Eco-Friendly Cigar Box Options for Sustainable Brands

- Eco-Friendly Cigar Box Options for Sustainable Brands

- Why sustainable cigar boxes matter for modern brands (Cigar Box)

- Overview of Best Pack product: secure, sustainable, and brandable

- Material choices for eco-friendly cigar boxes

- Comparing materials: environmental and functional trade-offs

- Child-resistant packaging: requirements and sustainable solutions

- Design & branding: making eco-friendly cigar boxes stand out

- Manufacturing, certifications, and end-of-life options

- Cost considerations and scalability

- Real-world applications and case examples

- Practical checklist for switching to eco-friendly child-resistant cigar boxes

- How Best Pack supports sustainable packaging transitions

- FAQ — Frequently asked questions about eco-friendly cigar boxes

- Next steps — contact and view product

- Authoritative references and resources

- Final summary of brand advantages

- Contact Best Pack

Eco-Friendly Cigar Box Options for Sustainable Brands

Why sustainable cigar boxes matter for modern brands (Cigar Box)

Sustainability is no longer optional for many consumers and retailers. A Cigar Box is more than a container — it communicates brand values at the point of sale and after purchase. Consumers increasingly expect packaging to minimize environmental impact while retaining functionality and aesthetics. For tobacco and cigar brands, the challenge is balancing High Quality presentation, regulatory safety (including child-resistant features), and a reduced environmental footprint. Brands that adopt eco-friendly cigar boxes can reduce waste, meet retailer and regulatory demands, and build stronger loyalty among environmentally conscious customers.

Overview of Best Pack product: secure, sustainable, and brandable

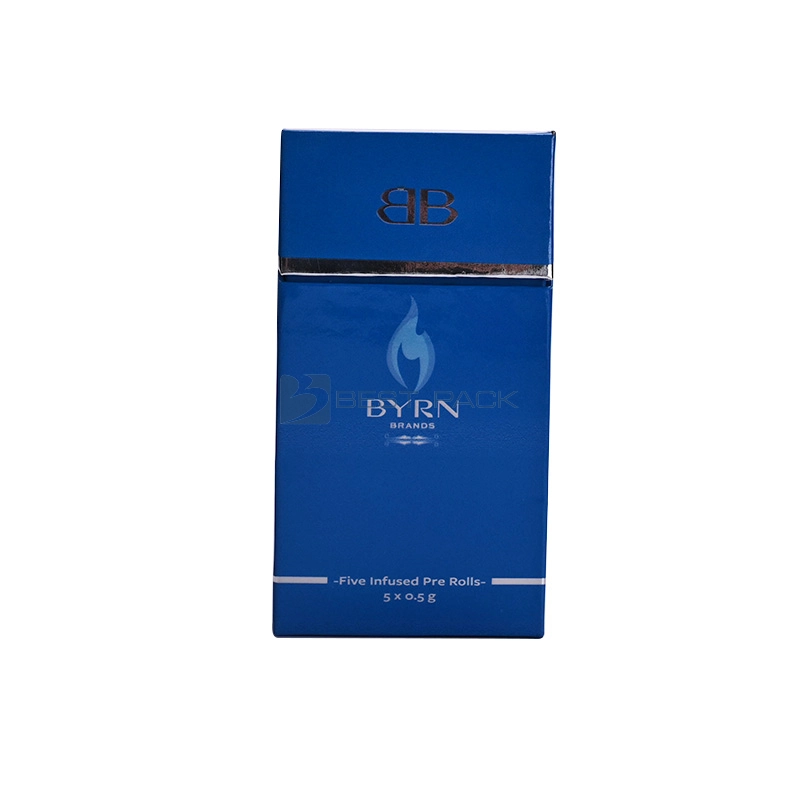

Best Pack offers Custom Logo Cigarette Packaging Cigar Box Drawer Paper Boxes, featuring durable Child Resistant Paper Drawer Packaging. These Custom Cigarette Packaging Boxes combine safety with high-quality design, delivering a child-resistant solution that does not sacrifice style. Constructed from responsibly sourced or recycled materials and compatible with eco-friendly inks and coatings, this product line is well-suited to brands that need compliance and an elevated unboxing experience.

