Sustainable Materials for Custom Pre-Roll Paper Boxes

- Material Choices: What Makes a Pre-Roll Paper Box Sustainable?

- Recycled Paperboard and Post-Consumer Fiber

- Kraft and Uncoated Natural Boards

- Novel Fibers: Hemp, Bagasse, and Agricultural Residues

- Surface Treatments, Coatings and Printability

- Water-Based and Bio-Based Coatings

- Avoiding Plastic Lamination for Recyclability

- Printing Technologies and Sustainable Inks

- Performance: Protection, Child Safety, and Compliance

- Durability and Product Protection

- Child-Resistant Considerations and Standards

- Regulatory Compliance Across Markets

- Life-Cycle Comparison: Making Choices with Data

- Material Performance and End-of-Life Pathways

- Cost vs. Impact: Practical Tradeoffs

- Quick Reference Comparison Table

- Design, Customization and Brand Impact

- Balancing Custom Printing and Sustainability

- Structural Design: Reducing Material While Maintaining Strength

- Labeling and Traceability

- Manufacturing and Supply Chain Considerations

- Factory Capabilities and Certifications

- MOQ, Lead Times and Costing

- Sample and Testing Protocols

- Frequently Asked Questions (FAQ)

- Q: Are recycled paperboard boxes suitable for Cigarette Boxes and pre-roll packaging?

- Q: How can I ensure my custom pre-roll boxes are child-resistant?

- Q: Can I have a plastic-free window or scent barrier for freshness?

- Q: What certifications should I look for from suppliers?

- Q: Is hemp board a worthwhile investment for CBD product packaging?

This summary highlights how choosing sustainable materials for custom pre-roll paper boxes improves environmental outcomes while maintaining protection, brand presentation, and compliance. It outlines material choices, manufacturing and printing considerations, child-safety and regulatory references, and design tips to optimize the Factory Customized Printing LOGO Pack 10 20 5 Thick Case Pre Roll Non Tobacco Paper Box Cigarette Boxes for non-tobacco herbal products, CBD/THC joints, and Cigarette Boxes alike. The guidance below helps packaging buyers, brand managers, and manufacturers make evidence-based decisions for greener, commercially successful packaging.

Material Choices: What Makes a Pre-Roll Paper Box Sustainable?

Recycled Paperboard and Post-Consumer Fiber

Recycled paperboard is a top sustainable choice for pre-roll paper boxes and Cigarette Boxes because it reduces virgin fiber use and lowers carbon footprint. High-quality recycled board with a high post-consumer content (70%+) can deliver excellent stiffness and printability when correctly sourced and processed. For brands that need High Quality presentation, selecting white-lined recycled board or using recycled fiber with a high brightness level preserves appearance without sacrificing eco-credentials.

Kraft and Uncoated Natural Boards

Kraft paperboard, particularly brown kraft, offers a rustic, authentic look and is inherently recyclable and industrially compostable in many regions. Kraft’s natural color hides minor surface blemishes and performs well with spot printing and embossing. For companies positioning their pre-rolls as artisanal or organic, kraft boxes are a strong branding match. They also simplify end-of-life recycling because they are typically uncoated.

Novel Fibers: Hemp, Bagasse, and Agricultural Residues

Alternative fibers like hemp, sugarcane bagasse, and wheat straw are gaining traction in packaging because they use non-wood biomass and can reduce land-use pressure. Hemp fiberboard, in particular, has relevant synergies with hemp-derived products like CBD — both from a marketing and sustainability story perspective. When evaluating these materials, check for local supply reliability and certification claims that verify sustainably managed crops.

Surface Treatments, Coatings and Printability

Water-Based and Bio-Based Coatings

To keep pre-roll boxes recyclable, prefer water-based coatings, soy or vegetable inks, and bio-based varnishes instead of traditional solvent-based lacquers or plastic laminates. Water-based dispersions are compatible with most paperboards and maintain recyclability if the coating is removable in standard repulping processes. Look for coatings that are certified recyclable by local paper recycling facilities.

Avoiding Plastic Lamination for Recyclability

Thin plastic lamination improves moisture resistance but often renders Cigarette Boxes unrecyclable in curbside streams. Alternatives include: clay-coated board for moisture resistance, barrier papers, and cold-seal adhesives combined with structured box designs. If a barrier film is essential (e.g., for long-term freshness), consider mono-material solutions such as PLA or fully compostable liners, but verify industrial composting availability in your market.

