Top Industries Using Child Resistant Paper Boxes for Product Safety

- Introduction: Why Child Resistant Paper Boxes Matter for Product Safety

- Protecting children and brands with child resistant paper boxes for product safety

- Top Industries Using Child Resistant Paper Boxes

- Cannabis: custom cannabis cigarette packaging and cannabis protective packaging

- Pharmaceuticals and OTC Medicines

- Nutraceuticals and Vitamins

- Vape Cartridges and E-liquids: cartridge box packaging

- Household Chemicals and Cleaning Products

- Pesticides and Garden Chemicals

- Cosmetics and Personal Care

- Pet Medications and Animal Health

- Specialty Retail and Giftable Products

- Why Brands Choose Child Resistant Paper Boxes

- Compliance-first: meet regulations with proven child resistant paper boxes for product safety

- Branding & shelf presence: keep image while ensuring safety

- Sustainability: recyclable child resistant paper boxes for modern brands

- Design, Mechanisms, and Testing for Child Resistant Paper Boxes

- Common child resistant mechanisms in paper packaging

- Testing standards and certification

- Material considerations and production constraints

- Best Practices for Brands Choosing Child Resistant Paper Boxes

- Selecting an OEM/ODM partner with proven capabilities

- Balancing security with user accessibility

- Labeling, instructions, and supplementary safety elements

- Case Examples: How Child Resistant Paper Boxes Drive Value

- From prototype to shelf-ready: OEM/ODM case in cannabis packaging

- Cartridge box packaging with anti-counterfeit features

- How Best Pack Supports Brands with Child Resistant Paper Boxes

- One-stop solutions from design to manufacturing

- Commitment to innovation and information-age responsiveness

- Conclusion: Choosing the Right Child Resistant Paper Boxes for Product Safety

- Make safety a differentiator while maintaining brand excellence

- Frequently Asked Questions

Introduction: Why Child Resistant Paper Boxes Matter for Product Safety

Protecting children and brands with child resistant paper boxes for product safety

Child resistant paper boxes for product safety are increasingly essential as regulators, retailers, and consumers demand safer packaging. Enacted U.S. legislation such as the Poison Prevention Packaging Act (PPPA) of 1970 and global test protocols like ISO 8317 have created clear expectations: products that pose a risk to children must use packaging that reduces accidental access. For companies in regulated sectors—especially cannabis and pharmaceuticals—choosing certified child resistant packaging is not just compliance; it protects brand reputation, reduces liability, and increases shopper trust.

