Materials Comparison for Child Resistant Cigarette Packaging

- Materials Comparison for Child Resistant Cigarette Packaging

- Why material choice matters for custom cigarette boxes

- Regulatory context for child resistant packaging

- Overview of common materials for cigarette packaging

- Paperboard (SBS and CCNB) — best printability and cost-efficiency

- Rigid chipboard boxes — High Quality feel and structure

- Metal (tinplate and aluminum) — strong barrier and tamper evidence

- Plastic (PET, PP, HDPE) — durable and compatible with mechanical CR closures

- Barrier films and laminates — essential for product protection

- How materials compare—quick reference table

- Integrating child-resistant mechanisms with different materials

- Print finishing and brand presentation for custom cigarette boxes

- Cost considerations and manufacturing scale

- Sustainability trade-offs and consumer expectations

- Testing and certification to meet standards

- Practical recommendations by product need

- How Best Pack supports custom cigarette boxes with CR requirements

- Cost vs. performance: a real-world selection checklist

- FAQ — Frequently Asked Questions about materials for child resistant cigarette packaging

- Which material is most commonly used for custom cigarette boxes?

- Can paperboard boxes be made child-resistant?

- Are metal tins better for product preservation?

- How do sustainability goals affect material choice?

- How does Best Pack help ensure compliance with child-resistance standards?

- How should I start if I want custom cigarette boxes with child-resistant features?

Materials Comparison for Child Resistant Cigarette Packaging

Choosing the right material for child resistant cigarette packaging is a business and compliance decision. This guide compares the most common substrates and explains how each performs for custom cigarette boxes—covering protection, print quality, child-resistant mechanism integration, cost and recyclability.

Why material choice matters for custom cigarette boxes

The material you choose affects product safety, regulatory compliance, shelf appeal, and production cost. Child resistant cigarette packaging must not only be difficult for children to open but also preserve product quality (moisture, light, odor), present brand graphics at high quality, and remain manufacturable at scale.

Regulatory context for child resistant packaging

Before selecting materials, remember regulatory requirements. In many jurisdictions (for example, under the U.S. Poison Prevention Packaging Act and international standards like ISO 8317), child resistant packaging must meet prescribed performance tests. For cannabis cigarette products, jurisdictions such as Canada and many U.S. states require child-resistant, tamper-evident packaging. Material and mechanism must work together to pass test protocols.

Overview of common materials for cigarette packaging

The main material families used for custom cigarette boxes are paperboard (various grades), rigid/chipboard constructions, metal (tinplate or aluminum), plastic (PET, PP), and multi-layer laminates or foil. Each offers trade-offs in barrier properties, print surface, cost, and sustainability.

Paperboard (SBS and CCNB) — best printability and cost-efficiency

Paperboard grades like Solid Bleached Sulfate (SBS) and Clay Coated News Back (CCNB) are popular for branded custom cigarette boxes. Benefits include excellent print surface for high-fidelity graphics, low weight, and competitive cost. Paperboard can be combined with child-resistant mechanics (e.g., tuck‑lock systems with internal locking tabs) and can include inner barriers or foil liners for moisture control.

Rigid chipboard boxes — High Quality feel and structure

Rigid or set-up boxes made from chipboard provide a High Quality unboxing experience and structural strength for complex child-resistant mechanisms (like hinged-lid locking devices). They pair well with High Quality finishes—soft-touch lamination, embossing—and are often used for higher-end custom cigarette boxes where brand image is critical.

Metal (tinplate and aluminum) — strong barrier and tamper evidence

Metal tins and slide boxes deliver excellent moisture and light barrier performance and inherent durability. Metal enables secure hinge and latch designs that can be made child-resistant. Downsides include higher material cost and more limited print finishes compared with coated paper. Metal is a good choice when preservation and reusability are priorities.

Plastic (PET, PP, HDPE) — durable and compatible with mechanical CR closures

Rigid plastics like PET and PP are used where durability and complex mechanical child-resistant closures are required. Plastics can integrate locking mechanisms molded into the part, offer excellent impact resistance, and provide clear visibility for product designs that require it. Considerations include recyclability of mixed materials and perceived sustainability by consumers.

Barrier films and laminates — essential for product protection

Multi-layer films (foil laminates, metallized films, or EVOH layers) provide critical moisture and oxygen barriers and are often used as inner liners inside paperboard or rigid boxes. For items sensitive to moisture—like cannabis cigarettes—laminated inner liners maintain product freshness without requiring a full metal container.