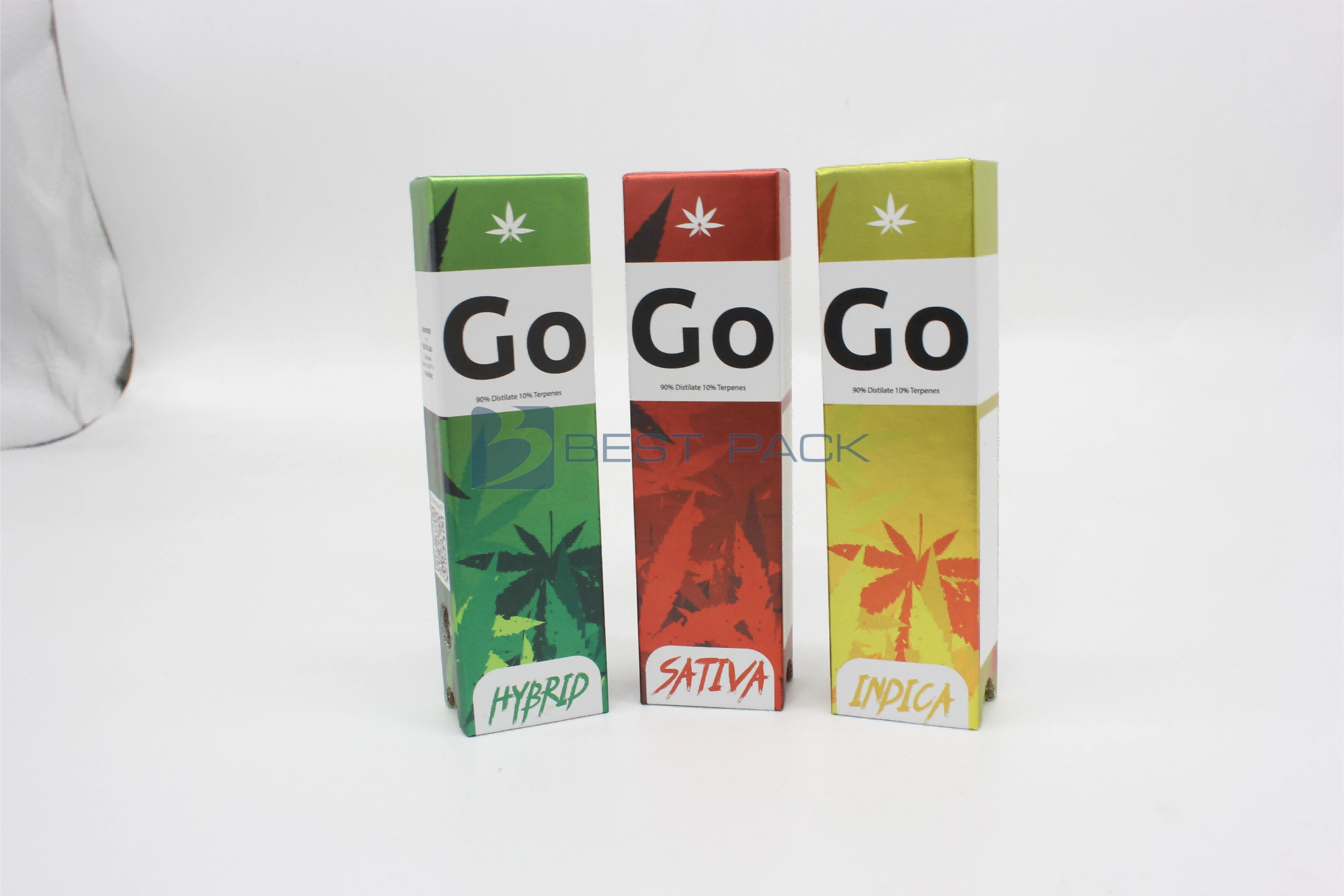

Printing Technologies and Sustainable Inks

Digital and flexographic printing using vegetable-based inks reduces VOCs and is compatible with recycled boards. For short runs of customized pre-roll packaging, digital print avoids make-ready waste and allows personalization without large plate production. For high-volume production, water-based flexo offers low environmental impact and consistent color reproduction for High Quality branding.

