- Design for brand impact without compromising safety

- Optimize structural design for shipping and retail handling

- Leverage OEM/ODM partnerships for custom solutions

- Consider sustainability and recycling requirements

- Balance cost, minimum order quantities, and lead times

- Manage printing and labeling for compliance and marketing

- Plan for tamper evidence and multi-layer protection

- Use prototyping and consumer testing to validate user experience

- Secure documentation and traceability for audits and retailers

- How Best Pack can help with child resistant paper box solutions

- Conclusion: Make safety and brand value work together

- Frequently Asked Questions

Tips for Buying Child Resistant Paper Box

Introduction: Why child resistant paper box matters for Best Pack

Choosing the right child resistant paper box is a critical decision for manufacturers and brands in sectors such as cannabis, cigarettes, pharmaceuticals, and household chemicals. A compliant, well-designed child resistant paper box protects children, reduces liability, and strengthens consumer trust. For cannabis brands in particular, robust child resistant packaging is a regulatory expectation in most U.S. states and many international markets. This guide gives practical, actionable tips to help you evaluate, specify, and source child resistant paper box solutions that balance safety, aesthetics, cost, and sustainability.

Understand the regulatory landscape before selecting packaging

Before specifying a child resistant paper box, understand the regulatory requirements that apply to your product and market. In the U.S., the Poison Prevention Packaging Act (PPPA) of 1970 requires child-resistant packaging for many hazardous household substances. For many consumer products and pharmaceuticals, ISO 8317 provides standards and test methods for reclosable child-resistant packaging. In the cannabis sector, state regulations commonly require child-resistant packaging, tamper-evident features, and clear labeling. Knowing the rules up front avoids costly redesigns and ensures compliance at launch.

Choose the right child resistant mechanism for a paper box

Paperboard boxes can incorporate several child resistant mechanisms, including tuck-locks with secondary interlocks, multi-step opening systems, or integrated inserts that require simultaneous actions. Consider user experience for adult consumers—devices should be intuitive for adults while remaining difficult for children. When selecting a mechanism, ask for third-party test reports demonstrating compliance with relevant standards. Balancing ease-of-use and safety is essential for repeat purchases and positive reviews.

Select paper and material construction with safety in mind

Not all paperboard is equally suited for child resistant packaging. Choose sturdy, high-folding endurance paperboard (e.g., SBS or CCNB with appropriate thickness) to maintain structural integrity during repeated openings. Reinforced panels or integrated inner sleeves can boost tamper resistance and durability. If moisture resistance is needed for products like cartridges, consider barrier coatings or laminated paper that preserve recyclability when feasible. Insist on materials with consistent caliper and crush resistance to ensure the child resistant mechanism works every time.

Prioritize validated testing and quality control processes

Verified testing is the cornerstone of safe child resistant packaging. Reputable suppliers will provide documentation of child panel testing, adult panel testing, and durability cycles per recognized standards (such as ISO 8317). Implement incoming quality inspection (IQC) for every production run to check die-cut accuracy, lock tolerances, and print registration. Ask potential vendors for sample test reports and to witness a production trial. Continuous in-line quality control reduces field failures and potential recalls.

