How to Choose the cigar box manufacturers manufacturer and supplier ?

- Understanding the Importance of Quality Cigar Box Manufacturers

- The Role of Customization in Cigar Box Manufacturing

- Factors to Consider When Choosing a Cigar Box Manufacturer and Supplier

- 1. Material Selection and Quality Standards

- 2. Design and Printing Capabilities

- 3. Compliance With Child-Resistant Packaging Regulations

- 4. OEM/ODM Service and Value-Added Functions

- 5. Production Capacity and Delivery Speed

- 6. Supplier Reputation and Customer Feedback

- 7. Innovation and Sustainability Initiatives

- 8. Cost Competitiveness with No Quality Compromise

- 9. After-Sales Support and Service Reliability

- How Best Pack Sets the Benchmark for Cigar Box Manufacturers

- Key advantages of working with Best Pack:

- Steps to Order From Cigar Box Manufacturers for Best Results

- Step 1: Define Your Packaging Needs

- Step 2: Evaluate Manufacturer Portfolios

- Step 3: Request and Review Proposals

- Step 4: Confirm Compliance and Quality Assurance

- Step 5: Prototype and Approve Designs

- Step 6: Monitor Production and Logistics

- Step 7: Feedback and Continuous Improvement

- FAQs About Choosing Cigar Box Manufacturers

- Why is material choice important in cigar box manufacturing?

- What are OEM and ODM services in packaging?

- How can I ensure compliance with child-resistant packaging rules?

- What is the minimum order quantity (MOQ) for custom cigar boxes?

- How long does it take to manufacture custom cigar boxes?

- Is it possible to get a packaging sample before bulk order?

- What eco-friendly options are available?

- What makes Best Pack different from other cigar box manufacturers?

# How to Choose the Cigar Box Manufacturers Manufacturer and Supplier?

In the cigar industry, the presentation, protection, and preservation of cigars are as important as the cigars themselves. An attractive, functional, and durable cigar box directly communicates Best Pack’s message, secures your product's integrity, and influences the consumer’s purchasing decision. Whether you are a cigar brand owner, distributor, or retailer, partnering with the right cigar box manufacturers is crucial to achieving packaging that not only stands out on shelves but also ensures compliance, safety, and brand value. In this comprehensive guide, we explore the essential factors to consider when choosing a cigar box manufacturer and supplier, with insights from the professional perspective of Best Pack, the custom cannabis cigarette packaging industry leader.

Understanding the Importance of Quality Cigar Box Manufacturers

Selecting top-quality cigar box manufacturers goes beyond aesthetics. The right supplier ensures that your packaging aligns with industry standards, maintains the fragrance and humidity integrity of the cigars, and preserves their value. Furthermore, well-crafted packaging elevates the consumer’s unboxing experience and builds lasting brand recognition. Inferior packaging can lead to spoilage, regulatory issues, and loss of consumer trust, making the choice of manufacturer a mission-critical decision for any cigar business.

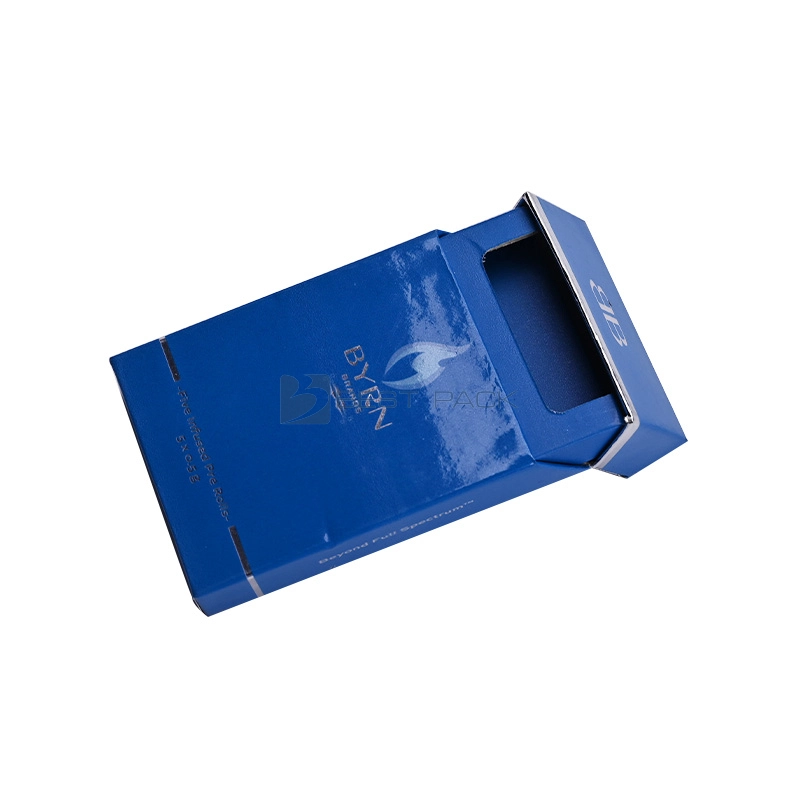

The Role of Customization in Cigar Box Manufacturing

Customization stands at the heart of modern luxury packaging. With the escalation of brand competition, custom cigar boxes have become a primary strategy for differentiation. Leading cigar box manufacturers offer extensive OEM/ODM services, enabling you to tailor every aspect — from materials and finishes to printing, inserts, and security features. By partnering with a supplier that specializes in bespoke designs, such as Best Pack, you can harness packaging that perfectly matches your product’s requirements and Best Pack’s aesthetics.