Material choices for eco-friendly cigar boxes

Selecting the right material is the foundation of sustainable packaging. Each option below balances recyclability, strength, printability, and compatibility with child-resistant mechanisms.

- Recycled paperboard: High recycled content lowers lifecycle impact and is fully recyclable in most municipal streams. Good for drawer-style Cigar Box constructions when paired with proper lamination or wax-resistant finishes.

- FSC-certified virgin paperboard: Ensures responsible forest management where recycled content is low. Offers High Quality finish and structural integrity for luxury Cigar Box designs.

- Kraft and uncoated paper: Minimal processing, excellent recyclability and a natural aesthetic; best with water-based inks.

- Molded fiber or agricultural-waste composites: Compostable options using bagasse or wheat straw; good for inserts or secondary packaging but may need protective coatings for long-term storage.

- Thin sustainably sourced wood (where permitted): Provides a luxury feel but typically higher environmental and cost impacts; should be FSC-certified.

These materials are commonly used in configurations such as drawer boxes, rigid slipcases, or hybrid constructions that incorporate child-resistant features.

Comparing materials: environmental and functional trade-offs

| Material | Environmental Impact | Child-Resistant Compatibility | Typical Cost | Recommended Finishes |

|---|---|---|---|---|

| Recycled paperboard | Low lifecycle impact; widely recyclable | Good — well suited for drawer mechanisms | Low to medium | Water-based varnish, matte coatings |

| FSC-certified paperboard | Responsible sourcing; moderate impact | Excellent — structural strength supports child-resistant closures | Medium | Soy-based inks, soft-touch coatings |

| Kraft/uncoated | Low processing; highly recyclable | Good for simpler child-safety designs | Low | Spot UV (limited), water-based inks |

| Molded fiber / bagasse | Compostable (if certified); low impact | Limited — best as inserts, not primary drawer material | Medium | Natural finishes, minimal coating |

| Thin FSC wood | Higher impact; High Quality look | Possible with design adjustments | High | Natural oils, FSC-certified varnish |

Child-resistant packaging: requirements and sustainable solutions

Child-resistant packaging (CRP) is essential for tobacco-related products in many jurisdictions. While regulations vary by country, common objectives are to reduce accidental access by young children while keeping products reasonably accessible to adults. Brands must consider:

- Design mechanisms: Drawer locks, push-and-slide tabs, or two-step openings that can be integrated into paper drawer systems without adding heavy plastic components.

- Testing and compliance: Using certified test labs to validate child-resistance performance (tests often involve panels of children and adults per relevant standards).

- Material choices: Paper-based CRP is achievable by combining precise die-cutting, reinforced board layers, and mechanical interlocks. This approach avoids plastics and supports recyclability if adhesives and coatings are chosen carefully.

Best Pack's Child Resistant Paper Drawer Packaging Box integrates mechanical drawer resistance with paperboard construction, enabling brands to meet safety expectations with recyclable materials. For formal compliance, consult national regulators or accredited testing labs to confirm your design meets local requirements.

Design & branding: making eco-friendly cigar boxes stand out

A sustainable cigar box must still reflect the brand's identity. Key design considerations:

- Printing: Use soy- or vegetable-based inks and low-VOC varnishes. These inks improve recyclability and reduce environmental toxins.

- Spot finishing: Embossing, debossing, and foil can be used selectively; choose recycled foil or vegetable-based alternatives where possible.

- Color strategy: Fewer colors can reduce processes and energy use; natural kraft or uncoated finishes communicate sustainability.

- Structural design: Drawer boxes (slip-in-drawer) offer High Quality feel and are compatible with child-resistant features. Integrate a subtle embossed instruction for opening to improve adult usability while maintaining resistance for children.

- Customization: Best Pack's Custom Logo Cigarette Packaging Cigar Box Drawer Paper Boxes allow clear brand marking while maintaining sustainable specs — ideal for limited edition runs or serialized branding.

Manufacturing, certifications, and end-of-life options

Manufacturing choices and certifications drive credibility with consumers and procurement professionals. Key certifications and standards to consider:

- FSC (Forest Stewardship Council) or PEFC certification for wood and paper products.

