Beyond the Pack: 5 Innovative Trends Revolutionizing Cigarette Box Design (2026 Outlook)

- Introduction

- Key Takeaways: The Future of Tobacco Packaging

- What are the latest innovations in cigarette box design?

- Core Areas of Innovation:

- Trend 1: Smart Packaging & Digital Integration

- Benefits of Smart Integration:

- Trend 2: The Shift to 100% Biodegradable Materials

- Sustainable Material Breakthroughs:

- Trend 3: Haptic Branding (Feeling the Difference)

- Techniques for Tactile Impact:

- Trend 4: Ergonomic and Structural Disruption

- Structural Trends to Watch:

- Trend 5: Minimalist Compliance Art

- Strategies for Restricted Markets:

- Expert Tips: Avoiding Common Manufacturing Mistakes

- Critical Manufacturing Checkpoints:

- Gap Analysis: Cost Implications & The 2026 Forecast

- 2026 Cost-Benefit Forecast:

- FAQ

- What is the standard size of a cigarette box?

- How does plain packaging affect cigarette box design?

- Are eco-friendly cigarette boxes more expensive?

- What is the difference between hard packs and soft packs?

- Conclusion

Introduction

The humble cigarette pack has come a long way since the soft paper wrappers of the early 20th century. Today, cigarette boxes are high-tech, regulatory-compliant engineering marvels that balance brand identity with strict legal constraints. As we look toward 2026, the industry is pivoting toward smart integration and eco-conscious materials, fundamentally changing how consumers interact with their favorite brands.

Key Takeaways: The Future of Tobacco Packaging

The future of tobacco packaging lies in the convergence of digital authentication, sustainability, and tactile sensory experiences. Brands are moving away from purely visual designs to structural and material innovations that comply with global regulations while offering premium value.

- Smart Tech: NFC and QR codes are becoming standard for anti-counterfeit verification.

- Eco-Materials: Hemp and recycled kraft are replacing virgin pulp and plastic films.

- Tactile Focus: Embossing and soft-touch finishes are the new "visuals" in plain-packaging regions.

- Structural Shifts: Slim and slide-pack designs are challenging the traditional flip-top.

What are the latest innovations in cigarette box design?

The latest innovations in cigarette box design focus on sustainable materials like hemp and recycled cardboard, smart technology integration for authentication, and haptic sensory experiences. These advancements allow custom cigarette boxes to maintain a premium feel and regulatory compliance without relying solely on flashy graphics.

Innovation is no longer just about aesthetics; it is about survival and adaptation. With plain packaging laws expanding globally, brands must find new ways to differentiate. At Guangzhou Best Pack Co.,Ltd, we have seen a 40% increase in requests for "smart" cigarettes box prototypes that incorporate digital triggers, proving that the physical pack is becoming a digital gateway.

Core Areas of Innovation:

- Material Science: transitioning to 100% biodegradable substrates.

- Digital Layering: embedding invisible data for supply chain tracking.

- Structural Engineering: creating child-resistant yet ergonomic opening mechanisms.

Trend 1: Smart Packaging & Digital Integration

Smart packaging refers to the embedding of Near Field Communication (NFC) chips and dynamic QR codes directly into the packaging structure to enable authentication and user engagement. This technology addresses the critical issue of illicit trade while creating a direct communication channel with the consumer.

In an era where advertising is heavily restricted, the pack itself becomes the media channel. By tapping a smartphone against the box, consumers can verify authenticity—a crucial feature given the rise of counterfeit goods. According to a market analysis by Grand View Research, the global anti-counterfeit packaging market is projected to reach significant heights by 2030, driven largely by the pharmaceutical and tobacco sectors.

Benefits of Smart Integration:

- Authentication: Instant verification prevents the sale of fake products.

- Compliance: Digital leaflets can replace bulky physical inserts.

- Engagement: Unlock exclusive content or loyalty rewards without traditional ads.

- Supply Chain: Real-time tracking from the factory to the retailer.

Trend 2: The Shift to 100% Biodegradable Materials

The shift to biodegradable materials involves replacing plastic shrink wraps and foil liners with cellulose-based films and water-based coatings to ensure the entire cigarettes pack is compostable. This trend is driven by both consumer demand for sustainability and looming government bans on single-use plastics.

Standard cardboard is no longer enough. The modern cigarettes pack must demonstrate a commitment to the planet. Best Pack has pioneered the use of soy-based inks and hemp-derived paperboards that maintain the structural rigidity required for high-speed packing lines while being fully biodegradable.