Performance: Protection, Child Safety, and Compliance

Durability and Product Protection

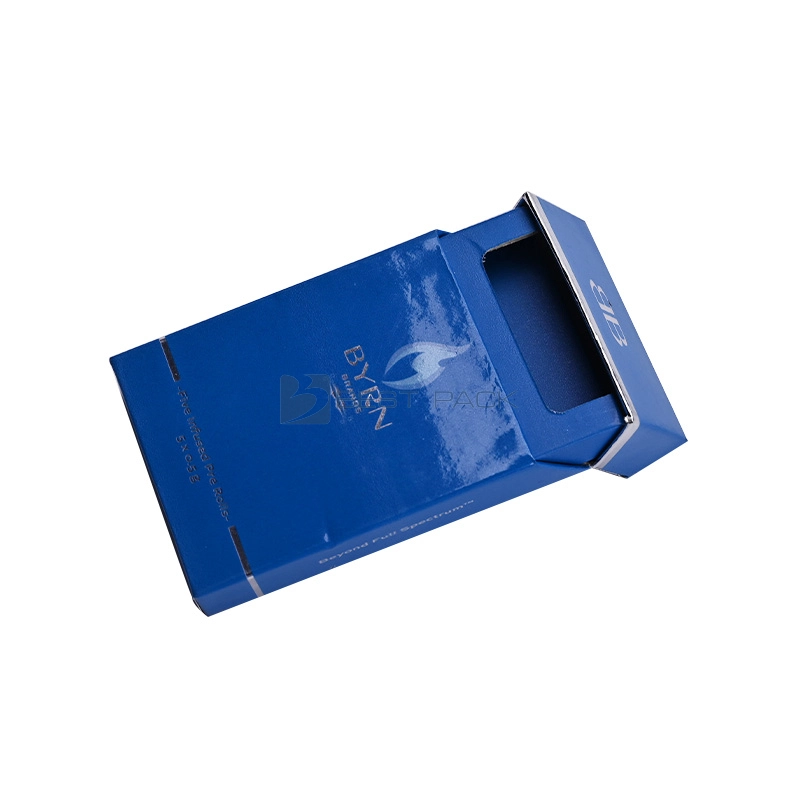

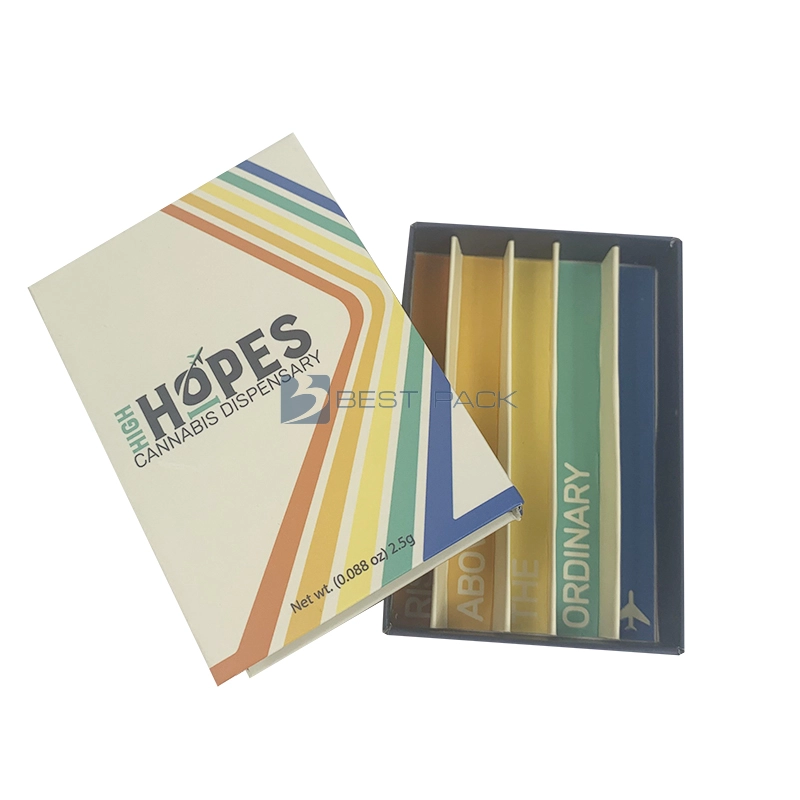

Packaging for pre-rolls and Cigarette Boxes must protect delicate items from crushing and moisture. Thick paperboard (as in the Factory Customized Printing LOGO Pack 10 20 5 Thick Case Pre Roll Non Tobacco Paper Box Cigarette Boxes) provides rigidity; combine it with internal dividers or inserts made from the same board to prevent friction damage. Carefully engineered tuck or hinge lids increase structural integrity while minimizing extra materials.

Child-Resistant Considerations and Standards

If you require child-resistant features, consult internationally recognized standards such as ISO 8317 for reclosable packages and country-specific regulations. Child-resistant mechanisms for paperboard boxes typically involve multi-step opening actions, additional closures, or combined inner child-resistant tubes. For regulatory background, see ISO 8317 (child-resistant packaging) at https://www.iso.org/standard/37144. and general child-resistant design concepts at Wikipedia - Child-resistant packaging. These references help manufacturers align product safety with validated testing protocols.