- Compostability standards such as ASTM D6400 (U.S.) or EN 13432 (EU) for components marketed as compostable.

- Recycled content certification (e.g., recycled post-consumer content verification).

- Testing for child-resistant performance (use accredited third-party labs).

End-of-life messaging is crucial: label materials clearly for recycling or composting, and avoid mixed-material laminates that prevent recovery. Where barrier properties are required (e.g., humidity protection for cigars), explore recyclable barrier coatings or removable inner sleeves that can be separated by consumers.

Cost considerations and scalability

Sustainable options can increase unit cost, especially for High Quality finishes and certifications. However, scalable design choices reduce per-unit cost as volumes increase. Practical tactics to control cost include:

- Standardizing a core drawer structure and customizing only the sleeve or lid for different SKUs.

- Opting for water-based coatings rather than costly foils.

- Combining recycled paperboard with a small amount of virgin fiber where structural strength is needed.

Brands should perform a lifecycle cost analysis to compare long-term benefits, such as reduced waste fees and improved retailer acceptance, against upfront packaging expenses.

Real-world applications and case examples

Several brands across High Quality tobacco and ancillary categories have adopted paper-based drawer packaging with child-resistant features. Common outcomes reported include improved shelf differentiation, positive consumer feedback on sustainability, and effective compliance with market safety expectations. In practice, the Best Pack approach — Custom Logo Cigarette Packaging Cigar Box Drawer Paper Boxes with Child Resistant Paper Drawer Packaging — has been used by brands seeking a middle ground: High Quality tactile experience, secure closure, and reduced plastic use.

Practical checklist for switching to eco-friendly child-resistant cigar boxes

Use this checklist to evaluate new packaging projects:

- Define regulatory requirements for child-resistant packaging in target markets.

- Choose material basis: recycled paperboard vs. FSC board vs. hybrid.

- Confirm recyclability or compostability and required certifications.

- Design for separability of mixed materials (easy disassembly by consumers).

- Test child-resistant performance with an accredited lab.

- Specify eco-friendly inks and coatings.

- Plan scalable tooling and estimate per-unit costs at target volumes.

How Best Pack supports sustainable packaging transitions

Best Pack provides end-to-end support from concept to delivery. The Custom Logo Cigarette Packaging Cigar Box Drawer Paper Boxes and Child Resistant Paper Drawer Packaging Box offerings include:

- Material sourcing guidance (recycled and FSC options).

- Child-resistant drawer designs engineered for paperboard.

- Printing with eco-friendly inks and responsible finishing options.

- Prototyping and third-party testing coordination for compliance.

This integrated approach shortens development cycles and helps brands launch sustainable, compliant packaging quickly.

FAQ — Frequently asked questions about eco-friendly cigar boxes

Q: Can a paper drawer cigar box be both child-resistant and recyclable?

A: Yes. Thoughtful engineering of paperboard drawer mechanisms, combined with minimal use of non-recyclable adhesives and coatings, can achieve both child-resistance and recyclability. Third-party testing is recommended to confirm child-resistance.

Q: What certifications should I seek for sustainable packaging?

A: Consider FSC or PEFC for responsible fiber sourcing, ASTM D6400 or EN 13432 for compostability claims (if relevant), and verified recycled content certificates. Also validate child-resistant performance with accredited labs.

Q: Are water-based inks durable enough for cigar packaging?

A: Modern water-based and soy inks can provide robust color and durability. If additional moisture protection is needed, choose recyclable barrier options or recommend a removable inner liner.

Q: How does the cost of sustainable cigar boxes compare to conventional options?

A: Costs vary by material and finish. Recycled paperboard options can be competitive, while certified or High Quality finishes increase cost. Economies of scale and design standardization help lower unit prices.

Q: Does Best Pack handle small batch or limited-edition runs?

A: Yes — Best Pack supports small runs and scalable production. Custom Logo Cigarette Packaging Cigar Box Drawer Paper Boxes can be tailored for limited editions with minimal tooling changes.