Top Industries Using Child Resistant Paper Boxes

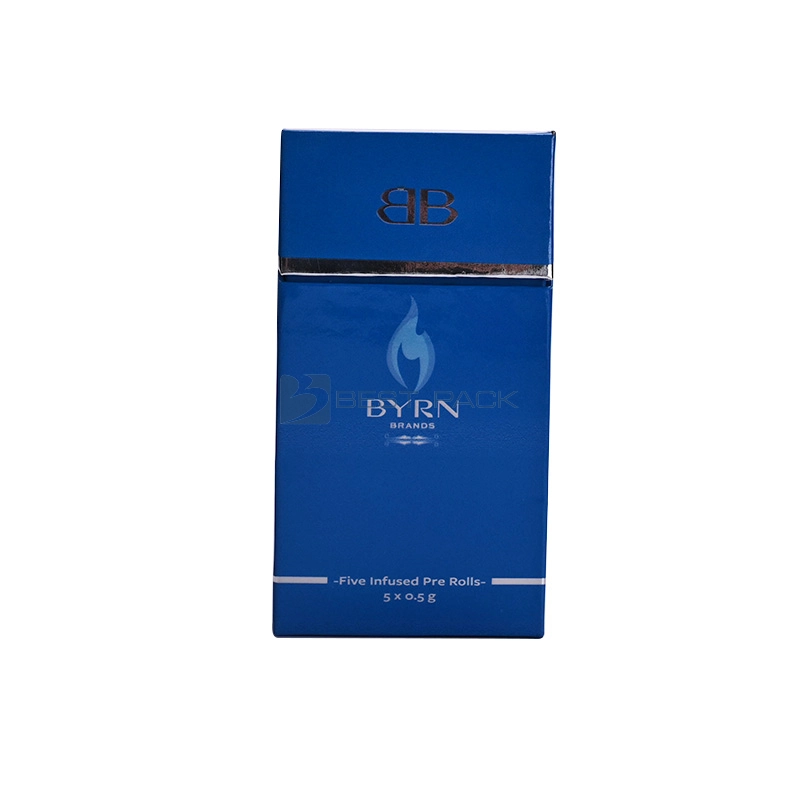

Cannabis: custom cannabis cigarette packaging and cannabis protective packaging

The cannabis industry is one of the fastest adopters of child resistant paper boxes for product safety. States and countries with legal cannabis markets typically require child resistant packaging for flower, pre-rolls, cartridges, and edibles. Brands choose custom cannabis cigarette packaging and cannabis protective packaging that combine compliance with shelf appeal. Using paper-based CR boxes allows for high-quality printing, tamper-evident features, and integration with inner child-resistant mechanisms while supporting sustainable brand claims.

Pharmaceuticals and OTC Medicines

Prescription drugs, controlled substances, and many over-the-counter medications rely on child resistant packaging to prevent accidental ingestion. Pharmaceutical brands favor child resistant paper boxes for product safety because they can be precisely labeled with dosing information and safety warnings while incorporating certified locking features. For many manufacturers, switching to recyclable paper CR boxes supports both regulatory needs and corporate sustainability goals.

Nutraceuticals and Vitamins

Vitamins and dietary supplements are common household items that attract interest from children due to candy-like shapes and flavors. Companies use child resistant paper boxes for product safety to reduce poisoning risk and maintain retailer access. Packaging that balances child resistance with ease of use for older adults preserves marketability while showing care for consumer safety.

Vape Cartridges and E-liquids: cartridge box packaging

The vaping industry uses cartridge box packaging and child resistant paper boxes for product safety to comply with regulations and retail policies. Nicotine-containing e-liquids and cartridges are hazardous if consumed by children; brands therefore implement secure paper boxes with inner locking trays, tamper-evident seals, and clear hazard labeling. These solutions also allow High Quality branding and anti-counterfeit features to protect both consumers and margins.

Household Chemicals and Cleaning Products

Household cleaners, adhesives, and solvents are another major category adopting child resistant paper boxes for product safety. Paperboard packaging can be engineered with liners, inner closures, or child-resistant outer sleeves that meet safety standards while being stackable and shelf-ready for retail environments. Clear hazard icons and instructions printed on the box improve safe handling and storage.

Pesticides and Garden Chemicals

Pesticides, rodenticides, and certain garden chemicals must be packaged to reduce accidental access by children and pets. Child resistant paper boxes for product safety are used in this sector to provide compliant packaging that also resists moisture and protects contents. Brands often pair CR paper boxes with inner sachets or sealed containers to ensure long-term product integrity.

Cosmetics and Personal Care

Certain cosmetics and personal care items containing active ingredients (retinoids, certain acids, essential oils) are moving toward child resistant packaging. Luxury brands leverage child resistant paper boxes for product safety to meet regulatory requirements while maintaining High Quality unboxing experiences. Custom printing and embossing preserve brand image even when safety is prioritized.

Pet Medications and Animal Health

Pet medications are an overlooked source of child and accidental poisonings. Animal health companies increasingly specify child resistant paper boxes for product safety—especially for chewables and liquid formulations—reducing risks for both children and pets while giving pet owners confidence that products are stored securely.

Specialty Retail and Giftable Products

Retailers selling specialty items (e.g., artisanal fragrances with alcohol content, hobby chemicals, craft adhesives) adopt child resistant paper boxes for product safety to expand distribution and reduce in-store risk. Properly engineered CR paper packaging can blend into giftable presentations for High Quality outlets without compromising safety.

Why Brands Choose Child Resistant Paper Boxes

Compliance-first: meet regulations with proven child resistant paper boxes for product safety

Regulatory compliance is the primary driver. Markets reference standards such as the U.S. PPPA, 16 CFR Part 1700, and international standards like ISO 8317 for reclosable child-resistant packaging. Brands rely on tested child resistant paper boxes for product safety to ensure they meet retailer requirements, avoid fines, and minimize legal exposure.

