The Ultimate Cigarette Box Guide 2026: Design Trends, Global Dimensions, and Sustainable Standards

- Quick Summary: Key Takeaways for 2026 Packaging Trends

- What is a Cigarette Box and Why is its Design Evolving?

- Core Functions of Modern Packaging

- Standard Cigarette Box Dimensions: A 2026 Technical Breakdown

- Common Dimension Standards

- Material Science: The Shift to Eco-Friendly Substrates

- Key Material Innovations

- Navigating Regulatory Compliance and Plain Packaging Laws

- Compliance Checklist for 2026

- Expert Tips for Custom Brand Integration

- Strategies for Differentiation

- Conclusion

- Frequently Asked Questions (FAQ)

- What are the standard dimensions of a 20-pack cigarette box?

- Which material is best for eco-friendly cigarette packaging?

- What is the difference between a hard pack and a soft pack?

- Are cigarette boxes recyclable?

- How many cigarettes are in a standard box?

- What is plain packaging for cigarettes?

- Why do cigarette boxes have a foil or paper lining?

- What is a "hinge-lid" cigarette box?

- References

Quick Summary: Key Takeaways for 2026 Packaging Trends

- Eco-First Materials: The transition to 100% biodegradable and plastic-free materials, such as plant-based cellulose films, is now a market standard.

- Smart Security: Smart packaging features, including anti-counterfeit NFC tags and QR codes, are essential for brand protection and "track and trace" compliance.

- Global Standardization: Sizes across EU and North American markets are converging to optimize logistical efficiency and automation.

What is a Cigarette Box and Why is its Design Evolving?

In the rapidly evolving tobacco industry, the cigarette box is no longer just a container; it is a complex intersection of regulatory compliance, sustainable engineering, and brand survival. As we move into 2026, manufacturers face strict mandates for plain packaging alongside consumer demand for eco-friendly materials.A cigarette box is a rigid, protective container typically constructed from 18pt to 24pt SBS (Solid Bleached Sulfate) paperboard, designed to preserve tobacco freshness and comply with strict legal labeling requirements.

Beyond simple storage, the modern cigarette pack serves as the primary barrier against environmental factors like moisture and physical crushing. The design evolution has been dramatic—shifting from the soft paper wraps of the early 20th century to the revolutionary "flip-top" hard pack introduced in the 1950s. Today, the focus has shifted again toward carbon-neutral production and child-resistant features.

At Guangzhou Best Pack Co.,Ltd, we have observed this shift firsthand. Our clients increasingly request custom cigarette packaging that not only meets the visual standards of a premium brand but also integrates complex Child Resistant (CR) locking mechanisms to satisfy safety regulations in markets like the US and Canada.

Core Functions of Modern Packaging

- Preservation: Foil or metallized paper liners maintain humidity to prevent tobacco from drying out.

- Protection: Rigid box structures prevent cigarettes from breaking during transit or in a user's pocket.

- Compliance: Surfaces are engineered to host high-resolution mandatory health warnings without warping.

Standard Cigarette Box Dimensions: A 2026 Technical Breakdown

The global benchmark for a standard King Size (20 count) cigarette box is approximately 85-86mm in height, 55mm in width, and 20-23mm in depth.

Precision is critical. Even a millimeter of variance can jam high-speed automated packing lines. While "King Size" remains the dominant format, niche markets have popularized slimmer profiles to appeal to aesthetic preferences and reduce material usage.

Common Dimension Standards

- King Size (Standard 20s):

- Dimensions: 86mm x 55mm x 23mm

- Capacity: 20 cigarettes (standard diameter approx. 8mm)

- Usage: The universal standard for most global markets.

- Super Slims:

- Dimensions: 100mm x 45mm x 12mm

- Capacity: 20 slim cigarettes (reduced diameter approx. 5-6mm)

- Usage: Optimized for high-end aesthetic appeal and portability.

- 100s (Longs):

- Dimensions: 100mm x 55mm x 23mm

- Usage: Designed for longer cigarettes (100mm length) often preferred in specific demographics.

- Bulk Cartons:

- Structure: Typically holds 10 individual packs (200 cigarettes total).

- Logistics: Standardized for palletization to maximize shipping container space.

When designing a cigarette box template, designers must account for the "crease lines" and glue flaps. A generic template often fails because it does not account for the specific thickness of the paperboard (caliper), which affects how the box folds.

Material Science: The Shift to Eco-Friendly Substrates

Modern sustainable cigarette packaging prioritizes FSC-certified Kraft or SBS board and replaces traditional aluminum foil liners with biodegradable metallized paper.

Sustainability is no longer optional. With the EU and other regions enforcing strict plastic reduction laws, the industry is moving away from non-recyclable multi-layer laminates. Data indicates that the market for sustainable tobacco packaging is growing at a CAGR of over 8% through 2028.