Next steps — contact and view product

To evaluate sustainable, child-resistant cigar packaging for Best Pack, request a sample or consultation with Best Pack. Our team can provide prototypes of Custom Logo Cigarette Packaging Cigar Box Drawer Paper Boxes and advise on the right Child Resistant Paper Drawer Packaging Box configuration for your needs. Contact Best Pack sales to view product options and get a quote.

Authoritative references and resources

- Packaging (overview) — Wikipedia: https://en.wikipedia.org/wiki/Packaging

- Sustainable packaging — Wikipedia: https://en.wikipedia.org/wiki/Sustainable_packaging

- Child-resistant packaging — Wikipedia: https://en.wikipedia.org/wiki/Child-resistant_packaging

- Forest Stewardship Council (FSC): https://www.fsc.org

- ASTM D6400 (compostability standard): https://www.astm.org/standards/d6400.htm

- EN 13432 (compostability): https://en.wikipedia.org/wiki/EN_13432

- U.S. Environmental Protection Agency — Facts & figures about materials, waste and recycling: https://www.epa.gov/facts-and-figures-about-materials-waste-and-recycling

- Consumer Product Safety Commission (CPSC): https://www.cpsc.gov

Final summary of brand advantages

Choosing sustainable cigar boxes such as Best Pack's Custom Logo Cigarette Packaging Cigar Box Drawer Paper Boxes and Child Resistant Paper Drawer Packaging Box gives brands a clear competitive advantage: it combines High Quality presentation with child-resistant safety and environmental responsibility. By selecting the right materials, finishes, and validated child-resistant mechanisms, brands can reduce environmental impact, meet regulatory requirements, and strengthen consumer trust.

Contact Best Pack

For product samples, testing assistance, or quotes on Custom Logo Cigarette Packaging Cigar Box Drawer Paper Boxes and Child Resistant Paper Drawer Packaging Box, contact Best Pack's sales team today to discuss requirements and next steps. Sustainable materials don’t mean sacrificing experience. In fact, how drawer style cigar boxes enhance the unboxing experience shows how structure and design can create memorable brand moments.

Quality Control Checklist for Factory-Customized Cigarette Boxes

How to create child-resistant prototypes for cigarette boxes

Custom print finishes that elevate pre roll packaging

Best printing finishes for custom cigarette box branding

About us

How many kinds the printing process you have?

We can make Silk screen printing, offset printing, and also hot silver stamping

Leading time for samples production?

Normally we need 3-7 days for samples making, 10-12 days to complete your orders,but the delivery time more depends on the order QTY.

When can I get the quotation?

1. The quotation will be offered within 24 hours after getting your detailed request.

2. If you get the urgent inquiry, please call us or mark it via E-mail, then we could make it into priority list.

FAQs

What services do you provide?

We offer one-stop packaging solutions, including design, printing, and handicraft processing for electronic boxes, plastic boxes, paper boxes, paper bags, and book printing.

Can you ship internationally?

Yes, we export worldwide and work with reliable logistics partners for timely delivery.

Custom Logo Cigarette Packaging Cigar Box Drawer Paper Boxes Child Resistant Paper Drawer Packaging Box

Custom CR Vape Packaging Cardboard Boxes with Child-Resistant Design

CR custom vape packaging cardboard boxes are specially designed child-resistant packaging solutions crafted to ensure safety, protection, and premium presentation for vape products. Made from sturdy cardboard materials, these boxes balance regulatory compliance with brand aesthetics.

Custom Luxury Pre Roll Packaging Boxes with Child-Resistant Paper Tray

Our luxury pre-roll packaging boxes are designed to combine elegant presentation with top-tier safety features. Featuring a child-resistant mechanism and a custom paper tray insert, these boxes ensure secure storage while delivering a premium unboxing experience for pre-roll products.

Custom Child-Lock Pre-Roll 5-Pack Packaging Boxes

Our custom child-lock packaging for pre-roll 5-packs is purposefully engineered to combine premium design with certified safety. This packaging solution ensures that five pre-rolls are securely housed in a compact, stylish, and child-resistant format—ideal for compliant cannabis brands that value both form and function.

Best pack

Best pack

Best pack