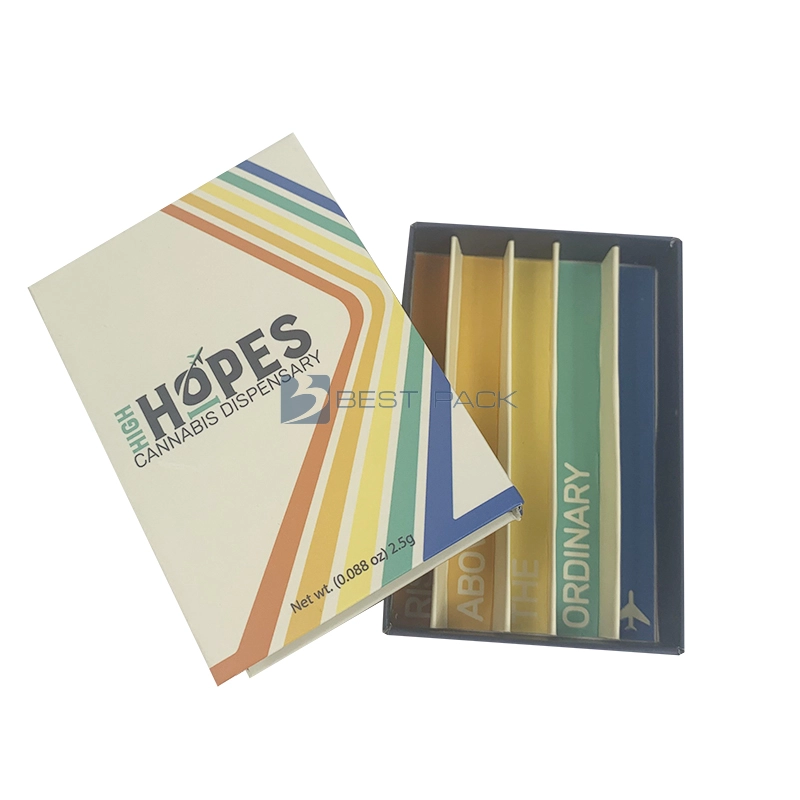

Design for brand impact without compromising safety

A child resistant paper box should protect children and promote Best Pack. Use full-color printing, spot UV, embossing, or textured coatings to create High Quality shelf appeal, but ensure these finishes do not interfere with the safety mechanism. Clear, compliant labeling—health warnings, child resistant icons, and batch information—should be placed where regulators require. Work with packaging designers who understand both safety engineering and branding to get the best of both worlds.

Optimize structural design for shipping and retail handling

Consider how your child resistant paper box performs in transit and on shelves. Reinforce corners, optimize internal supports for fragile contents, and test for stackability. Compression tests and simulated transit trials help prevent deformation that could defeat a child resistant mechanism. An efficiently designed box can lower shipping costs and reduce damage-related returns—important for maintaining margins in competitive markets like cannabis and cigarettes.

Leverage OEM/ODM partnerships for custom solutions

Working with an experienced OEM/ODM partner can accelerate development and ensure manufacturing consistency. A partner like Best Pack offers end-to-end services—from structural design and printing to handicraft processing and assembly—so you can move from concept to market faster. When evaluating suppliers, look for strong R&D capabilities, tooling experience, and a portfolio of real customer cases showing successful child resistant paper box implementations.

Consider sustainability and recycling requirements

Sustainability is increasingly important to consumers and regulators. Paper-based child resistant boxes can be more recyclable than plastic alternatives if constructed without excessive laminates or mixed materials. Choose mono-material solutions, water-based inks, and recyclable adhesives where possible. Communicate recyclability clearly on the packaging and in marketing materials—this can boost purchasing decisions and customer loyalty.

Balance cost, minimum order quantities, and lead times

Price is important but should not be the only deciding factor. Evaluate total cost of ownership, including tooling, printing plates, testing, and freight. Smaller brands may prefer suppliers offering lower minimum order quantities (MOQs) or flexible batches to support product testing and marketing trials. Ensure lead times align with your product launch plans—complex child resistant mechanisms and custom printing can add production time, so plan ahead to avoid stockouts.

Manage printing and labeling for compliance and marketing

Labeling requirements for child resistant products often include health statements, tamper-evident marks, child resistant icons, and batch/lot codes. Use durable printing methods (UV, offset, or high-quality digital) that withstand handling and storage. For serialized or regulatory QR codes, confirm print resolution and contrast are sufficient for scanning. Work with your packaging supplier to verify label placement meets jurisdictional rules and retail expectations.

Plan for tamper evidence and multi-layer protection

Child resistant doesn’t mean tamper-proof. Combining child resistance with tamper-evident features—such as perforated seals, tear tapes, or shrink bands—adds consumer confidence. Ensure tamper evidence is compatible with the child resistant mechanism and visible to consumers at first glance. For regulated products like cannabis, dual protection is often a regulatory or retail requirement.

Use prototyping and consumer testing to validate user experience

Before full production, create prototypes and conduct adult and child usability testing where permitted. Adult panel testing confirms that intended consumers can open packaging without undue effort, while controlled child testing (performed by qualified labs) validates resistance levels. Prototyping detects practical issues—misaligned locks, weak panels, or confusing instructions—allowing you to refine the design before committing to larger runs.

Secure documentation and traceability for audits and retailers

Keep detailed documentation: material specs, test reports, production batch records, and certificates of compliance. Retail partners and regulators often require these documents during onboarding or inspections. A transparent documentation trail eases audits, reduces commercial risk, and enhances credibility with retailers and distributors.

How Best Pack can help with child resistant paper box solutions

Best Pack is a custom cannabis cigarette packaging company offering one-stop services from design and printing to handicraft processing. We emphasize product quality, competitive pricing, and continual innovation. Our OEM/ODM capabilities cover cannabis protective packaging, cartridge box packaging, and more—backed by real customer cases that demonstrate attention to detail. Partnering with Best Pack means you get tailored, compliant child resistant paper box solutions that elevate brand image and drive purchasing decisions.