Key Material Innovations

- Biodegradable Overwrap: Replacing clear polypropylene (plastic) wrap with wood-pulp-based cellulose films that decompose naturally.

- Metallized Paper Liners: These offer the same moisture barrier as aluminum foil but are fully recyclable within standard paper streams.

- Soy-Based Inks: Moving away from petroleum-based inks to reduce volatile organic compounds (VOCs) during printing.

At Best Pack, we offer cannabis protective packaging and cigarette boxes that utilize these eco-friendly substrates without compromising the "premium feel" of the product. Our manufacturing process ensures that even recycled boards maintain the necessary rigidity to protect the contents.

Navigating Regulatory Compliance and Plain Packaging Laws

Plain packaging laws mandate the removal of all branding, requiring boxes to be a standard drab color (Pantone 448 C) with brand names printed in a specified generic font.

As of 2025, countries like Canada, Australia, and the Netherlands have fully implemented these strict measures, with others like Georgia and Cote d'Ivoire joining the list. In these jurisdictions, the physical structure of the box becomes the only way to differentiate quality (e.g., a sturdy hinge-lid vs. a flimsy soft pack).

Compliance Checklist for 2026

- Graphic Warnings: Most regions now require graphic health warnings to cover 50% to 90% of the front and back panels.

- Minimum Size: Laws often dictate a minimum pack size (usually 20 sticks) to prevent "kiddie packs" that are cheaper and more accessible to youth.

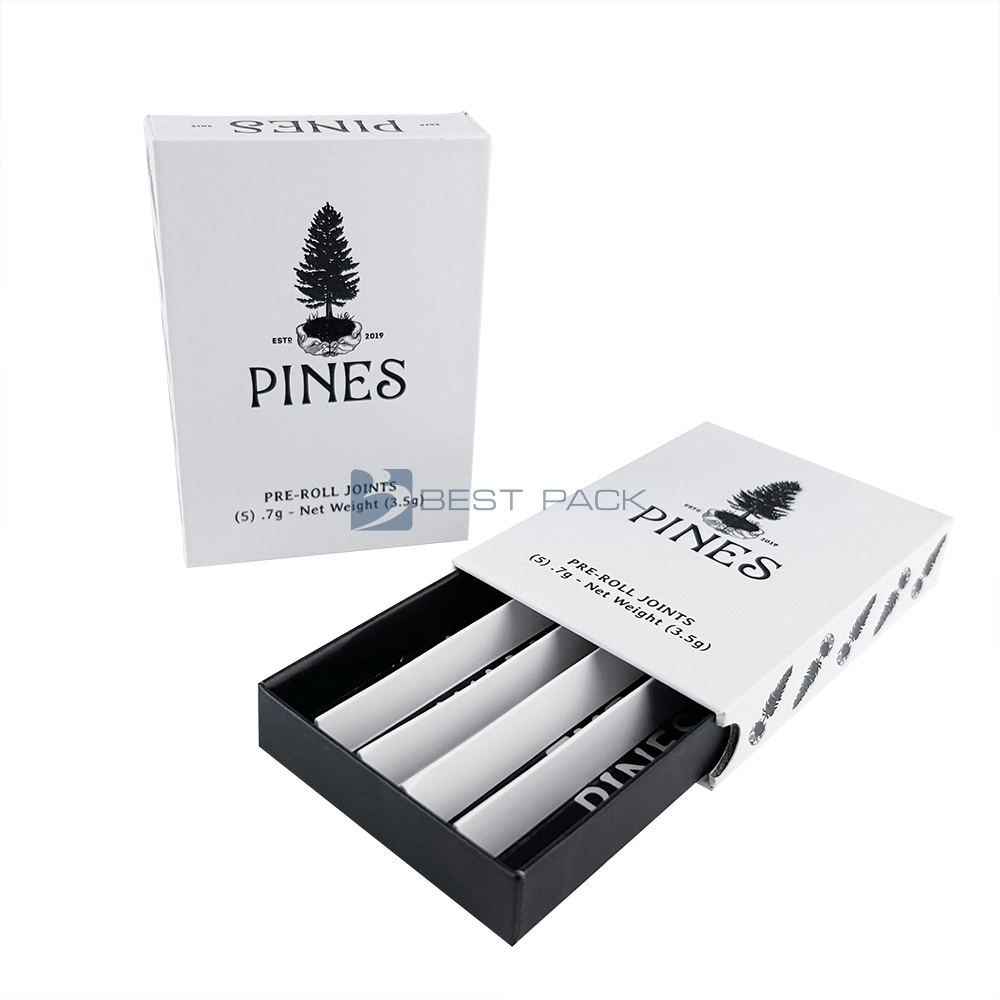

- Child-Resistant (CR) Tech: For related products like e-cigarettes or cannabis pre-rolls, ISO 8317 certified closures are mandatory. We specialize in engineering Child Resistant Packaging Box solutions that pass these rigorous tests while remaining easy for adults to open.