Branding & shelf presence: keep image while ensuring safety

Paperboard offers superior printability compared with many rigid plastics. Companies can incorporate high-resolution graphics, embossing, spot UV, and eco-friendly inks, enabling child resistant paper boxes for product safety that reinforce brand identity and support marketing campaigns without sacrificing protection.

Sustainability: recyclable child resistant paper boxes for modern brands

Consumers and retailers increasingly prefer recyclable or compostable packaging. Paper-based CR boxes can be designed with recyclable liners or mechanical locking systems that avoid mixed-material laminates, allowing brands to communicate environmental responsibility while maintaining child safety features.

Design, Mechanisms, and Testing for Child Resistant Paper Boxes

Common child resistant mechanisms in paper packaging

Mechanisms include slide-and-lock inner trays, tuck-lock systems with secondary catches, squeeze-and-slide paper constructions, and integrated locking tabs that require coordinated actions. For cartridge box packaging and custom cannabis cigarette packaging, manufacturers often combine an outer printed sleeve with an inner child-resistant tray to balance aesthetics and function.

Testing standards and certification

Certified testing uses panels of children and older adults to validate effectiveness and usability per ISO 8317 and similar protocols. Packaging suppliers should provide test reports demonstrating that child resistant paper boxes for product safety meet the applicable national or state requirements. Always request documentation from vendors to ensure legal compliance.

Material considerations and production constraints

Paper grade, board thickness, and finishing processes influence performance. High-Bend Test and tear-strength values are important for durable locking features. Coatings, liners, and barrier treatments must be selected to preserve recyclability when possible while protecting the product from moisture, especially for cartridges or edibles.

Best Practices for Brands Choosing Child Resistant Paper Boxes

Selecting an OEM/ODM partner with proven capabilities

Work with packaging suppliers who offer OEM/ODM capabilities, provide prototype services, and supply child-resistance testing documentation. Best Pack, for example, provides end-to-end services from design and printing to handicraft processing, showcasing real customer cases in cannabis protective packaging and cartridge box packaging that highlight attention to detail and commitment to best quality.

Balancing security with user accessibility

Child resistant packaging must still be operable by intended adult users, including older adults. Include clear instructions on the box and test your finished packaging with user panels where feasible. Consider multiple access methods—e.g., tamper-evident initial seal plus reclosable child-resistant mechanism—to preserve safety throughout the product lifecycle.

Labeling, instructions, and supplementary safety elements

Include clear hazard warnings, storage instructions, batch codes, and QR codes that link to product safety datasheets or instructional videos. These elements increase consumer trust and reduce misuse. For cannabis products, compliance labeling is also critical for legal market access.

Case Examples: How Child Resistant Paper Boxes Drive Value

From prototype to shelf-ready: OEM/ODM case in cannabis packaging

A cannabis brand seeking High Quality custom cannabis cigarette packaging partnered with an experienced supplier to prototype a slide-and-lock paper box with embossing and a tamper-evident seal. The final child resistant paper boxes for product safety passed required test protocols, improved shelf presence, and reduced retailer pushback while keeping costs competitive.

Cartridge box packaging with anti-counterfeit features

For a vape cartridge line, brand managers integrated a custom cartridge box packaging with a concealed QR code and holographic label inside the child-resistant tray. This approach preserved exterior branding while protecting consumers through track-and-trace, demonstrating how child resistant paper boxes for product safety can be part of a broader authentication strategy.

How Best Pack Supports Brands with Child Resistant Paper Boxes

One-stop solutions from design to manufacturing

Best Pack provides complete services covering concept design, structural engineering, printing, and handicraft processing. Our OEM/ODM capabilities allow brands to create tailor-made child resistant paper boxes for product safety that reflect brand values and meet regulatory requirements. We emphasize best quality, excellent services, and competitive prices.

Commitment to innovation and information-age responsiveness

With a team-working spirit and continuous innovation, Best Pack helps clients adapt to changing regulations and market trends. From cannabis protective packaging to cartridge box packaging, our real customer cases show how high-quality child resistant paper boxes for product safety drive purchasing decisions and elevate brand value.