Sustainable Material Breakthroughs:

- Hemp & Straw Paper: stronger fibers that require less water to process than wood pulp.

- Cellulose Films: clear, protective overwraps that decompose in weeks, not centuries.

- Water-Based Coatings: replacing plastic laminates for moisture resistance.

Trend 3: Haptic Branding (Feeling the Difference)

Haptic branding utilizes raised textures, embossing, and soft-touch laminates to create a distinct physical sensation that consumers associate with brand quality. In markets where visual branding is stripped away by plain packaging laws, the "feel" of the box becomes the primary differentiator.

Imagine picking up a vintage cigarette box from the 1950s; it was likely smooth and simple. Today, luxury requires texture. Brands are using micro-embossing to create patterns that are felt rather than seen. This is particularly effective in regions like Australia and the UK, where regulations strictly control color and font size.

Techniques for Tactile Impact:

- Blind Embossing: Creating raised logos or patterns without ink.

- Soft-Touch Lamination: A velvet-like finish that implies luxury and reduces slip.

- Spot UV Varnishing: contrasting matte and high-gloss textures to highlight specific elements.

Trend 4: Ergonomic and Structural Disruption

Structural disruption involves altering the standard flip-top architecture to introduce slim formats, slide-packs, and book-style openings that enhance portability and user experience. Changing the cigarette box dimensions creates a unique shelf presence and caters to modern lifestyle preferences for compact, durable carrying cases.

While the classic flip-top is efficient, it is also ubiquitous. To stand out, brands are experimenting with "Super Slim" formats (often 40-45mm wide) and side-slide mechanisms. These designs not only look futuristic but also offer better protection for the product inside.

Structural Trends to Watch:

- Slide-Packs: A drawer-style opening that adds a ritualistic element to access.

- Slim Formats: Narrower packs that fit easily in pockets, appealing to minimalist aesthetics.

- Beveled Edges: Rounded corners that prevent snagging and damage in pockets.

Trend 5: Minimalist Compliance Art

Minimalist compliance art is the strategic use of limited color palettes, holographic foils, and high-quality inner liners to maximize branding within the strict confines of health warning regulations. This approach turns regulatory constraints into a design challenge, often resulting in sleek, dark, and sophisticated aesthetics.

Take the cigarette box Marlboro uses in regulated markets; even with graphic restrictions, the quality of the cardstock and the precision of the inner frame communicate the brand's premium status. Designers are now focusing on the "unboxing" experience—the inner foil and the frame—where regulations are sometimes less intrusive.

Strategies for Restricted Markets:

- Holographic Foils: Using light-refracting materials that don't rely on pigment.

- Inner Frame Branding: Printing logos or patterns on the collar of the box.

- Dark Palettes: Matte black or charcoal finishes that look premium despite large warning labels.

Expert Tips: Avoiding Common Manufacturing Mistakes

Avoiding manufacturing mistakes requires precise control over cardstock grain direction, adhesive selection, and dimensional prototyping to ensure compatibility with automated packers. A beautifully designed box is useless if it jams the cigarette packing machine or crushes during transit.

At Best Pack, we emphasize the "Grain Direction Rule." If the grain runs parallel to the main crease, the box will bulge; if it runs perpendicular, it offers maximum strength. Ignoring this simple rule is the cause of structural failure in custom packaging.

Critical Manufacturing Checkpoints:

- Grain Direction: Ensure it opposes the main load-bearing walls for stackability.

- Adhesive Cure Time: Use heat-resistant glues if the pack will be shrink-wrapped immediately.

- GSM Selection: A minimum of 250-275 GSM is recommended for standard hard packs.

- Prototype Testing: Always run a blank sample through your packing line before mass printing.

For more insights on manufacturing leaders, check our guide on the Top 10 Cigarette Pack Manufacturers.

Gap Analysis: Cost Implications & The 2026 Forecast

The cost gap between traditional and innovative packaging is narrowing, as the reduction in counterfeit losses via smart tech offsets the higher initial material costs. While the box of cigarettes price for the consumer may rise slightly, the value added through freshness and authenticity justifies the premium.

Many brands ask, "How much are pack of cigarettes going to cost if we switch to hemp board?" Initially, eco-materials may cost 15-20% more than virgin pulp. However, as noted by the World Health Organization, the long-term cost of environmental non-compliance and illicit trade is far higher. Smart packaging is an investment in brand survival, not just a cost center.

2026 Cost-Benefit Forecast:

- Initial Cost: Smart/Eco packs cost $0.03 - $0.05 more per unit.

- ROI Factors: Reduced counterfeiting (-10% loss), lower carbon tax liabilities.