Expert Tips for Custom Brand Integration

Effective brand integration in restrictive markets relies on tactile finishes like embossing and the structural "unboxing experience" rather than flashy graphics.

When visual real estate is limited by regulation, the physical interaction with the cigarette box design becomes your primary branding tool. The audible "click" of a well-made flip-top lid signals quality to the consumer.

Strategies for Differentiation

- Tactile Textures: Use UV spot varnishes or embossing on allowed areas to create a premium hand-feel.

- Smart Packaging: Integrate NFC tags or QR codes (where legally permitted) to bridge the physical-digital gap. This allows brands to tell their story or verify authenticity digitally.

- Custom Inserts: For markets allowing it, a personalized cigarette box can include unique interior prints or inserts that engage the user after opening.

Designers looking for inspiration can explore our guide on Top Trends for Custom Cigarette Boxes to see how structural innovation is replacing graphical clutter.

Conclusion

The humble cigarette box has become a marvel of modern packaging engineering. Whether you are sourcing a vintage cigarette box look or a futuristic, child-resistant shell, success lies in understanding the balance between strict global regulations and user experience. As manufacturers like Guangzhou Best Pack Co.,Ltd continue to innovate with biodegradable materials and smart tech, the standard for what defines a "quality" pack will only rise.

For businesses looking to source compliant packaging at scale, reviewing the Top 10 Cigarette Pack Manufacturers is an essential next step to finding a partner who understands these 2026 standards.

Frequently Asked Questions (FAQ)

What are the standard dimensions of a 20-pack cigarette box?

The standard King Size box is typically 86mm in height, 55mm in width, and 23mm in depth. These dimensions can vary slightly (by 1-2mm) depending on the cardstock thickness and specific brand engineering.

Which material is best for eco-friendly cigarette packaging?

Recyclable SBS paperboard and biodegradable cellulose films are the leading choices for 2026. These materials offer the necessary durability while meeting global sustainability mandates to reduce plastic waste.

What is the difference between a hard pack and a soft pack?

A hard pack is a rigid paperboard box with a flip-top lid that protects cigarettes from crushing. A soft pack is made of paper and foil, offering less protection but a distinct tactile feel often associated with vintage brands.

Are cigarette boxes recyclable?

The outer paperboard is generally recyclable; however, the internal foil liners and plastic overwraps often require specialized processing. Modern cigarette pack designs are increasingly using metallized paper to make the entire package curbside recyclable.

How many cigarettes are in a standard box?

Most global markets standardize at 20 cigarettes per pack. However, specific regions may allow or require different counts, such as 25-packs or smaller 10-packs, though many countries have banned packs smaller than 20 to deter youth access.

What is plain packaging for cigarettes?

Plain packaging is a regulation that requires the removal of all brand colors, logos, and imagery. Packs must be a standard drab color (often Pantone 448 C) with the brand name printed in a mandated neutral font.

Why do cigarette boxes have a foil or paper lining?

The lining creates a barrier to maintain the tobacco's moisture content (approx. 12-14%) and prevents it from absorbing external odors or drying out, which would spoil the flavor.

What is a "hinge-lid" cigarette box?

The hinge-lid, or flip-top, is the most common rigid box design. It features a lid permanently attached to the body via a back crease, providing easy re-closing and superior protection compared to soft packs.

References

Cigarette Packaging Market Outlook 2026-2032

- Tobacco plain packaging: global status 2021 update

- Smart Packaging Market 2025 | RFID, NFC & QR-Enabled Packaging Growth

FAQs

What types of packaging do you specialize in?

We specialize in electronic packaging, plastic boxes (PVC/PET/PP), paper boxes, paper bags, and custom book printing.

About us

Leading time for samples production?

Normally we need 3-7 days for samples making, 10-12 days to complete your orders,but the delivery time more depends on the order QTY.

How many kinds the printing process you have?

We can make Silk screen printing, offset printing, and also hot silver stamping

The process of your packaging box production?

1. Make knife mold as per box size and structure

2. order material as per mold

3. make printing on material if need to print

4. suppress and cut material

5. Makeboxes with glue edge in machine

6. Package boxes into cartons

When can I get the quotation?

1. The quotation will be offered within 24 hours after getting your detailed request.

2. If you get the urgent inquiry, please call us or mark it via E-mail, then we could make it into priority list.

The CR telescoping box is a sophisticated and secure packaging solution designed specifically for vape products. Featuring a telescoping (two-piece) structure, this box offers excellent protection and an elegant presentation, enhancing both the unboxing experience and brand appeal.

Get in Touch with Best Pack

We’re here to help bring your ideas to life!

Best pack

Best pack

Best pack