Regulatory Compliance Across Markets

For any packaging that contains tobacco, nicotine, or hemp derivatives, consult your local regulatory authority. In the United States, the FDA provides guidelines on tobacco product regulation and associated packaging requirements; consult https://www.fda.gov/tobacco-products. For non-tobacco herbal pre-rolls and CBD/THC products, legal classification varies by country and state, so coordinate labeling, health warnings, and child-resistant compliance with counsel and regulators.

Life-Cycle Comparison: Making Choices with Data

Material Performance and End-of-Life Pathways

To pick the most sustainable material, evaluate the full life-cycle: raw material sourcing, manufacturing energy, transportation, consumer disposal, and recyclability or compostability. Recycled paperboard typically scores well across the full life-cycle when compared to virgin coated boards. Biobased liners and compostable coatings can be favorable if industrial composting infrastructure exists in your target market.

Cost vs. Impact: Practical Tradeoffs

Sustainable materials often come with nuanced cost implications. Recycled board may be slightly cheaper or competitive with virgin board, while novel fibers (hemp, bagasse) can be more expensive depending on supply. Carefully model costs against brand value uplift and potential regulatory savings (e.g., avoiding single-use plastics taxes).

Quick Reference Comparison Table

| Material | Durability | Recyclability/Compostability | Branding/Print Quality | Typical Use Case |

|---|---|---|---|---|

| Recycled Paperboard (high PCF) | Medium-High | Recyclable (curbside) | High (white-lined options) | High Quality pre-roll packs, Cigarette Boxes |

| Kraft (uncoated) | Medium | Recyclable and industrially compostable | Good (natural aesthetic) | Artisanal or organic positioning |

| Hemp/Agricultural Fiberboard | High | Potentially compostable/recyclable (verify locale) | Good (textured, High Quality story) | Niche High Quality CBD/hemp products |

| Coated with Water-Based Varnish | High (moisture/abrasion resistance) | Generally recyclable if removable | Very High | Long-shelf products, retail display |

Sources and lifecycle reviews for sustainable packaging include industry and academic analyses; a recent review on sustainable packaging options provides lifecycle context and material comparisons (see ScienceDirect review on sustainable packaging).

Design, Customization and Brand Impact

Balancing Custom Printing and Sustainability

Highly customized Cigarette Boxes can still be sustainable. Use spot varnish instead of full film lamination, and favor water-based or soy inks. Digital print enables short runs and variable data printing without plate setup waste. For the Factory Customized Printing LOGO Pack 10 20 5 Thick Case Pre Roll Non Tobacco Paper Box Cigarette Boxes, request proofs on the intended recycled board to ensure color fidelity.

Structural Design: Reducing Material While Maintaining Strength

Thoughtful die-cut engineering reduces unused material and minimizes box weight without compromising protection. Internal partitions, minimal filler, and snug-fit trays can replace heavier outer packaging. Consider a nested insert made from the same recyclable board to avoid mixed-material adhesives and simplify recycling.

Labeling and Traceability

Clearly mark material content and recycling instructions on the box to help consumers dispose correctly. Including a QR code linking to sustainability information and certifications can enhance transparency and consumer trust. Traceability is also important for regulatory audits, particularly for CBD/THC products.

Manufacturing and Supply Chain Considerations

Factory Capabilities and Certifications

Work with manufacturers who provide chain-of-custody or third-party certifications (FSC, PEFC) when using virgin or mixed fiber boards. Confirm the factory’s printing tech, waste management, and water/energy efficiency claims. This strengthens E-E-A-T (Experience, Expertise, Authority, Trustworthiness) when you make claims on packaging or marketing materials.

MOQ, Lead Times and Costing

Sustainable materials and specialty fibers may have higher minimum order quantities or longer lead times. Digital printing can reduce MOQ but at a slightly higher per-unit cost. Plan production schedules and inventory to avoid rush orders, which often increase carbon footprint through expedited shipping.

Sample and Testing Protocols

Always request material samples and finished-box prototypes before full runs. Perform drop, crush, humidity, and fit tests with actual product units. If child-resistant features are required, include validation testing aligned with ISO 8317 or local standards as part of the sample acceptance criteria.

Frequently Asked Questions (FAQ)

Q: Are recycled paperboard boxes suitable for Cigarette Boxes and pre-roll packaging?