- Consumer Perception: 60% of consumers prefer sustainable packaging, driving sales volume.

FAQ

What is the standard size of a cigarette box?

A standard King Size cigarette box typically measures approximately 85-90mm in height, 55-60mm in width, and 20-25mm in depth. However, cigarette box dimensions can vary significantly for Slims (approx. 45mm width) and Super Slims to accommodate different product types.

How does plain packaging affect cigarette box design?

Plain packaging laws restrict the use of logos and colors, mandating a standard drab color (often Pantone 448C). Designers must rely on structural quality, tactile finishes, and high-quality inner liners to differentiate the brand without violating visual restrictions.

Are eco-friendly cigarette boxes more expensive?

Yes, initially. Materials like hemp or recycled board can be 10-20% more expensive than standard SBS board. However, efficient structural designs and the removal of plastic overwraps can help offset these costs over large production runs.

What is the difference between hard packs and soft packs?

Hard packs (flip-tops) are made of rigid cardboard and offer superior protection against crushing. Soft packs are made of paper and foil, offering a nostalgic feel and lower manufacturing costs, but they provide less protection for the cigarettes inside.

Conclusion

The cigarette packaging landscape is undergoing a radical transformation, driven by the triple threats of strict regulation, environmental urgency, and the digital revolution. Brands that cling to traditional methods risk obsolescence, while those that embrace smart integration and sustainable materials will dominate the shelves in 2026. Whether you are exploring Top Trends for Custom Cigarette Boxes or need a partner to engineer a compliant, high-tech solution, the future is in the details.

Contact Best Pack today to discuss your specific needs and request a free consultation.

About us

When can I get the quotation?

1. The quotation will be offered within 24 hours after getting your detailed request.

2. If you get the urgent inquiry, please call us or mark it via E-mail, then we could make it into priority list.

How many kinds the printing process you have?

We can make Silk screen printing, offset printing, and also hot silver stamping

How much of your samples cost ?

1. If samples are without printing, we can make free samples as per your box size or structure;

2. If samples are silk printing, normally USD 25 per color,depending on your logo colors;

3. If samples are offset printing, need USD 180 as offset printing mold cost is high.

The process of your packaging box production?

1. Make knife mold as per box size and structure

2. order material as per mold

3. make printing on material if need to print

4. suppress and cut material

5. Makeboxes with glue edge in machine

6. Package boxes into cartons

FAQs

Do you support custom designs?

Yes, we provide custom packaging designs tailored to your brand and product needs.

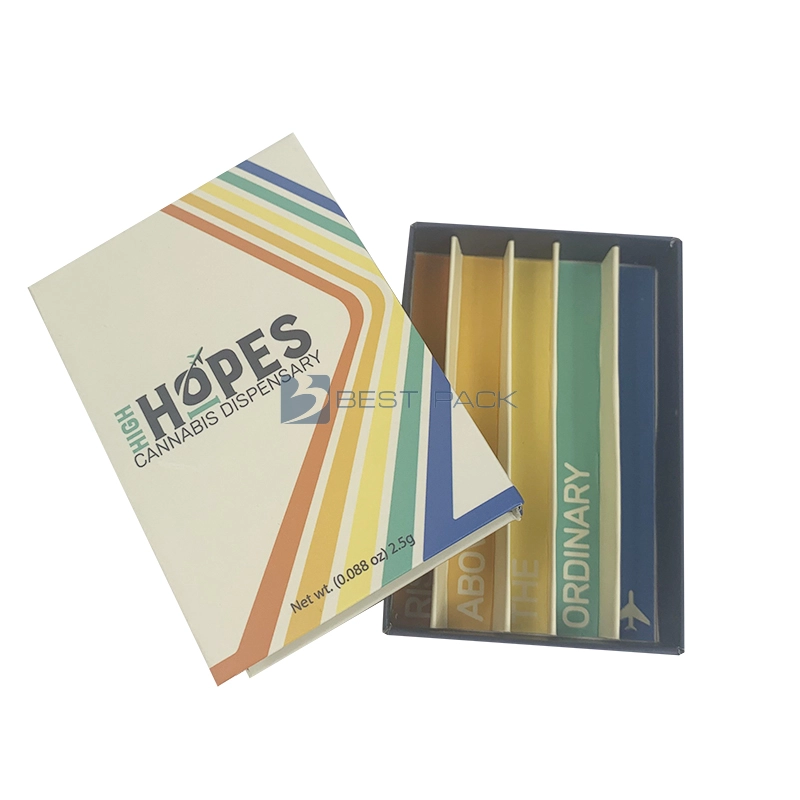

Discover Best Pack’s Factory Paperboard Child-Resistant Childproof Button Box—an ideal cigarette packing box featuring a secure drawer craft packing design. Engineered for safety and style, this childproof button box ensures reliable child resistance while enhancing your cigarette storage experience.