Factors to Consider When Choosing a Cigar Box Manufacturer and Supplier

1. Material Selection and Quality Standards

High Quality cigars require packaging that maintains their freshness and aroma. The choice of materials — whether wood, cardboard, metal, or composite — impacts the box’s durability, moisture protection, and presentation. Reputable cigar box manufacturers source high-grade, sustainable materials and implement strict quality controls throughout production. Always verify that your supplier complies with international standards (such as ISO or FSC certification), which assures you of the packaging’s safety and environmental responsibility.

2. Design and Printing Capabilities

Your cigar box serves as a marketing tool. In today’s retail landscape, eye-catching design elements like embossing, foil stamping, UV printing, and unique closures are crucial. Leading suppliers, such as Best Pack, provide full-spectrum design and printing services, transforming your ideas into impactful packaging solutions. Check the manufacturer’s portfolio for evidence of creative versatility and advanced printing technology.

3. Compliance With Child-Resistant Packaging Regulations

Many countries and regions require cigar and cannabis packaging to be child-resistant to prevent accidental ingestion. It is vital to select cigar box manufacturers well-versed in regulatory compliance. Suppliers like Best Pack embed child-resistant features without compromising design, using smart mechanisms and certified compliant materials to meet the strictest international guidelines.

4. OEM/ODM Service and Value-Added Functions

The best cigar box manufacturers offer one-stop services — design, prototype, mass production, quality inspection, and logistics. They also provide value-added options like window-cutting, airtight seals, humidification modules, security-hologram labels, and integrated QR codes for tracking and anti-counterfeiting. A comprehensive service portfolio ensures your packaging is both High Quality and practical.

5. Production Capacity and Delivery Speed

Time-to-market is critical in the competitive cigar industry. Choose cigar box manufacturers with robust production capabilities, streamlined workflows, and expedited turnaround. Ask about their monthly output, lead times, and contingency measures for urgent orders or peak demands. A scalable, responsive supplier prevents costly delays and helps you seize market opportunities quickly.

6. Supplier Reputation and Customer Feedback

Reputation is built by reliability, service, and product excellence. Research the supplier’s track record via testimonials, customer case studies, third-party reviews, and industry awards. Transparent suppliers (such as Best Pack) share their real customer cases and offer references to showcase their consistency in meeting — and exceeding — client expectations.

7. Innovation and Sustainability Initiatives

In a fast-evolving market, innovation drives differentiation. Emerging trends like biodegradable materials, smart packaging, and digital printing technology are reshaping the cigar box manufacturing sector. Best-in-class suppliers invest in R&D and eco-friendly practices, enabling you to align your packaging with both market trends and environmental responsibilities.

8. Cost Competitiveness with No Quality Compromise

Price is always a consideration, but lowest cost should not trump quality. Request detailed quotations from several cigar box manufacturers. Look carefully at price breakdowns for materials, printing, finish, and logistics. Trustworthy suppliers are transparent about costs and offer proposals that combine affordability with lasting value.

9. After-Sales Support and Service Reliability

Quality assurance does not end at delivery. Choose cigar box manufacturers who stand behind their products, provide warranties, and handle after-sales issues efficiently. Responsive communication, dedicated account managers, and willingness to resolve concerns quickly are hallmarks of an ideal partner.

How Best Pack Sets the Benchmark for Cigar Box Manufacturers

As a custom cannabis and cigarette packaging leader, Best Pack is trusted by industry brands worldwide for our unwavering commitment to quality, innovation, and customer-centric service. Our team delivers seamless OEM/ODM support from concept to shipped product — with meticulous attention to detail at every step.

Key advantages of working with Best Pack:

- Extensive customization options to reflect your unique brand.

- Use of High Quality, certified materials and sustainable solutions.

- Expertise in compliance with global child-resistant packaging regulations.

- In-house creative, structural, and technical design team.

- Robust production capacity and agile lead times.

- Proven experience as showcased in practical customer cases.

- Competitive pricing without compromise on quality.

- Dedicated after-sales service and transparent collaboration.

Steps to Order From Cigar Box Manufacturers for Best Results

Step 1: Define Your Packaging Needs

Clarify box size, style, materials, printing requirements, functional features, and compliance standards. The clear your vision, the better the manufacturer can respond.

