How Recycling Impacts Child-Resistant Cigarette Box Materials 2026

- Introduction

- The Evolution of Child-Resistant Packaging

- Recycling's Influence on Packaging Materials

- Regulatory Pressures and Sustainability Goals

- Innovations in Child-Resistant Packaging

- Best Pack's Commitment to Sustainable Packaging

- Conclusion

- Frequently Asked Questions (FAQ)

- What are child-resistant cigarette boxes?

- How does recycling impact cigarette packaging?

- What are some sustainable materials used in cigarette packaging?

- How is Best Pack contributing to sustainable packaging?

- Where can I learn more about Best Pack's products?

- Contact Us

- Explore Our Products

Introduction

The tobacco industry is undergoing significant transformations, particularly in the realm of packaging. As environmental concerns intensify and regulations tighten, the design and production of child-resistant cigarette boxes are being profoundly influenced by recycling initiatives. This article delves into how recycling is shaping the materials and manufacturing processes of these specialized packaging solutions in 2026.

The Evolution of Child-Resistant Packaging

Child-resistant packaging is designed to prevent children from accessing hazardous substances, thereby reducing accidental poisonings. In the context of tobacco products, such packaging serves a dual purpose: ensuring safety and complying with stringent regulations. Over the years, the design of child-resistant cigarette boxes has evolved to balance safety, functionality, and environmental responsibility.

Recycling's Influence on Packaging Materials

Recycling initiatives have significantly impacted the materials used in cigarette packaging. Manufacturers are increasingly adopting sustainable materials to reduce environmental footprints. For instance, biodegradable films and plant-based fiber composites are emerging as viable alternatives to traditional plastic laminates. These materials not only enhance recyclability but also align with global sustainability goals.

Regulatory Pressures and Sustainability Goals

Governments worldwide are implementing regulations that mandate the use of recyclable or compostable materials in packaging. The European Union's Single-Use Plastics Directive (SUPD) requires 50% recycled content in cigarette filters and packaging components by 2025. Similarly, Canada's tobacco plain packaging regulations specify minimum recycled fiber content. These policies drive investment in alternative materials and encourage manufacturers to innovate in packaging design.

Innovations in Child-Resistant Packaging

The quest for sustainable child-resistant packaging has led to notable innovations. In 2025, Contempo Specialty Packaging introduced the world's first child-resistant and plastic-free cigarette box. This design addresses the vulnerabilities of traditional flip-top boxes by offering a durable, secure, and environmentally friendly structure that passes rigorous child-resistant testing. Such innovations demonstrate the industry's commitment to safety and sustainability.

Best Pack's Commitment to Sustainable Packaging

At Best Pack, we are dedicated to providing high-quality, custom cannabis cigarette packaging solutions that prioritize both safety and environmental responsibility. Our product range includes child-resistant packaging boxes, cannabis protective packaging, vape packaging, and custom vape cartridge boxes. We utilize sustainable materials and innovative designs to meet the challenges of the Information Technology Age, ensuring our products not only protect consumers but also the planet.

Conclusion

The integration of recycling into the design and production of child-resistant cigarette boxes is reshaping the packaging landscape. As regulations become more stringent and environmental concerns grow, manufacturers are compelled to innovate and adopt sustainable practices. Best Pack remains at the forefront of this evolution, offering packaging solutions that are both safe and eco-friendly.

Frequently Asked Questions (FAQ)

What are child-resistant cigarette boxes?

Child-resistant cigarette boxes are specially designed packaging that prevents children from accessing the contents, thereby reducing the risk of accidental poisonings.

How does recycling impact cigarette packaging?

Recycling initiatives encourage the use of sustainable materials in cigarette packaging, leading to designs that are both environmentally friendly and compliant with safety regulations.

What are some sustainable materials used in cigarette packaging?

Sustainable materials include biodegradable films, plant-based fiber composites, and recyclable mono-material structures, which enhance recyclability and reduce environmental impact.

How is Best Pack contributing to sustainable packaging?

Best Pack is committed to providing high-quality, custom cannabis cigarette packaging solutions that prioritize both safety and environmental responsibility, utilizing sustainable materials and innovative designs.

Where can I learn more about Best Pack's products?

For more information on our products and services, please visit our website at https://www.gzbestpack.com/.

Contact Us

If you have further questions or need assistance, feel free to contact us. Our team is here to help you find the best packaging solutions for your needs.

Explore Our Products

Discover our range of child-resistant packaging solutions designed to meet your specific requirements. Visit our product page to learn more and place an order.

Ultimate Guide to Child Resistant Paper Boxes

Where to Buy cigarette case folding paper box

Top Industries Using Child Resistant Paper Boxes for Product Safety

Eco-Friendly Cigar Box Options for Sustainable Brands

About us

How much of your samples cost ?