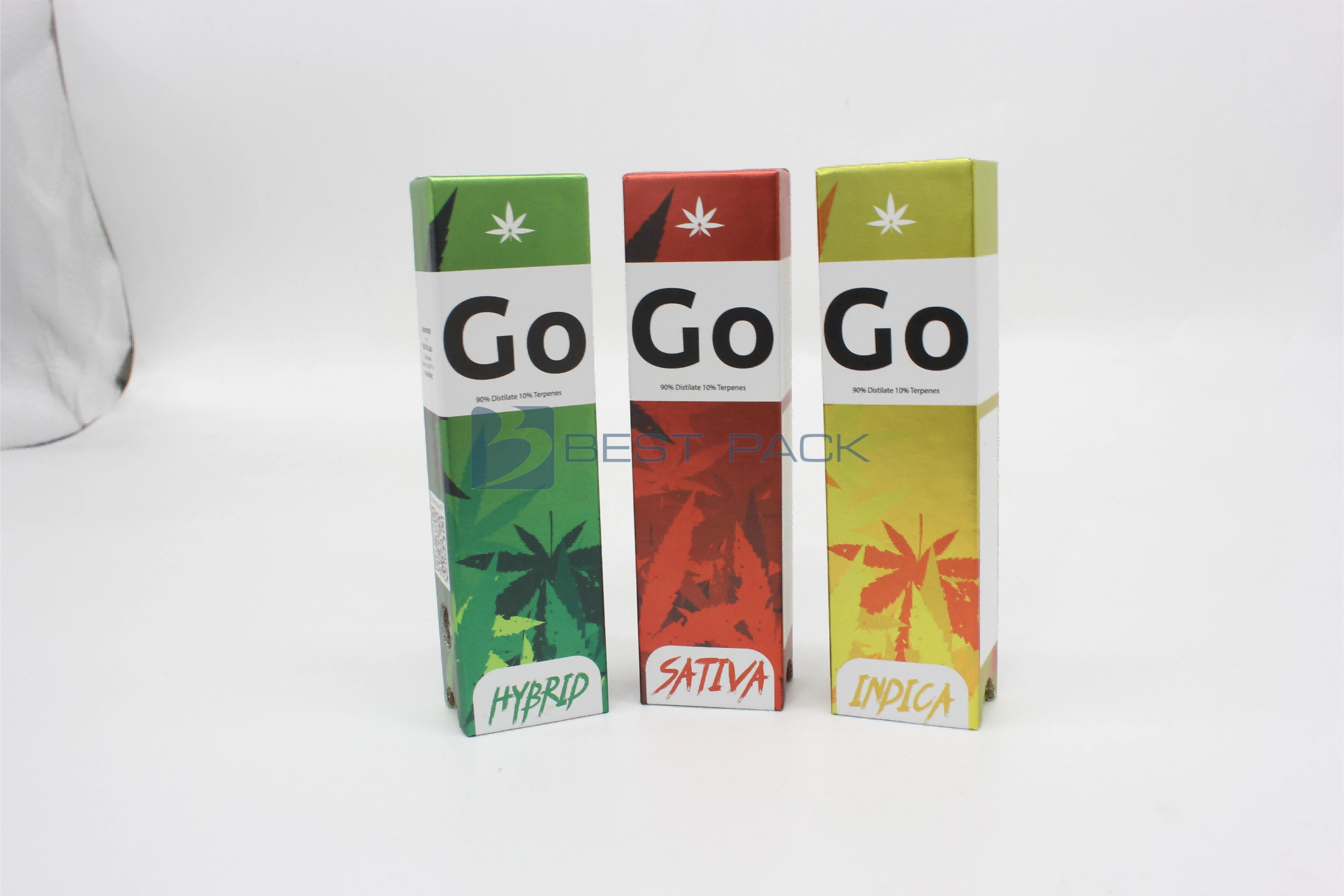

CR custom vape packaging cardboard boxes are specially designed child-resistant packaging solutions crafted to ensure safety, protection, and premium presentation for vape products. Made from sturdy cardboard materials, these boxes balance regulatory compliance with brand aesthetics.

Get in Touch with Best Pack

We’re here to help bring your ideas to life!

Best pack

Best pack

Best pack