How materials compare—quick reference table

| Material | Barrier (moisture/light) | Print Quality | Child-resistance Compatibility | Cost | Sustainability / Recyclability |

|---|---|---|---|---|---|

| Paperboard (SBS / CCNB) | Medium (can add liners) | High | Medium (mechanical inserts, locking tabs) | Low–Medium | High (widely recyclable if uncoated) |

| Rigid chipboard | Medium–High (with inner liner) | High (High Quality finishes) | High (stable base for complex mechanisms) | Medium–High | Medium (depends on laminates/foils) |

| Metal (tinplate / aluminum) | High | Medium (limited finishing) | High (robust mechanical closures) | High | High (recyclable metal) |

| Plastic (PET, PP) | High (if solid) | Medium | High (molded CR closures possible) | Medium | Variable (depends on resin, recycling streams) |

| Laminates / Foil liners | Very High | Not applicable (used internally) | High (enable CR seals and tamper evidence) | Medium | Low–Variable (harder to recycle mixed layers) |

Integrating child-resistant mechanisms with different materials

Material determines which CR mechanisms are practical. Paperboard often uses engineered tuck locks, hidden flaps, or internal plastic/metal inserts. Rigid boxes can accommodate hinge-and-latch or spring-loaded locks. Plastics allow molded push‑and‑slide or squeeze‑and‑turn systems. Metal enables robust mechanical latches and sliding locks. In most cases, a hybrid approach—paperboard exterior with plastic or foil internal components—balances cost and performance.

Print finishing and brand presentation for custom cigarette boxes

High-quality graphics are central to cigarette packaging. SBS paperboard yields the best CMYK and specialty print results, while rigid boxes allow luxury finishes like soft-touch or foil stamping. Metal offers limited printing but High Quality embossing and color options. Consider how the chosen material will support the visual identity of your custom cigarette boxes.

Cost considerations and manufacturing scale

Material cost and manufacturing complexity drive per-unit pricing. Paperboard solutions are typically the most cost-effective for large runs. Rigid, metal, and complex plastic mechanisms increase tooling and unit costs. Discuss projected volumes with your packaging partner—many child-resistant designs become more affordable at scale.

Sustainability trade-offs and consumer expectations

Consumers increasingly expect sustainable packaging. Paper-based boxes score well when free of mixed laminates or plastic windows. Metal is recyclable, while multi-layer laminates and mixed-material constructions can complicate recycling. If sustainability is a core brand promise, prioritize mono-material designs or clearly communicate recyclability and responsible sourcing on your custom cigarette boxes.

Testing and certification to meet standards

Regardless of material, your packaging must be validated through child-resistance testing protocols defined by local authorities or international standards (for example, ISO 8317 and national regulations). Testing often evaluates ease of opening by children and usability by adults. Work with a certified lab and keep documentation for compliance and retail requirements.

Practical recommendations by product need

- For High Quality brands focused on presentation and a sturdy CR mechanism: choose rigid chipboard with internal locking hardware.- For value and high-fidelity print at scale: use SBS paperboard with foil or plastic liners for barrier and a paperboard-based child-resistant tuck with internal inserts.- For maximum barrier and reusability: consider metal tins or aluminum slide boxes with engineered latches.- For molded mechanical CR features: select appropriate plastics (PET/PP) and design closures that meet test protocols.

How Best Pack supports custom cigarette boxes with CR requirements

Best Pack provides end-to-end services—from design and printing to handicraft processing—so brands can develop compliant, attractive custom cigarette boxes. We combine OEM/ODM experience in cannabis protective packaging and cartridge box packaging with knowledge of CR mechanisms and barrier solutions to create packages that meet regulatory needs while reflecting brand identity.

Cost vs. performance: a real-world selection checklist

When deciding, use this checklist: product sensitivity (moisture/light), required child-resistance level, print and shelf appeal, target retail environment, sustainability goals, and budget. Prioritize materials that enable your chosen CR mechanism and align with Best Pack’s sustainability claims.

FAQ — Frequently Asked Questions about materials for child resistant cigarette packaging

Which material is most commonly used for custom cigarette boxes?

Paperboard (SBS or CCNB) is the most common due to its printability, cost-efficiency, and ease of manufacturing. It often uses internal liners or inserts to meet barrier and child-resistant needs.

Can paperboard boxes be made child-resistant?

Yes. Paperboard boxes can incorporate engineered locking tabs, internal inserts, or combined plastic/foil components to achieve required child-resistant performance when designed and tested properly.

Are metal tins better for product preservation?

Metal offers superior moisture and light barrier properties and durable protection, making it an excellent choice for products requiring long shelf life or strong physical protection.

How do sustainability goals affect material choice?

If recyclability is a priority, mono-material paperboard or recyclable metal are strong options. Avoid mixed-material laminates unless necessary, or provide clear recycling instructions to consumers.

How does Best Pack help ensure compliance with child-resistance standards?