Conclusion: Choosing the Right Child Resistant Paper Boxes for Product Safety

Make safety a differentiator while maintaining brand excellence

Child resistant paper boxes for product safety are essential across multiple industries—from cannabis and pharmaceuticals to household chemicals and vape cartridges. The right solution balances regulatory compliance, adult usability, sustainability, and brand expression. Partnering with an experienced OEM/ODM like Best Pack enables companies to deliver compliant, attractive, and eco-conscious packaging that protects consumers and strengthens market position.

Learn more about custom solutions and view real case studies at https://www.gzbestpack.com/.

Frequently Asked Questions

Q: What standards govern child resistant packaging for paper boxes?

A: Child resistant packaging is commonly governed by national regulations like the U.S. Poison Prevention Packaging Act (PPPA) and test standards such as ISO 8317 for reclosable CR packaging. Specific industries (e.g., cannabis) may have additional state or provincial requirements. Always request test reports and certification from your packaging supplier.

Q: Can paper boxes be truly child resistant while remaining recyclable?

A: Yes. Designers can use mechanical paper-based locking systems, recyclable liners, and mono-material constructions to create child resistant paper boxes for product safety that are recyclable. Avoiding mixed-material laminates and selecting appropriate coatings helps preserve recyclability.

Q: How do child resistant paper boxes affect branding and unboxing experience?

A: Paperboard provides excellent printability and finishing options—embossing, foil, spot UV—that allow High Quality unboxing experiences. By placing the CR mechanism internally or using elegant outer sleeves, brands can maintain visual appeal while ensuring product safety.

Q: Are there testing services available to validate my packaging design?

A: Yes. Accredited labs and specialized testing centers conduct child and senior usability panels per ISO 8317 or local protocols. Packaging suppliers often coordinate testing as part of their OEM/ODM services; always obtain the formal test report for compliance documentation.

Q: How much does child resistant paper box production cost compared to plastic options?

A: Costs vary by design complexity, materials, volume, and finishing. Paper-based CR boxes can be cost-competitive, especially at scale, and offer savings through lower material costs and recyclability benefits. Request quotes from qualified suppliers and compare total landed costs including testing and certifications.

Q: Can Best Pack produce custom child resistant paper boxes for cannabis products?

A: Yes. Best Pack specializes in custom cannabis cigarette packaging and cannabis protective packaging, offering end-to-end OEM/ODM capabilities, testing coordination, and high-quality printing and handicraft processing to deliver compliant, brand-forward solutions.

Child-Resistant Closure Types for Pre-Roll Boxes

Integrating Security Features into Custom Cigarette Packaging

Choosing Suppliers: Key Questions for Custom Packaging Orders

Where to Buy paper cigarette box in Guangzhou

About us

How many kinds the printing process you have?

We can make Silk screen printing, offset printing, and also hot silver stamping

Are you able to do design for my products?

Yes, just send us your logo artwork in Vector file, such as AI or PDF format,and text information you want to print ,we can put it on box to make the design to let you check. Once you say ok, then we go on to make samples or production.

FAQs

What services do you provide?

We offer one-stop packaging solutions, including design, printing, and handicraft processing for electronic boxes, plastic boxes, paper boxes, paper bags, and book printing.

Can you ship internationally?

Yes, we export worldwide and work with reliable logistics partners for timely delivery.

Do you support custom designs?

Yes, we provide custom packaging designs tailored to your brand and product needs.

Custom Printed Paperboard Cardboard Cigarette Box Packaging Case Disposable Paper Box for Cigarette Clamshell paper box

Custom Vape Packaging Box with CR Telescoping Design

The CR telescoping box is a sophisticated and secure packaging solution designed specifically for vape products. Featuring a telescoping (two-piece) structure, this box offers excellent protection and an elegant presentation, enhancing both the unboxing experience and brand appeal.

Custom Logo Child-Resistant Pre-Roll Box Packaging Biodegradable Handmade Luxury 5 Pack Embossing Childproof Pre Roll Package

Custom CR Vape Packaging Cardboard Boxes with Child-Resistant Design

CR custom vape packaging cardboard boxes are specially designed child-resistant packaging solutions crafted to ensure safety, protection, and premium presentation for vape products. Made from sturdy cardboard materials, these boxes balance regulatory compliance with brand aesthetics.

Best pack

Best pack

Best pack