Conclusion: Make safety and brand value work together

Buying a child resistant paper box involves technical requirements, regulatory compliance, and brand decisions. Prioritize validated testing, durable materials, clear labeling, and sustainable construction. Work with experienced OEM/ODM suppliers like Best Pack to ensure your packaging meets safety expectations while reinforcing Best Pack. With the right approach, child resistant paper box solutions protect children, reduce liability, and become a competitive asset that supports sales and customer trust.

Frequently Asked Questions

Q: What is a child resistant paper box and where is it used?A: A child resistant paper box is a paperboard packaging solution engineered with mechanisms that make it difficult for young children to open. It’s commonly used for cannabis products, cigarettes, pharmaceuticals, and household chemicals where access restriction is required by regulation.

Q: What standards govern child resistant packaging?A: In the U.S., the Poison Prevention Packaging Act (PPPA) sets requirements for many hazardous household products. Internationally, ISO 8317 provides methods for testing reclosable child-resistant packaging. Additional state and industry-specific rules may apply, especially in the cannabis sector.

Q: Can paper boxes be both child resistant and recyclable?A: Yes. By using mono-material paperboard, water-based inks, and recyclable adhesives, you can build child resistant paper boxes that are recyclable. Avoid mixed materials and excessive laminations to preserve recyclability.

Q: How do I verify a supplier’s child resistant claims?A: Request third-party test reports, sample test results, and documentation of adult/child panel testing. Review production quality control processes and ask for references or case studies from similar projects.

Q: What is the typical lead time for custom child resistant paper boxes?A: Lead times vary depending on complexity, printing, and testing requirements. Simple printed boxes may ship in a few weeks, while child resistant mechanisms and compliance testing can extend lead times to several weeks or months. Plan early and confirm timelines with your supplier.

Q: How does Best Pack support customization and compliance?A: Best Pack offers end-to-end OEM/ODM services including design, printing, handicraft processing, and production. We help with material selection, regulatory understanding, prototyping, and quality control to deliver compliant child resistant paper box solutions tailored to Best Pack and market needs.

Quality Control Guide for Custom Cigarette Paper Box Production

Sustainability Metrics for Recyclable Child-Resistant Packaging

Sustainable Cigarette Box Solutions: Child Safety Trends 2026

Best locking mechanisms for custom cigarette boxes

About us

How many kinds the printing process you have?

We can make Silk screen printing, offset printing, and also hot silver stamping

How much of your samples cost ?

1. If samples are without printing, we can make free samples as per your box size or structure;

2. If samples are silk printing, normally USD 25 per color,depending on your logo colors;

3. If samples are offset printing, need USD 180 as offset printing mold cost is high.

When can I get the quotation?

1. The quotation will be offered within 24 hours after getting your detailed request.

2. If you get the urgent inquiry, please call us or mark it via E-mail, then we could make it into priority list.

Leading time for samples production?

Normally we need 3-7 days for samples making, 10-12 days to complete your orders,but the delivery time more depends on the order QTY.

FAQs

Can you ship internationally?

Yes, we export worldwide and work with reliable logistics partners for timely delivery.

Custom Logo Cigarette Packaging Cigar Box Drawer Paper Boxes Child Resistant Paper Drawer Packaging Box

Custom Recyclable Cardboard Childproof Child Resistant Packaging Child Proof Round Paper Tube Box with Lock Button

Best Pack’s Custom Recyclable Cardboard Childproof Packaging Box offers secure, eco-friendly storage with a child-resistant lock button. Designed as a round paper tube box, it ensures safety and sustainability, ideal for protecting products while supporting green packaging solutions.

Various Style Design Drawer-Style Packaging Paper Cigarette Boxes Flip Top Closure Pre Rolled Cones Box With Dividers With Child Resistant.

Custom Logo Cigarette Packaging Box Drawer Sliding Boxes With PET Window Child Resistant Paper Drawer Packaging Box

Custom Logo Cigarette Packaging Box – Child Resistant Paper Drawer Box by Best Pack Upgrade Best Pack with Best Pack’s Custom Logo Cigarette Packaging Box. Featuring a sliding drawer design and PET window for High Quality visibility, our child-resistant paper box ensures safety and compliance. Ideal for secure, stylish packaging. Customize with your logo for a professional touch. Keywords: Cigarette Packaging Box, Child Resistant Paper Box

Best pack

Best pack

Best pack