Best Pack works with clients to select appropriate materials and mechanisms, prototype designs, and coordinate third-party testing to meet local and international CR standards. We support documentation and iterations needed to pass certification tests.

How should I start if I want custom cigarette boxes with child-resistant features?

Begin by defining product protection needs, desired visual identity, target markets (to know regulatory requirements), and budget. Contact a packaging partner like Best Pack to explore material options, prototype CR mechanisms, and plan testing and production.

For tailored solutions and OEM/ODM expertise in custom cigarette boxes, visit https://www.gzbestpack.com/ or contact Best Pack to discuss materials, child-resistant mechanisms, and samples that meet Best Pack and regulatory needs.

Moisture Control Solutions for Vintage Cigar Boxes

What are the application scenarios of paper cigarette case?

Where to Buy smoking paper box in Guangzhou

Sample Approval Process for Custom Cigarette Box Manufacturers

About us

What is the box size and structure?

1. All boxes are customized and all detailed requirements can be provided by clients, we are definitely your OEM service supplier.

2. If you have no idea about the measurements and structure on your products, our professional design team can suggest and solute for you .

Are you able to do design for my products?

Yes, just send us your logo artwork in Vector file, such as AI or PDF format,and text information you want to print ,we can put it on box to make the design to let you check. Once you say ok, then we go on to make samples or production.

FAQs

What types of packaging do you specialize in?

We specialize in electronic packaging, plastic boxes (PVC/PET/PP), paper boxes, paper bags, and custom book printing.

Do you support custom designs?

Yes, we provide custom packaging designs tailored to your brand and product needs.

What services do you provide?

We offer one-stop packaging solutions, including design, printing, and handicraft processing for electronic boxes, plastic boxes, paper boxes, paper bags, and book printing.

Custom Printed Paperboard Cardboard Cigarette Box Packaging Case Disposable Paper Box for Cigarette Clamshell paper box

Custom Vape Packaging Box with CR Telescoping Design

The CR telescoping box is a sophisticated and secure packaging solution designed specifically for vape products. Featuring a telescoping (two-piece) structure, this box offers excellent protection and an elegant presentation, enhancing both the unboxing experience and brand appeal.

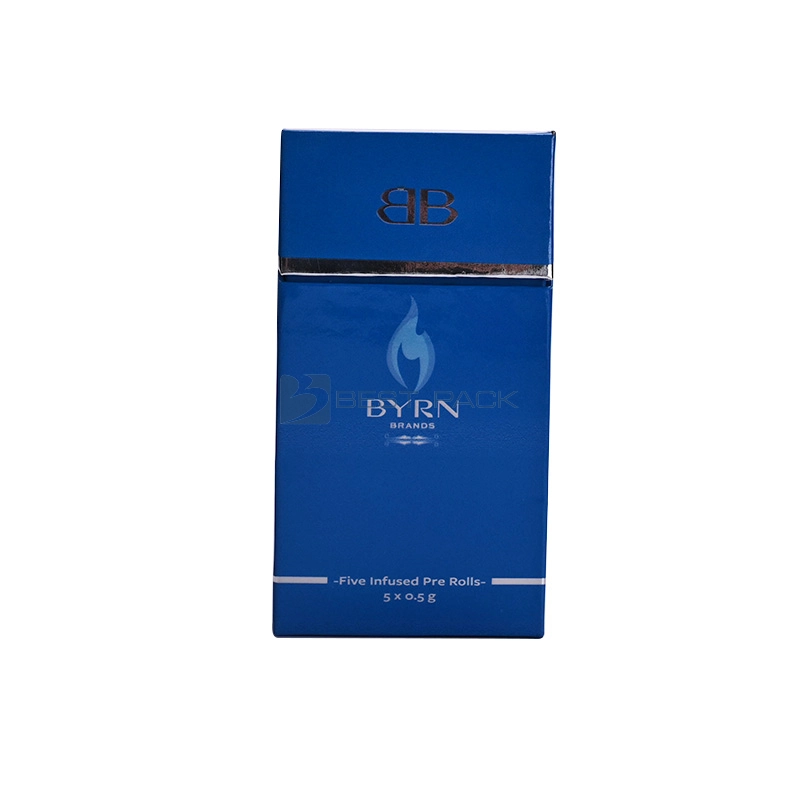

Custom Logo Child-Resistant Pre-Roll Box Packaging Biodegradable Handmade Luxury 5 Pack Embossing Childproof Pre Roll Package

Custom CR Vape Packaging Cardboard Boxes with Child-Resistant Design

CR custom vape packaging cardboard boxes are specially designed child-resistant packaging solutions crafted to ensure safety, protection, and premium presentation for vape products. Made from sturdy cardboard materials, these boxes balance regulatory compliance with brand aesthetics.

Best pack

Best pack

Best pack