A: Yes. High-quality recycled paperboard can provide the necessary stiffness and printability for High Quality Cigarette Boxes and pre-roll packs. Choose white-lined recycled options for superior branding and request samples to confirm performance.

Q: How can I ensure my custom pre-roll boxes are child-resistant?

A: Implement multi-step openings, inner child-resistant tubes, or certified closure mechanisms and validate them through testing procedures consistent with international standards such as ISO 8317 and local regulations. Work with an experienced packaging manufacturer to design and certify the mechanism.

Q: Can I have a plastic-free window or scent barrier for freshness?

A: Plastic-free windows are possible using cellulose-based films or tightly engineered die-cuts and inner liners. For scent and moisture barrier, consider recyclable barrier papers or mono-material solutions; if a plastic film is unavoidable, use the thinnest possible mono-material that supports recycling streams and disclose it on the packaging.

Q: What certifications should I look for from suppliers?

A: Common certifications include FSC/PEFC (sustainable fiber sourcing), ISO management standards, and any local recyclability or compostability certifications. Ask for chain-of-custody documentation and sample test reports for claims like 'recyclable' or 'compostable.'

Q: Is hemp board a worthwhile investment for CBD product packaging?

A: Hemp board can be an excellent fit for CBD/hemp products, offering a strong sustainability narrative and good mechanical properties. However, evaluate cost, supplier reliability, and local recycling infrastructure before committing to large runs.

Product example: Factory Customized Printing LOGO Pack 10 20 5 Thick Case Pre Roll Non Tobacco Paper Box Cigarette Boxes

Our factory-direct custom pre-roll and cigarette paper boxes are designed for High Quality presentation, protection, and branding. Made with thick, durable paperboard, these boxes are ideal for non-tobacco herbal pre-rolls, cigarettes, or CBD/THC joints. Available in various capacities (5-pack, 10-pack, 20-pack) and fully customizable with your logo and design.

To learn more about how we can create sustainable, high-impact packaging for your pre-rolls and Cigarette Boxes, contact our packaging specialists or view the product details and request a quote: View Factory Customized Printing LOGO Pack 10 20 5 Thick Case Pre Roll Non Tobacco Paper Box Cigarette Boxes. For direct inquiries, contact customer service.

References and further reading: Wikipedia – Child-resistant packaging, ISO 8317 information, U.S. FDA – Tobacco products, ScienceDirect review on sustainable packaging.

Quality control checklist for factory-customized pre rolls

Top cigarette box case Manufacturers and Suppliers in China

What are the application scenarios of pre roll box packaging?

How to Choose a Manufacturer for Pre-Roll Boxes

FAQs

What services do you provide?

We offer one-stop packaging solutions, including design, printing, and handicraft processing for electronic boxes, plastic boxes, paper boxes, paper bags, and book printing.

About us

Leading time for samples production?

Normally we need 3-7 days for samples making, 10-12 days to complete your orders,but the delivery time more depends on the order QTY.

Are you able to do design for my products?

Yes, just send us your logo artwork in Vector file, such as AI or PDF format,and text information you want to print ,we can put it on box to make the design to let you check. Once you say ok, then we go on to make samples or production.

The process of your packaging box production?

1. Make knife mold as per box size and structure

2. order material as per mold

3. make printing on material if need to print

4. suppress and cut material

5. Makeboxes with glue edge in machine

6. Package boxes into cartons

How much of your samples cost ?

1. If samples are without printing, we can make free samples as per your box size or structure;

2. If samples are silk printing, normally USD 25 per color,depending on your logo colors;

3. If samples are offset printing, need USD 180 as offset printing mold cost is high.

Manufacture Personalized Blank Cigarette Boxes Custom Pre Roll Box Child Resistant Drawer Cardboard Childproof Box

Various Style Design Drawer-Style Packaging Paper Cigarette Boxes Flip Top Closure Pre Rolled Cones Box With Dividers With Child Resistant.

Factory Paperboard Child Resist Childproof Button Box Drawer Craft Packing Box Cigarette Box for Cigarettes

Discover Best Pack’s Factory Paperboard Child-Resistant Childproof Button Box—an ideal cigarette packing box featuring a secure drawer craft packing design. Engineered for safety and style, this childproof button box ensures reliable child resistance while enhancing your cigarette storage experience.

Custom CR Vape Packaging Cardboard Boxes with Child-Resistant Design

CR custom vape packaging cardboard boxes are specially designed child-resistant packaging solutions crafted to ensure safety, protection, and premium presentation for vape products. Made from sturdy cardboard materials, these boxes balance regulatory compliance with brand aesthetics.

Best pack

Best pack

Best pack