1. If samples are without printing, we can make free samples as per your box size or structure;

2. If samples are silk printing, normally USD 25 per color,depending on your logo colors;

3. If samples are offset printing, need USD 180 as offset printing mold cost is high.

How many kinds the printing process you have?

We can make Silk screen printing, offset printing, and also hot silver stamping

Leading time for samples production?

Normally we need 3-7 days for samples making, 10-12 days to complete your orders,but the delivery time more depends on the order QTY.

The process of your packaging box production?

1. Make knife mold as per box size and structure

2. order material as per mold

3. make printing on material if need to print

4. suppress and cut material

5. Makeboxes with glue edge in machine

6. Package boxes into cartons

FAQs

Can you ship internationally?

Yes, we export worldwide and work with reliable logistics partners for timely delivery.

Custom Printed Paperboard Cardboard Cigarette Box Packaging Case Disposable Paper Box for Cigarette Clamshell paper box

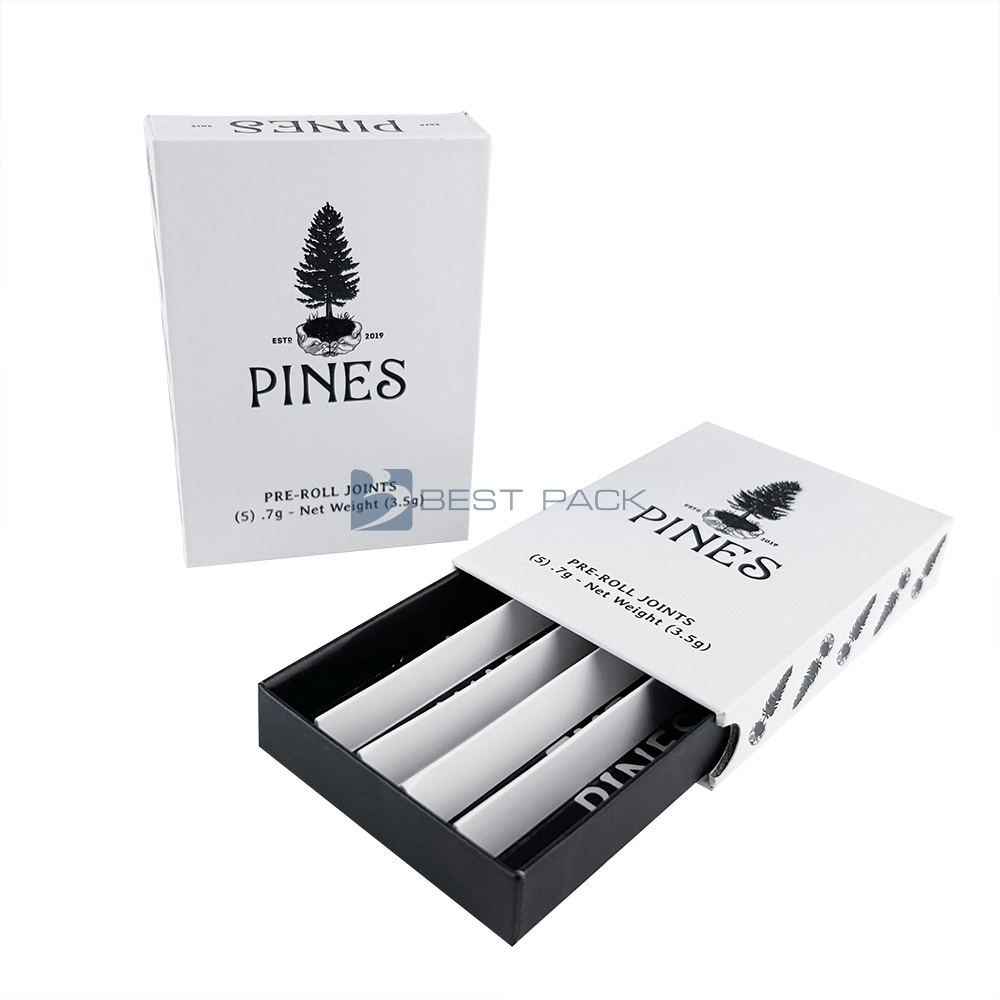

Factory Custom Child Resistant Paper Packaging Box Cardboard Drawer Sliding 5 Pack Pre Rolled Box Cigarette Box

Custom Vape Packaging Box with CR Telescoping Design

The CR telescoping box is a sophisticated and secure packaging solution designed specifically for vape products. Featuring a telescoping (two-piece) structure, this box offers excellent protection and an elegant presentation, enhancing both the unboxing experience and brand appeal.

Best pack

Best pack

Best pack