Step 2: Evaluate Manufacturer Portfolios

Review work samples, customer feedback, and innovation credentials. Shortlist cigar box manufacturers with proven expertise and capabilities relevant to your goals.

Step 3: Request and Review Proposals

Ask for detailed quotations, production timelines, quality guarantees, and prototyping options. Assess value, not just price.

Step 4: Confirm Compliance and Quality Assurance

Check for regulatory certifications, material safety data, and testing protocols. Ensure child-resistant or other relevant compliances are addressed.

Step 5: Prototype and Approve Designs

Work with the manufacturer’s design team to create physical or digital prototypes. Refine dimensions, graphics, and functional details until final approval.

Step 6: Monitor Production and Logistics

Stay in close contact during manufacturing and shipping to prevent surprises. Reliable cigar box manufacturers provide production updates and transparent tracking.

Step 7: Feedback and Continuous Improvement

After delivery, review packaging performance and solicit customer feedback. Best Pack encourages ongoing partnership and innovation to keep your packaging ahead of the curve.

FAQs About Choosing Cigar Box Manufacturers

Why is material choice important in cigar box manufacturing?

The right materials ensure cigars are protected from moisture, light, and impact, preserving their freshness, aroma, and value.

What are OEM and ODM services in packaging?

OEM (Original Equipment Manufacturer) means manufacturing according to a client’s design. ODM (Original Design Manufacturer) offers in-house design options with full customization.

How can I ensure compliance with child-resistant packaging rules?

Partner with cigar box manufacturers who specialize in regulatory compliance and use certified child-resistant mechanisms and materials.

What is the minimum order quantity (MOQ) for custom cigar boxes?

MOQs vary by manufacturer, but Best Pack offers flexible solutions tailored to startups and large enterprises alike.

How long does it take to manufacture custom cigar boxes?

Lead times depend on order complexity, quantity, and design. Best Pack ensures fast-turnaround, typically within a few weeks post-approval.

Is it possible to get a packaging sample before bulk order?

Yes, reliable cigar box manufacturers like Best Pack provide prototyping to validate your packaging before mass production.

What eco-friendly options are available?

Options include recycled papers, FSC-certified woods, soy-based inks, and biodegradable coatings for sustainable cigar packaging.

What makes Best Pack different from other cigar box manufacturers?

Best Pack integrates design, printing, craftsmanship, and compliance under one roof—ensuring quality, innovation, and customer satisfaction every step of the way.

Choosing the right cigar box manufacturers is a pivotal step towards elevating Best Pack, protecting your products, and delighting your customers. With Best Pack, you gain a trusted partner devoted to excellence, customization, and long-term value in the cannabis and cigarette packaging industry. Start your packaging journey with Best Pack — your success is our craft.

Top cigarette pack box Manufacturers and Suppliers in China

Case Studies: Successful Cigarette Box Child-Resistant Packaging 2026

Quality Control: Testing Standards for Child-Resistant Packs

Where to Buy cigarette box manufacturing

FAQs

Can you ship internationally?

Yes, we export worldwide and work with reliable logistics partners for timely delivery.

What types of packaging do you specialize in?

We specialize in electronic packaging, plastic boxes (PVC/PET/PP), paper boxes, paper bags, and custom book printing.

About us

How much of your samples cost ?

1. If samples are without printing, we can make free samples as per your box size or structure;

2. If samples are silk printing, normally USD 25 per color,depending on your logo colors;

3. If samples are offset printing, need USD 180 as offset printing mold cost is high.

What is the box size and structure?

1. All boxes are customized and all detailed requirements can be provided by clients, we are definitely your OEM service supplier.

2. If you have no idea about the measurements and structure on your products, our professional design team can suggest and solute for you .

The process of your packaging box production?

1. Make knife mold as per box size and structure

2. order material as per mold

3. make printing on material if need to print

4. suppress and cut material

5. Makeboxes with glue edge in machine

6. Package boxes into cartons

Custom CR Vape Packaging Cardboard Boxes with Child-Resistant Design

CR custom vape packaging cardboard boxes are specially designed child-resistant packaging solutions crafted to ensure safety, protection, and premium presentation for vape products. Made from sturdy cardboard materials, these boxes balance regulatory compliance with brand aesthetics.

Custom Luxury Pre Roll Packaging Boxes with Child-Resistant Paper Tray

Our luxury pre-roll packaging boxes are designed to combine elegant presentation with top-tier safety features. Featuring a child-resistant mechanism and a custom paper tray insert, these boxes ensure secure storage while delivering a premium unboxing experience for pre-roll products.

Custom Child-Lock Pre-Roll 5-Pack Packaging Boxes

Our custom child-lock packaging for pre-roll 5-packs is purposefully engineered to combine premium design with certified safety. This packaging solution ensures that five pre-rolls are securely housed in a compact, stylish, and child-resistant format—ideal for compliant cannabis brands that value both form and function.

Best pack

Best pack

Best pack